Sr<2+> doped CsPbBr3 quantum dot germanium borosilicate glass as well as preparation method and application thereof

A technology of quantum dot glass and borosilicate glass, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of environmental and human hazards, poisonous lead elements, etc., achieve convenient operation, improve stability, and improve luminescence efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The above CsPbBr 3 The preparation method steps of quantum dot glass are as follows:

[0048] 1) Weigh GeO respectively according to the molar ratio of S1 components as mentioned above 2 : 12.37g; H 3 BO 3 : 6.77g; SiO 2 : 0.10g; ZnO: 1.34g; CaCO 3 : 0.99g; Na 2 CO 3 : 0.70g; NaBr: 2.70g; Cs 2 CO 3 : 4.86g; PbBr 2 : 4.26g. Add alcohol and zirconia grinding balls to the weighed raw materials in the mixing bottle, put them into the sample mixer and mix them thoroughly, then place them in a closed corundum crucible and keep them warm at 1200°C for 30 minutes to obtain a glass melt;

[0049] 2) Place the glass melt in a copper mold to form it quickly, then place it in a muffle furnace at 360°C for 3 hours for annealing, and obtain a colorless transparent glass after cooling;

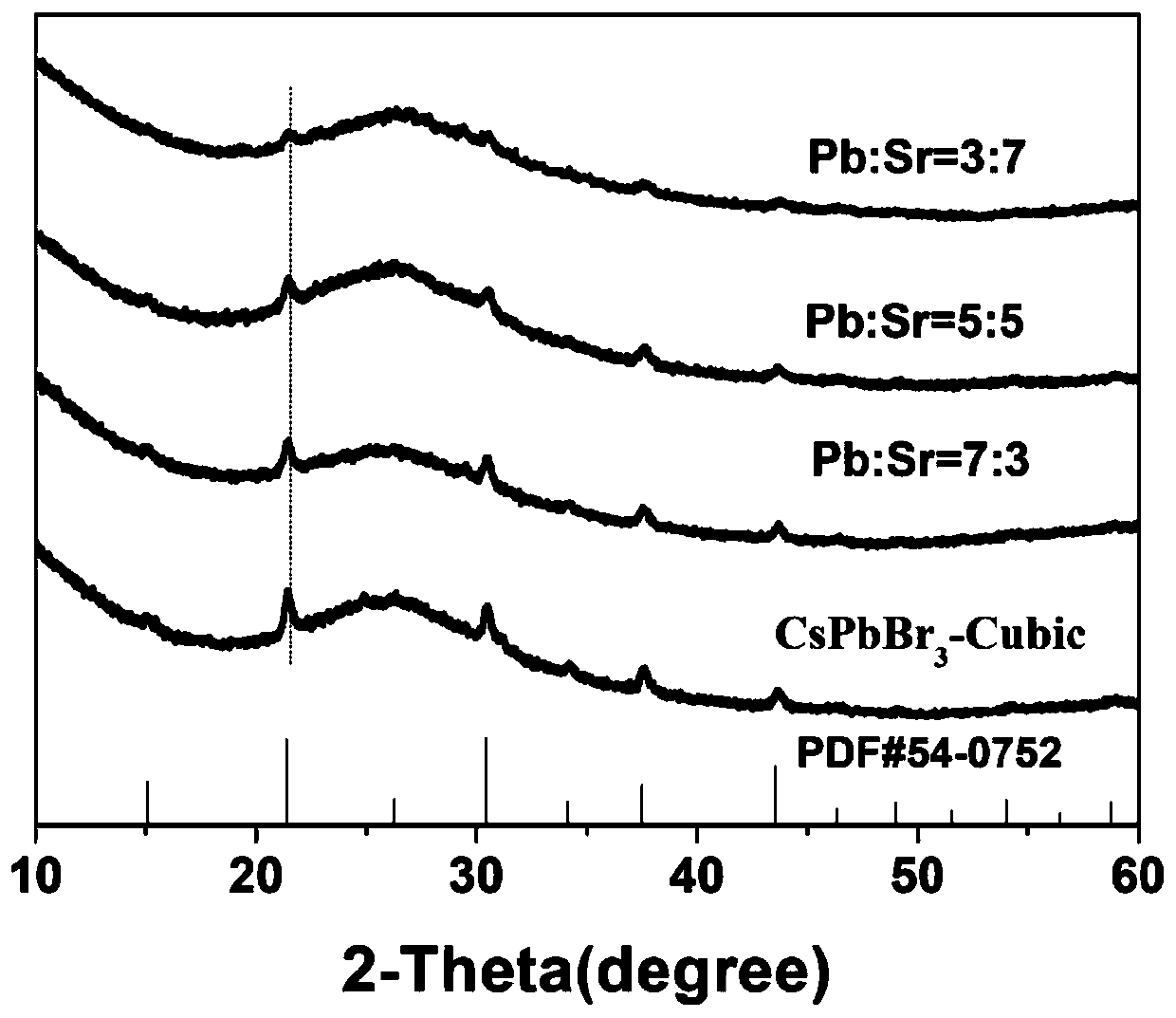

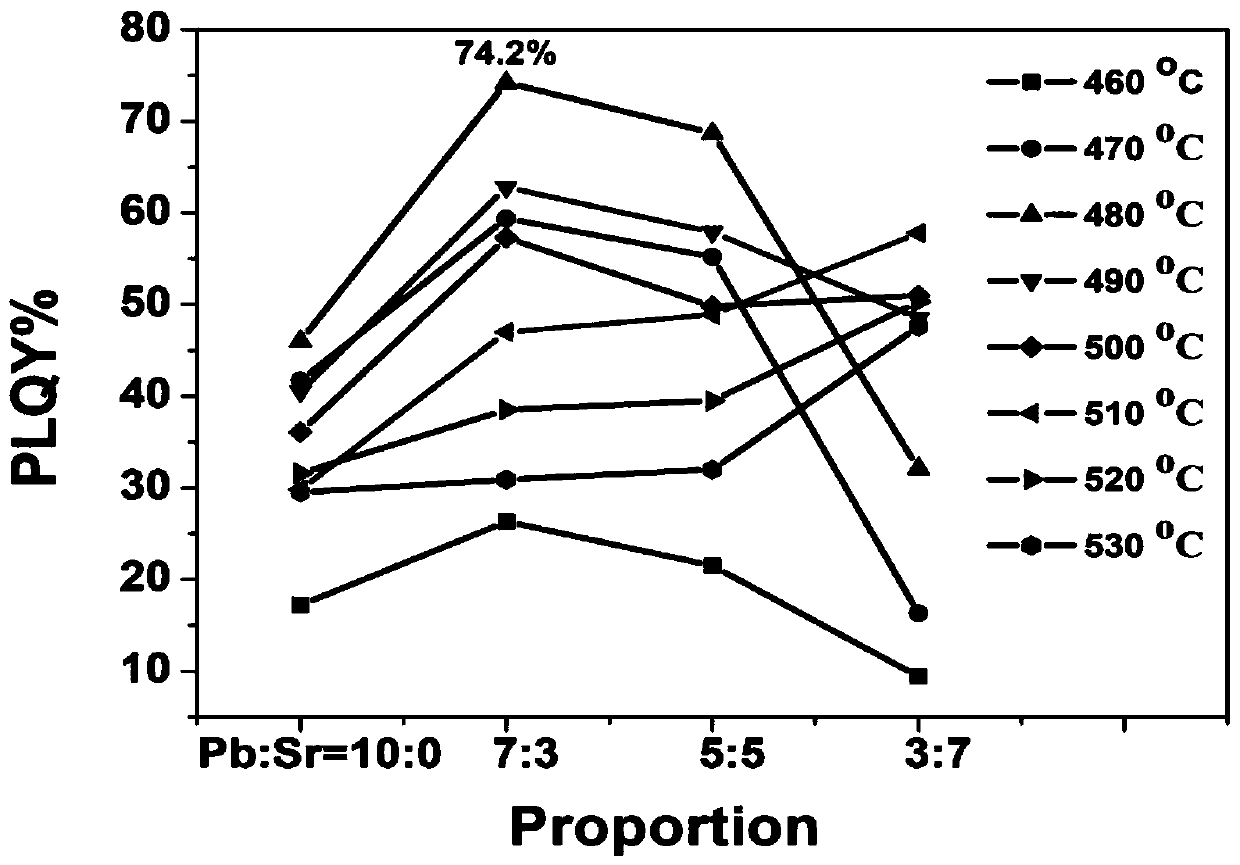

[0050] 3) Cut the obtained transparent glass into a specific size for heat treatment. The heat treatment system is 460-550 ° C for 10 hours to obtain a glass containing CsPbBr 3 Quantum do...

Embodiment 2

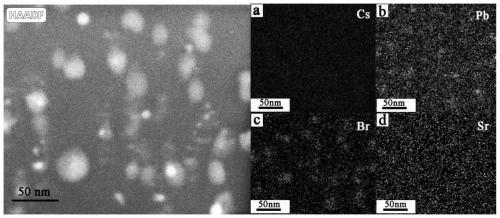

[0052] The strontium ion-doped CsPbBr 3 The preparation method steps of quantum dot germanium borosilicate glass material are as follows:

