Thermoplastic continuous fiber prepreg braided rope hot melt wound bellows and fabricating equipment thereof

A continuous fiber, braided rope technology, applied in rigid pipes, mechanical equipment, hoses, etc., can solve the problems of reducing strength, reducing tensile strength, reducing pipe strength, etc., to improve compressive and ring stiffness strength, improve Data, effect on cost savings of manufacturing materials and tubing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

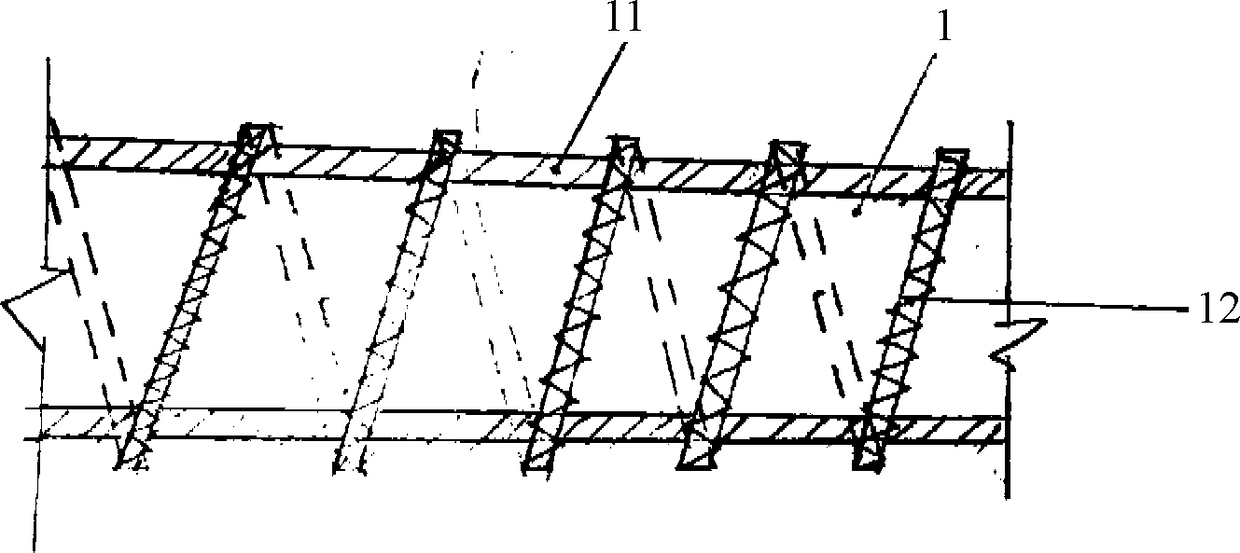

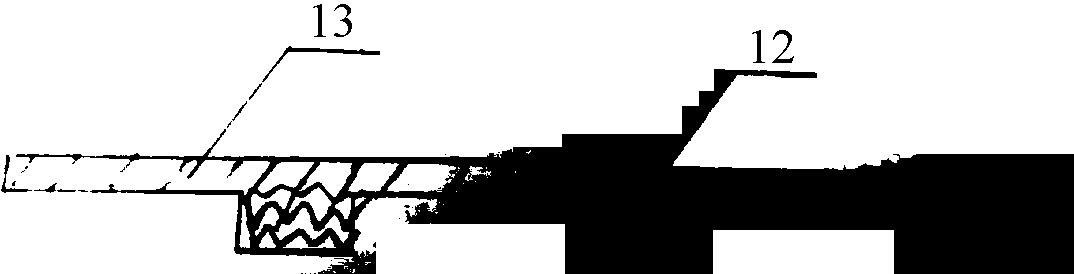

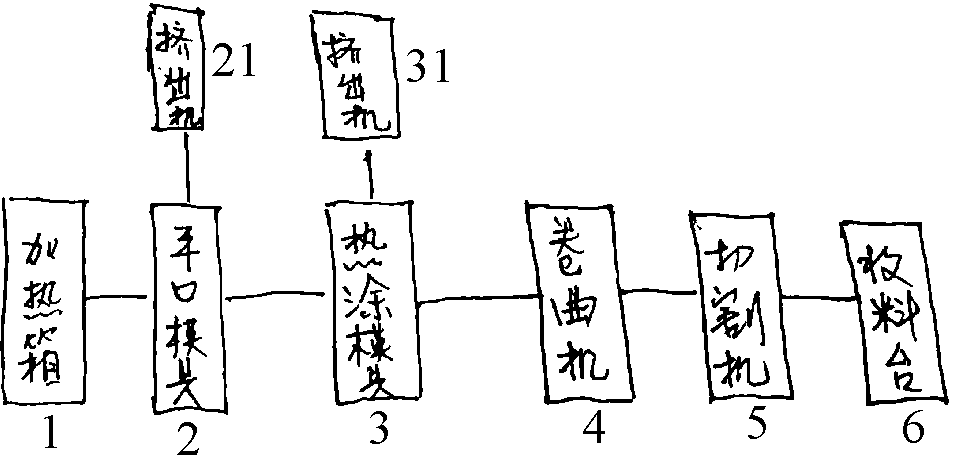

[0025] A thermoplastic continuous fiber pre-impregnated braided rope hot-melt wound corrugated pipe, such as figure 1 As shown, the specific structure is: the hot-melt winding corrugated pipe (10) is composed of a plastic inner layer pipe 11 and a thermoplastic continuous fiber prepreg braided rope 12 continuously wound on the outer wall of the inner layer pipe 11, as figure 1 shown;

[0026] The thermoplastic prepreg braided rope 12 is formed by fusing the thermoplastic prepreg braided rope with the outer wall of the plastic inner layer pipe 11 under the melting temperature condition to form multiple sets of parallel T-shaped plates, and then crimping and cooling as a whole to shape the bellows;

[0027] The continuous fiber prepreg braided rope is composed of multiple strands of continuous fiber prepreg bundles in a mass ratio of 30% to 40% of plastic and 70% to 60% of fiber under the melting condition;

[0028] The hot-melt winding corrugated pipe 10 is made of multiple se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com