Side-slope side supporting protecting method

A slope and frame technology, applied in excavation, construction, artificial islands, etc., can solve problems such as affecting the construction progress, easy cracking, damage, etc., to avoid mutual interference, improve construction efficiency, and ensure the effect of protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

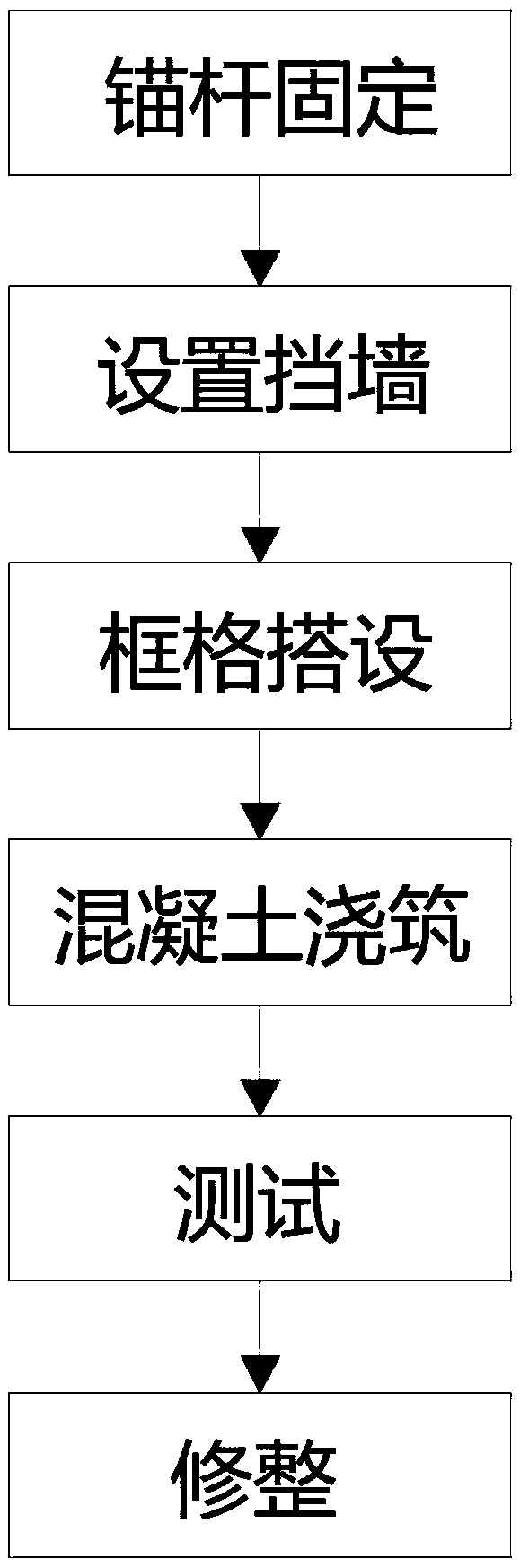

[0049] A side slope side support method, the side slope side support method comprises the steps of:

[0050] S1. Anchor fixing: Drill a hole on the slope, insert the prestressed anchor into the hole, and pour concrete grout to fix one end of the anchor.

[0051] S2. Set retaining wall: fix the gabion basket to the bottom of the slope to form a retaining wall structure.

[0052] S3. Sash erection: use sash beams to lay on the slope, and use thin steel wires and anchor rods to bind together to form a criss-cross grid structure to form a sash frame.

[0053] S4. Concrete pouring: Concrete is poured inside the retaining wall to form a concrete retaining wall structure, and concrete is poured on the surface of the grid to obtain a concrete protective surface and connected to the concrete retaining wall.

[0054] S5. Test: After the concrete is solidified, stretch the prestressed anchor rod to detect the protection strength.

[0055] S6. Trimming: cut off the end of the leaking an...

Embodiment 2

[0069] A side slope side support method, the side slope side support method comprises the steps of:

[0070] S1. Anchor fixing: Drill a hole on the slope, insert the prestressed anchor into the hole, and pour concrete grout to fix one end of the anchor.

[0071] S2. Set retaining wall: fix the gabion basket to the bottom of the slope to form a retaining wall structure.

[0072] S3. Sash erection: use sash beams to lay on the slope, and use thin steel wires and anchor rods to bind together to form a criss-cross grid structure to form a sash frame.

[0073] S4. Concrete pouring: Concrete is poured inside the retaining wall to form a concrete retaining wall structure, and concrete is poured on the surface of the grid to obtain a concrete protective surface and connected to the concrete retaining wall.

[0074] S5. Test: After the concrete is solidified, stretch the prestressed anchor rod to detect the protection strength.

[0075] S6. Trimming: cut off the end of the leaking an...

Embodiment 3

[0089] A side slope side support method, the side slope side support method comprises the steps of:

[0090] S1. Anchor fixing: Drill a hole on the slope, insert the prestressed anchor into the hole, and pour concrete grout to fix one end of the anchor.

[0091] S2. Set retaining wall: fix the gabion basket to the bottom of the slope to form a retaining wall structure.

[0092] S3. Sash erection: use sash beams to lay on the slope, and use thin steel wires and anchor rods to bind together to form a criss-cross grid structure to form a sash frame.

[0093] S4. Concrete pouring: Concrete is poured inside the retaining wall to form a concrete retaining wall structure, and concrete is poured on the surface of the grid to obtain a concrete protective surface and connected to the concrete retaining wall.

[0094] S5. Test: After the concrete is solidified, stretch the prestressed anchor rod to detect the protection strength.

[0095] S6. Trimming: cut off the end of the leaking an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com