Folding box, pontoon bridge, erection method, pile foundation load device and load providing method

A technology of folding boxes and pontoons, which is applied in the field of folding boxes, can solve the problems of difficult transportation and large space occupied by box storage, and achieve the effects of simple construction technology, simple folding and unfolding, and reduced height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0063] Embodiment two floating bridge

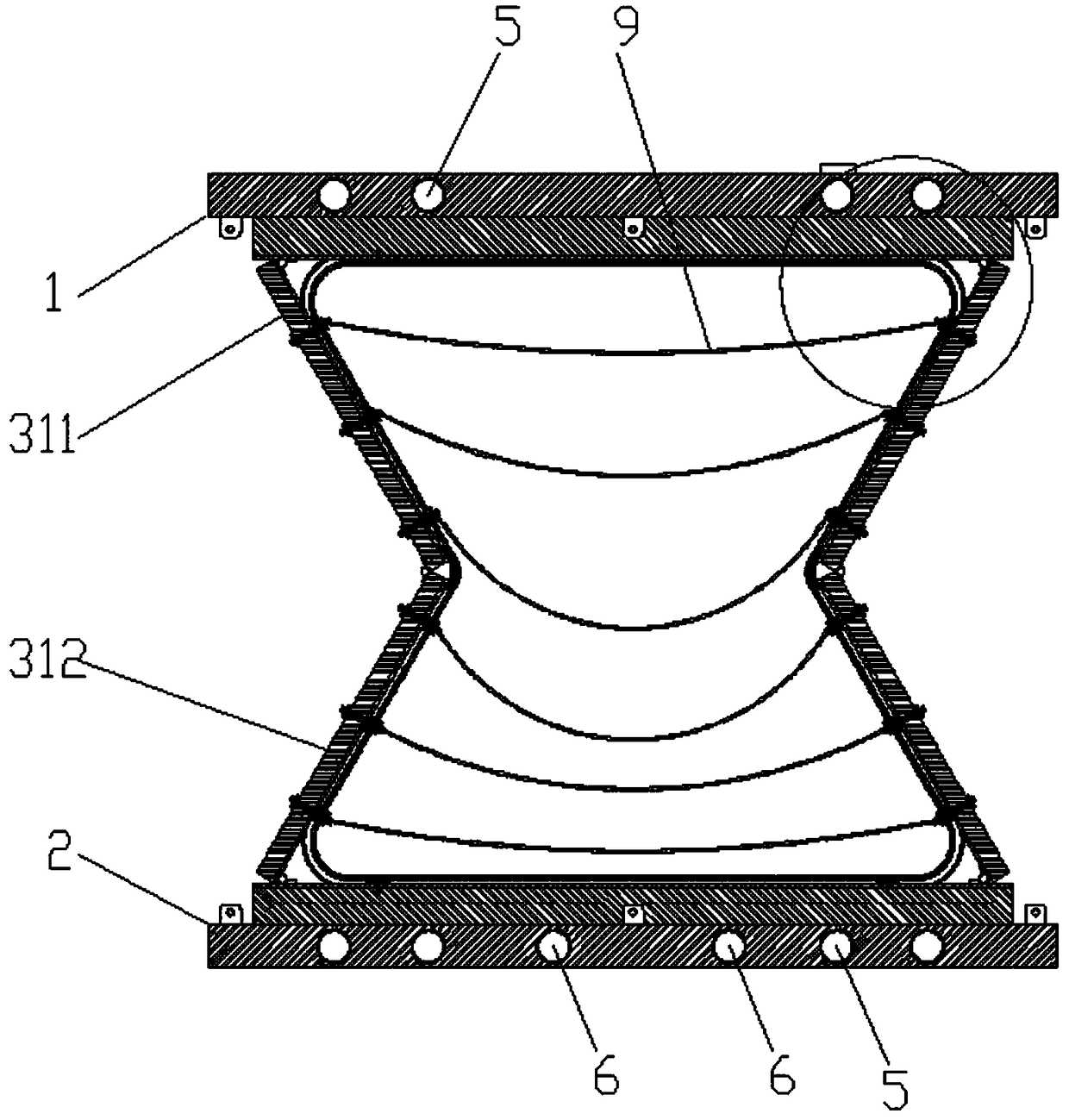

[0064] The floating bridge erected by the above-mentioned folding boxes includes multiple groups of folding boxes 16, inflated in the bag 8 of the folding boxes 16, and the multiple groups of folding boxes 16 are arranged side by side along the length and width directions of the floating bridge respectively to form a floating bridge. 17 is connected with a side anchor 18, and adjacent folding boxes 16 are fixedly connected by fasteners.

