Salt core manufacturing device and method for pressure casting

A technology for making a device and a salt core, applied in the field of casting, can solve the problems of low efficiency and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

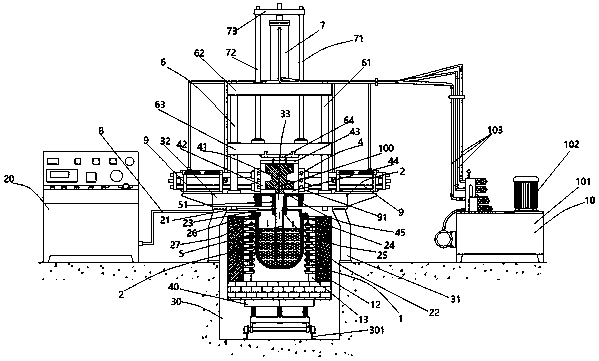

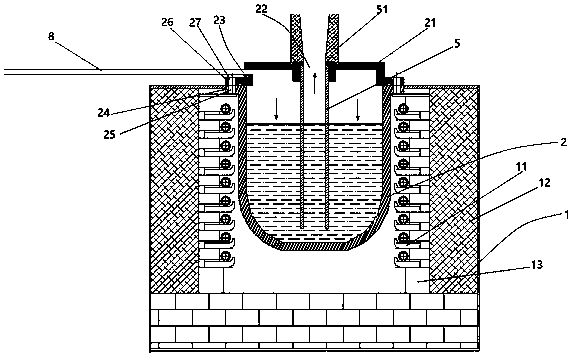

[0037] refer to figure 1 and figure 2, a salt core manufacturing device for pressure casting according to the present invention, said device comprising: a melting and holding furnace 1, a plurality of heating elements 11 are arranged on the inner wall along the circumference of the melting and holding furnace 1, and the plurality of heating elements 11 are arranged along the melting and holding furnace 1 are radially arranged on the inner wall of the melting and holding furnace 1; the melting crucible 2 is inserted in the melting and holding furnace 1 and the opening end corresponds to the mouth of the melting and holding furnace 1, and the opening end cover of the melting crucible 2 is provided with a pot cover 21, Form a seal to the opening end of the melting crucible 2, a liquid outlet 22 is provided in the middle of the surface of the pot cover 21, and an air inlet 23 is provided on the surface of the pot cover 21 at least one side of the liquid outlet 22; a casting workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com