Casing-entering device

A shell, together technology, applied in the field of product body and shell assembly equipment, can solve the problems of insufficient precision in the shelling operation, wear of the main structure of the product, difficulty in the same axis, etc., to avoid product wrinkles, accurate shelling, and shelling easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

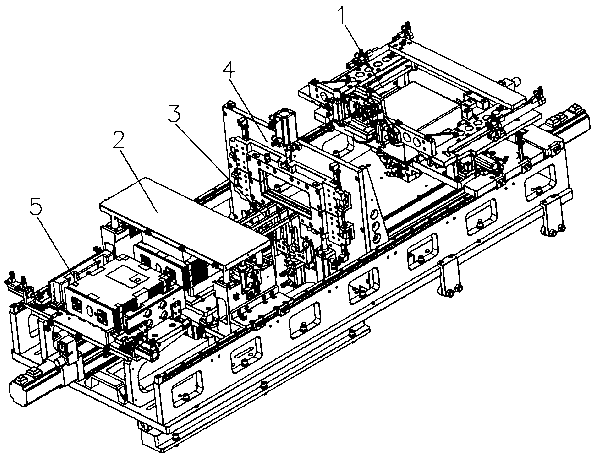

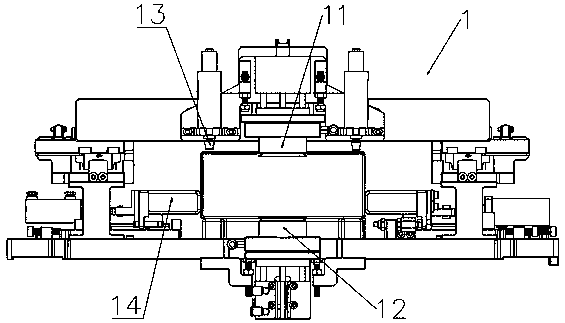

[0023] Refer to Figure 1~5 , A housing device, comprising a housing transfer mechanism 1, a core transfer mechanism 2, and an intermediate support platform 3. The shell transfer mechanism 1, the core transfer mechanism 2 and the intermediate support platform 3 are arranged along the same axis, and the intermediate support platform 3 Set at a position between the shell transfer mechanism 1 and the core transfer mechanism 2, the shell transfer mechanism 1 and the core transfer mechanism 2 can be slidably arranged; thus, the shell transfer mechanism 1 can move the shell of the product to the middle position, and the core The transfer mechanism 2 can transfer the internal structure of the product to an intermediate position. The shell transfer mechanism 1 remains stationary when the shell is inserted, and the core transfer mechanism 2 cooperates with the intermediate support 3 to send the internal structure of the product into the shell.

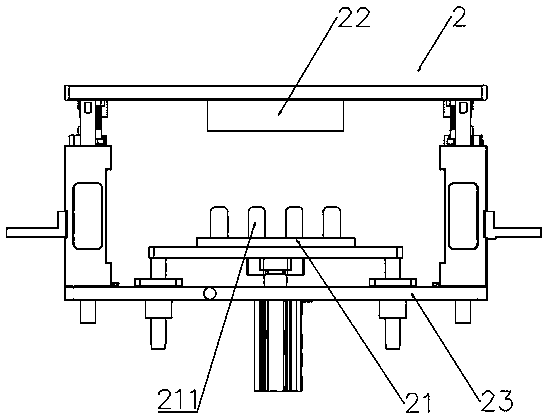

[0024] Refer to figure 1 with 3 The core tr...

Embodiment 2

[0029] Refer to Figure 4 , Based on the first embodiment, the housing entry device of this embodiment further includes a guide mechanism 4, which is fixedly arranged at a position between the housing transfer mechanism 1 and the intermediate support platform 3, and is connected to the housing transfer mechanism 1 and the intermediate support The table 3 is arranged on the same axis to provide a guide for the internal structure of the product to enter the shell, so as to avoid offset and scratches. The guide mechanism 4 includes an upper guide block 41 and a lower guide block 42. The upper guide block 41 and the lower guide block 42 are arranged opposite to each other, for example, arranged up and down. The position between the two can pass through the internal structure of the product and be in line with the product. The shape of the structure is consistent. The upper guide block 41 and the lower guide block 42 are both telescopically arranged to adjust the size of the telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com