Outdoor drop cable

A technology for introducing optical cables and optical cables, applied in the directions of light guides, optics, optical components, etc., can solve the problems of not fully meeting the laying requirements and inconvenient construction, and achieve the effect of shortening the laying period and use cost, convenient construction, and reducing connection points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

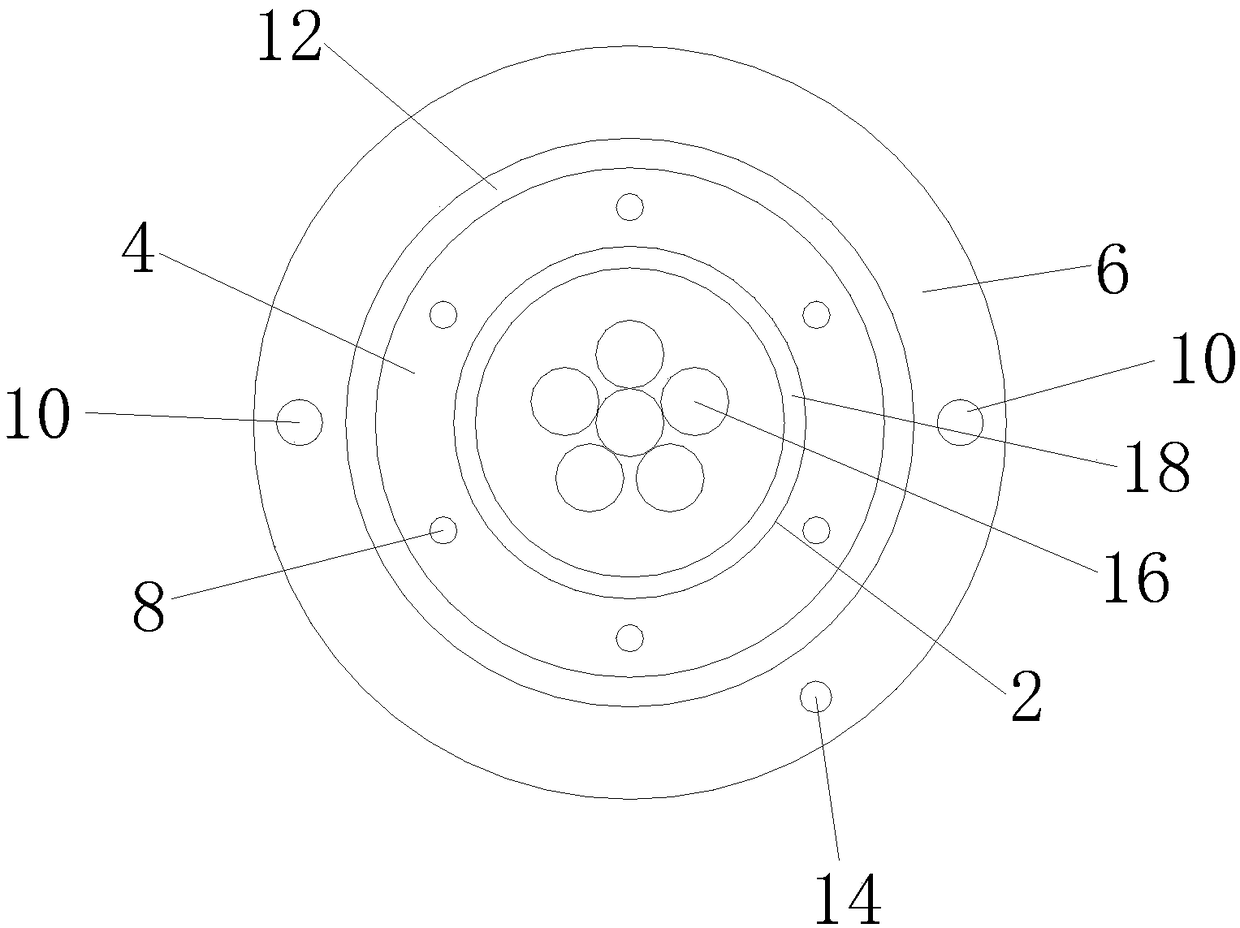

[0020] refer to figure 1 As shown, the present invention discloses an outdoor lead-in optical cable. The cross-section of the above-mentioned optical cable is circular, and it includes a cable core 2, an inner sheath layer 4 coated on the outside of the above-mentioned cable core 2, and an inner sheath layer coated on the outer side of the cable core 2. 4 the outer non-metallic protective layer 12, and the outer sheath layer 6 covering the outer side of the non-metallic protective layer 12. The cable core 2 includes an optical fiber unit 16 and an insulating layer 18 covering the optical fiber unit 16 , and fiber paste or dry flexible water-blocking yarn is filled between the optical fiber unit 16 and the insulating layer 18 .

[0021] Such as figure 1 As shown, the above-mentioned inner sheath layer 4 is embedded with six first non-metallic reinforcing cores 8, and the above-mentioned six first non-metallic reinforcing cores 8 are distributed on concentric circles with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com