Textile tool module and textile machine with textile tool module

A tool module, textile machine technology, applied in textiles and papermaking, knitting, warp knitting, etc., can solve problems such as misalignment or positioning, and achieve the effect of simplifying installation, avoiding deformation, and improving alignment and positioning without errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

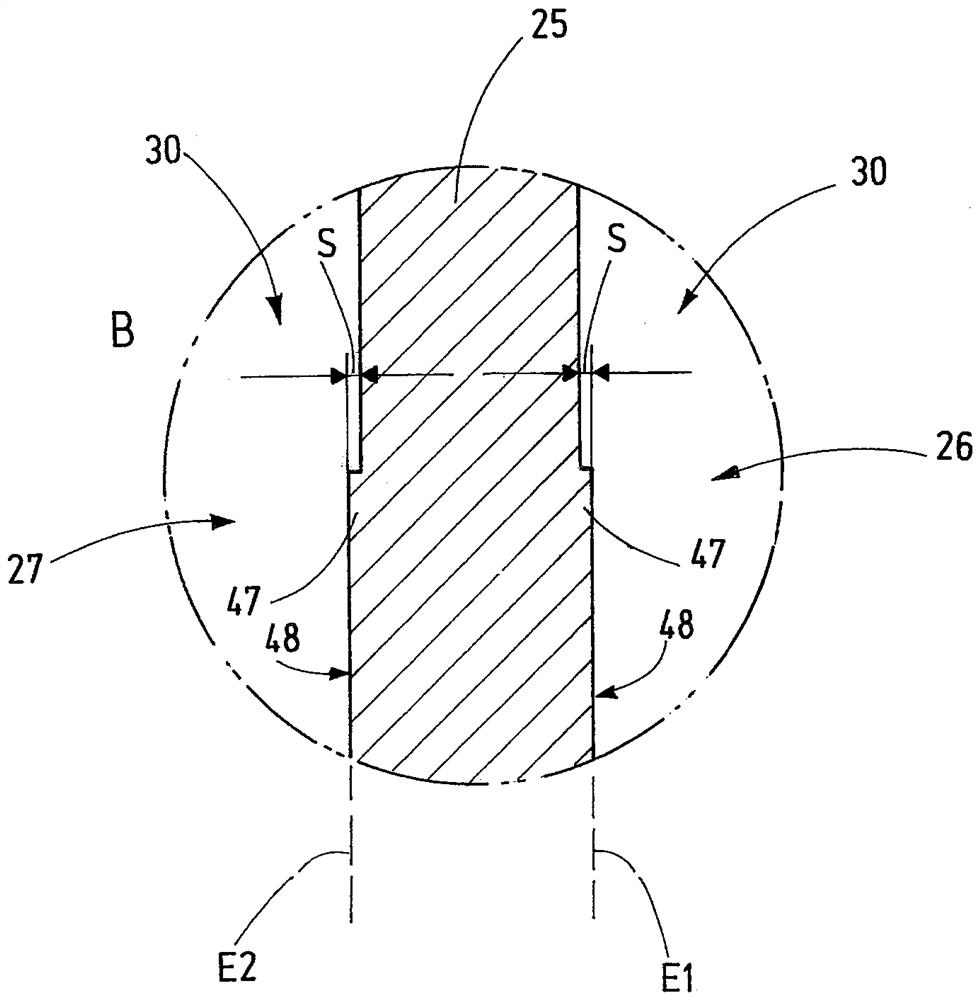

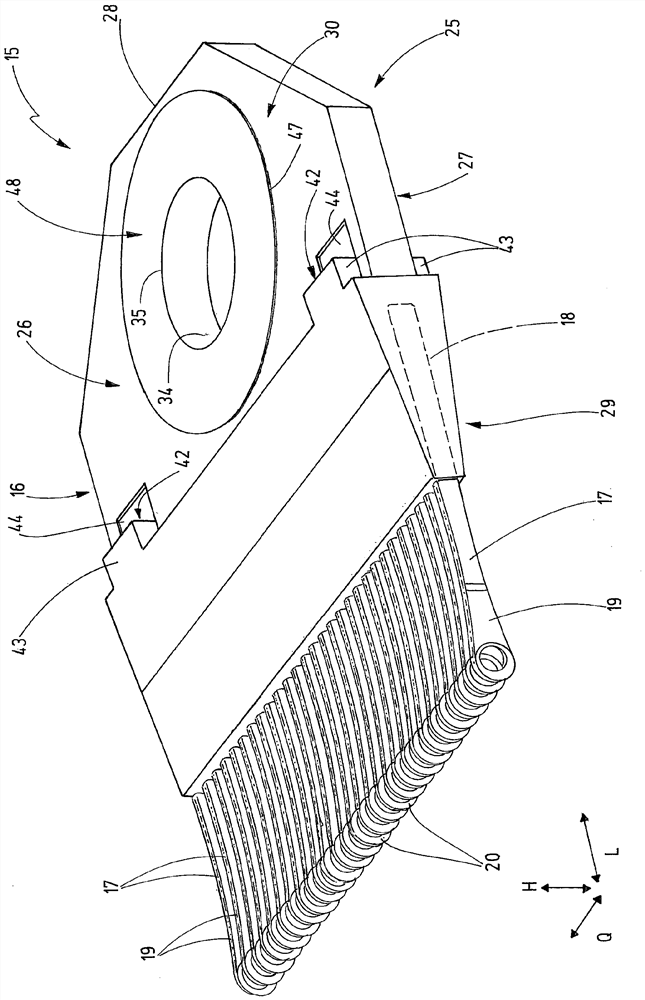

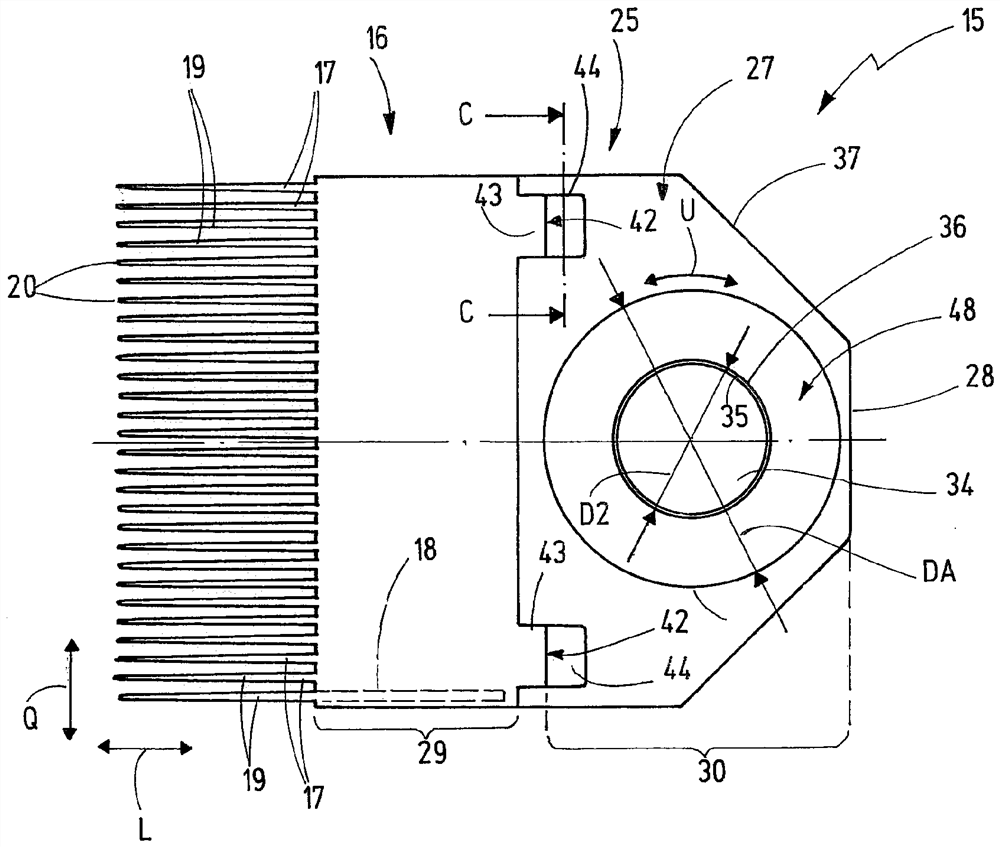

[0041] Figure 1 to Figure 7 An exemplary embodiment of a textile tool module 15 is shown, which in the present example is configured as a needle guide module for a warp knitting machine. The textile tool module 15 has a module body 16 on which a plurality of textile tools 17 are held so as to be immovable relative to the module body 16 and relative to each other. In the present example, the textile tool 17 is a guide needle. Each textile tool 17 has a holding section 18 by means of which the textile tool 17 is mounted to the module body 16 . For example, the holding section 18 is connected to the module body 16 in a form-fitting manner and / or in a material-fitting manner. In an exemplary embodiment, the module body comprises a plastic material or a composite material and is produced in shape by casting or injection molding around the holding section 18 , whereby the textile tool 17 is fastened to the module body 16 .

[0042] The textile tool 17 is preferably made of metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com