Vacuum cleaner

A vacuum cleaner and dust storage technology, applied in the field of cleaning, can solve problems such as false triggering and complex structure, and achieve the effect of avoiding the probability of false triggering and using safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

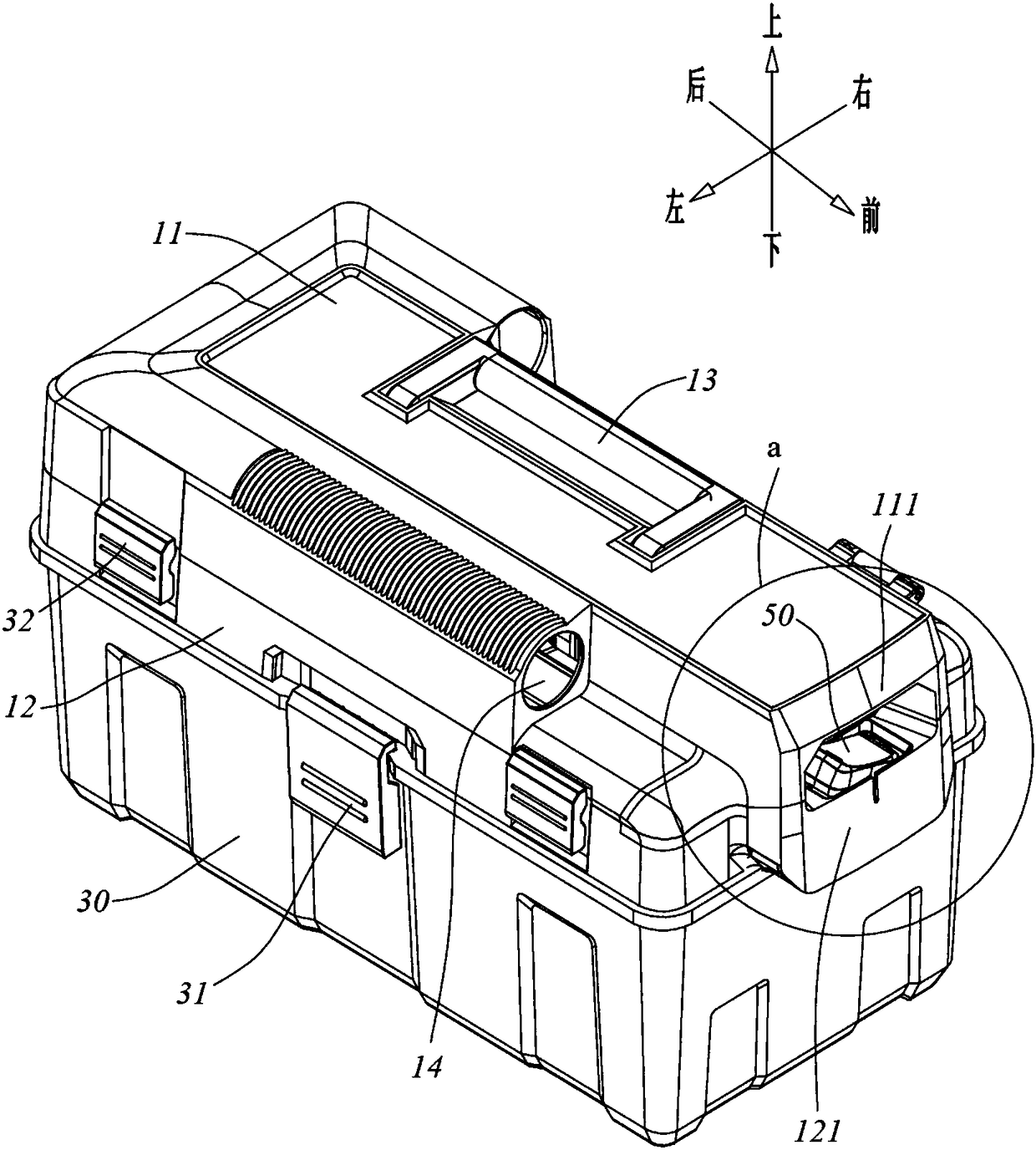

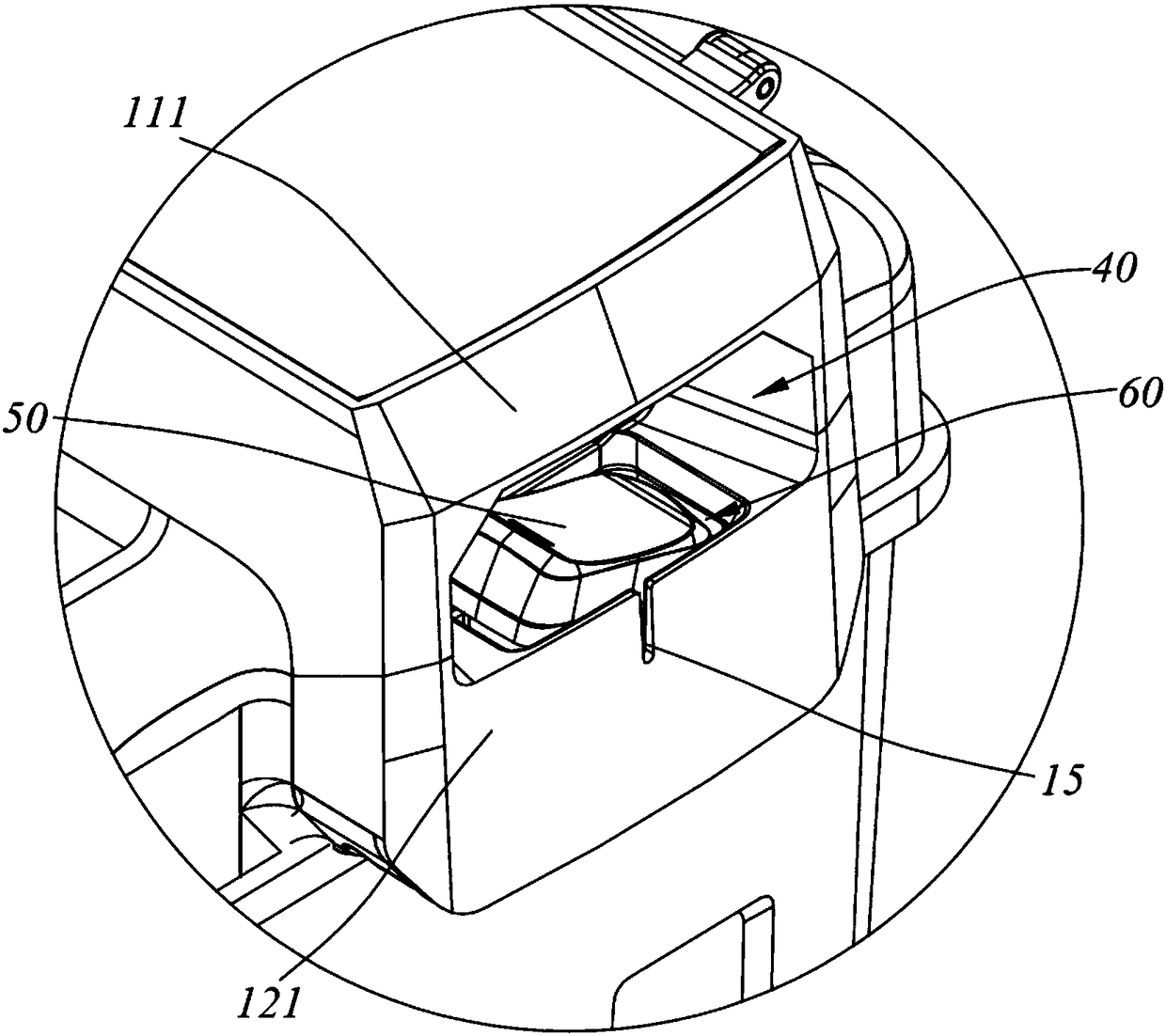

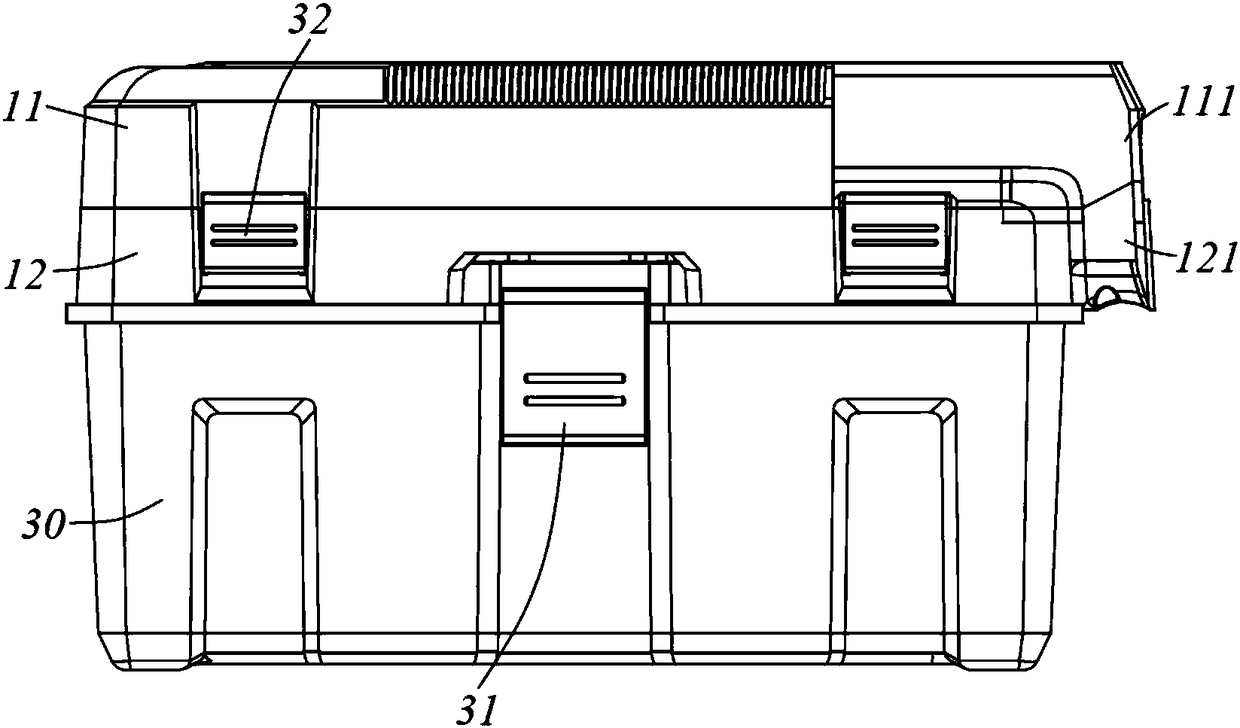

[0036] Please refer to Figure 1 to Figure 8 Shown is a preferred embodiment of the vacuum cleaner of the present invention. In this embodiment, the vacuum cleaner includes a head assembly, a dust storage cylinder 30 and a filter assembly (not shown) connected to the head assembly. Wherein, the dust storage tube 30 can be tightly fastened with the machine head assembly through the first buckle 31 , and in addition, rollers can be arranged under the dust storage tube 30 to facilitate the movement of the dust storage tube. The head assembly includes a casing and a fan