Efficient ceramic tile automatic grouting machine

A ceramic tile and automatic technology, which is applied in the direction of architecture and building construction, etc., can solve the problems of large tile area, low application efficiency, and high labor intensity, and achieve the effects of low labor cost, reduced labor intensity, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

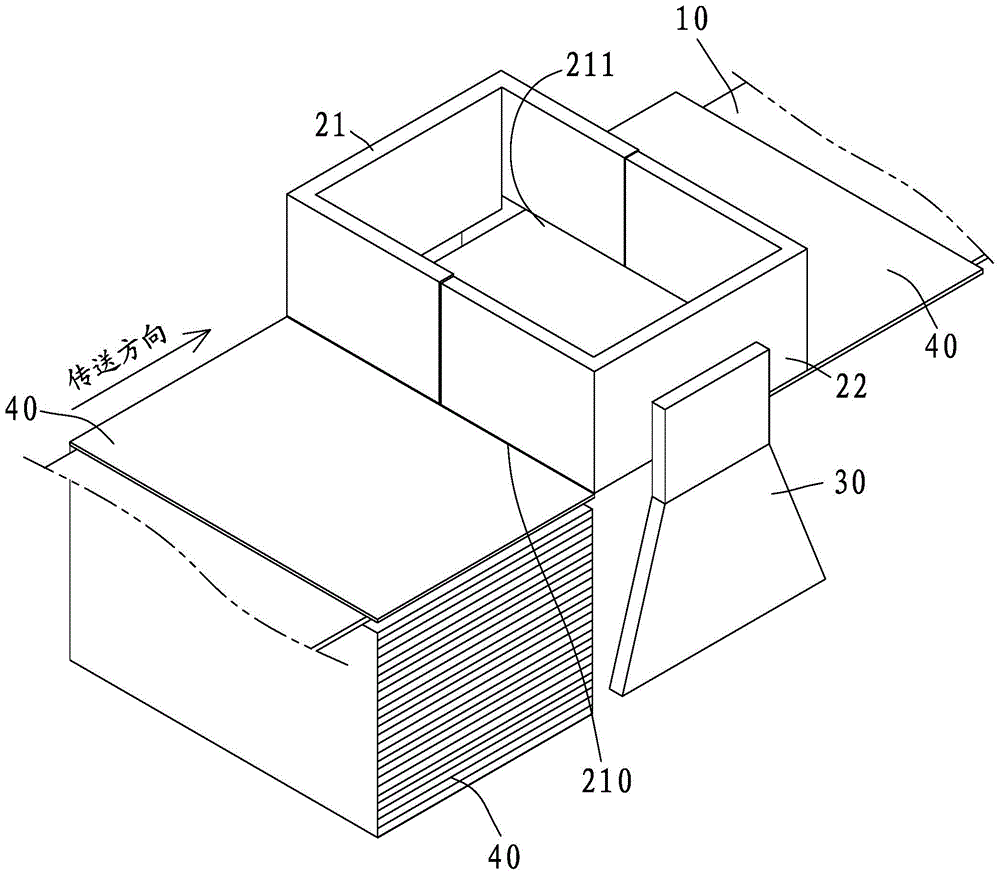

[0019] refer to figure 1 As shown, the present invention provides a high-efficiency ceramic tile automatic grouting machine, which includes a transmission mechanism and a square container, wherein the transmission mechanism is used to transmit tiles 40, and the transmission mechanism includes a conveyor belt 10 and a driving device that drives the conveyor belt 10 to move, The driving device can adopt a motor, a driving pulley and a driven pulley commonly used in the prior art. The conveyor belt 10 straddles the driving pulley and the driven pulley. The motor drives the driving pulley to rotate, and then drives the transmission belt to move horizontally. The square container is used to hold mortar or cement, and the square containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com