[0053] 1) Weigh GeO respectively according to the molar ratio of S2 components as mentioned above 2 : 12.38g; H 3 BO 3 : 6.77g; SiO 2 : 0.10g; ZnO: 1.34g; CaCO 3 : 0.99g; Na 2 CO 3 : 0.70g; NaBr: 2.70g; Cs 2 CO 3 : 4.86g; PbBr 2 : 4.26g; SrBr 2 : 1.24g. Add alcohol and zirconia grinding balls to the weighed raw materials in the mixing bottle, put them into the sample mixer and mix them thoroughly, then place them in a closed corundum crucible and keep them warm at 1200°C for 30 minutes to obtain a glass melt;

[0054] 2) Place the glass melt in a copper mold to form it quickly, then place it in a muffle furnace at 360°C for 3 hours for annealing, and obtain a colorless transparent glass after cooling;

[0055] 3) Cut the obtained transparent glass into a specific size for heat treatment, the heat treatment system is 460-550 ° C...

Embodiment 3

[0057] The preparation method of the above-mentioned quantum dot-doped glass, the specific steps are as follows:

[0058] Weigh the GeO according to the molar ratio of the S3 components as mentioned above 2 : 12.38g; H 3 BO 3 : 6.77g; SiO 2: 0.10g; ZnO: 1.34g; CaCO 3 : 0.99g; Na 2 CO 3 : 0.70g; NaBr: 2.70g; Cs 2 CO 3 : 4.86g; PbBr 2 : 2.13g; SrBr 2 : 2.07g. Add alcohol and zirconia grinding balls to the weighed raw materials in the mixing bottle, put them into the sample mixer and mix them thoroughly, then place them in a closed corundum crucible and keep them warm at 1200°C for 30 minutes to obtain a glass melt;

[0059] 2) Place the glass melt in a copper mold to form it quickly, then place it in a muffle furnace at 360°C for 3 hours for annealing, and obtain a colorless transparent glass after cooling;

[0060] 3) Cut the obtained transparent glass into a specific size for heat treatment, the heat treatment system is 460-550 ° C for 10 hours, and obtain the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com