Method for selecting hard turning tool for roll bearing ring groove

A rolling bearing and hard turning technology, applied in the field of bearing processing, can solve the problems of missing, hard turning tool selection of rolling bearing ring raceway, and numerical ambiguity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] In the processing of rolling bearing ring grooves in a bearing manufacturer, there are three alternative hard turning tools It is required to sort the pros and cons of these three alternative hard turning tools, and select the optimal hard turning tool.

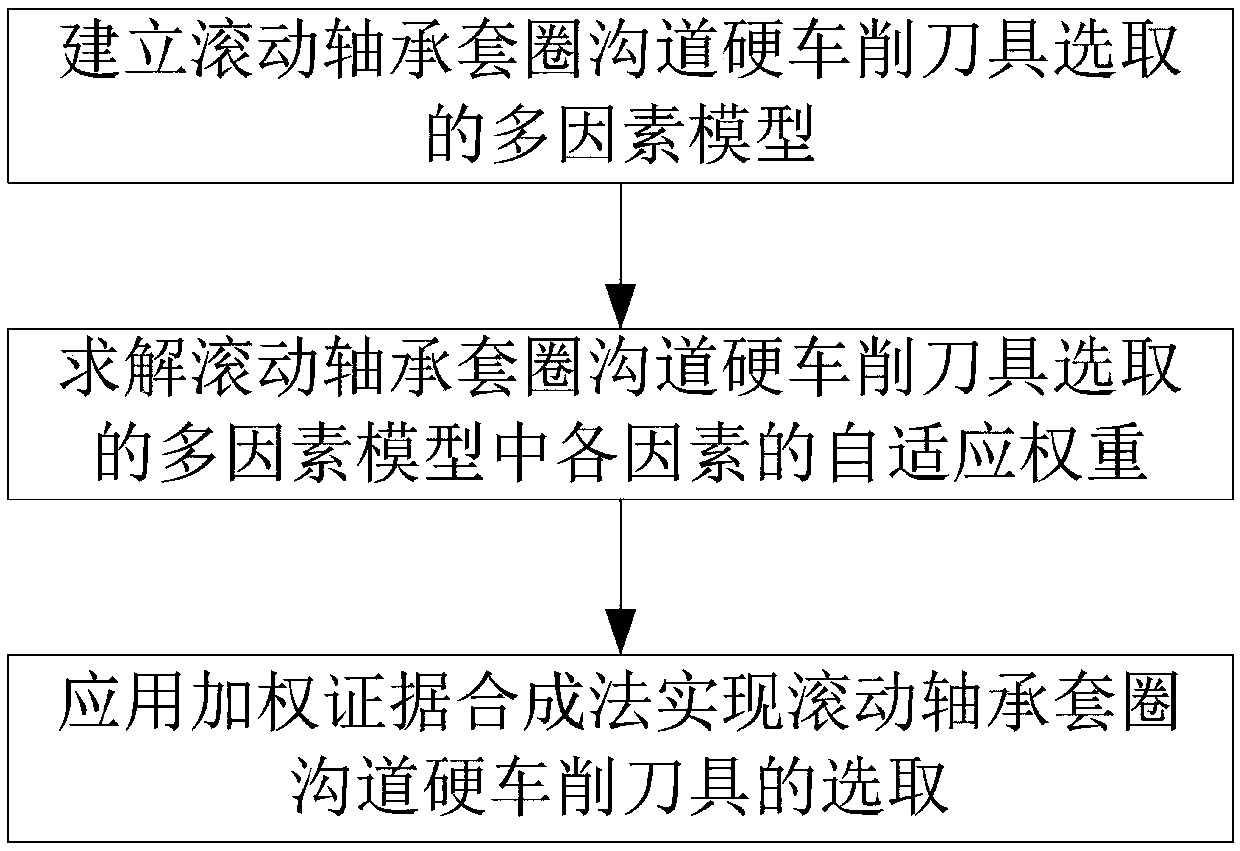

[0073] The implementation steps are as follows:

[0074] Step 1: Establish a multi-factor model for the selection of hard turning tools for the raceways of rolling bearing rings;

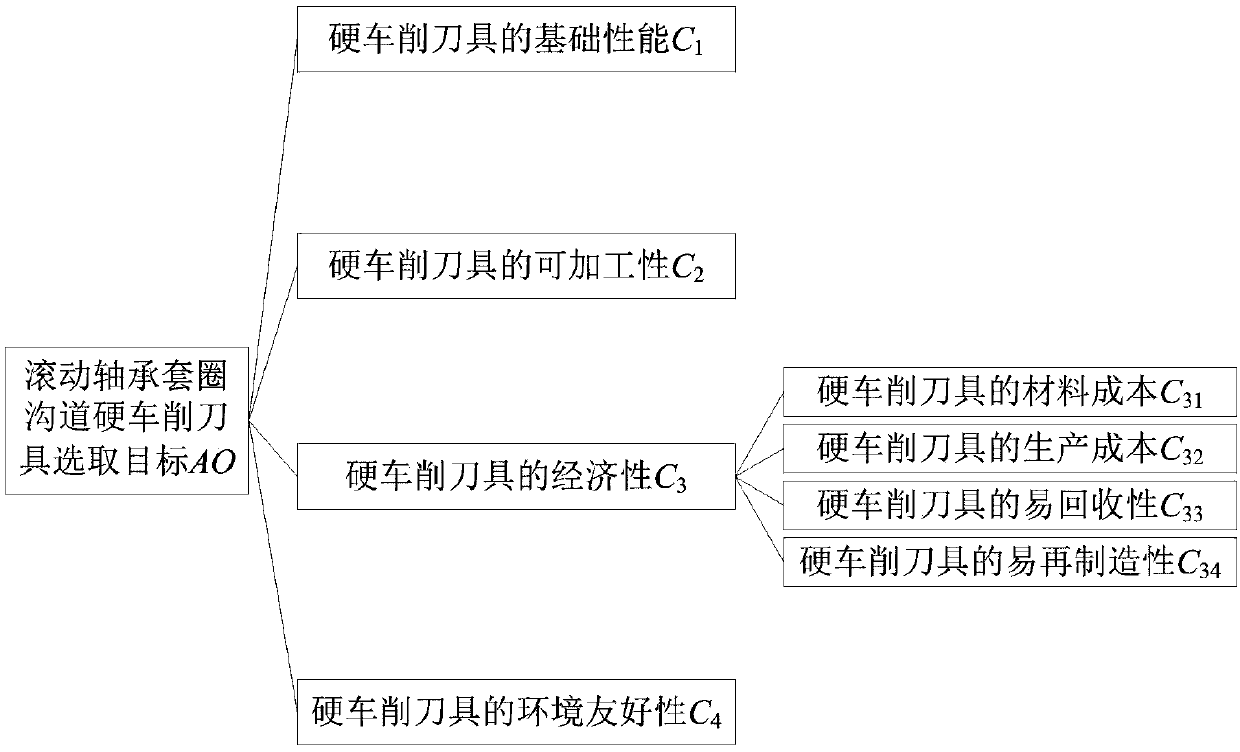

[0075] Use AO to represent the selection target of the hard turning tool for the raceway of the rolling bearing ring. AO is affected by four factors: the basic performance of the hard turning tool C 1 , the machinability of hard turning tools C 2 , the economy of hard turning tools C 3 and environmental friendliness of hard turning tools C 4 ;

[0076] in:

[0077] Basic performance of hard turning tools C 1 Including: (1) hardness and wear resistance of hard turning tools; (2) strength and toughness of hard turning tools; (3) heat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com