Pre-vacuum pressure steam sterilization fast biology challenge test bag

A pressure steam, pre-vacuum technology, applied in sanitary equipment, water supply devices, heating and other directions for toilets, can solve the problems of environmental damage, consumption of nature and human resources, etc., to achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

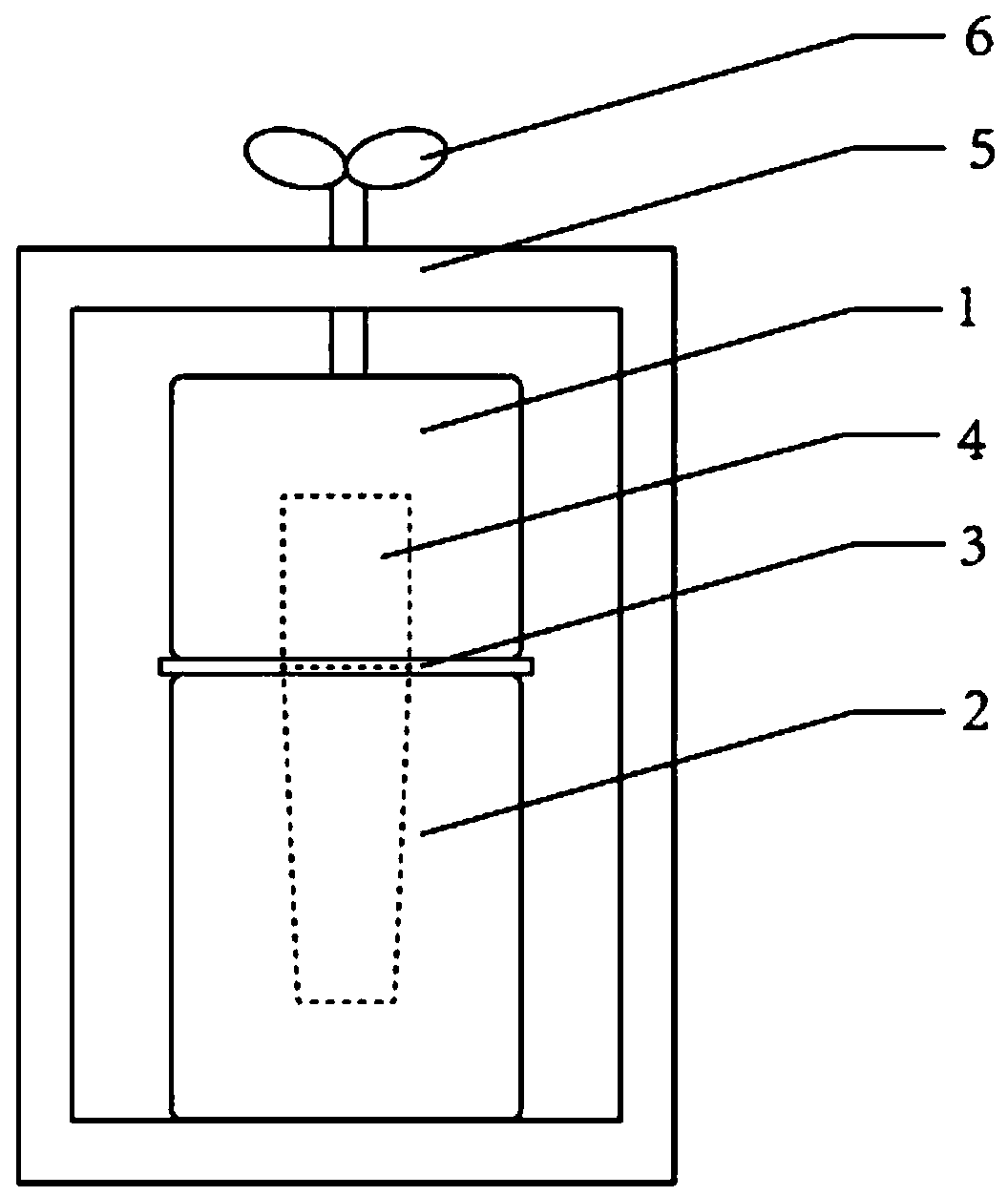

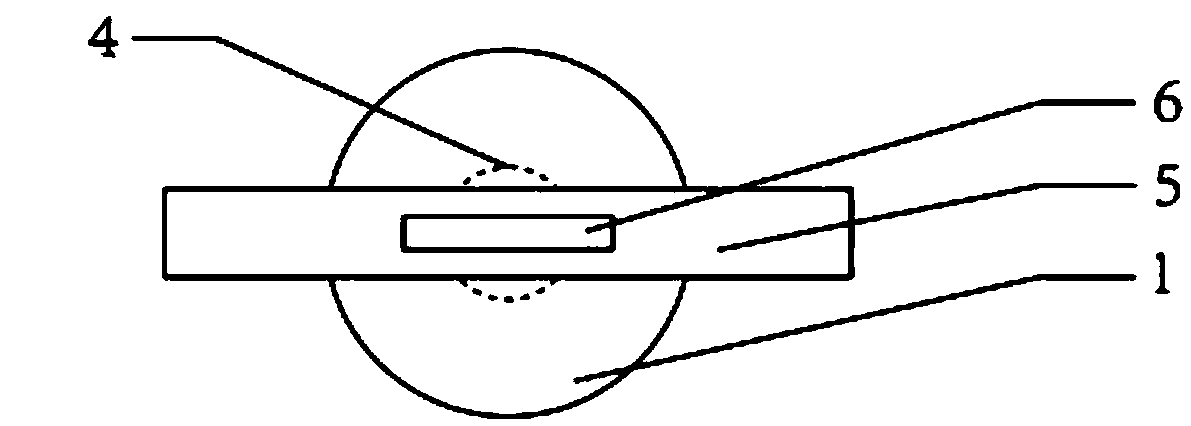

[0028] See figure 1 and figure 2 , In this embodiment, the wall thickness of the microporous ceramics is 15 mm, and the diameter of the micropores is 50 microns. The fastening frame 5 is a rectangular outer frame support, and the clamp 6 is a screw-on jackscrew. The tightening top wire passes through the tightening hole above the fastening frame 5, and the lower end of the tightening top wire is fixed on the top of the ceramic container loam cake 1, and a suitable screw is provided on the outside of the tightening top wire and the tightening hole. matching thread. By rotating and tightening the top wire, the upper cover 1 of the microporous ceramic container and the lower cover 2 of the microporous ceramic container can clamp the sealing gasket 3 .

