Lighting test module

A technology for testing modules and testing pads, applied in static indicators, instruments, etc., can solve problems such as complex process, binding size limitation, etc., and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

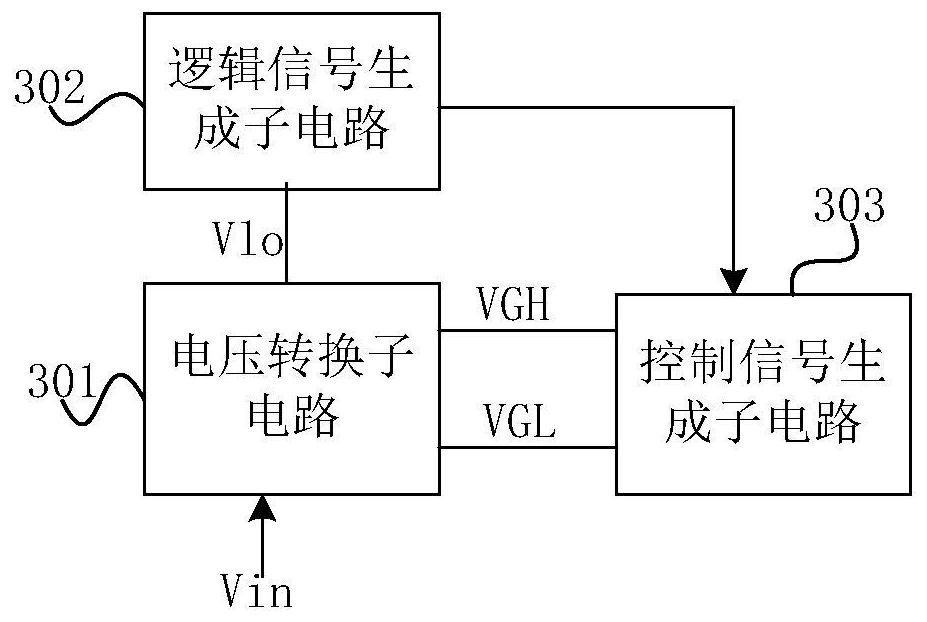

[0047] According to a specific implementation manner, the control signal generation circuit may include a voltage conversion subcircuit, a logic signal generation subcircuit and a control signal generation subcircuit, wherein,

[0048] The voltage conversion subcircuit is used to boost the input voltage to obtain the maximum on-state voltage and the minimum off-state voltage, and transmit the maximum on-state voltage and the minimum off-state voltage to the control signal generator The circuit is also used to step down the input voltage to obtain a logic voltage, and transmit the logic voltage to the logic signal generation sub-circuit;

[0049] The logic signal generating subcircuit is used to generate a logic signal according to the logic voltage;

[0050] The control signal generating subcircuit is used to generate the control signal according to the maximum on-state voltage and the minimum on-state voltage under the control of the logic signal.

[0051] Such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com