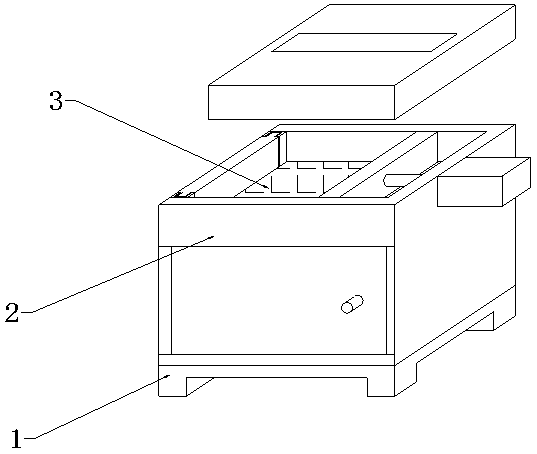

Textile dirt pressing device

A dirty and hollow technology, applied in the direction of presses, manufacturing tools, etc., can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

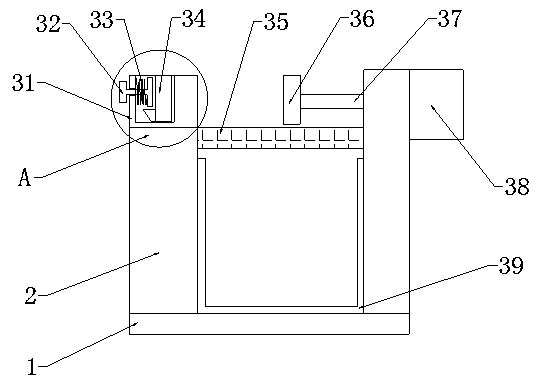

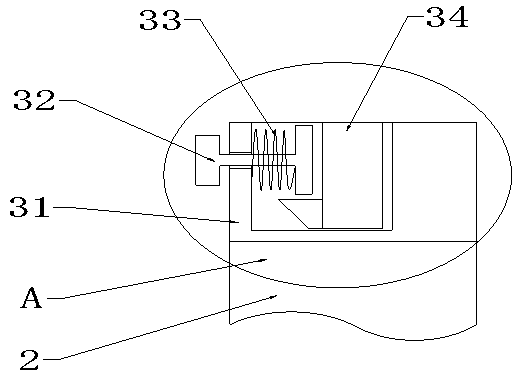

[0021] Specific implementation method: when using, the user should first fix the inserting plate 34 into the concave groove plate 31, the user first holds the inserting plate 34 and moves it downward, and the downward movement of the inserting plate 34 drives the triangular block to move downward. When the triangular block moves down to the upper side of the pull rod 32, continue to move the insert plate 34 downward, the triangular block produces a leftward force on the pull rod 32, and the pull rod 32 moves to the left under the leftward force, and the pull rod 32 moves to the left Cause the spring 33 to compress and generate elastic force. When the triangular block moves down to the lower side of the pull rod 32, the pull rod 32 moves to the right under the force of the spring 33. When the pull rod 32 moves right to its right end surface and the left end surface of the insert plate 34 When in close contact, the pull rod 32 stops moving, thereby realizing the function of fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com