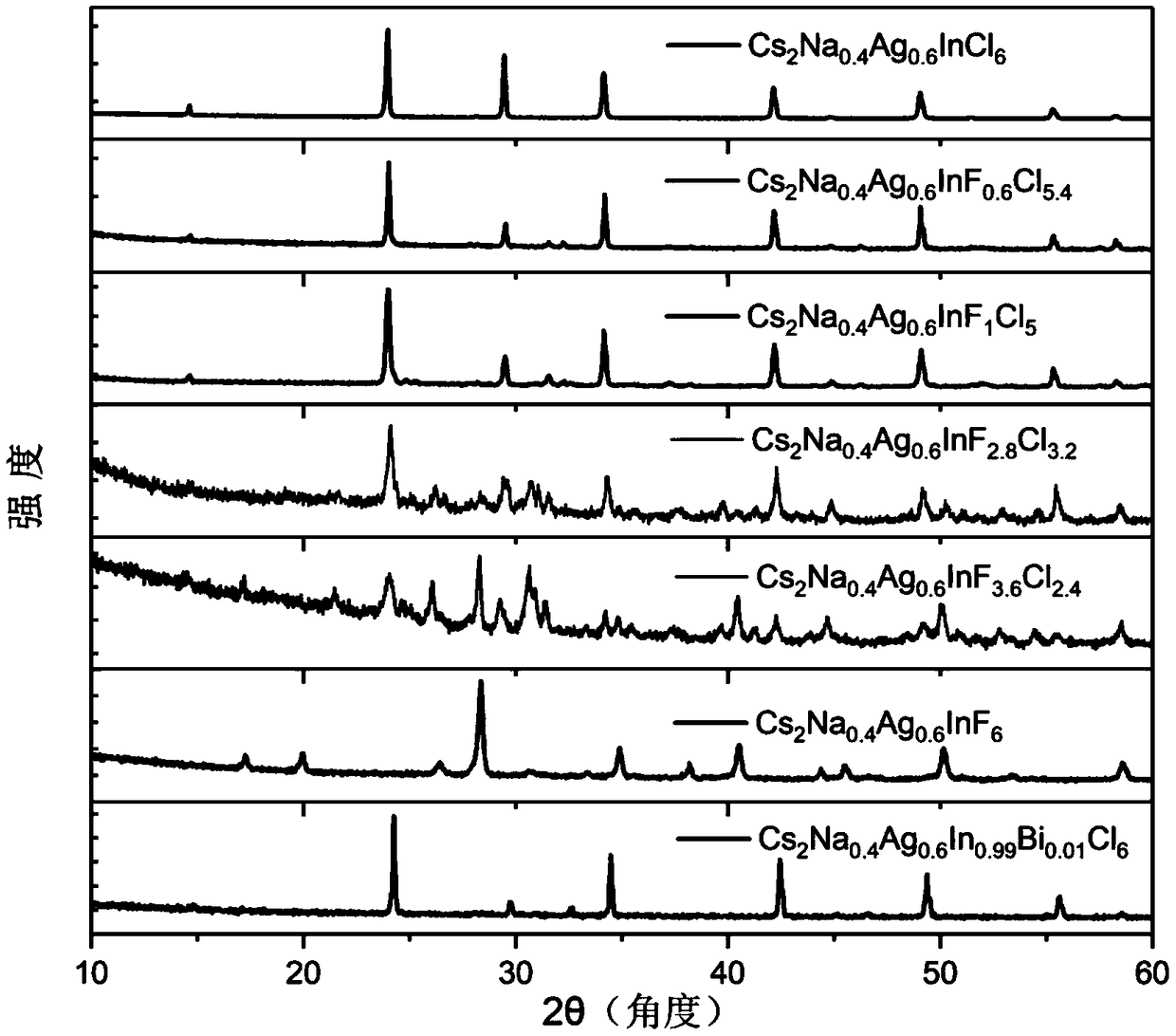

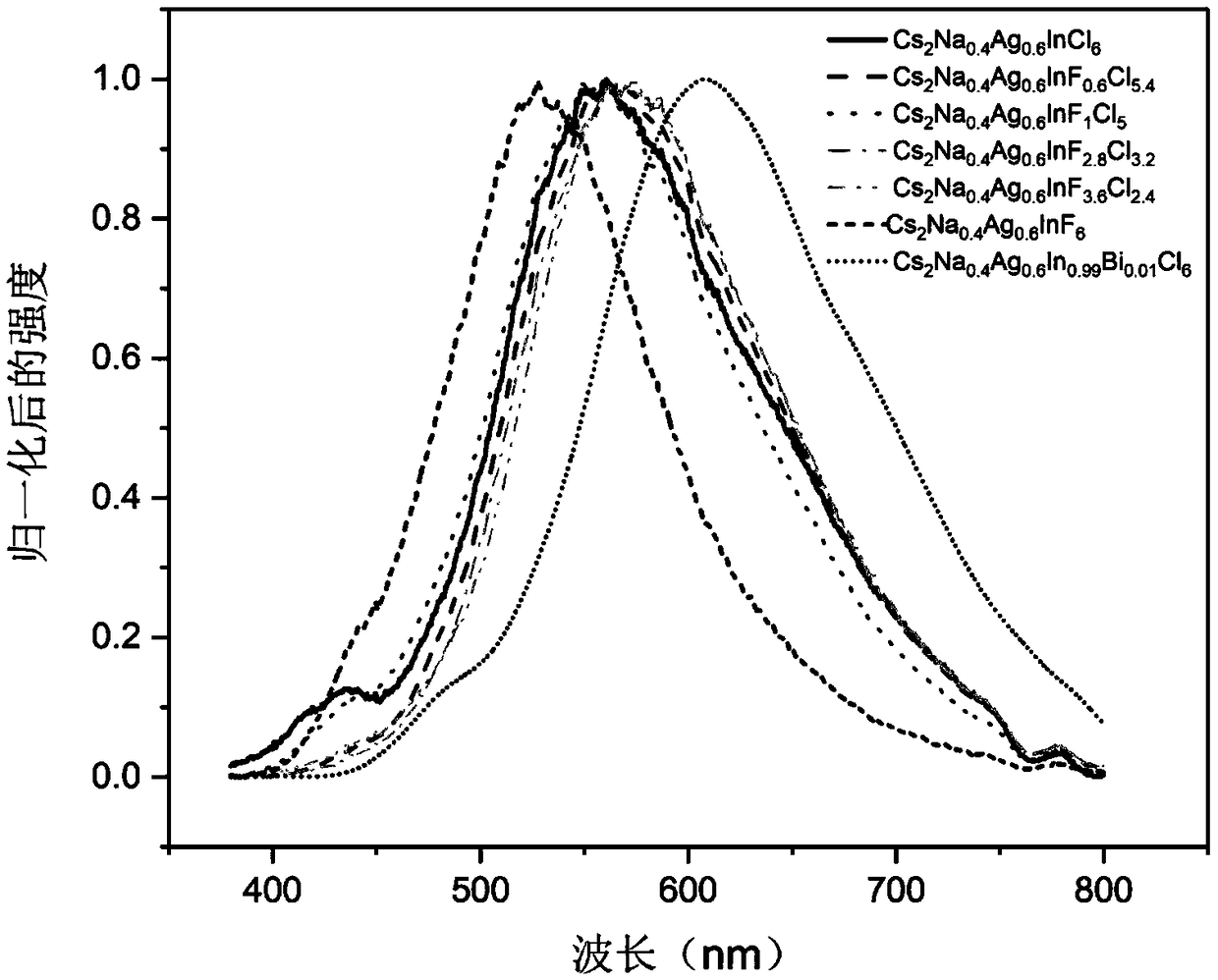

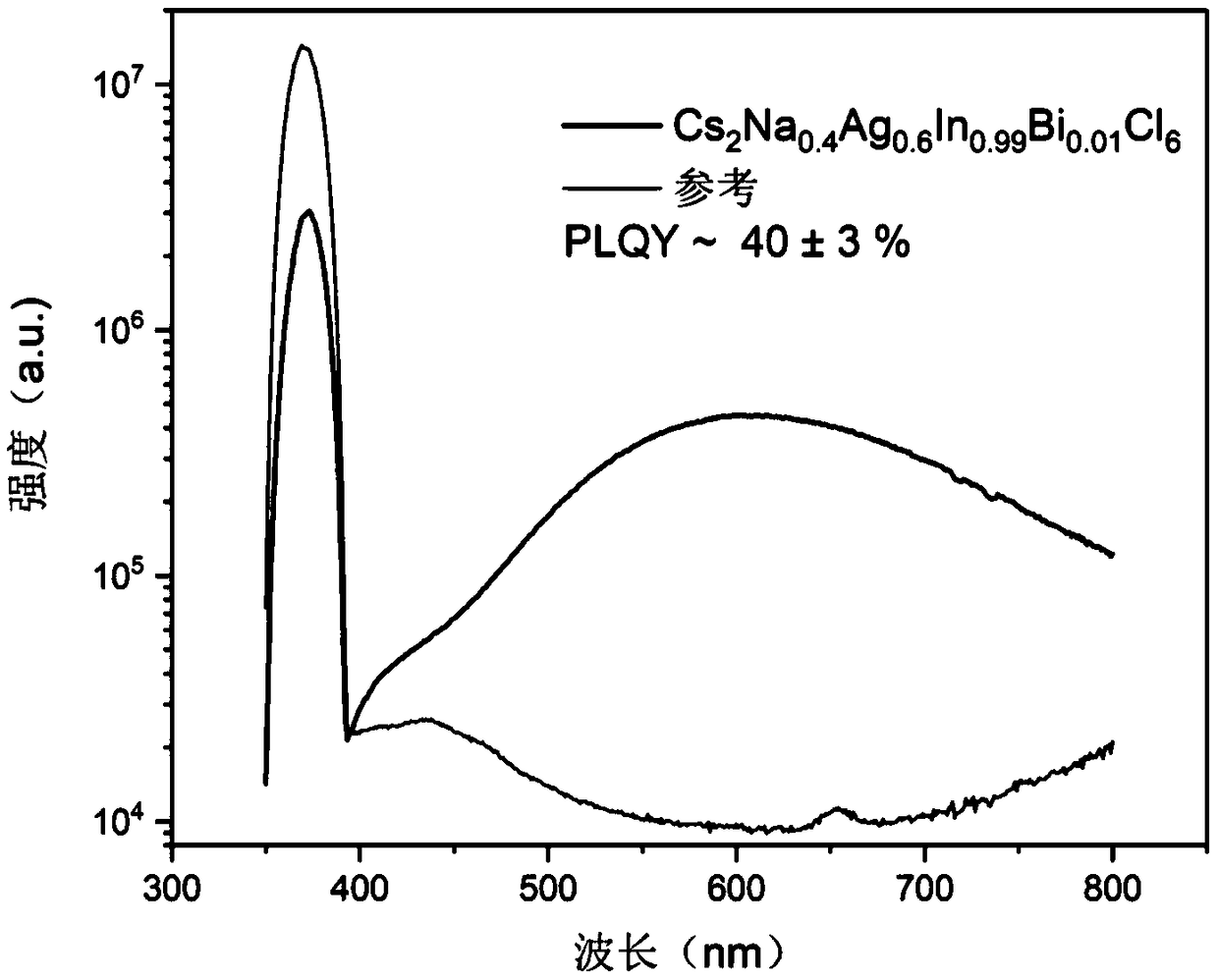

Ultraviolet excited white light polyhydric lead-free perovskite fluorescent powder and preparation method thereof

A technology of fluorescent powder and perovskite structure, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of high cost and low yield of liquid phase synthesis, and achieve high fluorescence quantum yield and emission spectrum Continuously adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention adopts a solid phase method to prepare the above-mentioned phosphor, and the method includes the following steps:

[0033] (1) Weigh B according to the quantity ratio of the substance x: 1-x 1 X and B 2 X, according to the quantity ratio of the substance y: 1-y weigh B 3 X 3 And B 4 X 3 , While ensuring that B 1 X and B 2 The sum of the amount of matter in X and B 3 X 3 And B 4 X 3 The sum of the material quantity is equal. Weigh and B 3 X 3 , B 4 X 3 , B 1 X, B 2 For CsX with the same amount of X, mix the basic raw materials uniformly and grind them into powder to obtain the reaction precursor;

