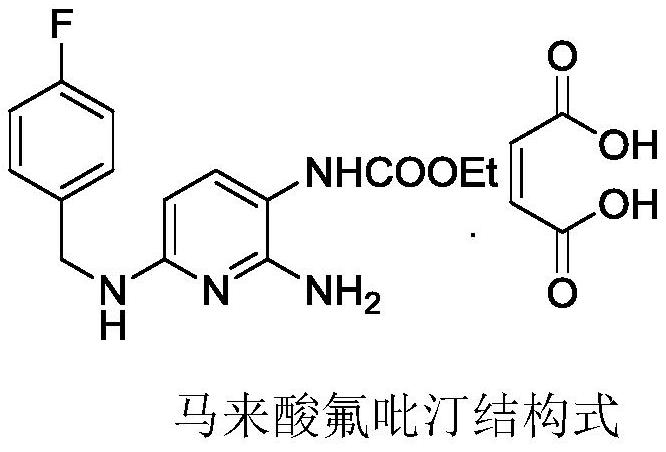

A method for preparing flupirtine maleate with a crystal form high bulk density

A technology of flupirtine maleate and flupirtine, applied in organic chemistry methods, organic chemistry, etc., can solve the problems of inability to obtain high bulk density crystal form A, failure to meet preparation requirements, serious electrostatic adsorption, etc., and achieve crystal The effect of stable type content, low cost and high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Under nitrogen protection, add 10 g of flupirtine white partial ash refined product into a 1000 m3 three-necked flask, add 250 g of isopropanol, 10 g of DMSO, heat the internal temperature to 30 ° C, mechanically stir to dissolve, the rotating speed is 200 rpm / min, 4.0 g of horse The acid was dissolved in 20.0 g isopropanol and added dropwise to a three-necked flask, reacted for 1 h, filtered, rinsed with a small amount of isopropanol, and drained to obtain white crystals, which were dried in vacuum to obtain pure flupirtine maleate 13.1 g, the yield is 95%. It was confirmed to be pure A crystal form by X powder diffraction.

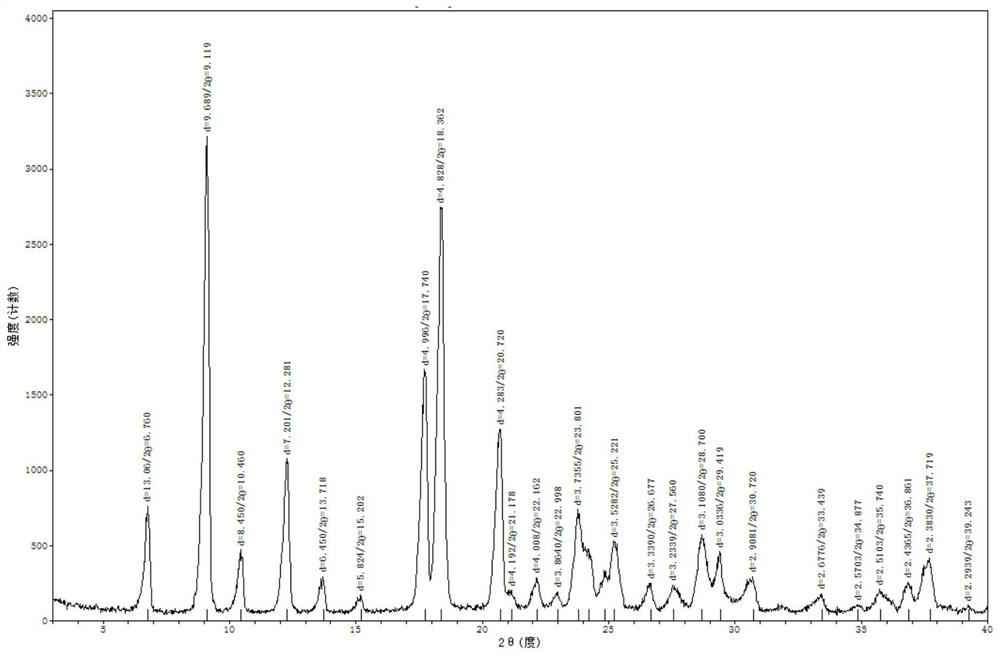

[0037] The diffraction angle, interplanar spacing and relative intensity of A crystal are shown in the following table:

[0038]

[0039] 1 HNMR (500MHz, DMSO-d6) δ:

[0040] 8.342(s,1H), 7-8(m,5H), 6.152(s,2H), 5.79(d,1H), 4.385(s,2H), 4.03(t,2H), 1.193(m,3H) .

