A load-bearing reinforce beam pushing device and method for dump locomotive

A technology of pushing device and reinforcing beam, which is applied in transportation and packaging, railway car body parts, railway auxiliary equipment, etc. High, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

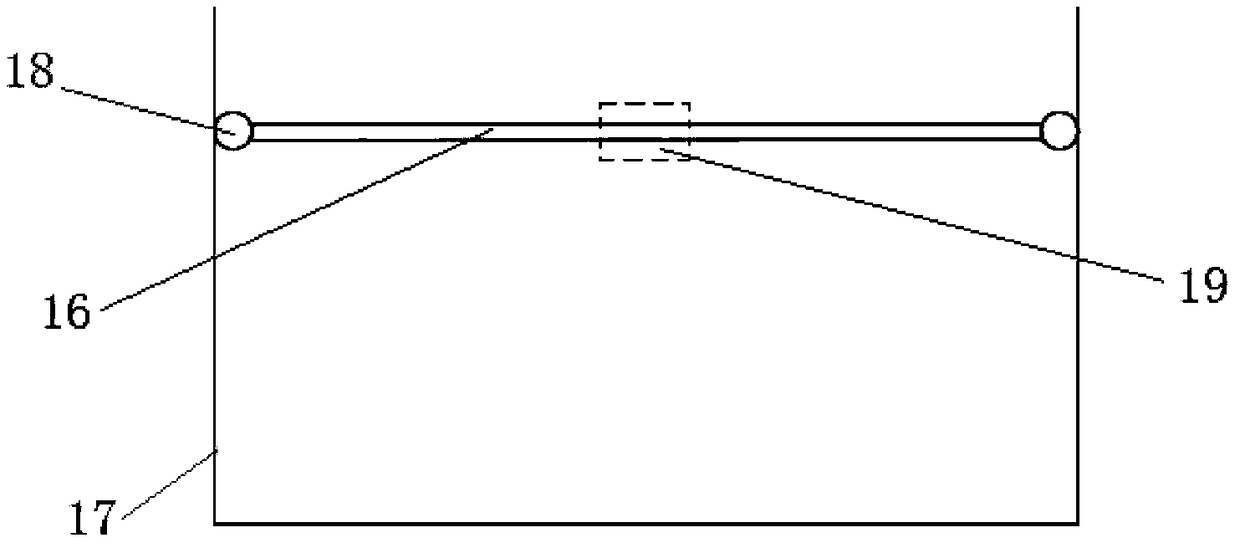

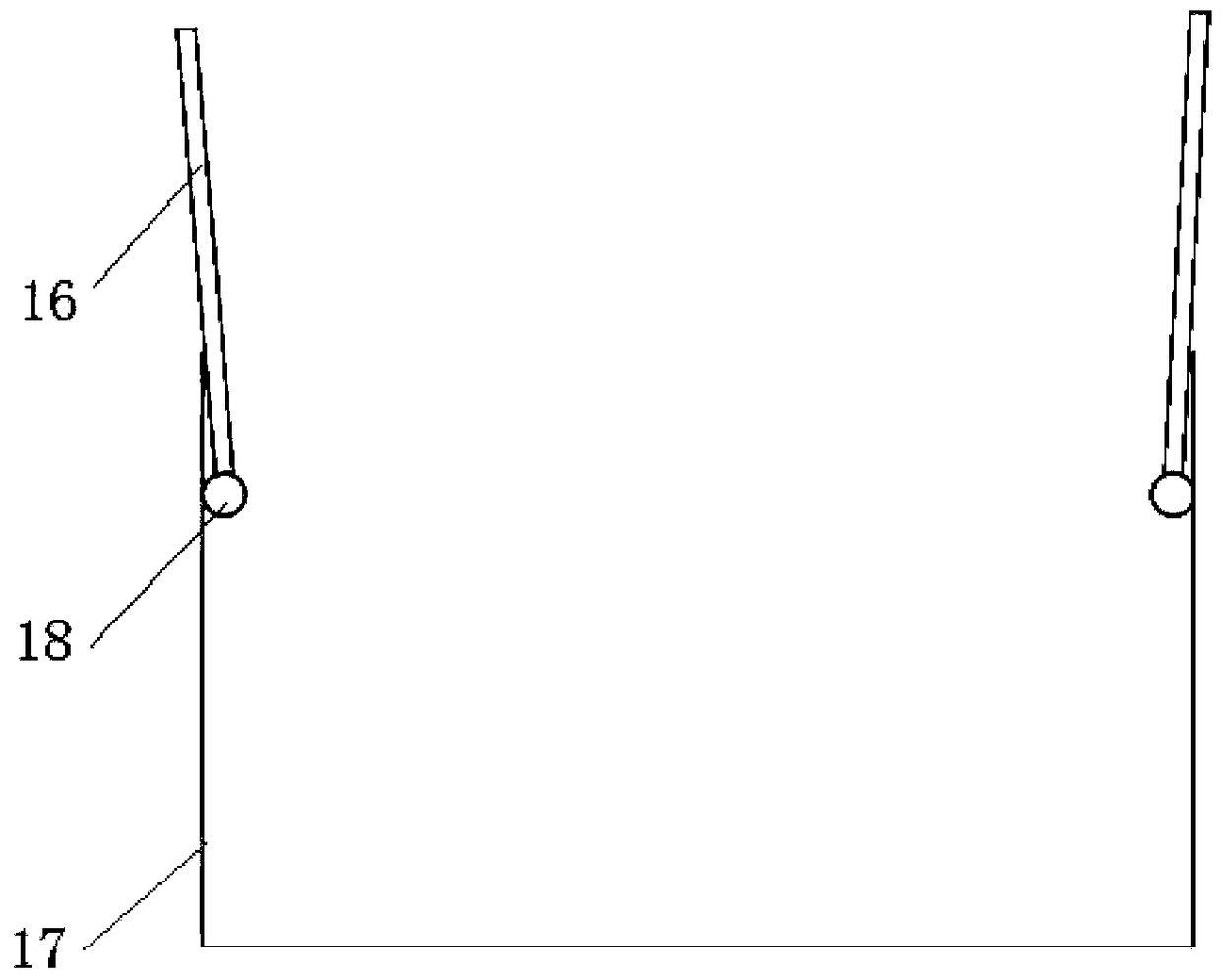

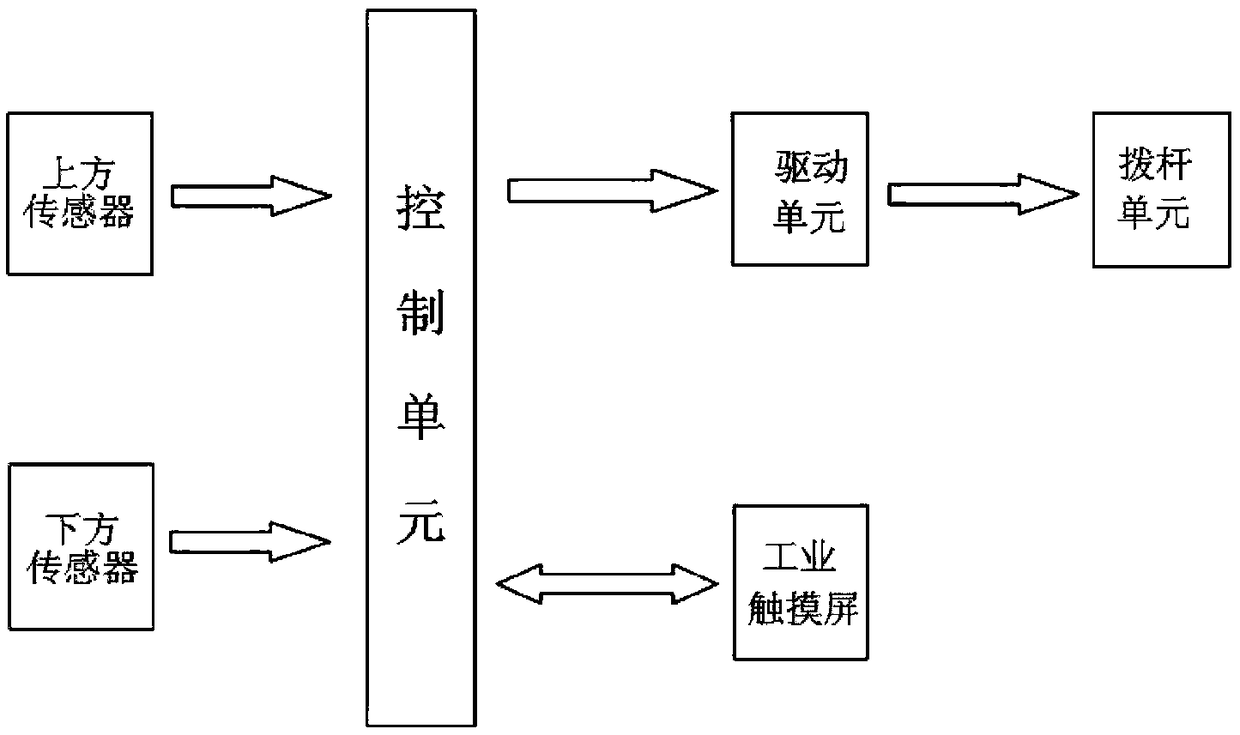

[0034] Such as Figure 2~3 As shown, a dump locomotive expenditure reinforcement beam pushing device of the present invention includes a detection unit, a control unit and a push plate unit 5, wherein the detection unit is installed on the column between the dump machine room 3 and the safety area 7, and the signal of the detection unit is sent to To the control unit; two sets of push plate units 5 are symmetrically installed on both sides of the rail 11, between the exit of the dumper room 3 and the detection unit, and the drive unit 4 of the push plate unit 5 receives the control signal of the control unit.

[0035] Such as image 3 , 4 As shown, the push plate unit 5 includes a workbench 12, a drive unit 4 (this embodiment adopts a servo drive motor), a guide rail 8, a support spring and a push plate 14, wherein the workbench is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com