A leakage positioning method for urban non-metallic pipelines based on inverse transient model

A pipeline leakage and transient model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as loss, damage leakage, casualties and property, and achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will now be described in detail in conjunction with examples. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

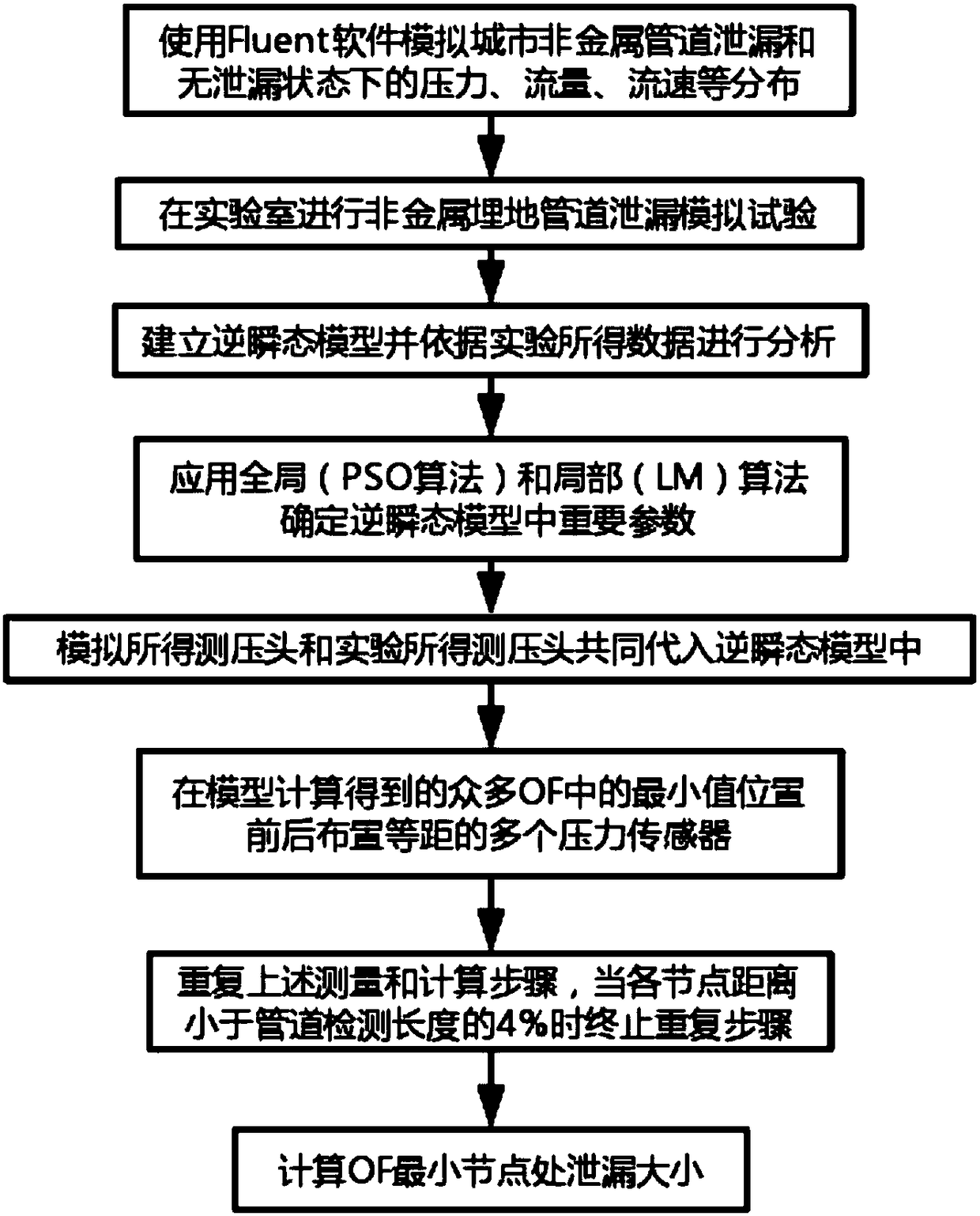

[0045] Such as figure 1 As shown, an urban non-metallic pipeline leakage location method based on the inverse transient model, this method is mainly used to detect the leakage under large flow pressure in urban pipelines with complex bends, many valves, instruments and branch pipes, Include the following steps:

[0046] S1: Use AnsysIcem to model the pipeline system 1, and use Fluent software to simulate.