Embodiment 2

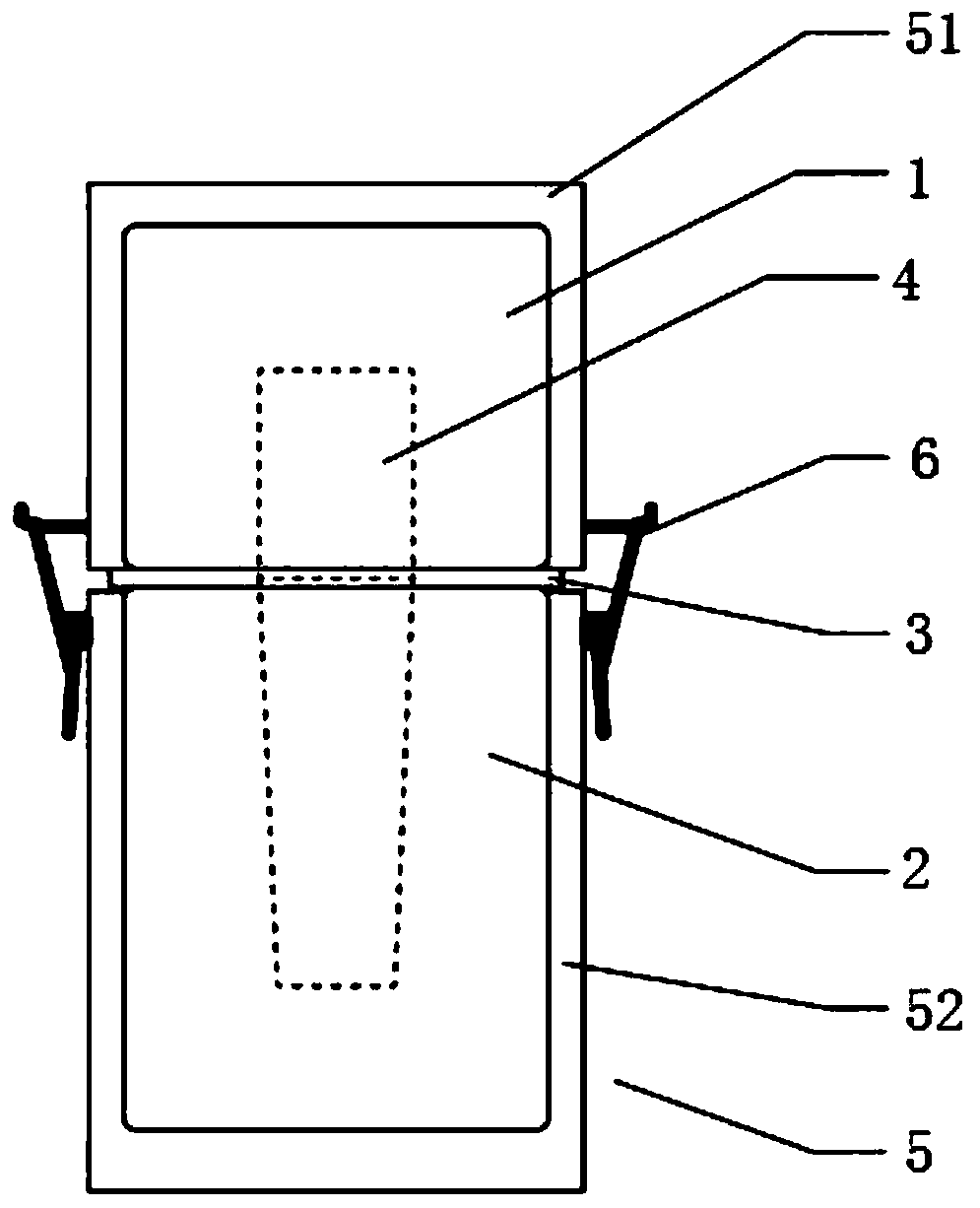

[0030] See image 3 and Figure 4 , In this embodiment, the wall thickness of the microporous ceramics is 20 mm, and the diameter of the micropores is 55 microns. The fastening frame 5 includes a first upper fastening cover 51 and a first lower fastening cover 52, and the clamp 6 is a hasp lock. The first upper fastening cover 51 is disposed on the first lower fastening cover 52 , and the first upper fastening cover 51 and the first lower fastening cover 52 are connected together by a hasp lock. A microporous ceramic container accommodating cavity is formed inside the first upper fastening cover 51 and the first lower fastening cover 52, and the microporous ceramic container is disposed in the microporous ceramic container accommodating chamber.

[0031] The sealing gasket 3 is arranged between the first upper fastening cover 51 and the first lower fastening cover 52. The function of the hasp lock is not only to connect the first upper fastening cover 51 and the first lower ...

Embodiment 3

[0033] See Figure 5 and Image 6 , In this embodiment, the wall thickness of the microporous ceramics is 15 mm, and the diameter of the micropores is 50 microns. The fastening frame includes a second upper fastening cover 53 and a second lower fastening cover 54, and the second upper fastening cover 53 is arranged on the second lower fastening cover 54, on the inner side of the lower end of the second upper fastening cover 53 The outside of the upper end of the second lower fastening cover 54 is provided with a screw thread 55 , and the second upper fastening cover 53 and the second lower fastening cover 54 are screwed together by the screw thread 55 . The microporous ceramic container is arranged in the fastening frame, and the fastening frame can make the upper cover 1 of the microporous ceramic container and the lower cover 2 of the microporous ceramic container clamp the sealing gasket 3 .

[0034] The invention discloses a pre-vacuum pressure steam sterilized rapid bio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com