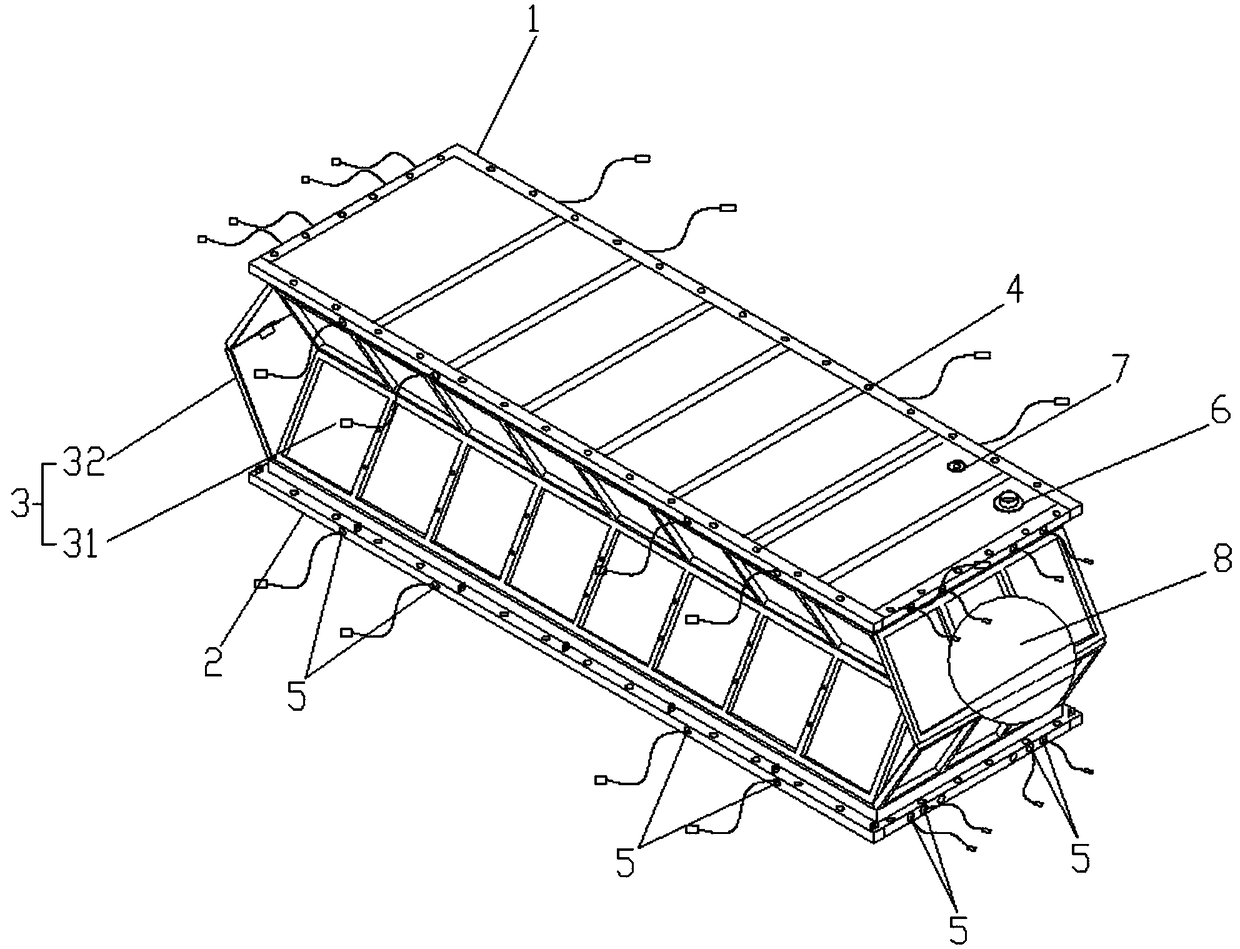

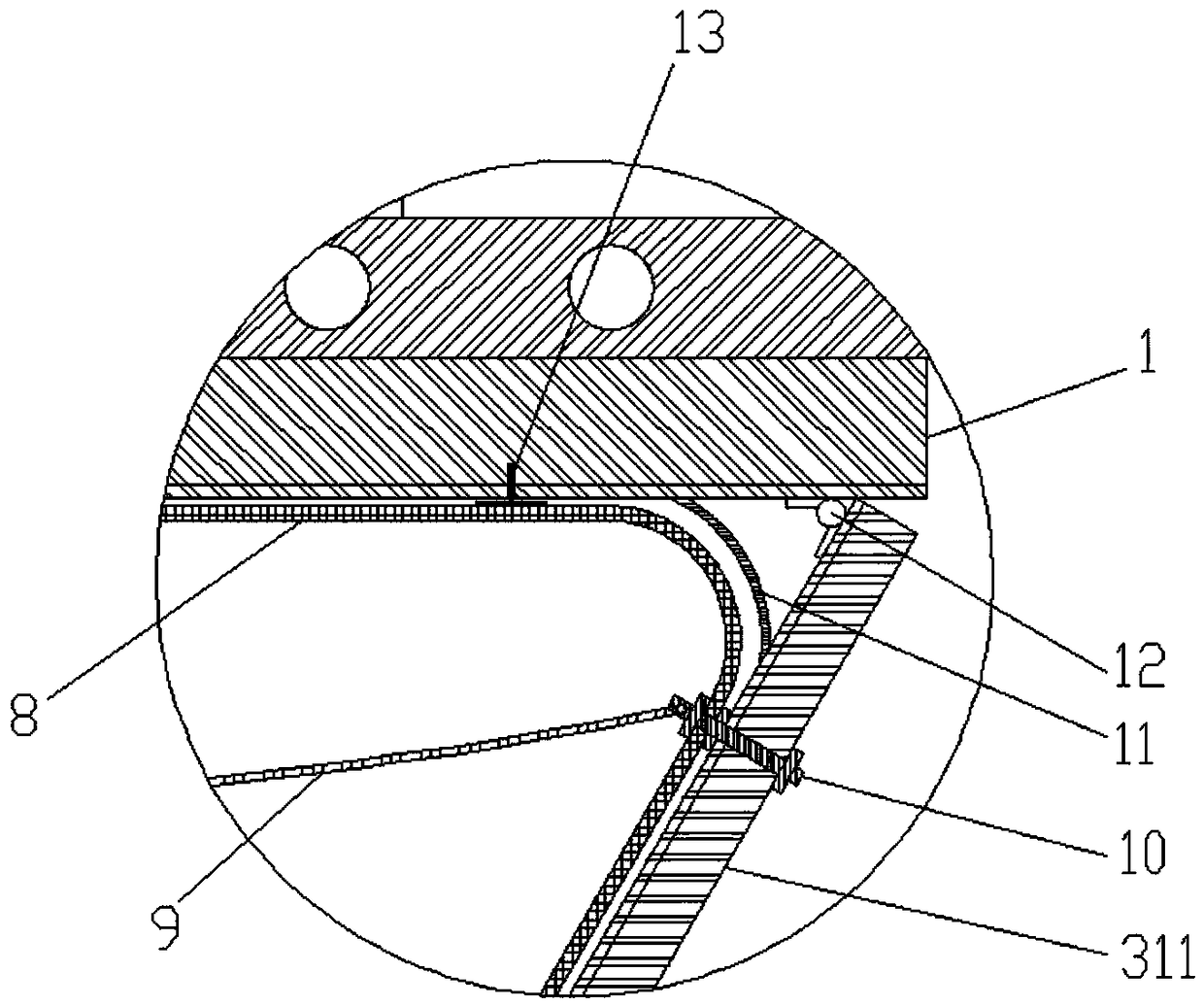

[0065] The upper support assembly 1 and the lower support assembly 2 are plate-shaped structural members, and the upper support assembly 1 and the lower support assembly 2 are provided with a plurality of vertical assembly holes 4 and a plurality of horizontal assembly holes 5, which are used to align two groups of adjacent groups. Assembling the folding box 16, the vertical assembly holes 4 are arranged along the upper surface of the upper support assembly 1 and the lower support assembly 2, penetrate ...

Embodiment 3

[0088] Embodiment three pile foundation loading device

[0089] The pile foundation loading device built by the above-mentioned folding box 21 includes a loading detection base 24, a folding box 21 and a support column, water is injected into the bag 8 of the folding box 21, and one or more layers are arranged on the loading detection base 24 Loading layers, each loading layer includes multiple sets of folding boxes 21 placed side by side, and multiple supporting columns 22 are arranged between the upper support assembly 1 and the lower support assembly 2 of each set of folding boxes 21 .

[0090] In this embodiment, the load detection base 24 is composed of a plurality of horizontally placed I-beams to form an upper and lower two-layer support structure, and the I-beams of each layer of support structure are arranged in parallel, and the upper and lower layers of I-beams are perpendicular to each other.

[0091] In this embodiment, the support column 22 is located outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com