Fluorescent nano-particle with composite silica shell structure and preparation thereof

A fluorescent nano-composite technology, applied in the field of fluorescent nanoparticles and its preparation, can solve the problems of low fluorescence efficiency of fluorescent nanoparticles, and achieve the effects of improved detection sensitivity, high fluorescence efficiency, and less dye leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

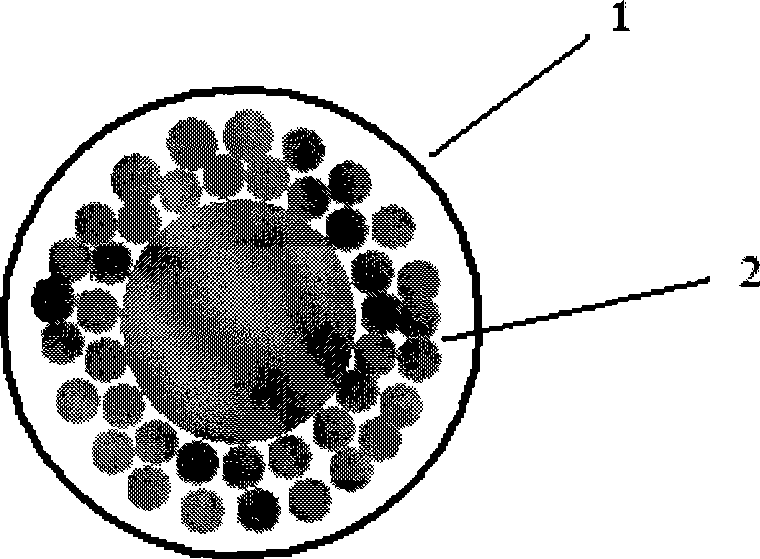

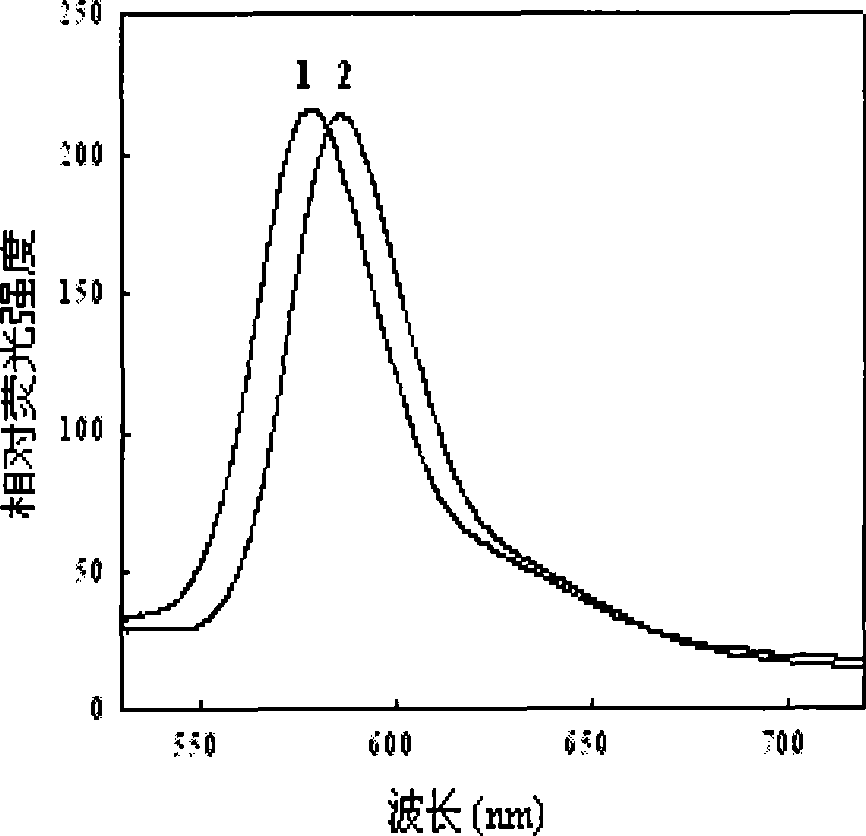

[0035] Example 1: Preparation of fluorescent nanoparticles with nano-gold / rhodamine B / silica composite silicon shell structure

