A kind of double-seat regulating valve with regulating rod and its assembling method

A technology for regulating valves and regulating rods, applied in the field of regulating valves, can solve the problems of inability to achieve a fully sealed state, difficult processing, large leakage, etc., and achieve the effects of good sealing, good anti-vibration performance, and high assembly pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

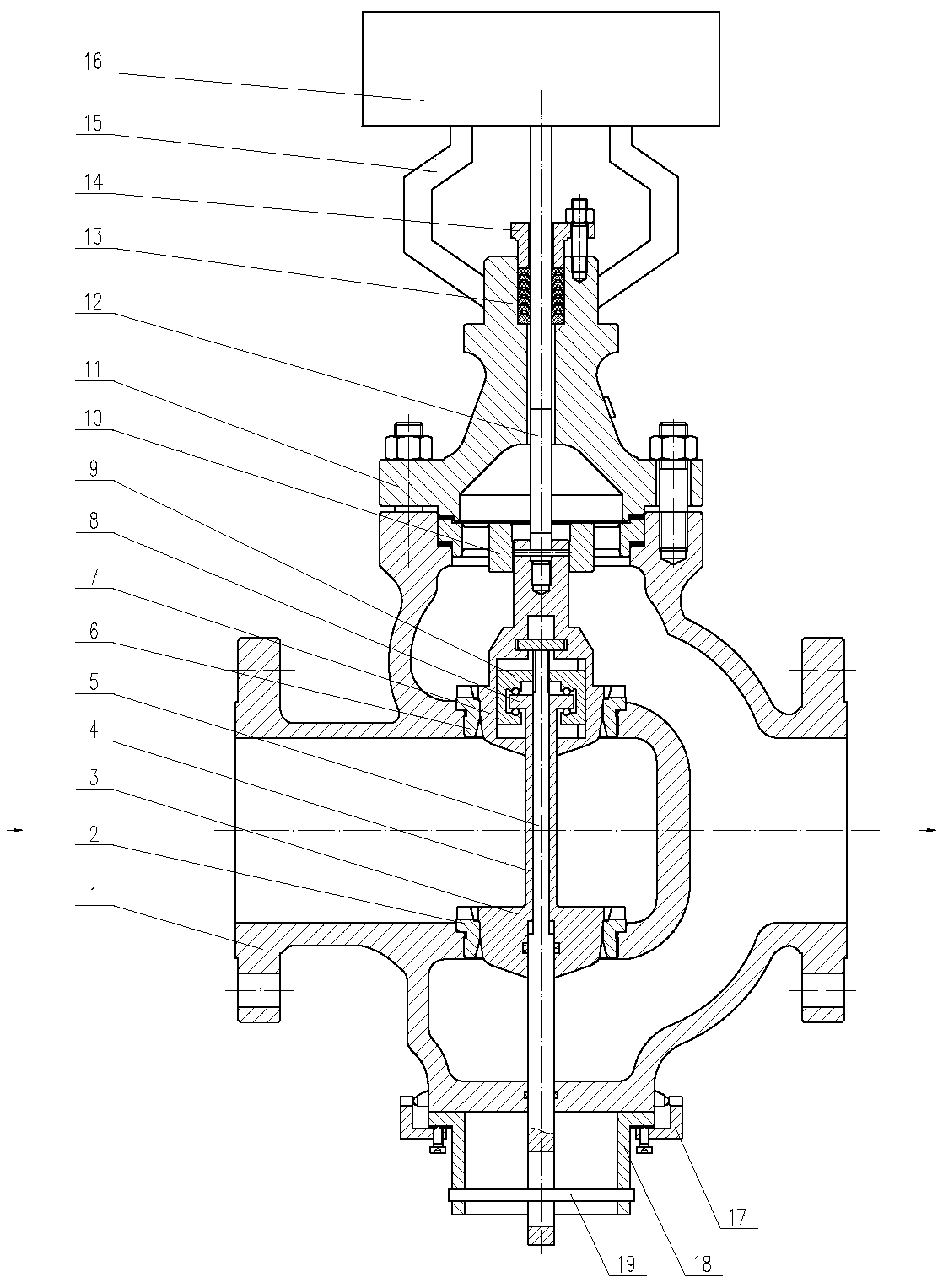

[0016] according to figure 1 It can be seen that this double-seat regulating valve with a regulating rod includes: a valve body 1, an upper valve seat 6, a lower valve seat 2, an upper valve disc 7, a lower valve disc 3, a valve cover 11, an upper valve rod 12, and a bracket 15 and the driving device 16, the valve body 1 is provided with an inlet channel and an outlet channel, the inlet channel is arranged horizontally, the outlet channel is arranged in a horizontal Y-shaped structure, and a cavity wall of a horizontal U-shaped structure is provided between the inlet channel and the outlet channel, and the upper valve The seat 6 is set on the upper part of the cavity wall, the lower valve seat 2 is set on the lower part of the cavity wall, the upper ends of the upper and lower valve seats 6, 2 are respectively provided with upper and lower valve seat sealing surfaces, and the upper and lower valve discs 7, 3 are Installed in series under the upper valve stem 12, the lower valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com