Intelligent hydraulic stapler

A stapler and hydraulic technology, applied in the direction of binding, can solve the problems of poor binding effect, insufficient depth and pressure, incomplete binding, etc., and achieve the effect of simple structure, convenient operation, fast and effective binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

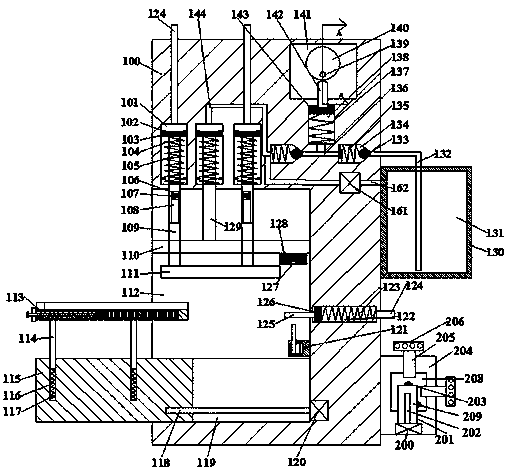

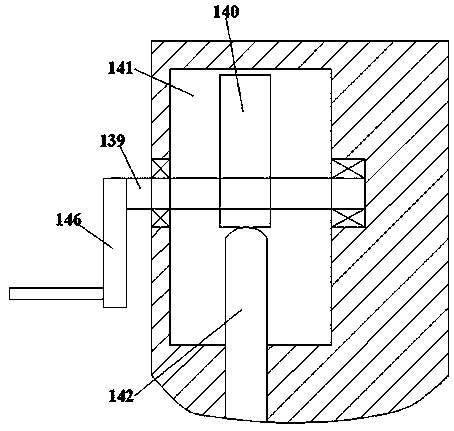

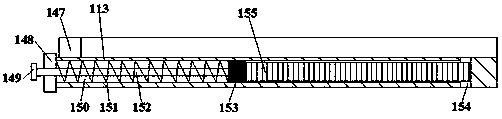

[0019] Such as Figure 1-Figure 4As shown, the intelligent hydraulic stapler of the present invention includes a fuselage 100 and a binding cavity 112 that is arranged in the fuselage 100 and opens to the left. Guide chute 119, the first guide chute 119 is slidably connected with a first guide slider 115, and the first guide slider 115 is internally threaded and connected with a first threaded rod 118 extending left and right. The right end of a threaded rod 118 is dynamically connected with a first motor 120, and the outer surface of the first motor 120 is embedded in the inner wall of the right end of the first guide chute 119 and is fixedly connected with it. The first guide slider 115 A first round hole 116 with an upward opening and symmetrical left and right is arranged in the top end face, and a first pressing rod 114 extending up and down is connected with sliding fit in the first round hole 116, and the top end of the first pressing rod 114 protrudes from the The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com