Assembly type house with changeable area and construction method

An assembled, housing technology, applied in building components, walls, buildings, etc., can solve the problems of insufficient dining room area and inconvenient use, and achieve the effect of saving the space occupied by the wall, convenient movement, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

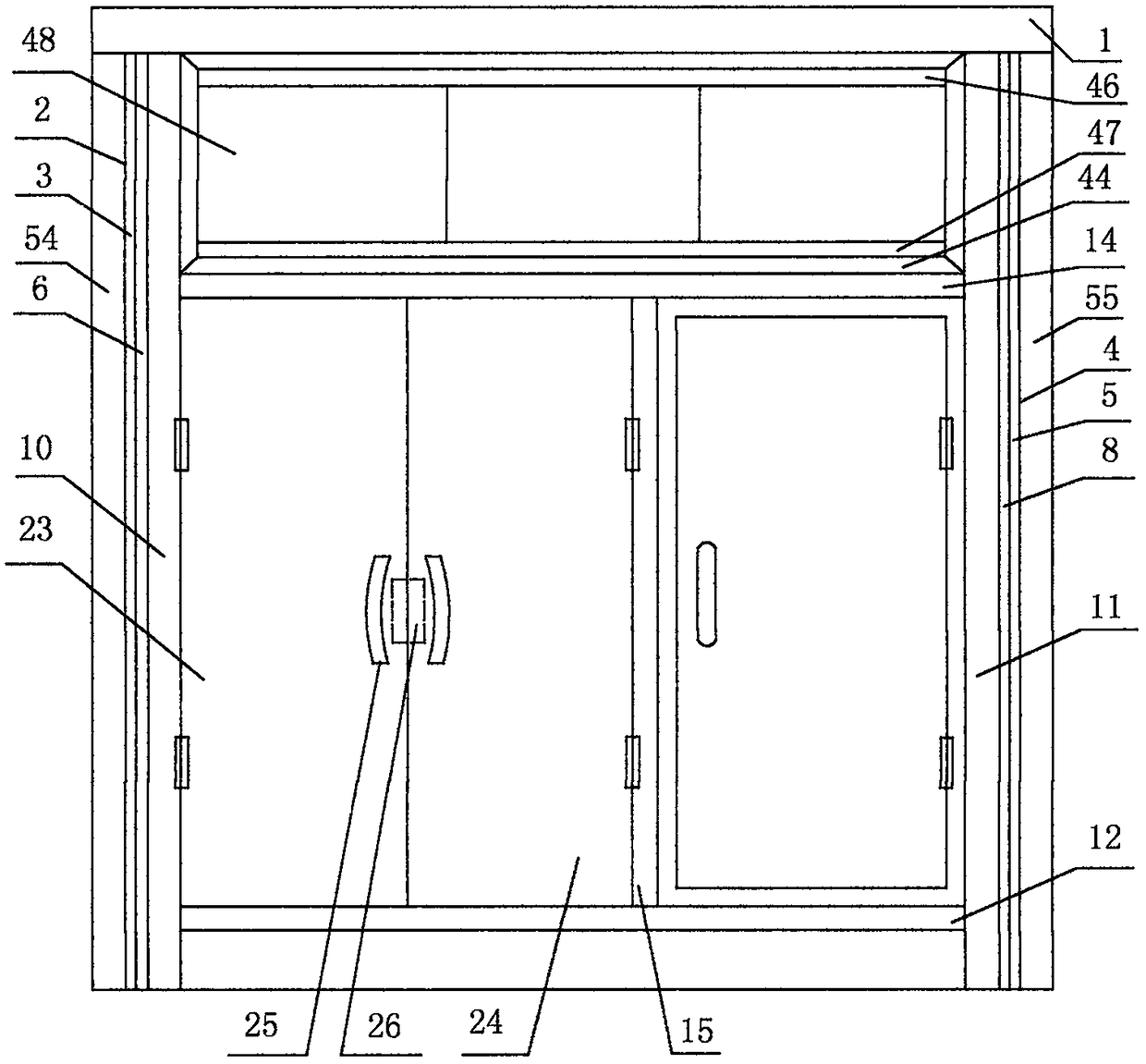

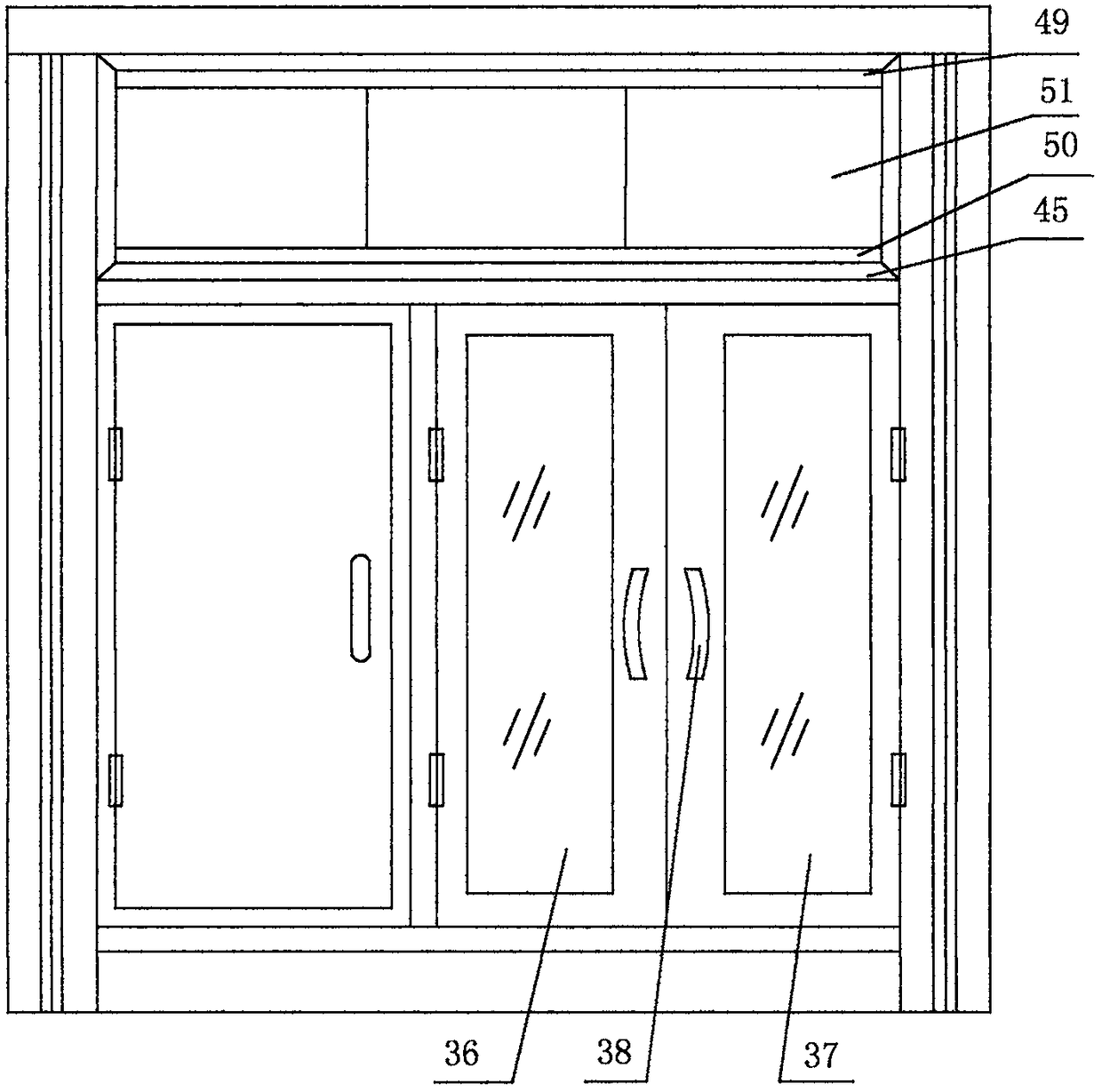

[0028] A prefabricated house with a variable area, which consists of: a house 1, a set of horizontally arranged grooves 2 are opened on one side wall 54 of the house, and the grooves are connected to the magnetic board 3, and the house The opposite side wall 55 has a group of transversely arranged pairs of grooves 4, the pair of grooves is connected to the magnetic plate 5, the magnetic plate is sucked and inlaid with the magnetic plate 6 or the magnetic hook 7, and the described magnetic plate is Adhesive mosaic magnetic board 8 or magnetic hook 9, described mosaic magnetic board is embedded on the wall panel 10, described mosaic magnetic board is embedded on the wall board 11, described wall board and described The opposite wall panels are connected through a bottom plate 12, and a set of universal wheels 13 with brakes are connected to the bottom of the bottom plate, and the wall panels are connected with the opposite wall panels through a top plate 14. The bottom plate and...

