One-time welding fluff seal strip and making method thereof

A technology for sealing tops and a manufacturing method, which can be used in sealing devices, engine sealing, other household appliances, etc., and can solve problems such as slow production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

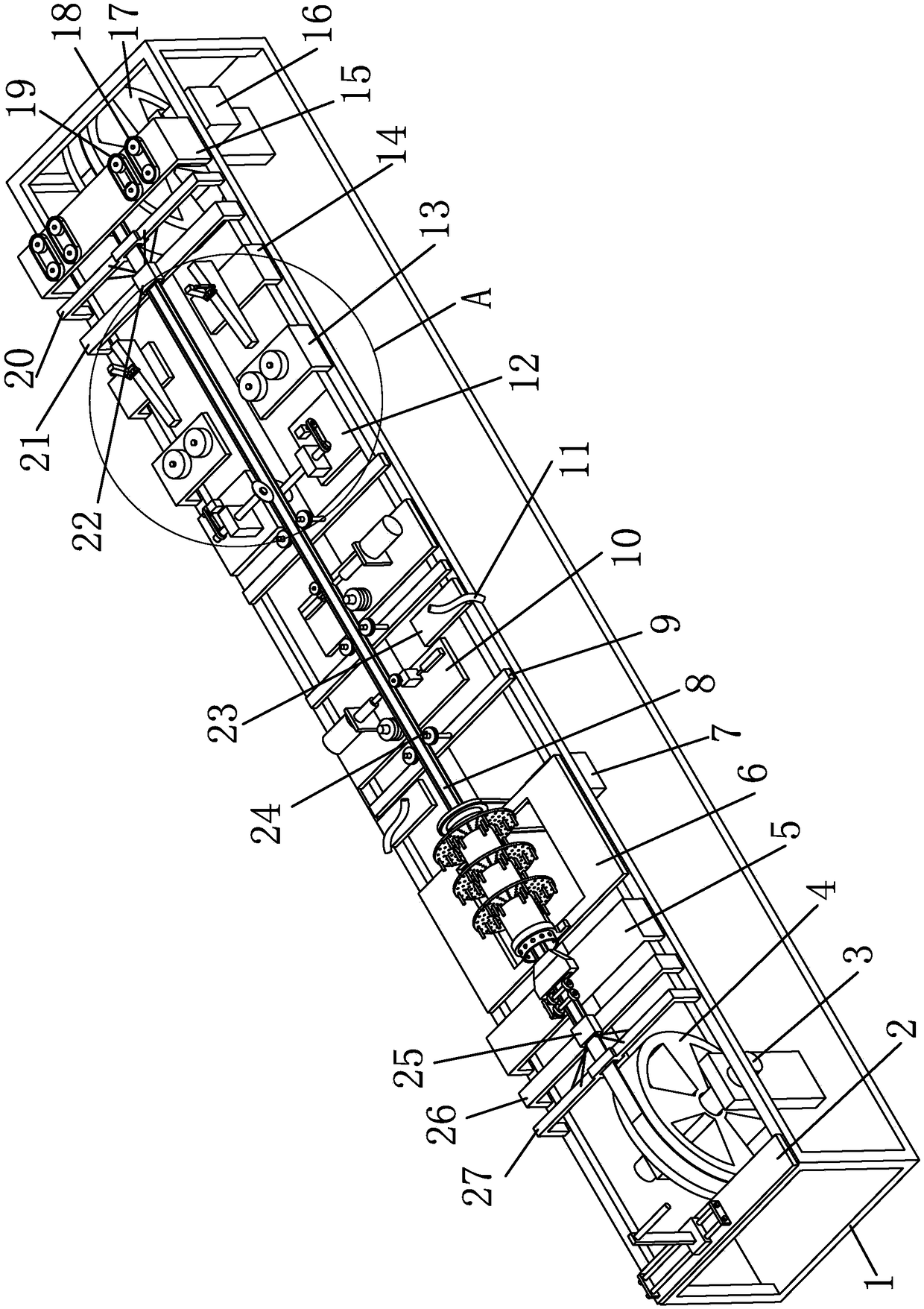

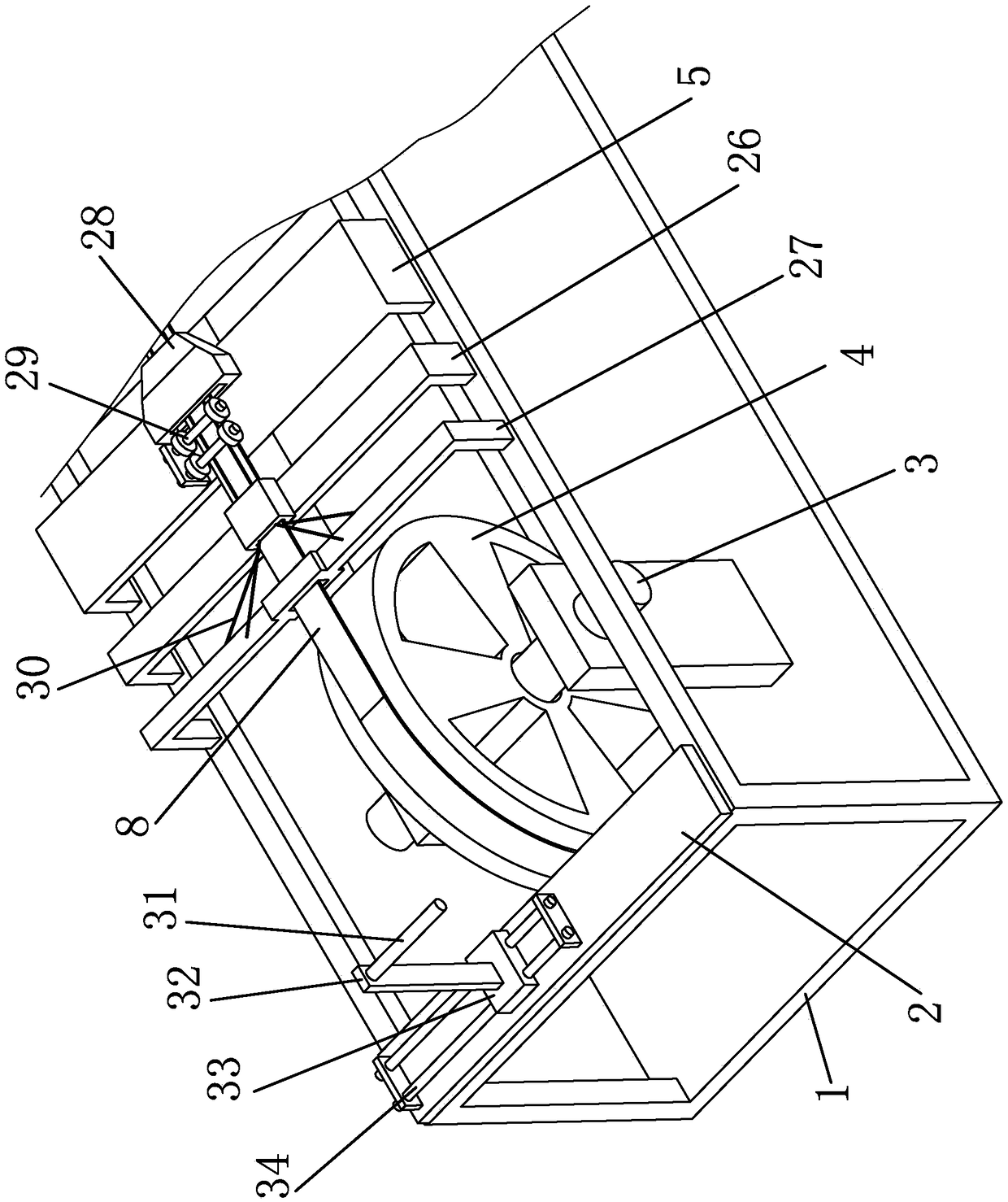

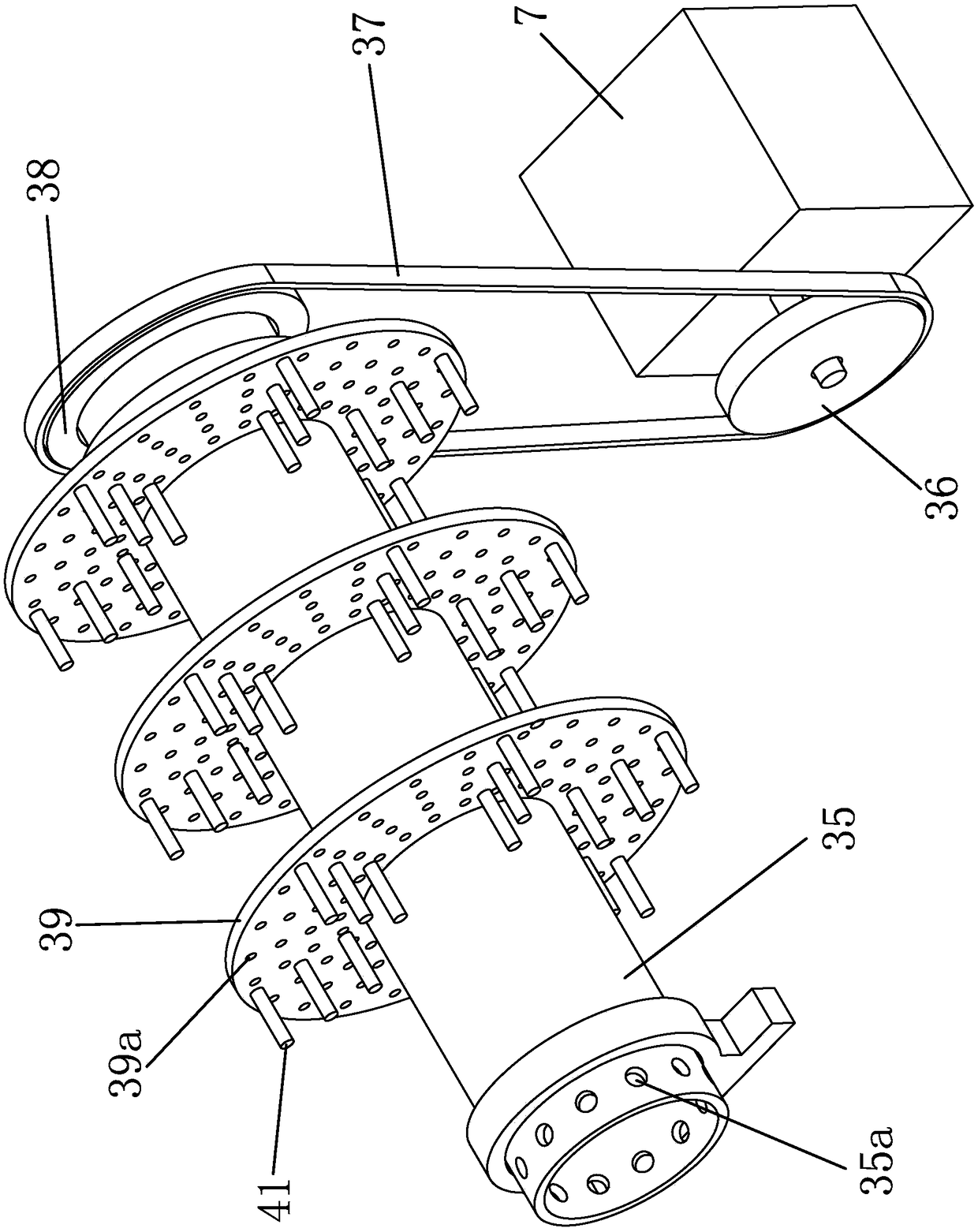

[0103]Embodiment 1 of the production method: the production method of this one-time welding fluff sealing top comprises the following steps: a, material preparation: prepare the base plate and yarn, and carry out appearance inspection to it; the width of the base plate is 5mm; the thickness of the base plate is 0.80mm The groove width of the installation groove is 2.1mm; the depth of the installation groove is 0.32mm; the width of the auxiliary part is 0.4mm; the height of the side wings is 0.60mm; The yarn on the bobbin is wound on the steel belt in the welding seed hair equipment to form a yarn roll for making fluff; the number of yarn bobbins in step b is 12; c, conveying bottom plate: by welding the seed wool The feeding