Color bar identification skylight construction optical cable and production method

A production method and optical cable technology are applied in the field of color bar identification and production of skylight construction optical cables, which can solve the problems of affecting construction efficiency, increasing the stripping length of optical cables, and unable to accurately locate the SZ twisting and reversing points of optical cables, saving labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

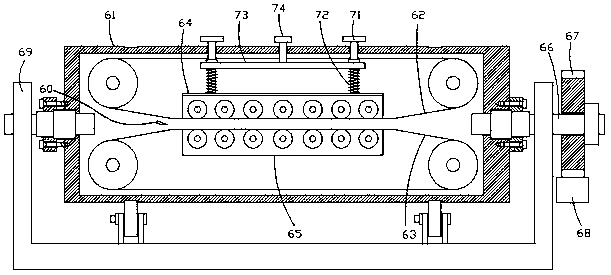

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

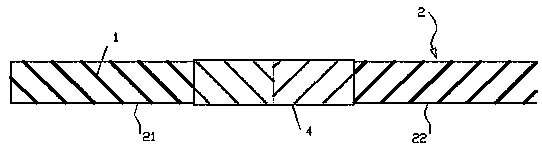

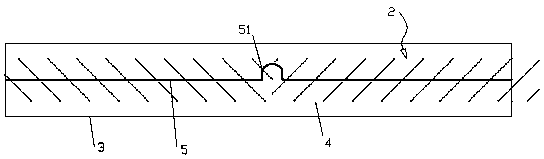

[0022] like figure 1 and figure 2 , a construction optical cable for color bar identification for opening skylights according to the present invention, comprising an optical fiber, a loose tube 1 and an outer sheath 3. The sleeve 3 is wrapped on the cable core 2 . The cable core 2 includes a forward twisted part 21 and a reverse twisted part 22. Both the forward twisted part 21 and the reverse twisted part 22 of the cable core are wrapped with a fixing belt, and the fixing belt ensures the twisted The cable core 2 is not loose, and the fixing belt includes a gauze tape and a transparent polyester tape wrapped on the cable core in turn from the inside to the outside.

[0023] A marker block 4 is attached at the position (junction) of the forward twisted part 21 and the reverse twisted part 22 of the cable core, and a colored ribbon 5 is arranged on the side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com