arranged in the casing. A hose (not shown) can be connected to the head assembly. An air inlet 14 is arranged on the head assembly. One end of the hose is connected to the air inlet 14 of the head assembly. The other end of the hose has a suction port connected to the external environment. Under the action of the fan, the external air can be filtered from the suction port through the air inlet 14 and then discharg...

Embodiment 2

[0042] Please refer to Figure 9 to Figure 10 Shown is another preferred embodiment of the vacuum cleaner of the present invention. In this embodiment, the vacuum cleaner includes a head assembly, a dust storage cylinder 30' and a filter assembly (not shown) connected to the head assembly. Wherein, the dust storage tube 30' is sealed and detachably connected with the machine head assembly, and the bottom of the dust storage tube 30' is equipped with rollers to facilitate the movement of the vacuum cleaner. The head assembly includes a casing and a fan installed in the casing. A hose can be connected to the dust storage cylinder. An air inlet 14' is set on the dust storage cylinder 30'. One end of the hose is connected to the air inlet 14 of the dust storage cylinder 30'. 'communication, the other end of the hose has a suction port connected to the external environment, under the action of the fan, the external air can be filtered from the suction port through the air inlet 14'...

Embodiment 3

[0045] refer to Figure 12 , The difference between this embodiment and Embodiment 1 is that the trigger operation direction of the switch trigger member 50 is inclined toward the opening of the hole portion 40 . This setting not only enables the user to operate the switch trigger 50 more conveniently, but also enables the user to observe the state of the switch trigger 50 more conveniently. Other basic structures and principles of the vacuum cleaner in this embodiment are the same as those in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com