mechanism in the equipment sends the two base plates vertically to both sides of the yarn roll respectively; d. Ultrasonic welding: the two base plates are respectively welded on both sides of the yarn roll through the ultrasonic welding mechanism in the we...

Embodiment 2

[0104] Embodiment 2 of the production method: the production method of this one-time welding fluff sealing top comprises the following steps: a, material preparation: prepare the base plate and yarn, and carry out appearance inspection to it; the width of the base plate is 5mm; the thickness of the base plate is 0.85mm The groove width of the installation groove is 1.7mm; the depth of the installation groove is 0.25mm; the width of the auxiliary part is 0.35mm; the height of the side wings is 0.50mm; The yarn on the bobbin is wound on the steel belt in the welding seed hair equipment to form a yarn roll for making fluff; the number of yarn bobbins in step b is 12; c, conveying bottom plate: by welding the seed wool The feeding mechanism in the equipment sends the two base plates vertically to both sides of the yarn roll respectively; d. Ultrasonic welding: the two base plates are respectively welded on both sides of the yarn roll through the ultrasonic welding mechanism in the ...

Embodiment 3

[0105] Embodiment three of the production method: the production method of this one-time welding fluff sealing top comprises the following steps: a, material preparation: prepare the base plate and yarn, and carry out appearance inspection to it; the width of the base plate is 7mm; the thickness of the base plate is 0.75mm The groove width of the installation groove is 2.1mm; the depth of the installation groove is 0.38mm; the width of the auxiliary part is 0.3mm; the height of the side wings is 0.55mm; The yarn on the bobbin is wound on the steel belt in the welding seed hair equipment to form a yarn roll for making fluff; the number of yarn bobbins in step b is 12; c, conveying bottom plate: by welding the seed wool The feeding mechanism in the equipment sends the two base plates vertically to both sides of the yarn roll respectively; d. Ultrasonic welding: the two base plates are respectively welded on both sides of the yarn roll through the ultrasonic welding mechanism in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com