[0034] For example, specifically weighing B at room temperature 1 X x mmol and B 2 X(1-x)mmol, weigh B 3 X 3 x mmol and B 4 X 3 (1-x) mmol, and then weigh 2 mmol of AX, mix them uniformly, and grind into powder to obtain a reaction precursor. A is Cs + , B 1 , B 2 For Na + , Ag + , B 3 , B 4 In 3+ , Bi 3+ , X stands for X 1 , X 2 , X 3 For F - , Cl - , Br - . ...

Embodiment 1

[0041] In the preparation method of the perovskite phosphor in this embodiment, the specific preparation steps are as follows:

[0042] a) Clean the crucible with deionized water for 3 minutes, and then blow dry with a nitrogen gun.

[0043] b) Weigh 0.3366g CsCl, 0.0234g NaCl, 0.0861g AgCl, 0.221g InCl 3 , Mix well, grind finely with a mortar, and put it in a crucible.

[0044] c) Place the crucible in the muffle furnace, and set the temperature of the muffle furnace to 30°C and raise it to 460°C for 1 hour, keep it for 5 hours, and then naturally cool down to room temperature.

[0045] d) Take out the crucible in the muffle furnace, take out the powder in the crucible and grind it evenly in a mortar. Put it in the crucible and proceed to operation c.

[0046] e) Take out the crucible in the muffle furnace and take out the powder in the crucible to obtain Cs 2 Na 0.4 Ag 0.6 InCl 6 Phosphor.

Embodiment 2

[0048] In the preparation method of the perovskite phosphor in this embodiment, the specific preparation steps are as follows:

[0049] a) Clean the crucible with deionized water for 3 minutes, and then blow dry with a nitrogen gun.

[0050] b) Weigh 0.3366g CsCl, 0.0234g NaCl, 0.0762g AgF, 0.221g InCl 3 , Mix well, grind finely with a mortar, and put it in a crucible.

[0051] c) Place the crucible in the muffle furnace, and set the temperature of the muffle furnace to 30°C and raise it to 460°C for 1 hour, keep it for 5 hours, and then naturally cool to room temperature.

[0052] d) Take out the crucible in the muffle furnace, take out the powder in the crucible and grind it evenly in a mortar. Put it in the crucible and proceed to operation c.

[0053] e) Take out the crucible in the muffle furnace and take out the powder in the crucible to obtain Cs 2 Na 0.4 Ag 0.6 InF 0.6 Cl 5.4 Phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com