Multi-functional compound dot printer

A printing device and composite technology, applied in the field of printing, can solve the problems of skewed fonts, low work efficiency, slow printing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

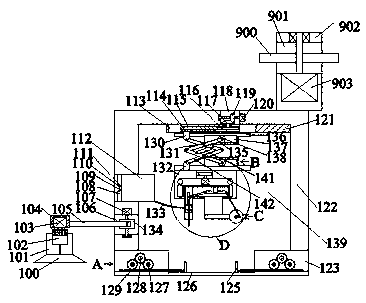

[0020] Combine below Figure 1-5 The present invention will be described in detail.

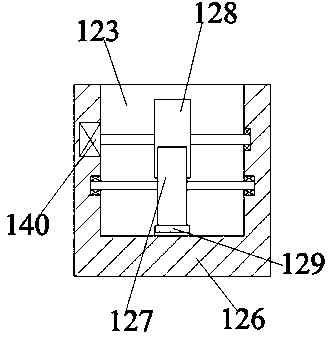

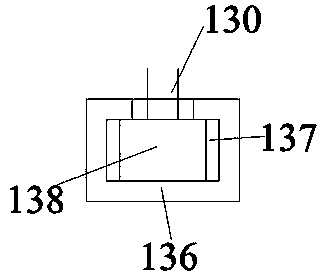

[0021]According to the embodiment of a multifunctional composite dot printing device, the multifunctional composite dot printing device includes a base 126, and a power cavity 123 that is left and right symmetrical and penetrates left and right is fixed inside the base 126, and the power chamber 123 is fixed inside the base 126. A rotary motor 140 is fixed in the rear end wall of the cavity 123, and the output shaft of the rotary motor 140 is connected to the rear end wall of the power chamber 123 in rotation, and a rotary gear 128 is fixed on the outer surface of the output shaft of the rotary motor 140. The outer end surface of the rotating gear 128 is meshed with a left-right symmetrical interlocking gear 127, the interlocking gear 127 is rotationally connected with the front and rear end walls of the power chamber 123, and the lower end surface of the interlocking gear 127 is meshed. A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com