Novel automatic thread slacking device of sewing machine

A technology of sewing machines and thread release devices, which is applied in the direction of sewing equipment, sewing machine components, sewing machine control devices, etc., can solve the problems of high requirements for parking workers, unfavorable parking workers, and troublesome operations, so as to save manpower and time, avoid Manual adjustment to avoid the effect of untimely operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

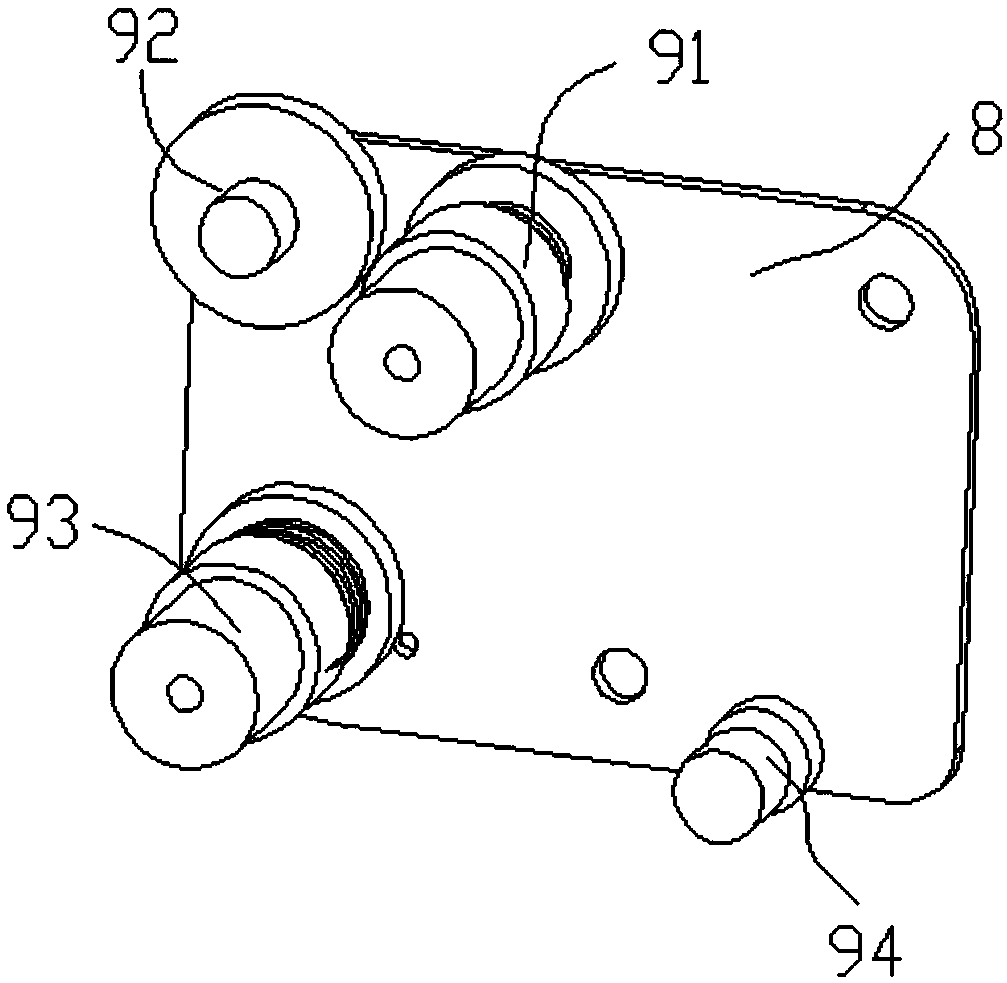

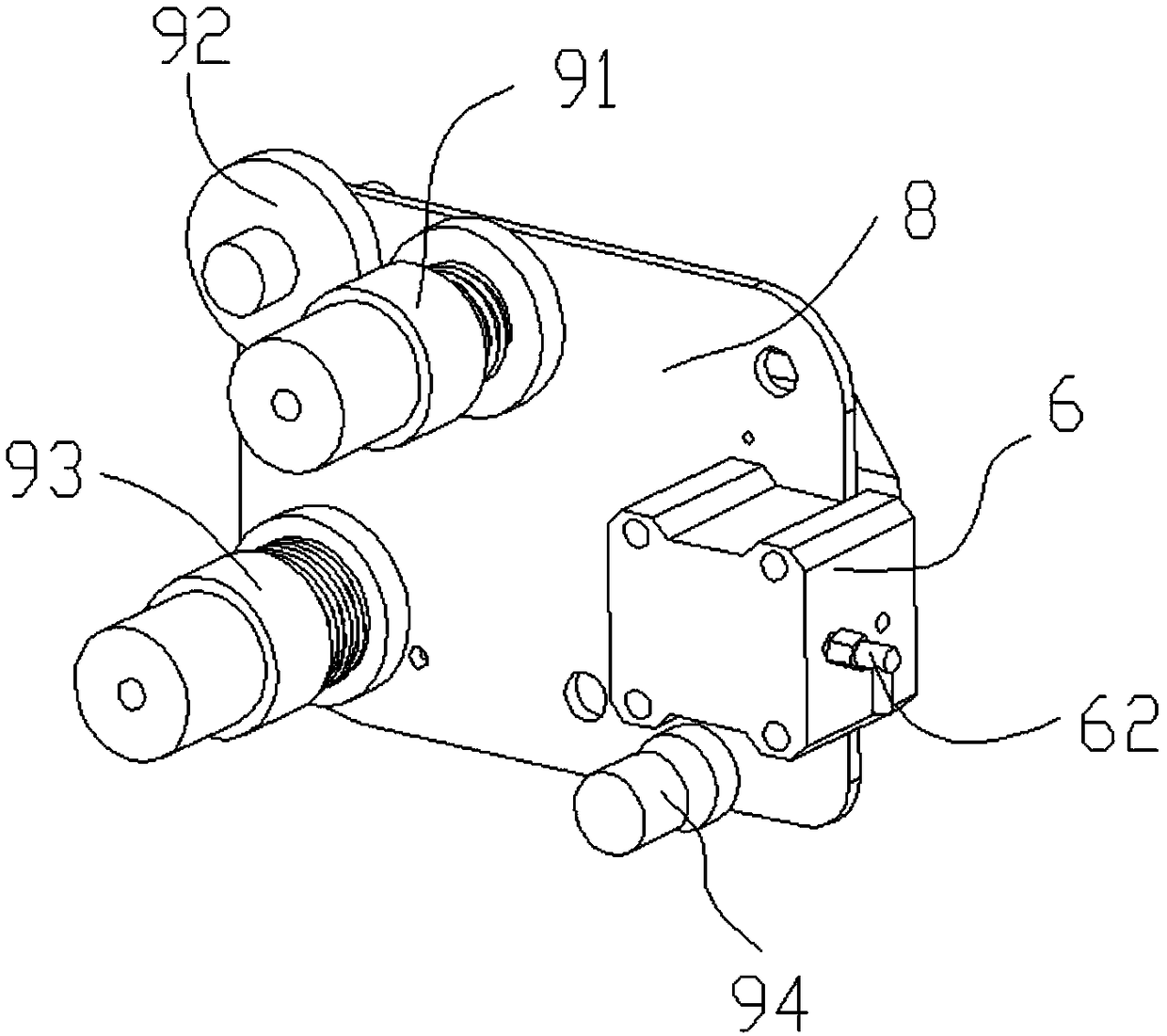

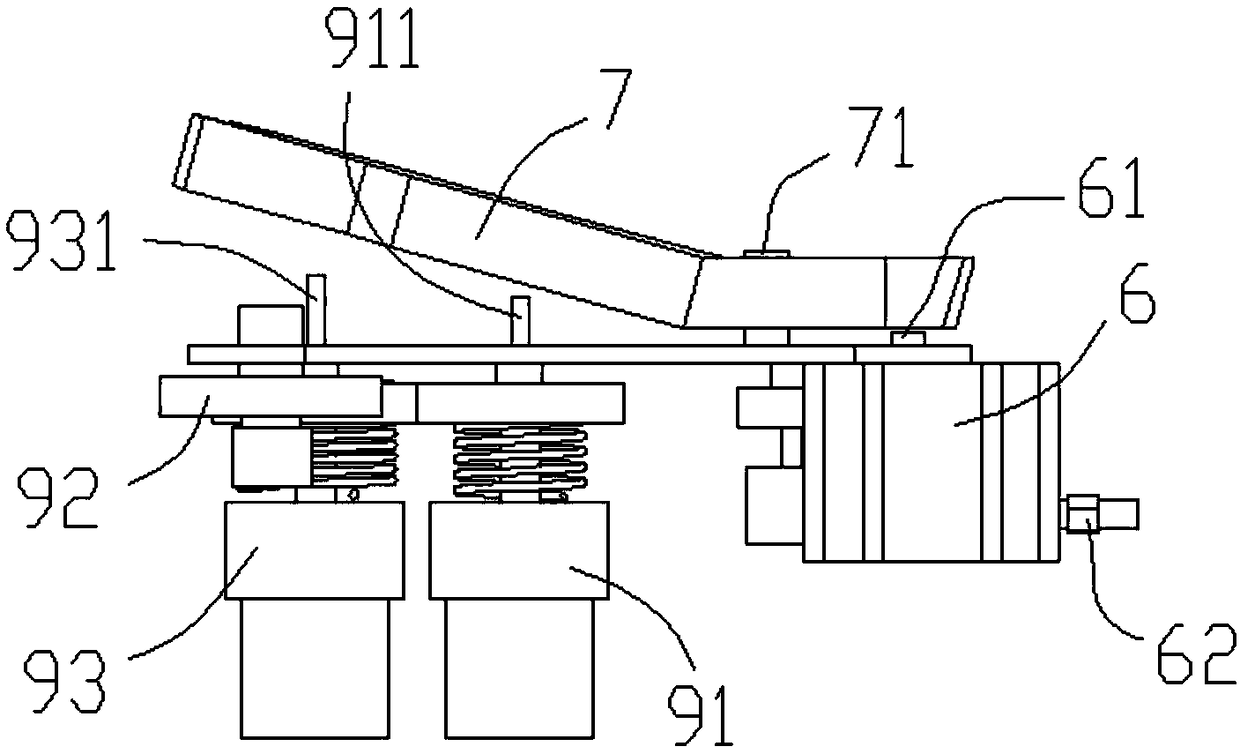

[0026] Such as Figure 2-Figure 5 As shown, the specific structure of the present invention is: a new automatic thread releaser for sewing machines, which includes a thread tensioner 8, on which a first thread tensioner 91, a tension coil 92, a second thread tensioner 93, The third thread tensioner 93, and the first thread tensioner 91 is provided with a first thread tensioner thimble 91 on the back of the thread tension plate 8, and the second thread tensioner 93 is provided with a second thread tensioner thimble on the back of the thread tension plate 8 93; It is characterized in that the back of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com