High-precision oil filling pen

A high-precision, pen holder technology, applied in the field of oil filling pens, can solve the problems of poor practicability and achieve the effect of strong practicability, stable installation, and small and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

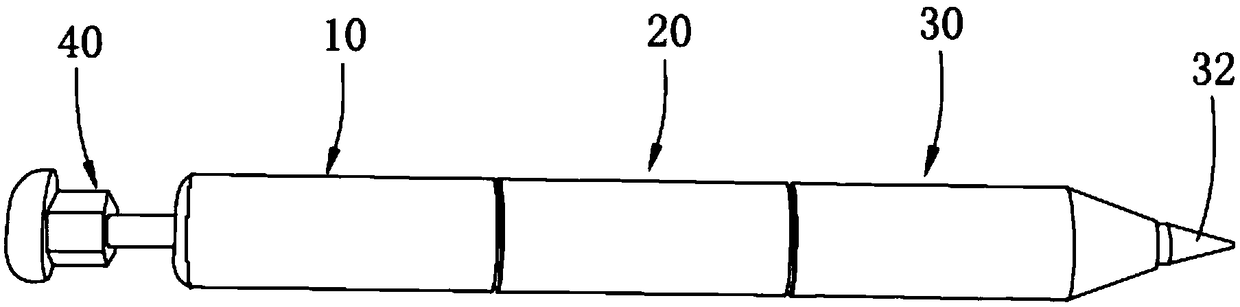

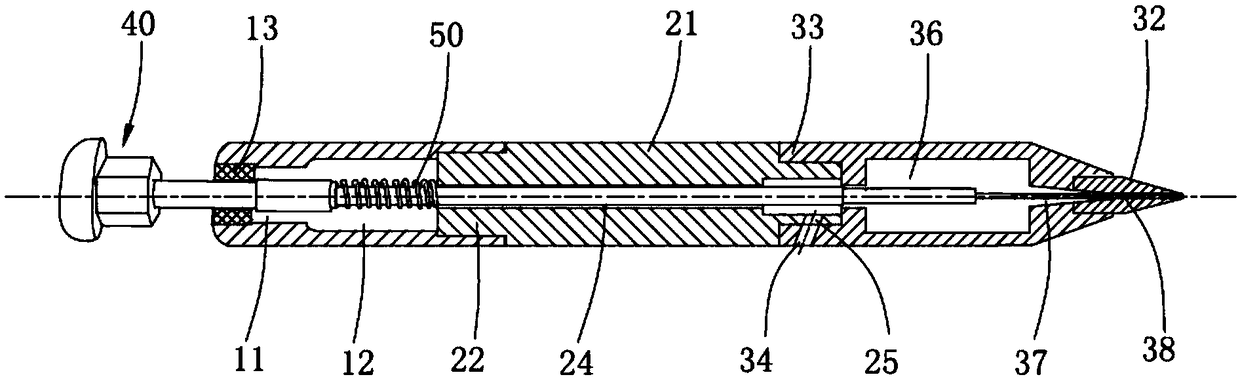

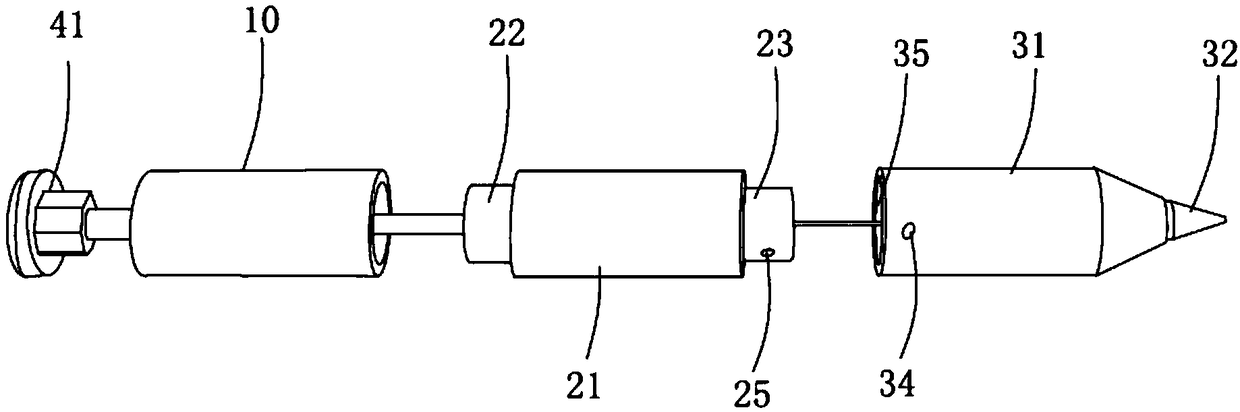

[0017] like Figure 1 to Figure 4 As shown, the present invention provides a high-precision oiling pen, which is used to add lubricating oil to clock axis holes and drill holes in watch manufacturing and maintenance. The high-precision oil filling pen includes a first pen holder 10 , a second pen holder 20 , a nib 30 , a refill 40 and a compression spring 50 , and the first pen holder 10 and the nib 30 are installed at both ends of the second pen holder 20 respectively. The compression spring 50 is installed in the first pen container 10 , and the lubricating oil is installed in the nib 30 . The pen refill 40 is installed in the first pen holder 10 , the second pen holder compression spring 50 and the nib 30 sequentially. Press the pen core 40 so that the pen core 40 extends from one end of the pen tip 30 , and the lubricating oil flows out from the pen tip 30 along the pen core 40 .

[0018] The first pen container 10 is provided with a first installation hole 11 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com