Multi-cylinder hot-air engine

A hot gas engine and fuselage technology, applied in gaseous engine fuels, engine components, combustion engines, etc., can solve the problems of multi-cylinder hot gas that cannot be used uniformly, excessive use of energy, insufficient power, etc., and is conducive to maintenance and maintenance. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

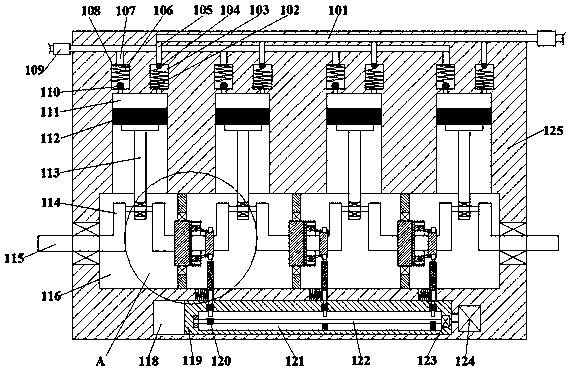

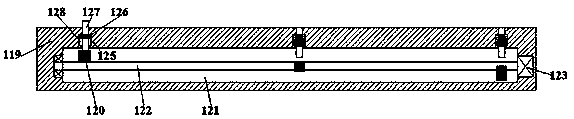

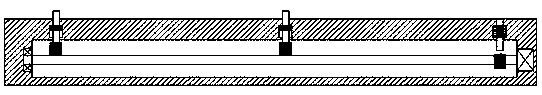

[0017] Such as Figure 1-Figure 5 As shown, the multi-cylinder heat engine of the present invention includes a fuselage 125 and a power chamber 116 arranged in the fuselage 125. The inner wall of the top of the power chamber 116 communicates with four cylinders distributed equidistantly from left to right. Cylinder 111, the top of the cylinder 111 communicates with an exhaust switch cavity 108, and the inner wall of the top of the cylinder 111 communicates with an intake switch cavity 103 located at the right end of the exhaust switch cavity 108, and the inside of the cylinder 111 is slidably fitted A piston 112 is connected, and the bottom of the piston 112 is hingedly connected with a first connecting rod 113 extending up and down. The output shaft 115 extending left and right, the output shaft 115 is provided with the crankshaft 114 at the bottom of the cylinder 111, a power connection mechanism is provided between every two crankshafts 114, and the power chamber 116 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com