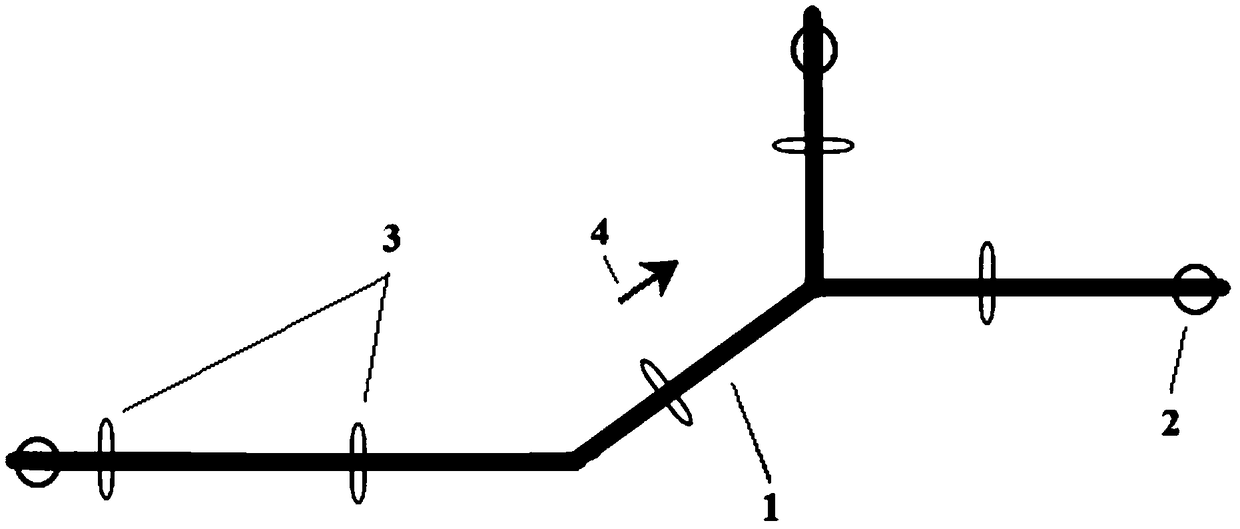

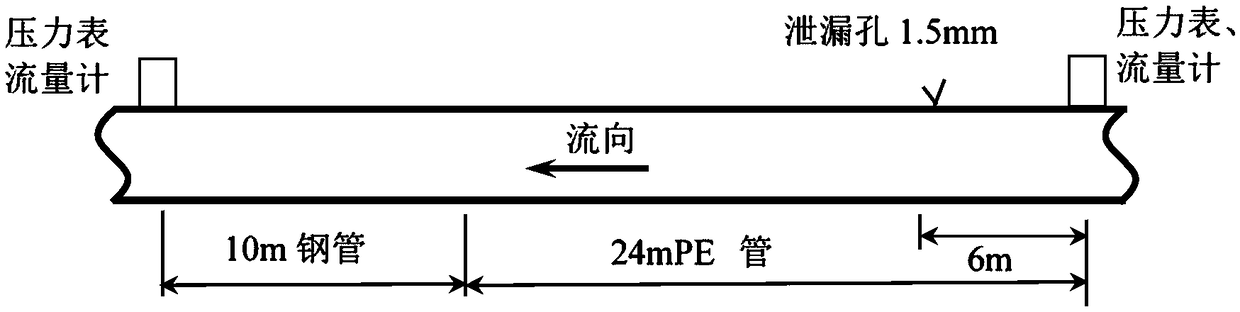

[0047] Such as figure 2 As shown, the experimental pipeline system 1 adopts a branched and bent pipeline structure formed by multi-section pipeline connections, and multiple pressure sensors 3 are installed on the pipeline system 1, and flowmeters 2 are installed on the upstream and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com