Packaging method of micro-light image tube

A packaging method and low-light image technology, which are applied in the field of processing and manufacturing, can solve the problems of low packaging quality and achieve the effects of improving packaging quality, good sealing and insulation, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a method for encapsulating a low-light image tube. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

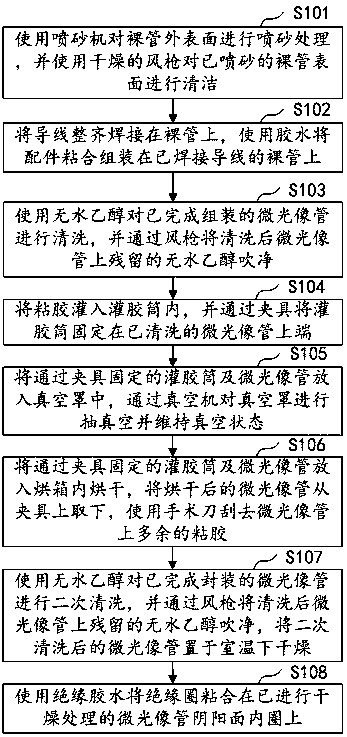

[0028] see figure 1 , figure 1 It is a schematic flow chart of the packaging method of the low-light image tube of the present invention.

[0029] A method for encapsulating a low-light image tube, wherein the method includes:

[0030] S101. Use a sandblasting machine to perform sandblasting on the outer surface of the bare pipe, and use a dry air gun to clean the surface of the sandblasted bare pipe.

[0031] More specifically, the particle size of the sand particles in the sandblasting treatment is 100-150 mesh, the time of the sandblasting treatment is 22-35 secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com