Indoor polishing device

A technology of grinding mechanism and mounting frame, which is applied in the direction of grinding driving device, grinding machine, grinding frame, etc., which can solve the problems of laborious and time-consuming grinding of the ceiling and poor grinding effect, so as to facilitate dust suction and improve dust prevention effect, the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

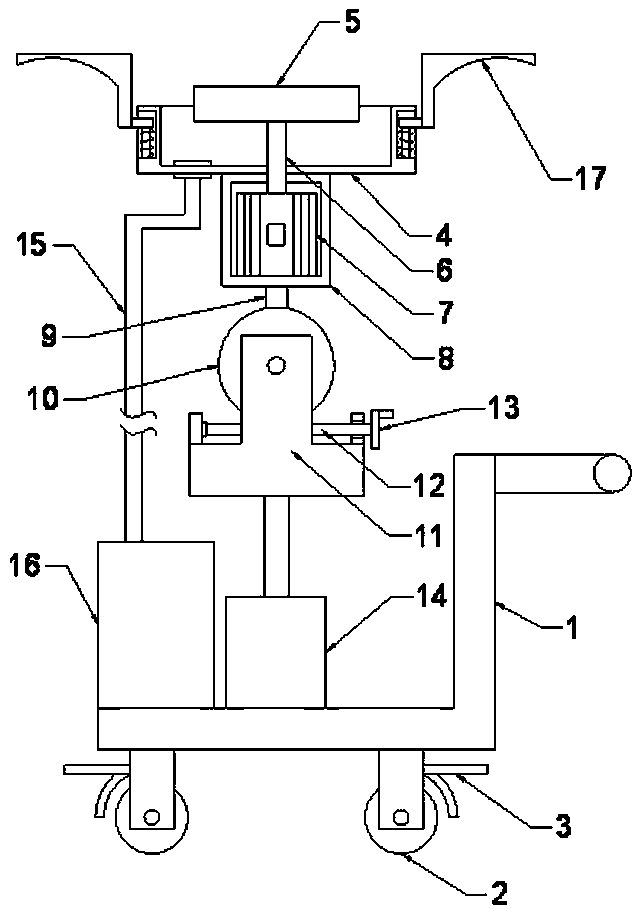

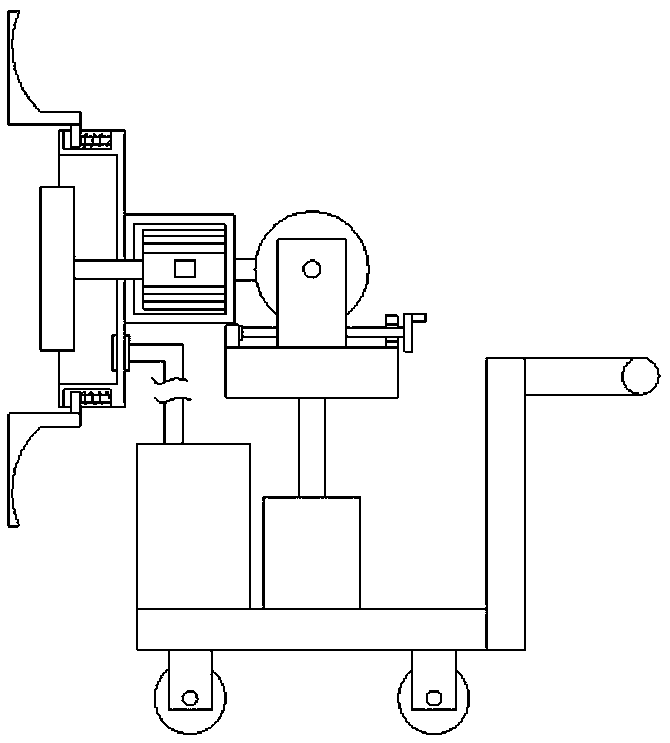

[0020] see Figure 1~3 , in an embodiment of the present invention, an indoor grinding device includes a trolley 1, a grinding mechanism and a steering mechanism; the bottom of the trolley 1 is provided with a roller 2, and the roller 2 is provided with a locking device 3, and the locking device 3 pairs the rollers 2 is fixed so that the trolley 1 remains stable, which is convenient for operation and easy to move at the same time; the top of the trolley 1 is provided with a grinding mechanism, and the grinding mechanism includes a dust collection cover 4, and a grinding wheel 5 is nested in the dust collection cover 4, and the grinding wheel 5 The rotating shaft 6 is fixedly connected, the rotating shaft 6 runs through the dust collecting cover 4 and is fixedly connected to the output shaft of the driving motor 7, the driving motor 7 is sleeved with a mounting frame 8, the driving motor 7 is electrically connected with an external power supply, and the driving motor 8 Drive th...

Embodiment 2

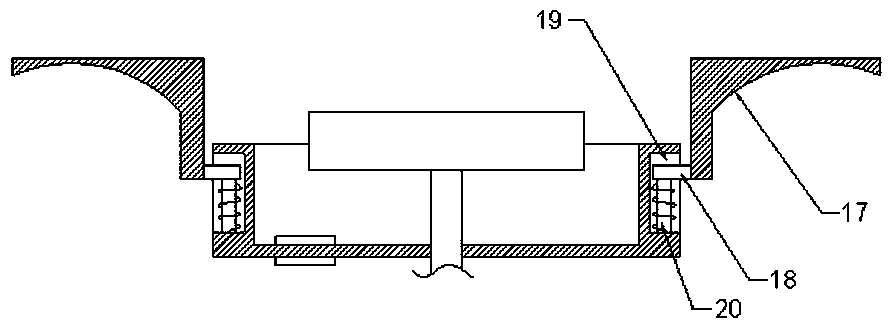

[0023] see figure 1 and figure 2 The difference between this embodiment and Embodiment 1 is that: the outer side of the dust collection cover 4 is covered with a conical cover 17, the inner side of the conical cover 17 is fixedly connected with a slider 18, and the outer wall of the dust collection cover 4 is provided with a chute 19, The slider 18 is nested in the chute 10 and is slidably connected with the chute 19; the slider 18 is connected with the inner wall of the chute 19 through the spring sleeve 20, so that the conical cover 17 is in contact with the working surface to prevent the dust from going out Diffusion, improve dustproof effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com