Automatic sorting device for teaching materials and sorting method

An automatic sorting and material technology, applied in sorting and other directions, can solve the problems of labor, limited automation, uneven workpieces, etc., to achieve the effect of improving work efficiency, enhancing awareness, and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

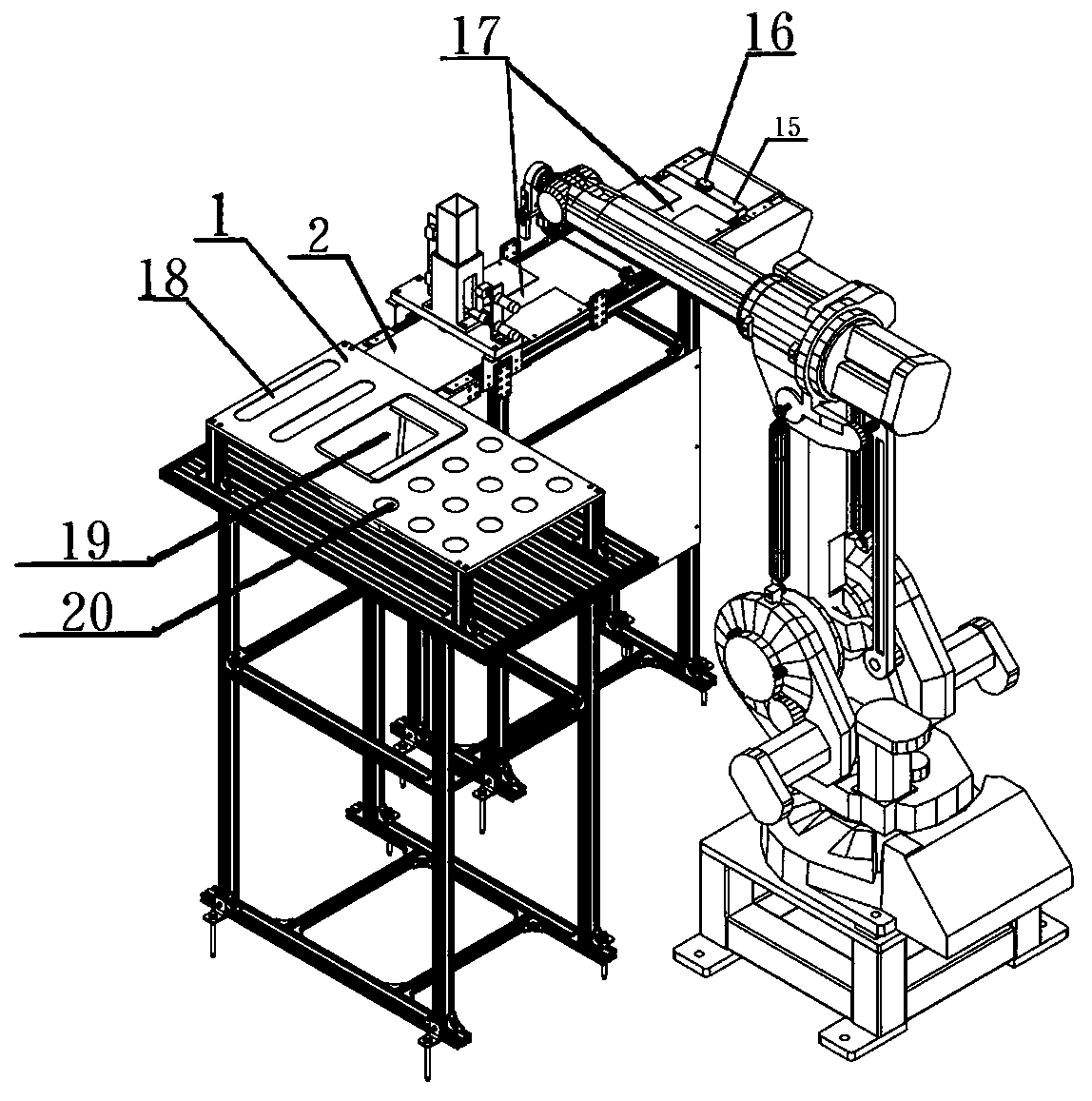

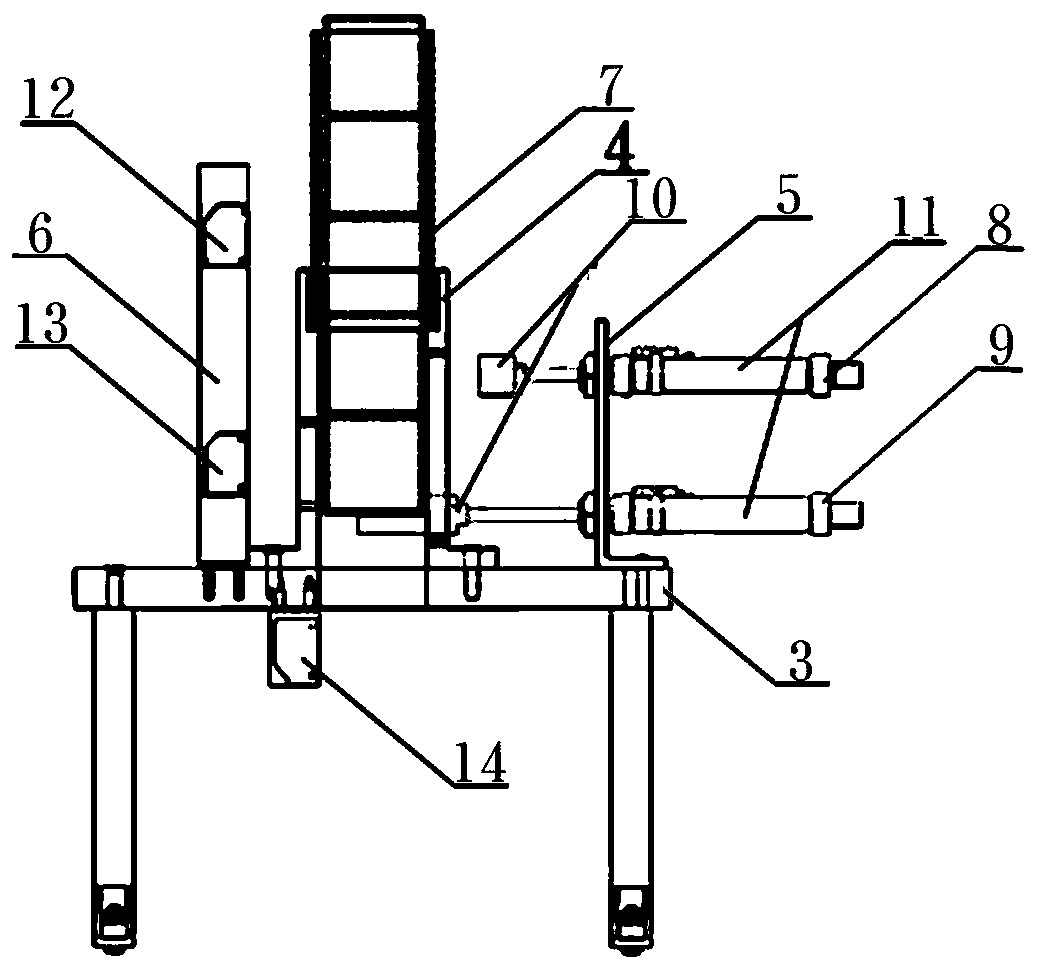

[0026] An automatic material sorting device for teaching, comprising a robot, a coding platform 1, a conveyor belt 2, a bracket arranged perpendicular to the direction of the conveyor belt 2, and an automatic feeding device fixed on the bracket; the automatic feeding device includes Be arranged on the table top 3 on the support, the orientation cylinder 4, the sensor bracket 6 arranged on the left side of the orientation cylinder 4 and the cylinder support 5 on the right side and the material guide cylinder 7 in the orientation cylinder 4; the orientation cylinder 4 is arranged on the table top 3 The top and bottom penetrate the table top 3, the left and right sides of the orientation cylinder 4 are provided with openings, and the cylinder bracket 5 is provided with a jacking cylinder 8 and a blanking cylinder 9 sequentially from top to bottom. The material cylinder 9 is composed of a cylinder 10 and a piston rod 11 facing the orientation cylinder 4, and the piston rod 11 is fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com