Device for waterproof coiled material

A waterproofing membrane and reel technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of low compression effect and inconvenient installation of waterproofing membrane, and achieve the effect of good compression effect and smooth and stable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

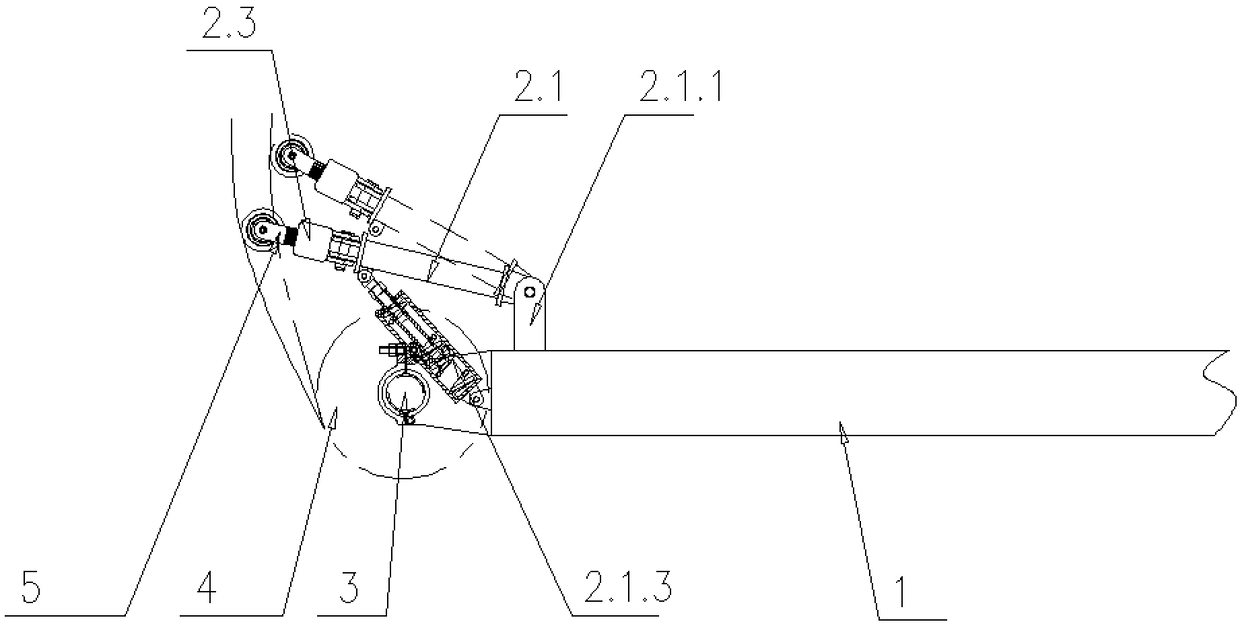

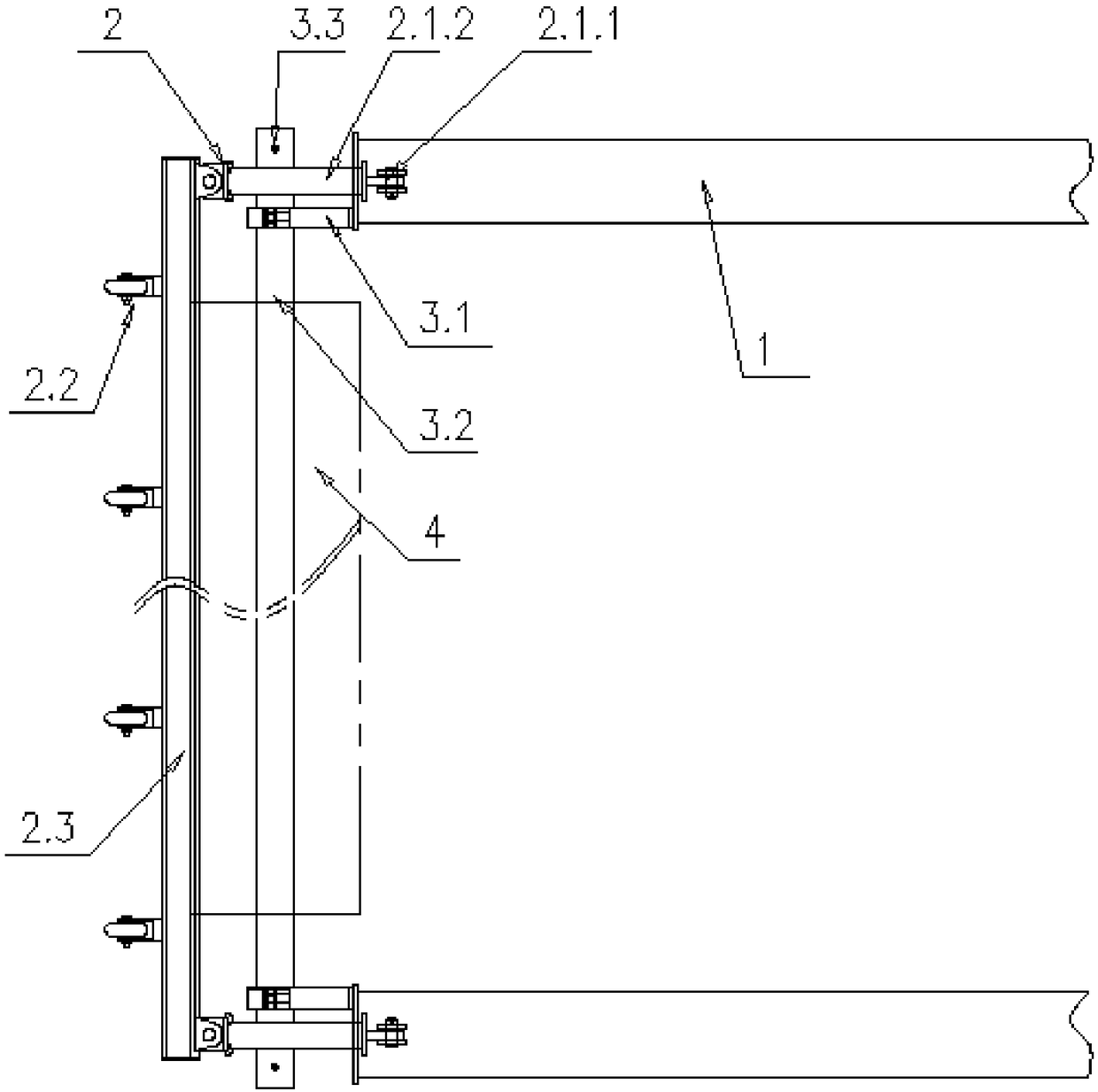

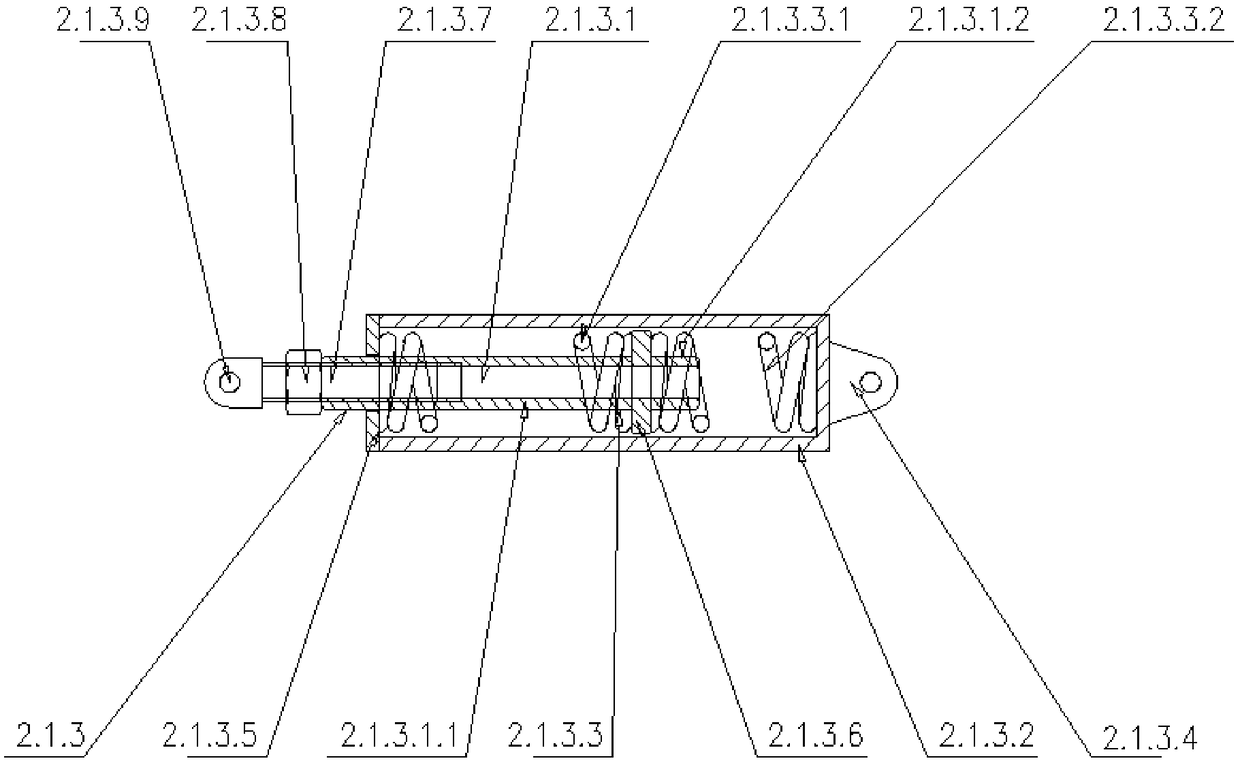

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a device for waterproof coiled material, specifically a waterproof coiled material installation and compression device, this embodiment is applied to the installation and compression of waterproof coiled material in tunnel construction.

[0032] A device for waterproof coiled material, comprising an arm frame 1, a pressing mechanism 2 and an installation mechanism 3.

[0033] The compression mechanism 2 includes a compression unit 2.1, a lifting compression group 2.2, and a longitudinal beam 2.3; each of the two ends of the longitudinal beam 2.3 is connected to a group of compression units 2.1; the longitudinal beam 2.3 is a square bar, and the longitudinal beam 2.3 is on the same surface At least four lifting and pressing groups 2.2 are installed along the length direction; the lifting and pressing groups 2.2 use rolling wheels 2.1 or pressing blocks 2.2; the contact position between the pressing blocks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com