Special maintenance sliding plate for automobile maintenance

A technology for car maintenance and skateboards, applied in workshop equipment, manufacturing tools, etc., can solve the problems of limiting the width and length of skateboards, weak positioning ability, fatigue, etc., and achieve the effects of reducing fatigue, convenient movement, and concentrated force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

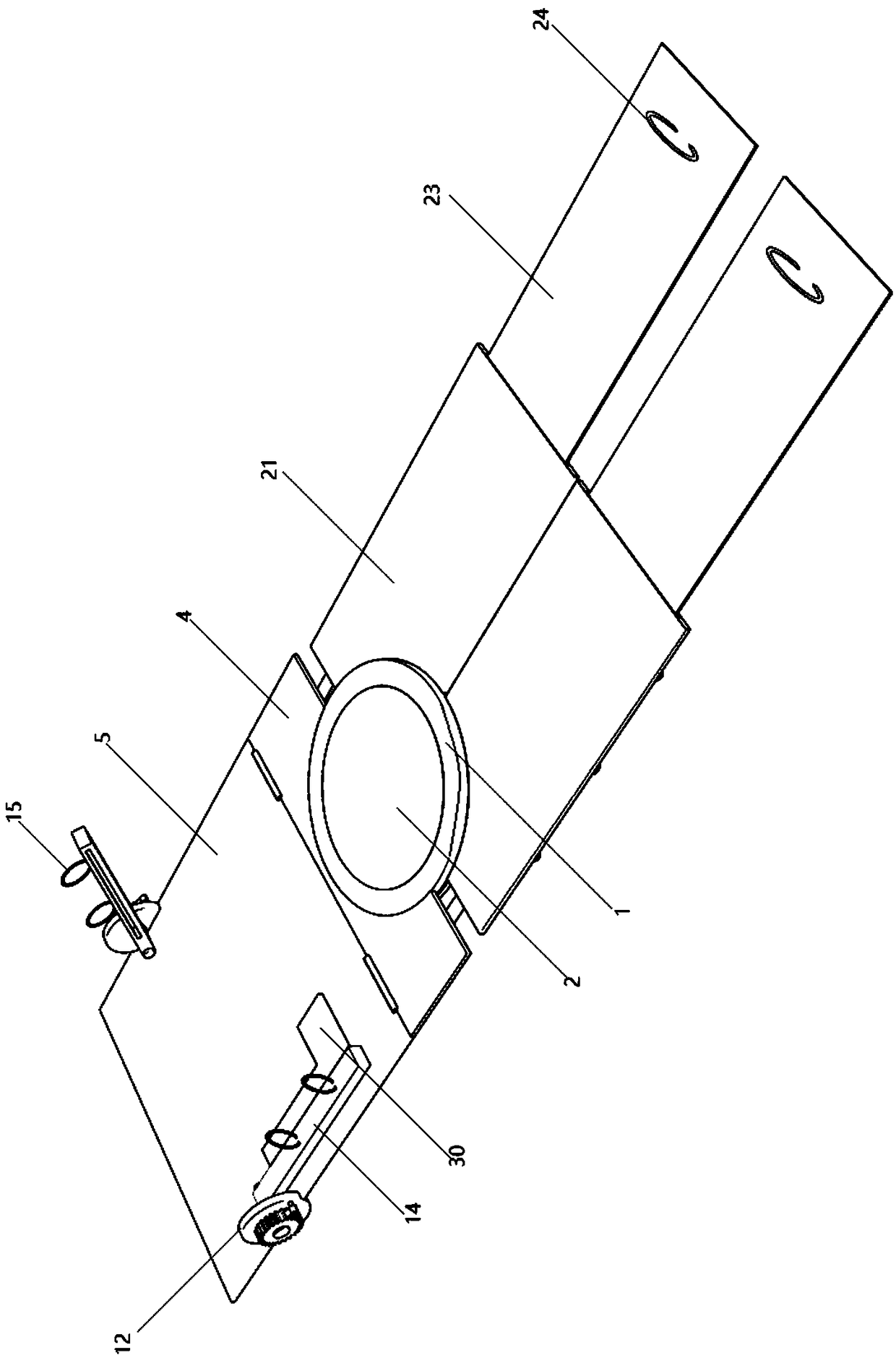

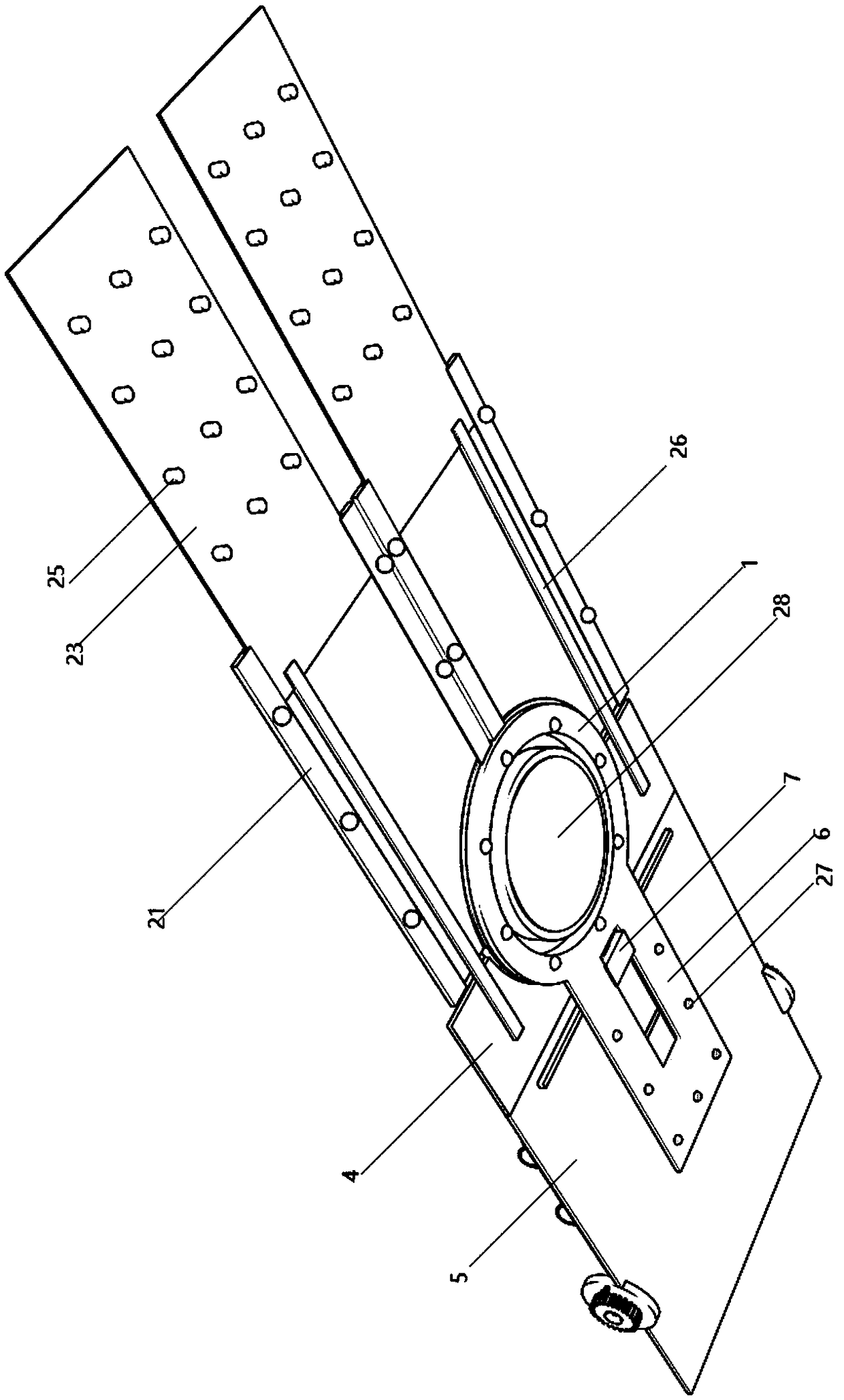