Embodiment 2

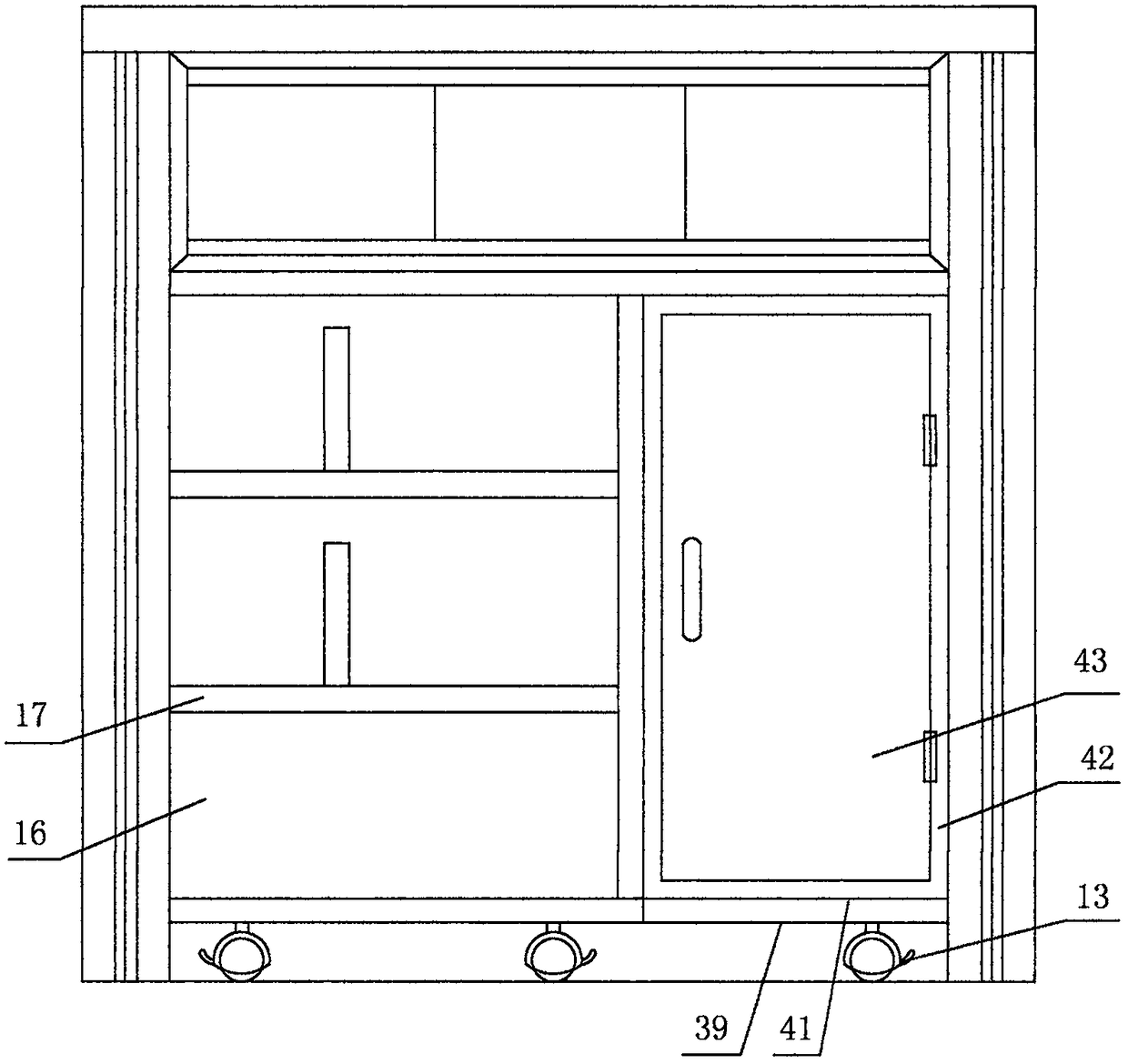

[0031] In the variable-area prefabricated house described in Embodiment 1, the top board and the bottom board are connected by a wall board 15, the top board, the bottom board, the wall board, the The middle position of the wall panel is connected by a middle partition 16, and the wall panel and the wall panel are connected by a set of transverse support plates 17, and the transverse trapezoidal cross-section slots 18 are opened on the transverse support plates. , the bottom of the transverse trapezoidal section slot is connected to the bottom magnetic plate 19, the trapezoidal section slider 20 is housed in the described transverse trapezoidal section slot, the bottom of the trapezoidal section slider is connected to the magnetic sheet 21, the described The trapezoidal cross-section slider slides in place, and is fixed by the magnetic sheet attracting the bottom magnetic plate, and the trapezoidal cross-section slider is connected to the vertical partition 22 .

[0032] The v...

Embodiment 3

[0034] In the variable-area prefabricated house described in Embodiment 2, the wall panels are connected to the door 23 of the glove cabinet through hinges, and the wall panels are connected to the glove cabinet door 24 through hinges. The door of the cabinet and the side-by-side door of the glove cabinet are all connected with a handle 25, and the door of the glove cabinet and the side-by-side door of the glove cabinet are closed by a magnetic buckle 26, and the glove box is placed on the horizontal support plate. thing.

[0035] The open door of the glove cabinet and the opposite door of the glove cabinet are fully enclosed cabinet doors, and the items put in are not exposed, making the room both beautiful and tidy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com