Stainless-steel U-shaped body for expansion joint and application method thereof

A stainless steel, expansion joint technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as poor fit and achieve the effect of preventing position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

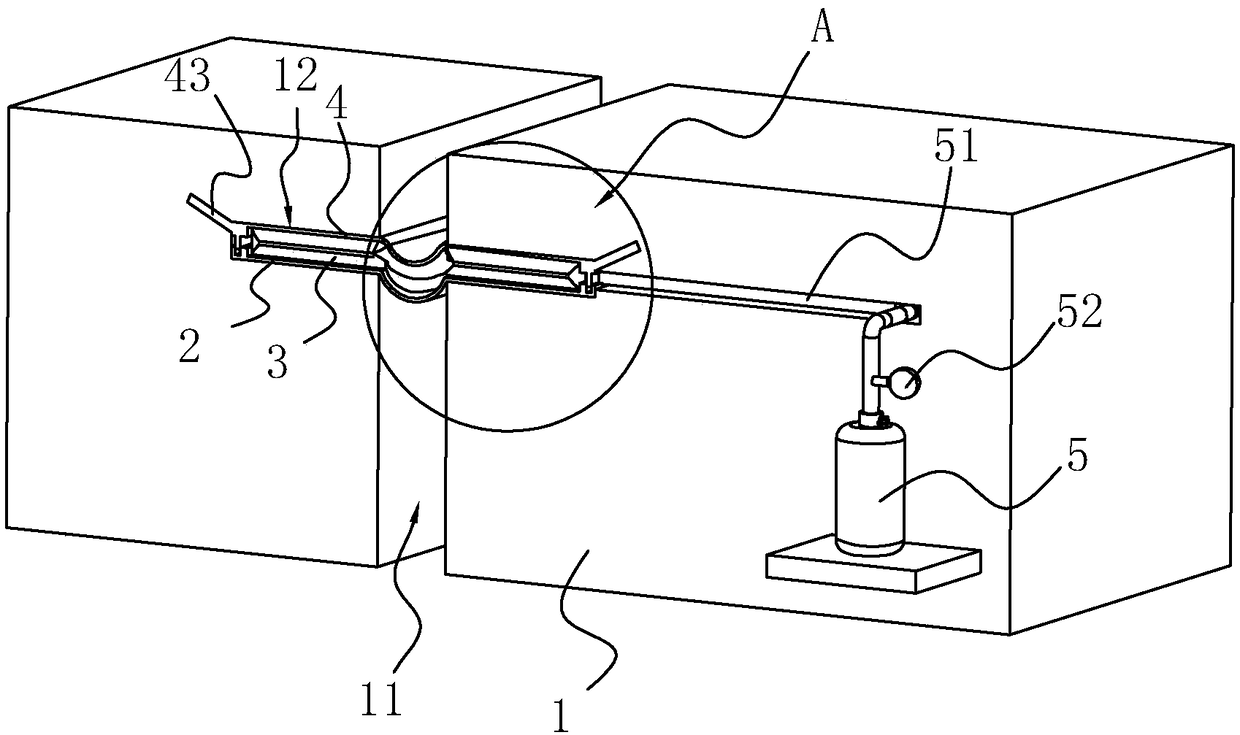

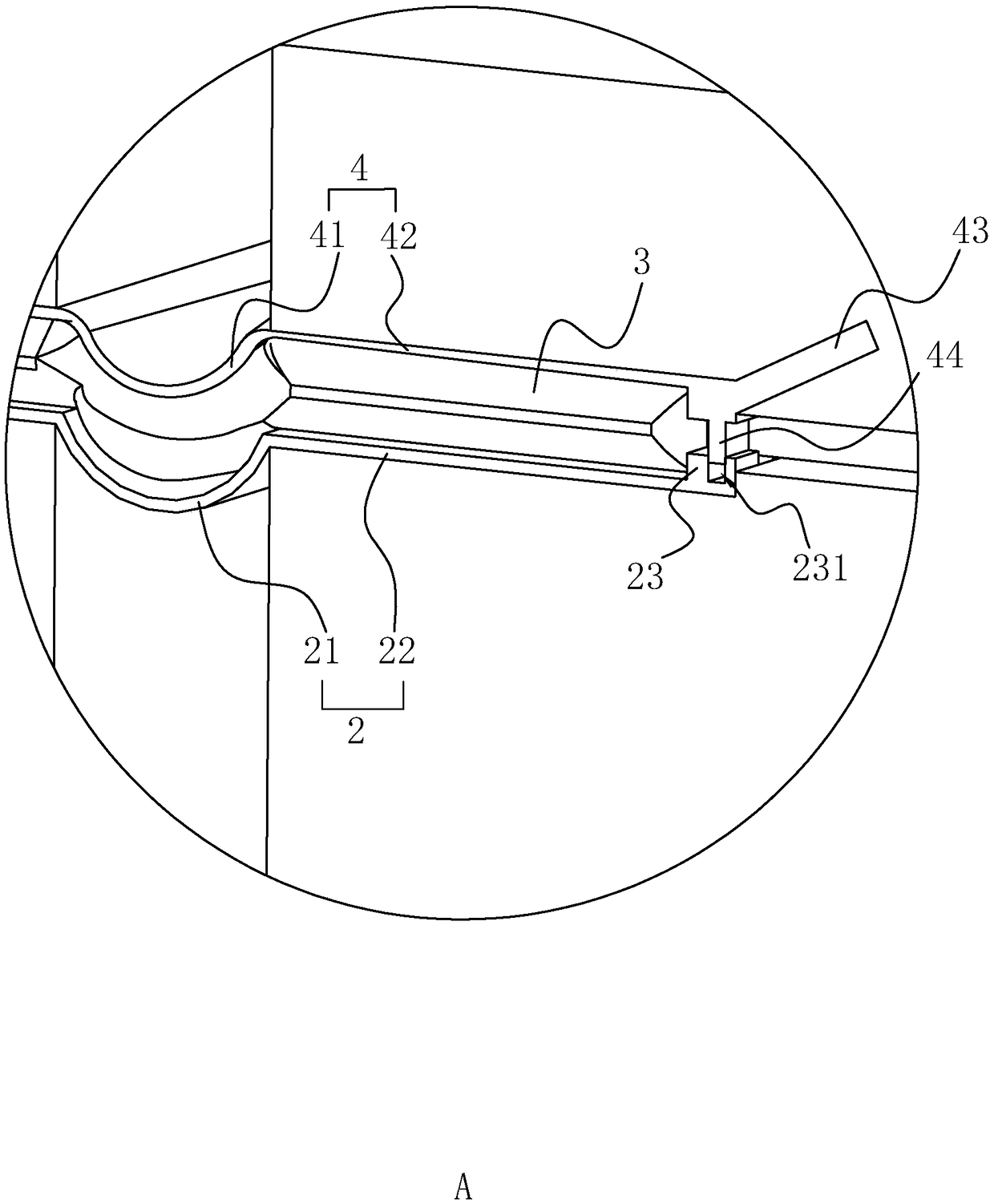

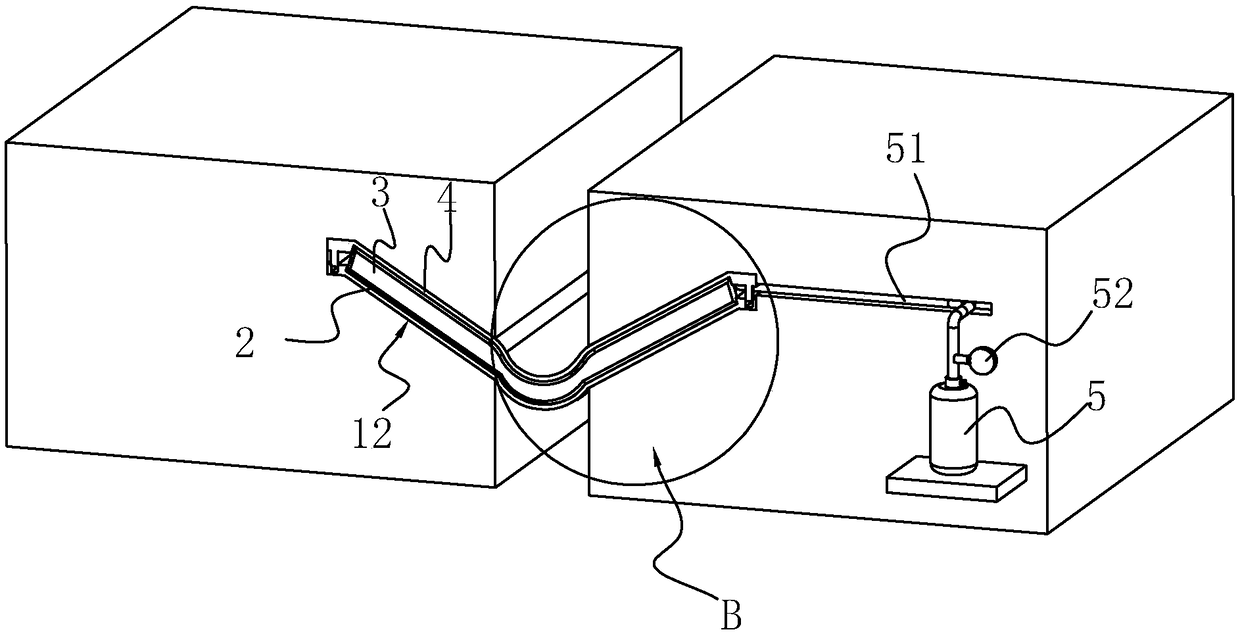

[0038] Embodiment 1: A stainless steel U-shaped body used for expansion joints, see the attached figure 1 And attached figure 2 , comprising a bottom plate 2, a connecting plate 4 arranged above the bottom plate 2, an air bag 3 arranged between the bottom plate 2 and the connecting plate 4, an air pump 5 fixedly connected to one side of the wall 1, and used for connecting the air pump 5 to the air bag 3 The connecting pipe 51 together and the pressure gauge 52 fixedly connected on the connecting pipe 51 for measuring the air pressure in the connecting pipe 51 and the air bag 3; the bottom plate 2 is made of stainless steel, and the connecting plate 4 is made of rubber; the air bag 3 The top and the bottom are in contact with the