A lithographic machine small workpiece clamp

A technology for small workpieces and lithography machines, which is applied in the field of lithography machine fixtures. It can solve the problems of workpiece movement, chip fine processing and fixing difficulties, and affect the accuracy of small workpieces, so as to achieve flexible and convenient use, overcome inability to process or inconvenient processing , a wide range of practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

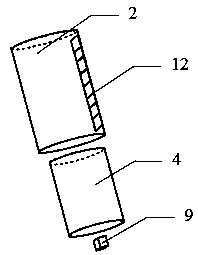

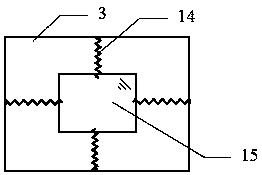

[0026] refer to Figure 1 to Figure 12 The shape structure of the lithography machine is a small workpiece fixture, which is composed of three parts: a lifting and rotating function device, a light spot positioning function device, and a fixing function device. It is characterized in that: the overall structure of the jig, from bottom to top, is the bottom base platform 1, the outer hollow column 6 and the inner hollow column 2, and the uppermost is the workpiece platform 3 made of transparent material.

[0027] The lifting and rotating function device is composed of an inner hollow column 2 and an outer hollow column 6, the inner hollow column 2 and the outer hollow column 6 are fitted together, and the inner hollow column 2 can move and rotate up and down in the outer hollow column 6 under control . The top of the inner hollow column 2 and the middle part of the lower bottom of the workpiece table 3 can be fixedly connected or disassembled; when the inner hollow column 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com