A quasi-zero stiffness shock absorber for high-speed train floors

A high-speed train, quasi-zero stiffness technology, applied in the direction of spring/shock absorber, railway car body, vibration suppression adjustment, etc., can solve the problems of large deformation of the floor, large static deflection of supports, etc., and achieve compact structure of the device and vibration isolation The effect of low initial frequency and high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

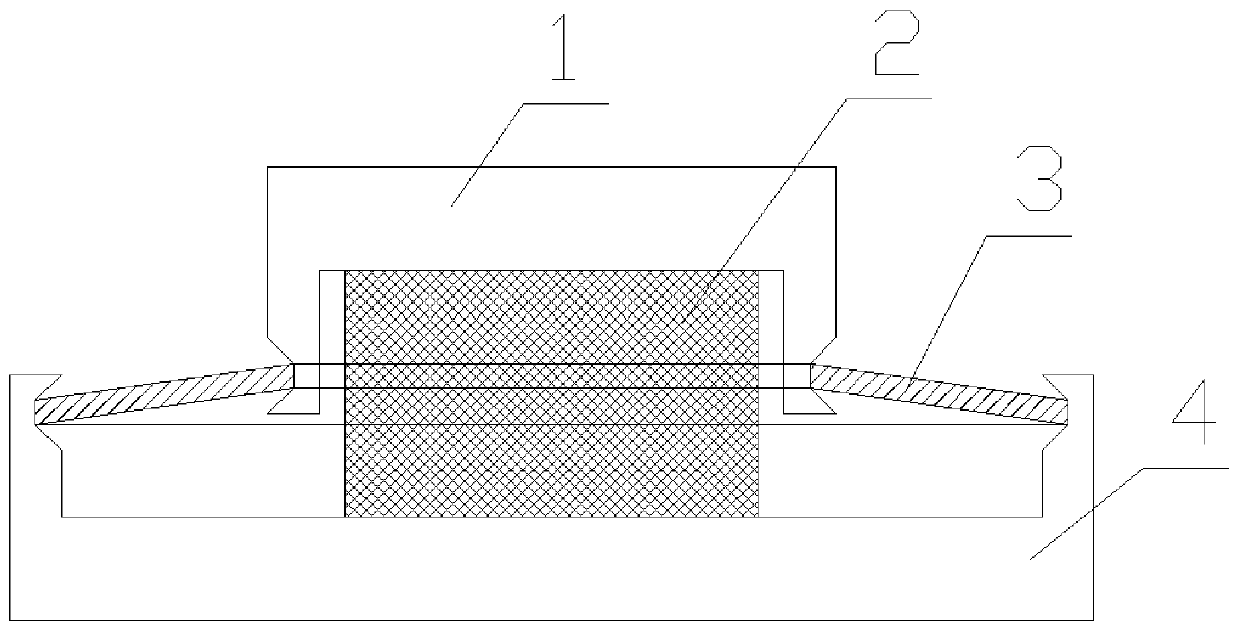

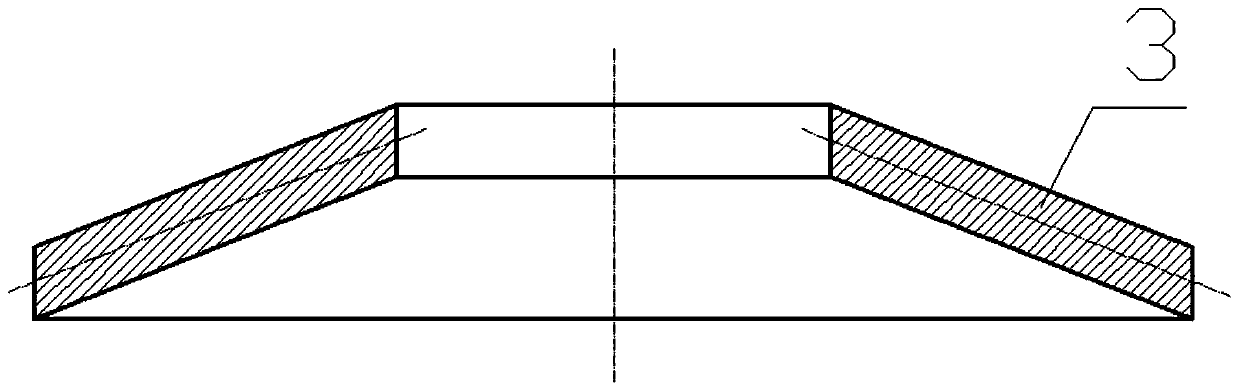

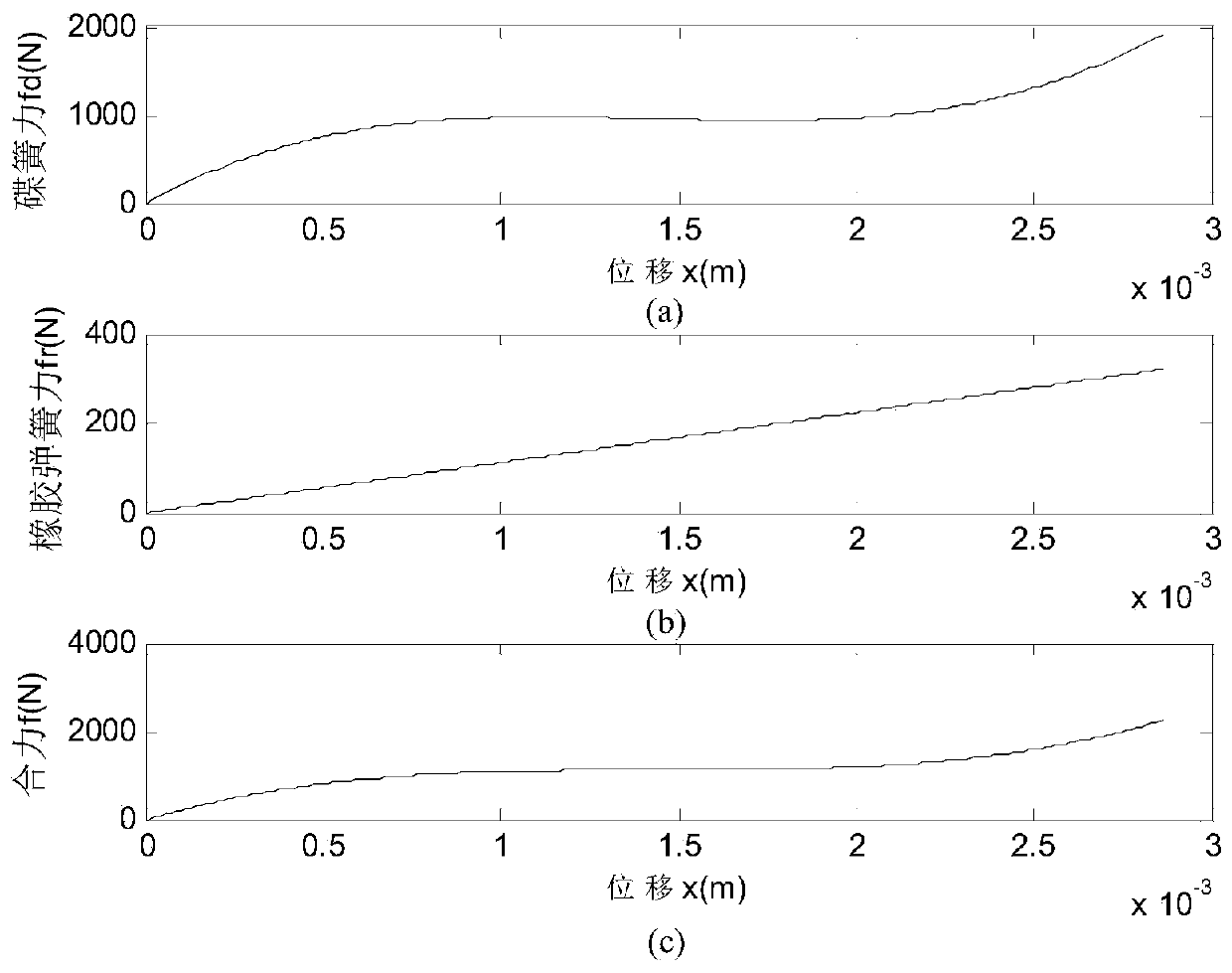

[0028] A quasi-zero stiffness shock absorber for high-speed train floors, such as figure 1 As shown, it includes the shock absorber upper support 1, the shock absorber lower support 4, the disc spring 3 arranged between the shock absorber upper support 1 and the shock absorber lower support 4, and the disc spring 3 arranged inside The rubber spring 2, the upper and lower ends of the rubber spring 2 abut against the upper support 1 of the shock absorber and the lower support 4 of the shock absorber respectively. The inner side of the upper end of the disc spring 3 is fixedly connected with the outer side of the side wall of the upper end support 1 of the shock absorber, and the outer side of the lower end of the disc spring 3 is fixedly connected with the inner side of the side wall of the lower end support 4 of the shock absorber. The rubber spring 2 is cylindrical or cuboid. There is a gap between the side of the rubber spring 2 and the inside of the side wall of the shock ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com