bottom of the bottom plate 2 and the top of the connecting plate 4 respectively; The mounting plate 22 in the groove 12; the connecting plate 4 includes a U-shaped part 41 with the opening facing upwards in the expansion joint 11 and a mounting part ...

Embodiment 2

[0042] Embodiment 2: A stainless steel U-shaped body for expansion joints, see attached figure 1 And attached figure 2 The difference between this embodiment and the first embodiment is that the mounting plate 22 and the mounting portion 42 are arranged obliquely, the side of the mounting plate 22 away from the U-shaped plate 21 is fixedly connected with the horizontal plate 24, and the mounting portion 42 is away from the U-shaped portion 41. One side is fixedly connected with a horizontal portion 45 , the limiting block is fixedly connected to the top of the horizontal plate 24 , and the limiting plate is fixedly connected to the bottom of the horizontal portion 45 . A side of the mounting plate 22 facing away from the U-shaped plate 21 is inclined upward.

[0043] The advantage of this embodiment over Embodiment 1 is that when the water flows to the top of the installation part 42, the installation part 42 is inclined, and the water flows into the U-shaped part 41 under t...

Embodiment 3

[0044] Embodiment three: a method for using a stainless steel U-shaped body for expansion joints, comprising the following steps:

[0045] a. Install the stainless steel U-shaped body: the bottom plate 2, the air bag 3 and the connecting plate 4 are installed together, so that the guide plate 44 is embedded in the guide groove 231;

[0046] b. Open installation groove 12: On the wall body 1 on both sides of the expansion joint 11, an installation groove 12 that cooperates with both sides of the stainless steel U-shaped body is opened;

[0047] c. Install the stainless steel U-shaped body: install the bottom plate 2, the air bag 3 and the connecting plate 4 installed together into the installation groove 12;

[0048] d. Install the air pump 5: install the air pump 5 on the side of the wall 1, connect the air pump 5 and the air bag 3 with the connecting pipe 51, and then install the air pressure gauge on the connecting pipe 51 near the air pump 5;

[0049] e. Inflation: Tu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap