Paper pressing device

A technology of pressing paper and fuselage, applied in the field of stationery, can solve problems such as paper pulling and offset, and achieve the effect of improving reliability, clear structure, and increasing smoothing arm span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

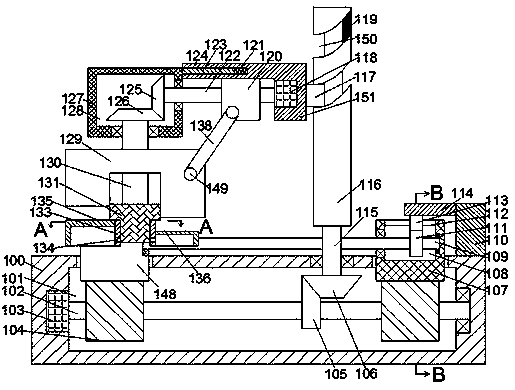

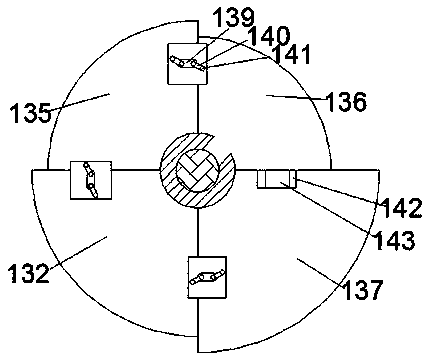

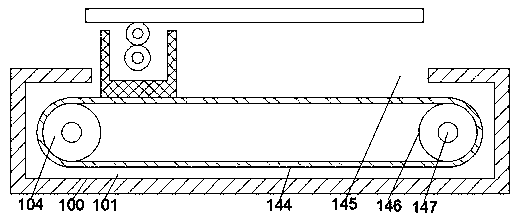

[0014] like Figure 1-Figure 3 As shown, the paper pressing device of the present invention includes a body 100 and a first cavity 101 disposed in the body 100, the upper end of the body 100 communicates with a left-right symmetrical first chute 145, the The inner wall of the top end of the first cavity 101 is rotatably connected with the first transmission shaft 115 extending up and down between the first chute 145, and the bottom end of the first transmission shaft 115 is provided with a first bevel gear 106, so that The top end of the first transmission shaft 115 is fixedly connected with the track barrel 116 located on the upper end surface of the fuselage 100, the track barrel 116 is surrounded by a track groove 150, and the upper end of the track groove 150 is fixedly connected with a limit block 119 , the track groove 150 is connected with a guide slider 117, the other end of the guide slider 117 is fixedly connected with an L-shaped power block 151, and the left end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com