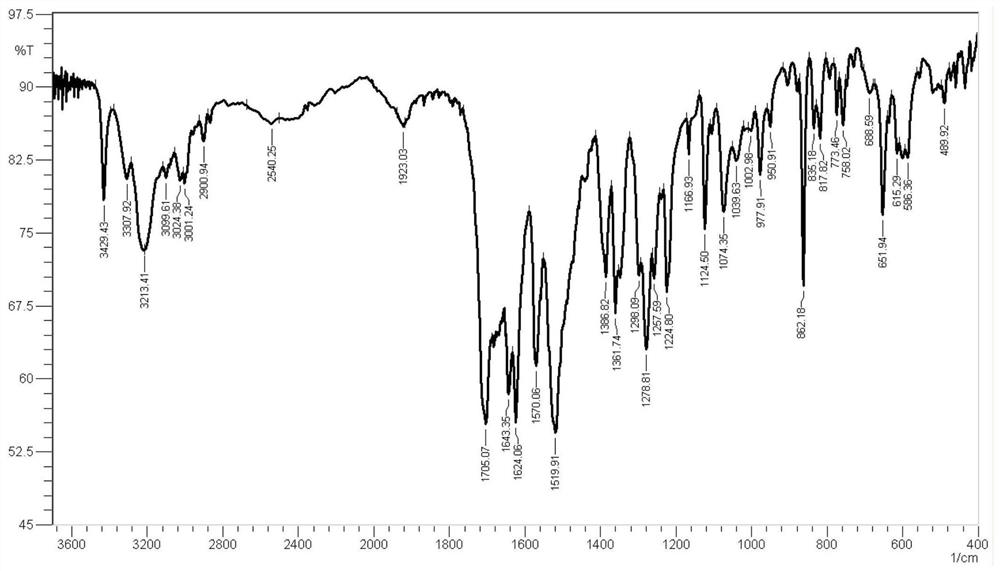

[0041] A crystal infrared spectrum at 1170cm -1 There is an absorption peak...

Embodiment 2

[0044] Under nitrogen protection, add 20 g of flupirtine white partial ash refined product into a 2000 ml three-necked flask, add 830 g of propanol, 40 g of DMSO, heat the internal temperature to 50 ° C, mechanically stir to dissolve, rotate at 400 rpm / min, and add 9.1 g of Malay The acid was dissolved in 50.0 g of propanol and added dropwise to a three-necked flask, reacted for 1 h, filtered, rinsed with a small amount of propanol, and drained to obtain white crystals, which were dried in vacuum to obtain 26.2 g of pure flupirtine maleate. rate 95%. It was confirmed to be pure A crystal form by X powder diffraction.

[0045] X-Powder Diffraction, 1 HNMR and infrared spectra were consistent with Example 1.

Embodiment 3

[0047] Under nitrogen protection, add 30 g of flupirtine white partial ash refined product into a 2000 ml three-necked flask, add 1200 g of acetonitrile, 60 g of DMSO, heat the internal temperature to 35 ° C, mechanically stir to dissolve, rotate speed 250 rpm / min, add 12.0 g of maleic acid Dissolve with 90.0 g of acetonitrile and add dropwise into a three-necked flask, react for 1 h, filter, rinse with a small amount of acetonitrile, and drain to obtain white crystals, which are dried in vacuum to obtain 39.7 g of pure flupirtine maleate, with a yield of 96% . It was confirmed to be pure A crystal form by X powder diffraction.

[0048] X-Powder Diffraction, 1 HNMR and infrared spectra were consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com