A fast-setting tile adhesive

A tile adhesive and fast technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as unfavorable construction by construction workers, indoor environmental pollution, and impact on people's health, and shorten the construction period. , Short setting time, the effect of enhancing the toughness of the glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

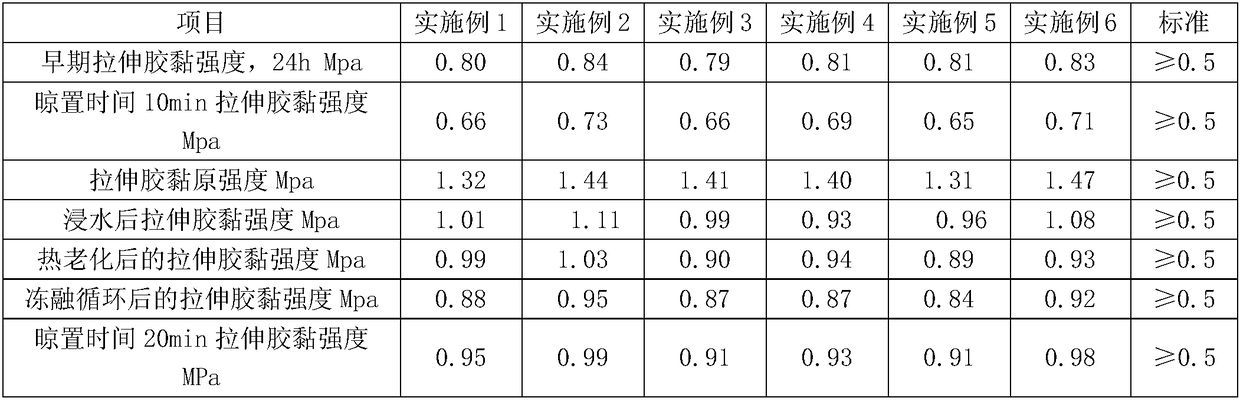

Examples

Embodiment 1

[0034] A fast-setting tile adhesive, consisting of the following raw materials: 20kg of rapid hardening cement, 40kg of quartz sand, 10kg of fly ash, 10kg of heavy calcium, 2kg of redispersible latex powder, 0.2kg of cellulose ether, and starch ether 0.1kg, water repellent 0.2kg, retarder 0.1kg, early strength agent 1kg. The water-repellent agent is composed of the following raw materials in parts by weight: 60 parts of organosilane water-repellent agent, 10 parts of calcium stearate, 10 parts of stearic acid, and 5 parts of silane coupling agent. The retarder is composed of the following raw materials in parts by weight: 15 parts of citric acid, 20 parts of boric acid, 15 parts of calcium gluconate, and 5 parts of sodium phosphate. The early strengthening agent is composed of the following raw materials in parts by weight: 40 parts of aluminum sulfate, 15 parts of calcium formate, 5 parts of sodium metaaluminate, 5 parts of calcium oxide, and 5 parts of copper sulfate. The p...

Embodiment 2

[0037] A fast-setting tile adhesive, consisting of the following raw materials in kilograms: rapid hardening cement 25kg, quartz sand 45kg, fly ash 15kg, heavy calcium 15kg, redispersible latex powder 3kg , 0.35kg of cellulose ether, 0.2kg of starch ether, 0.35kg of water repellent, 0.25kg of retarder, and 3kg of early strength agent. The water repellent is composed of the following raw materials in parts by weight: 65 parts of organosilane water repellent, 15 parts of calcium stearate, 15 parts of stearic acid and 8 parts of silane coupling agent. The retarder is composed of the following raw materials in parts by weight: 20 parts of citric acid, 30 parts of boric acid, 20 parts of calcium gluconate, and 10 parts of sodium phosphate. The early strengthening agent is composed of the following raw materials in parts by weight: 50 parts of aluminum sulfate, 20 parts of calcium formate, 10 parts of sodium metaaluminate, 10 parts of calcium oxide and 10 parts of copper sulfate. T...

Embodiment 3

[0040]A fast-setting tile adhesive, composed of the following raw materials: 40kg of rapid hardening cement, 50kg of quartz sand, 20kg of fly ash, 20kg of heavy calcium, 4kg of redispersible latex powder, 0.5kg of cellulose ether, and starch ether 0.3kg, water repellent 0.5kg, retarder 0.4kg, early strength agent 5kg. The water-repellent agent is composed of the following raw materials in parts by weight: 70 parts of organosilane water-repellent agent, 20 parts of calcium stearate, 20 parts of stearic acid, and 10 parts of silane coupling agent. The retarder is composed of the following raw materials in parts by weight: 25 parts of citric acid, 40 parts of boric acid, 25 parts of calcium gluconate, and 15 parts of sodium phosphate. The early strengthening agent is composed of the following raw materials in parts by weight: 60 parts of aluminum sulfate, 25 parts of calcium formate, 15 parts of sodium metaaluminate, 15 parts of calcium oxide and 15 parts of copper sulfate. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com