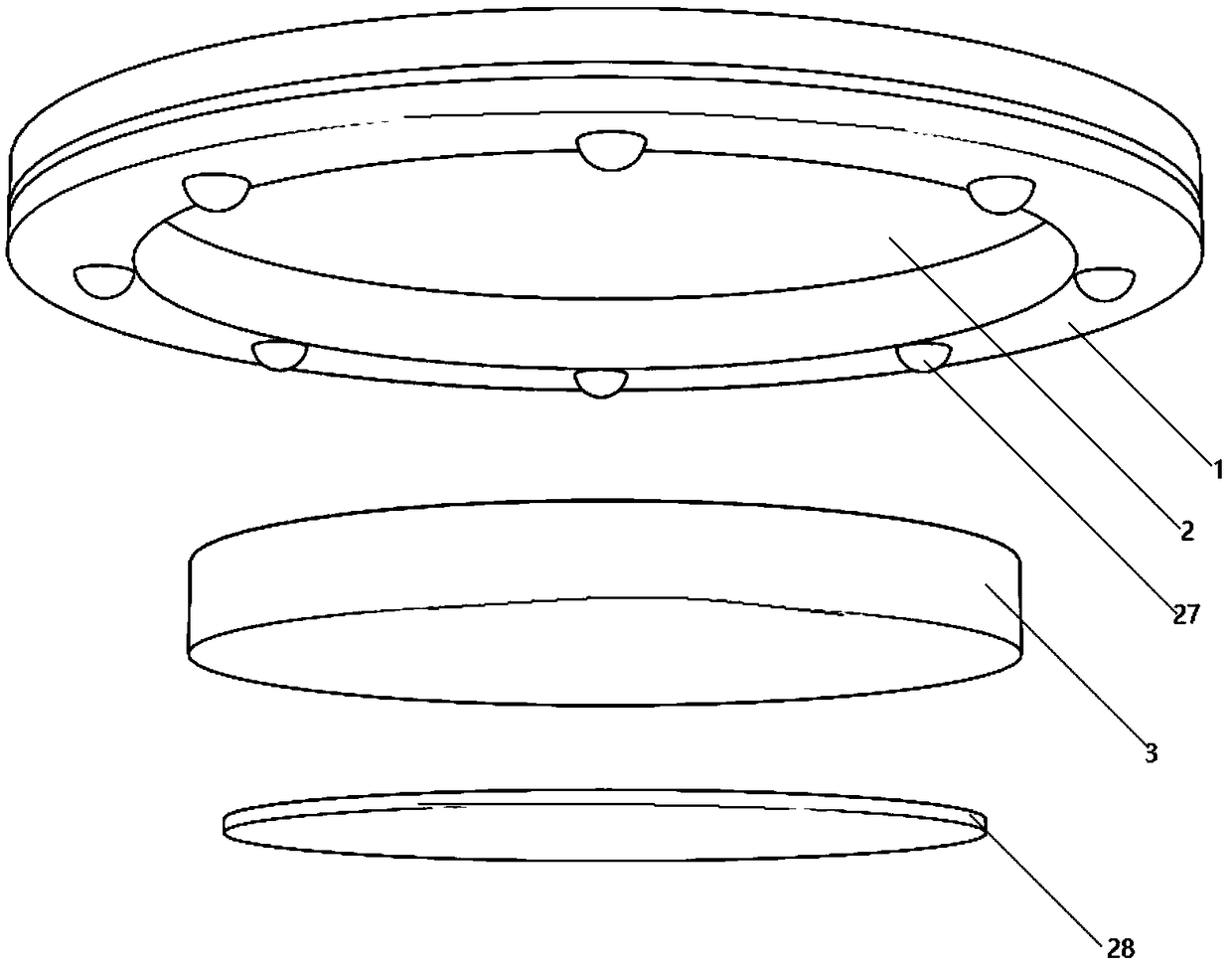

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1-8 As shown, the special maintenance skateboard for automobile maintenance includes an upper body support unit, an arm support unit, a hip support unit and a leg support unit; the hip support unit includes a mounting tube 1; the upper port of the mounting tube 1 is fixedly connected with a rubber pad 2. The lower end of the rubber pad 2 is fixedly connected with a positioning support column 3, and the positioning support column 3 slides up and down in the installation tube 1; the upper body support unit includes a base plate 4 fixedly connected to the upper part of the front side of the installation tube 1; the front end of the base plate 4 The upper body support plate 5 is connected in rotation; the front side lower part of the installation pipe 1 is fixedly connected with a base plate 6; the base plate 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com