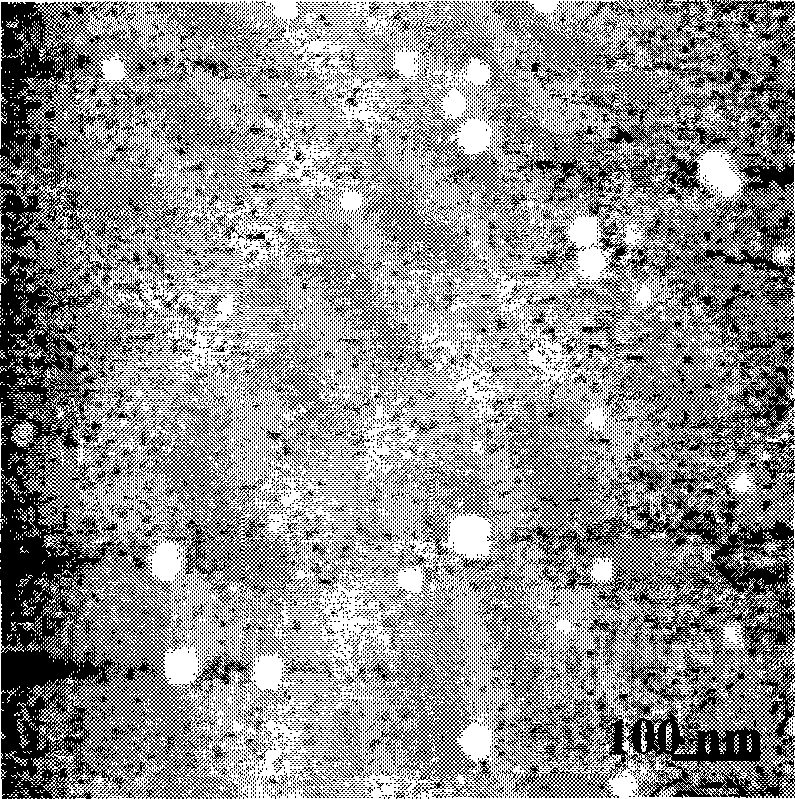

[0036] Adopting chloroauric acid-sodium citrate reduction method to prepare particle diameter is the nano-gold solution of 25 ± 5nm; Adding the rhodamine B solution (5.0 × 10 -6 mol / L), and the reaction continued for 6 hours to obtain a nano-gold solution coated with rhodamine B dye, which was called the reaction solution. The pH value of the reaction solution is adjusted between 10-11 by ammonia water. Under magnetic stirring, add an ethanol solution of ethyl orthosilicate (1.0×10 -3 mol / L), and react for 12 hours under magnetic stirring to obtain fluorescent nanoparticles with nano-gold / rhodamine B / silica composite silicon shell structure with a particle size of 50-60 nm.

Embodiment 2

[0037] Example 2: Preparation of fluorescent nanoparticles with nano-gold / rhodamine B / silica composite silicon shell structure (fluorescent nanoparticles with larger particle size)

[0038] Adopting chloroauric acid-sodium citrate reduction method to prepare particle diameter is the nano-gold solution of 25 ± 5nm; Adding the rhodamine B solution (1.0 * 10 -5 mol / L), and the reaction continued for 12 hours to obtain a nano-gold solution coated with rhodamine B dye, which was called the reaction solution. The pH value of the reaction solution is adjusted between 10-11 by ammonia water. Under magnetic stirring, add the ethanol solution (5.0 × 10 -3 mol / L), react under magnetic stirring for 24 hours to obtain fluorescent nanoparticles with nano-gold / rhodamine B / silica composite silicon shell structure with a particle size of 60-70 nm.

Embodiment 3

[0039] Example 3: Preparation of fluorescent nanoparticles with nano-gold / rhodamine 6G / silica composite silicon shell structure

[0040] Adopting chloroauric acid-sodium citrate reduction method to prepare particle diameter is the nano-gold solution of 25 ± 5nm; Adding the rhodamine 6G solution (1.0 * 10 -5 mol / L), and the reaction continued for 6 hours to obtain a nano-gold solution coated with rhodamine 6G dye, which was called the reaction solution. The pH value of the reaction solution is adjusted between 10-11 by ammonia water. Under magnetic stirring, add the concentration of 1.0×10 -3 mol / L ethyl orthosilicate ethanol solution reacts for 24 hours under magnetic stirring to obtain fluorescent nanoparticles with nano-gold / rhodamine 6G / silica composite silicon shell structure with a particle size of 50-60 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com