Automatic high-temperature testing machine for capacitor

A technology for capacitors and testing machines, which is applied to components of electrical measuring instruments, environmental/reliability testing, instruments, etc., can solve problems such as reducing the temperature of testing machines, product impact, and increasing energy consumption, so as to reduce energy consumption and temperature The effect of stability and convenient capacitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

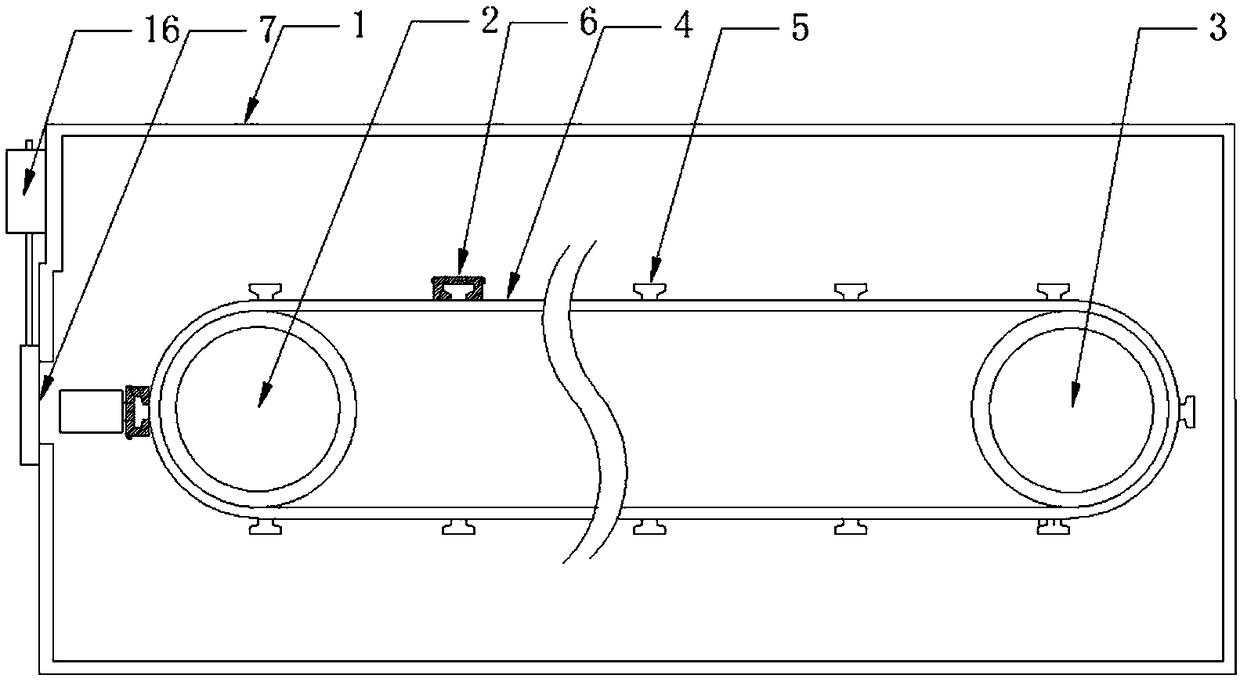

[0023] Such as figure 1 An automatic high temperature tester for capacitors is shown, including a body 1 and a door. The door is connected to the body 1. The two can form a closed cavity. The cavity is provided with a driving shaft 2 and a driven shaft 3, and the driving A belt 4 is arranged between the shaft 2 and the driven shaft 3, a base 5 is fixed on the belt 4, and a test clip 6 that can be movably connected to the capacitor on the base 5 is provided with a positive electrode conductive sheet 10 and a negative electrode conductive sheet 10 Sheet 11, the positive conductive sheet 10 on the test clip 6 is electrically connected to the driving shaft 2 through a conductive strip, and the negative conductive sheet 11 on the test clip 6 is electrically connected to the driven shaft 3 through a conductive strip; one side of the body 1 is provided There is a movable window 7.

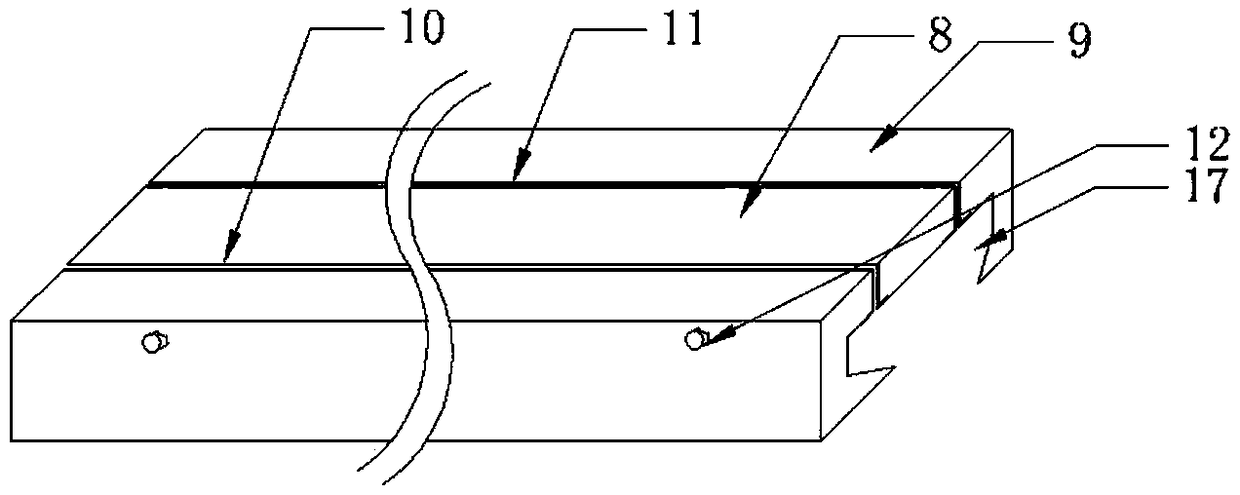

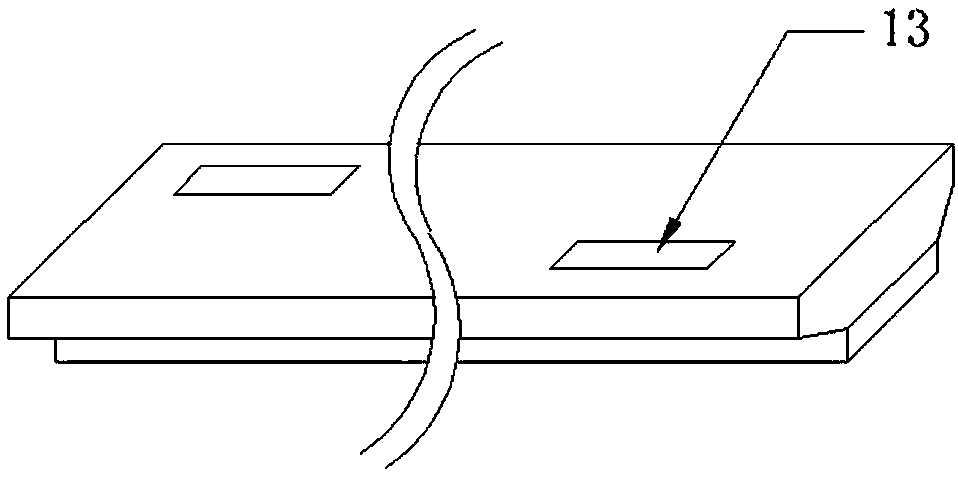

[0024] In this embodiment, such as figure 2 As shown, the test clip 6 includes an isolating block 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com