Electrical heating film warmer and assembly method of warmer

An electric heating film and heater technology, which is applied in the field of household appliances, can solve the problems of waste of materials, slow assembly efficiency of electric heating film heaters, easy damage to electric heating film, etc., to reduce installation difficulty, improve service life, and fix firmly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

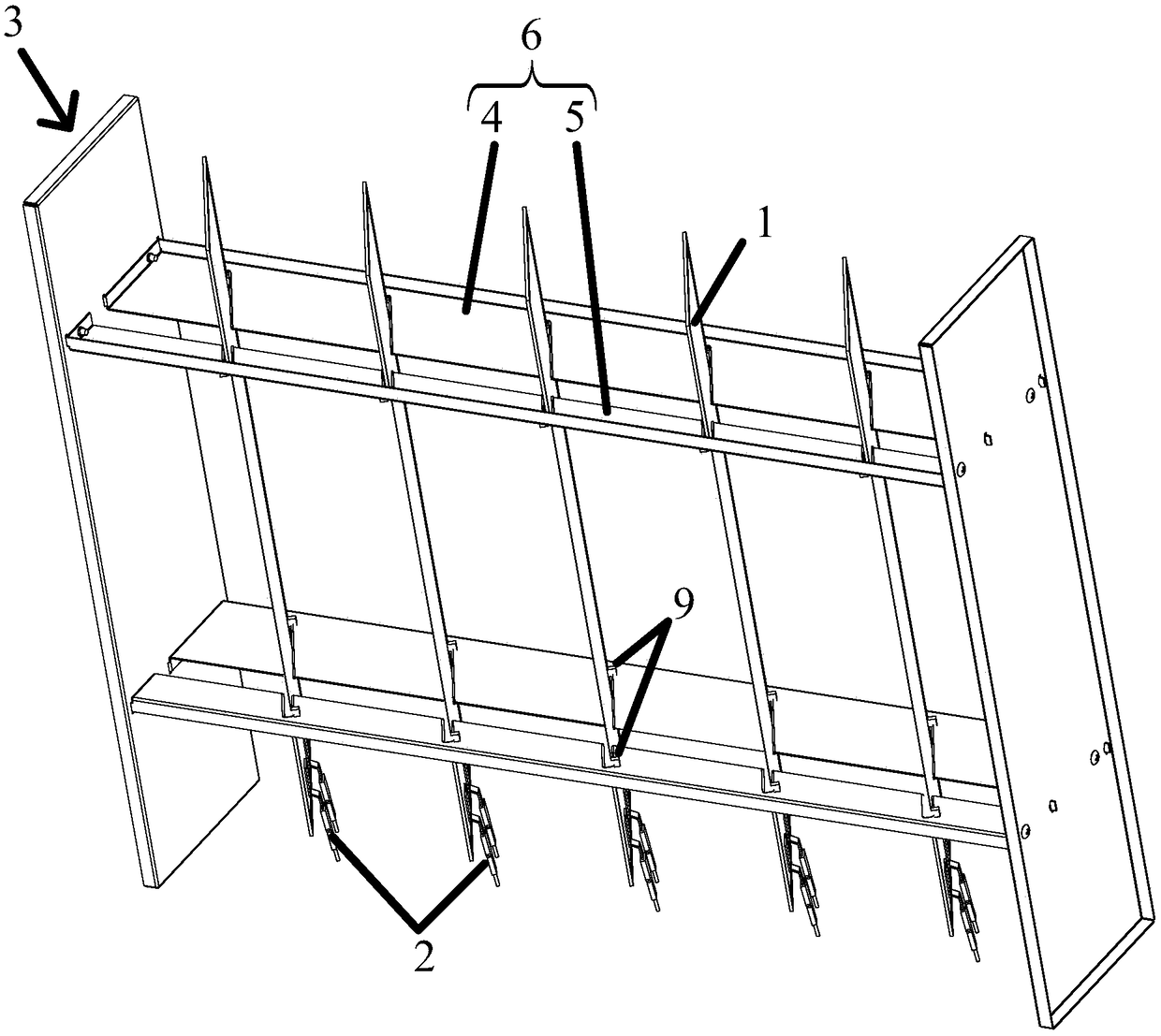

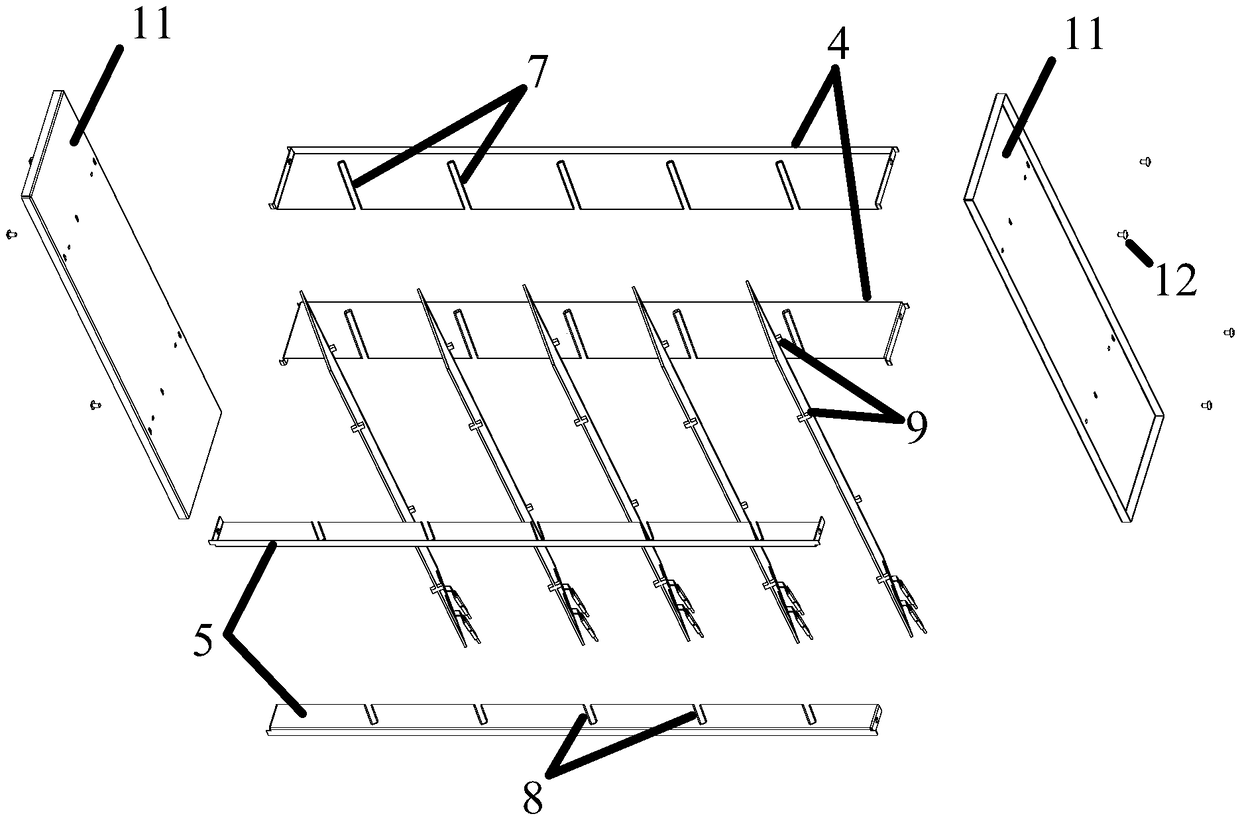

[0050] This embodiment provides an electric heating film heater, such as figure 1 with figure 2 shown, which includes

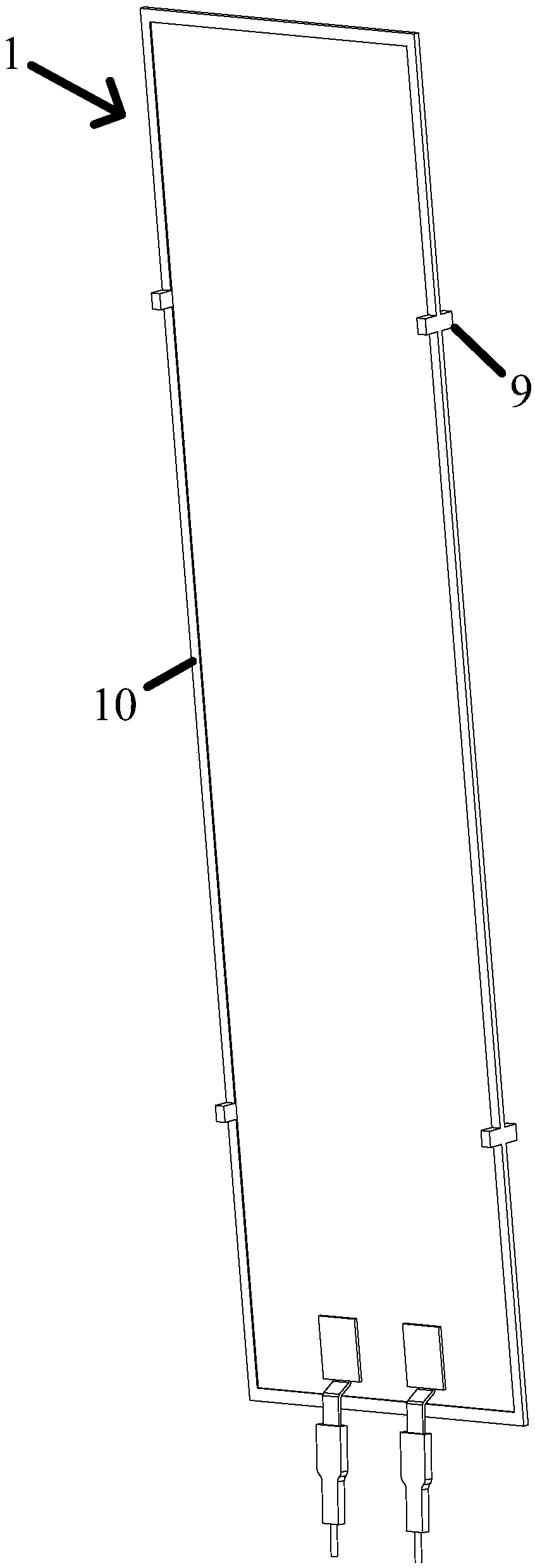

[0051] An electrothermal diaphragm 1, the lower end of the electrothermal diaphragm 1 is provided with a terminal 2, each of the electrothermal diaphragm 1 has two terminals 2, and the two sides of the electrothermal diaphragm 1 are respectively Two sets of protruding parts 9 are provided, and the protruding parts 9 are provided on the protective cover 10 of the outer contour edge of the electrothermal film 1;

[0052] The fixing frame 3 includes two clamping beams 6 that are clamped and connected to the electrothermal diaphragm 1 and a support plate that is respectively connected to both ends of the two clamping beams 6 for supporting the electrothermal diaphragm 1 . The clamping beam 6 includes a first clamping plate 4 and a second clamping plate 5 arranged on the same horizontal plane and perpendicular to the surface of the electrothermal film 1, and t...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that there is only one clamping beam 6 , and the electrothermal diaphragm 1 is vertically arranged to abut against the upper surface of the clamping beam 6 through the protrusion 9 under the action of gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com