Novel CNC machined five-shaft equipment

A new type of equipment technology, applied in the field of five-axis equipment for new CNC machining, can solve problems such as inconvenience and lack of motivation for equipment research and development, and achieve good practical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

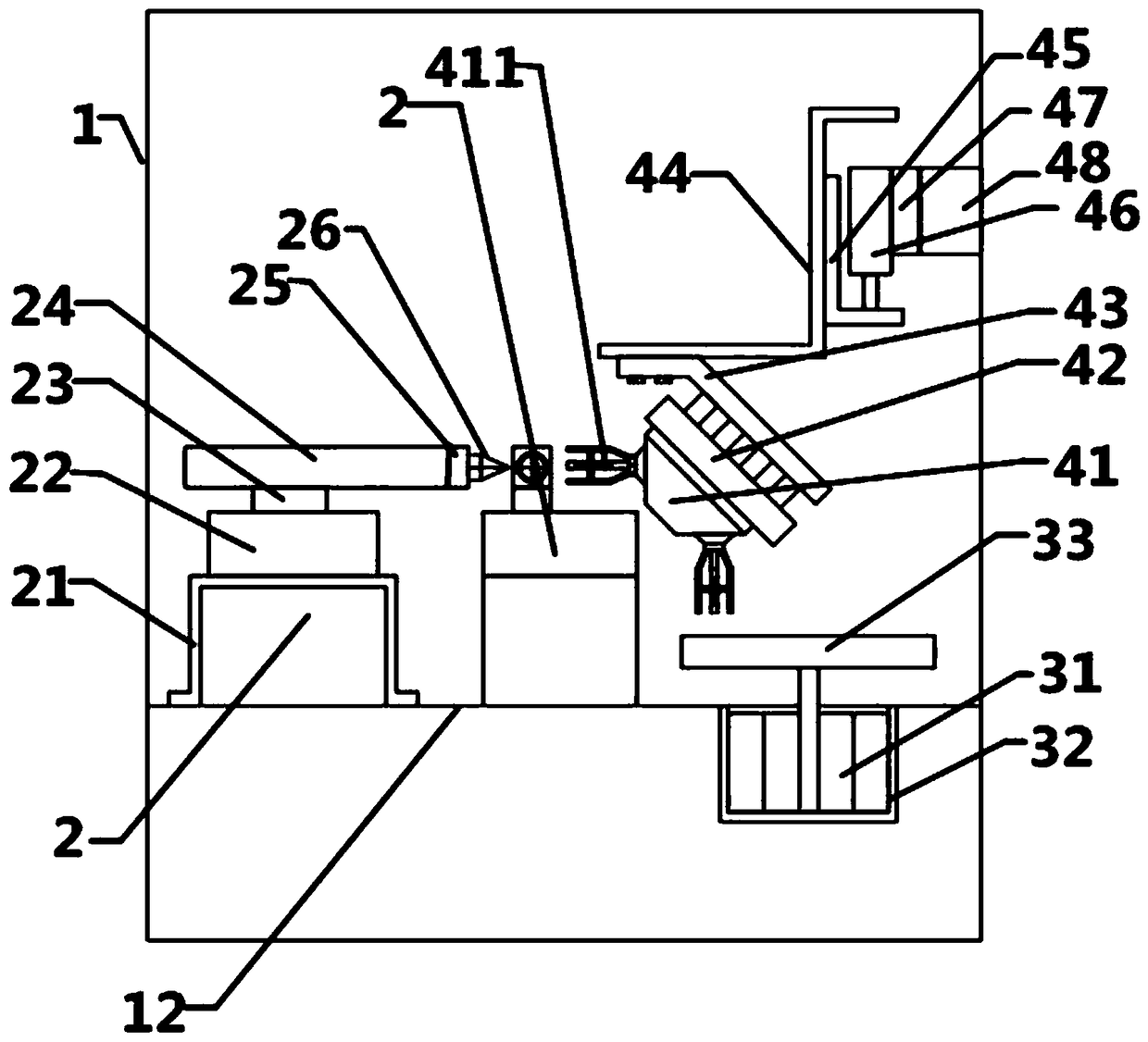

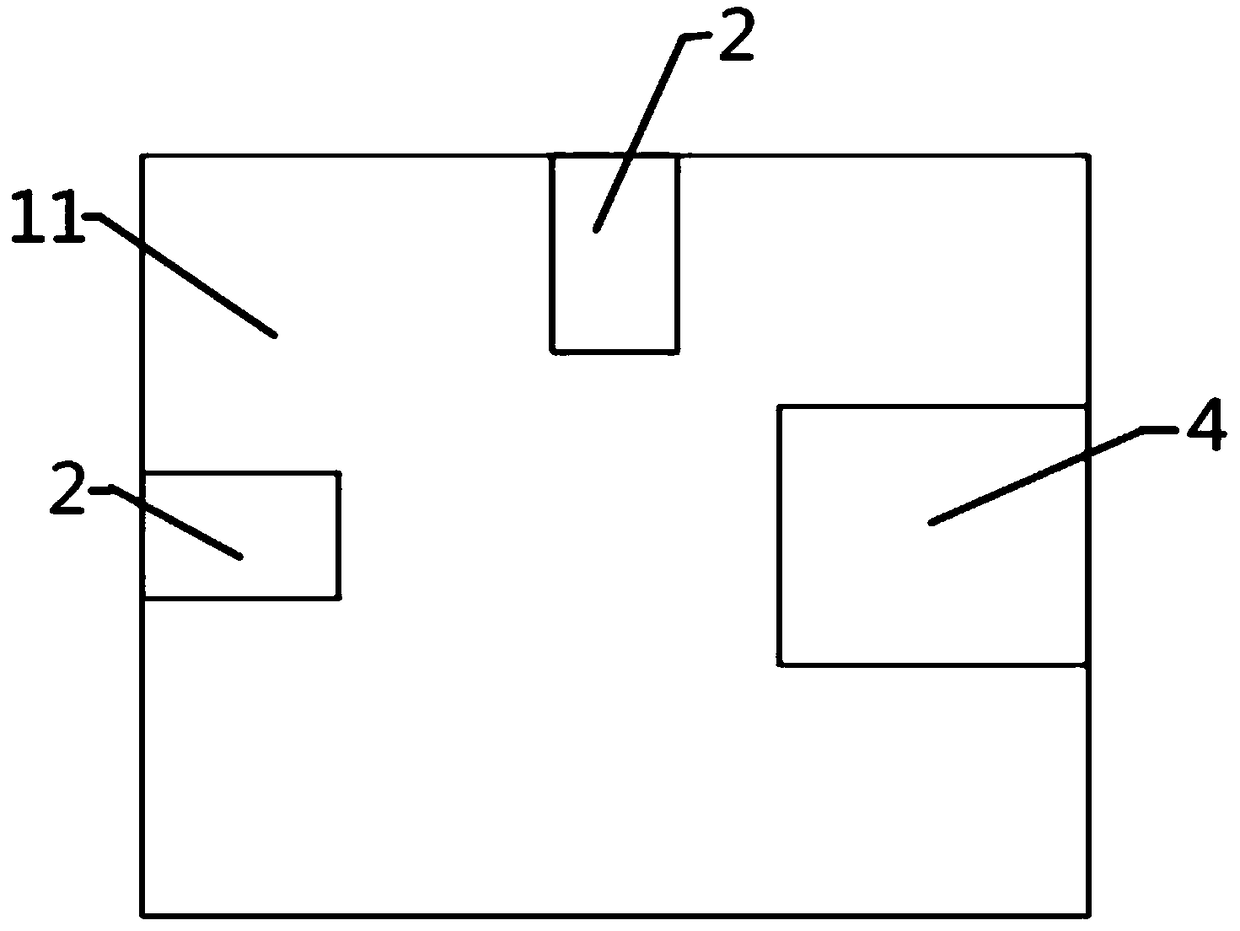

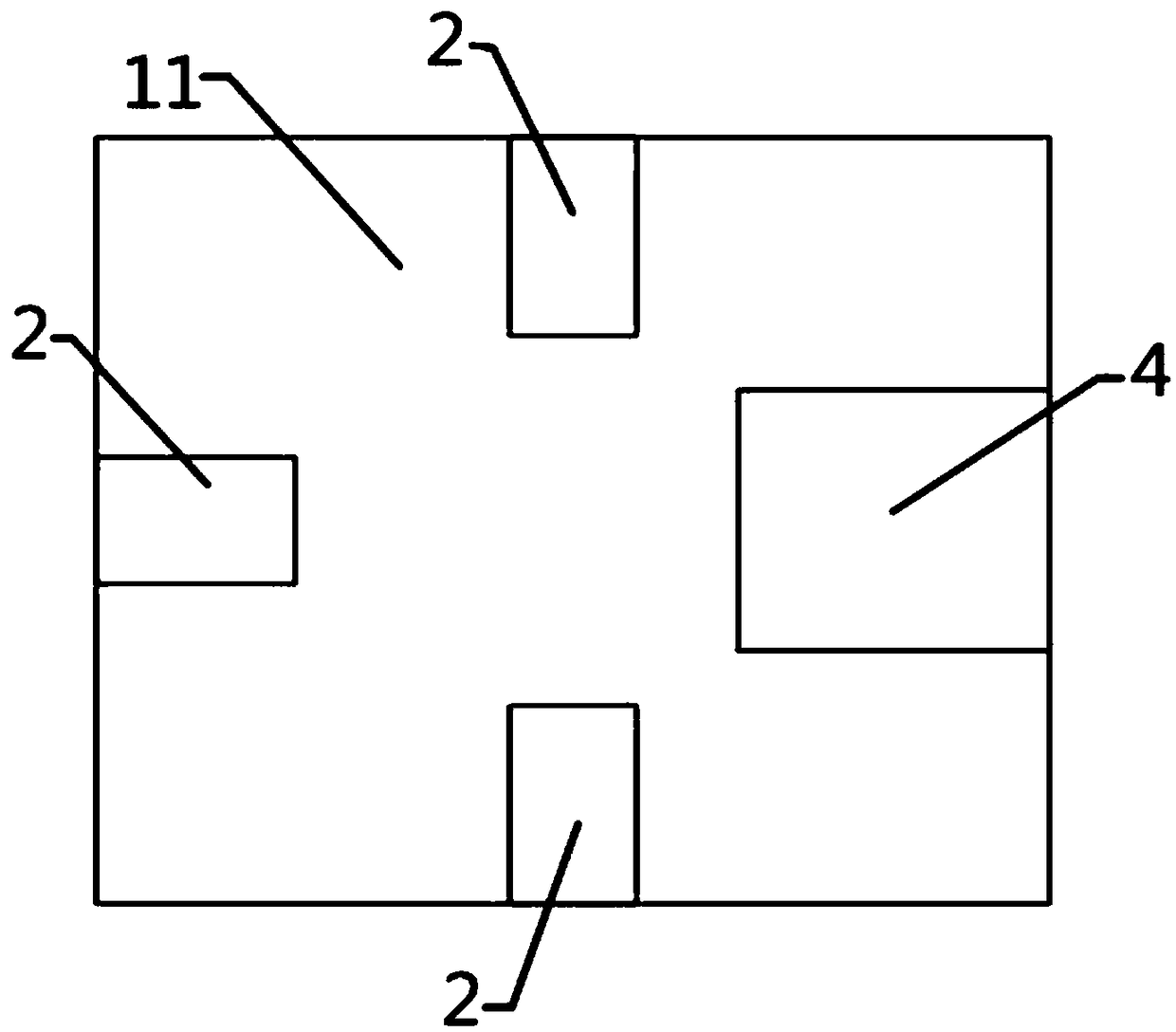

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] Such as Figure 1-Figure 3 As shown, a new type of CNC machining five-axis equipment includes a chassis 1. A workbench 11 is arranged inside the chassis 1. A rotary milling mechanism 2, a feeding mechanism and a grabbing mechanism 4 are installed on the workbench 11.

[0024] Specifically, the feeding mechanism packs the disc 33 , and the installation cover 32 is fixedly installed under the workbench 11 , and the motor 31 is arranged between the installation cover 32 and the workbench 11 , and the motor 31 and the disc 33 are connected by transmission.

[0025] The top of the feeding structure is provided with a grabbing mechanism 4. The grabbing mechanism 4 includes a push cylinder 46 fixed on the side wall of the cabinet 1. The bottom of the push cylinder 46 is invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com