Pre-buried sleeve used for channel installation and channel positioning method

A technology for pre-embedded sleeves and installations, which is applied to buildings and building structures, etc., can solve problems such as failure to replace, affect the protection of cables and pipes, and damage, and achieve convenient and fast installation and replacement, fast and efficient installation and replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

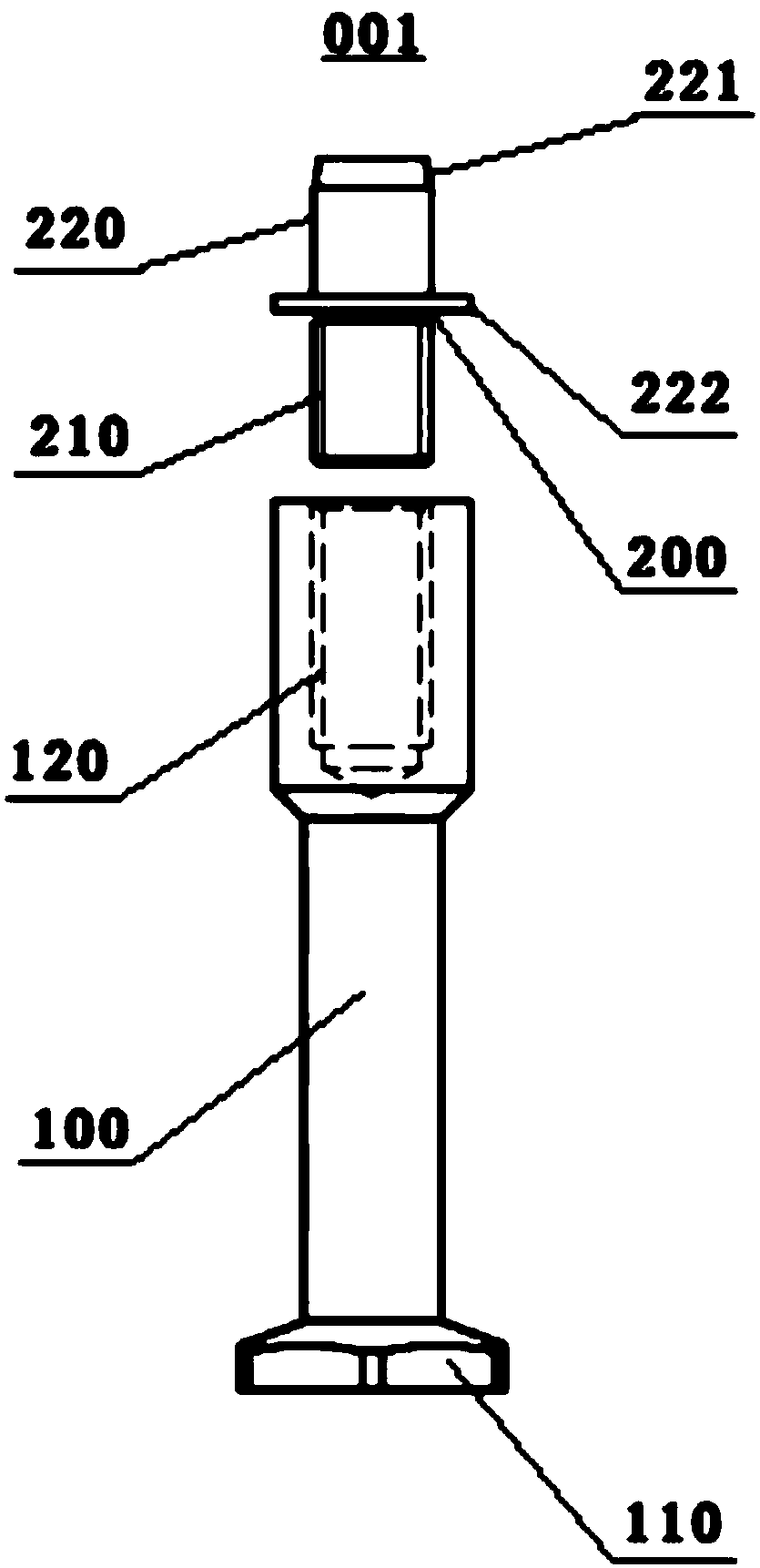

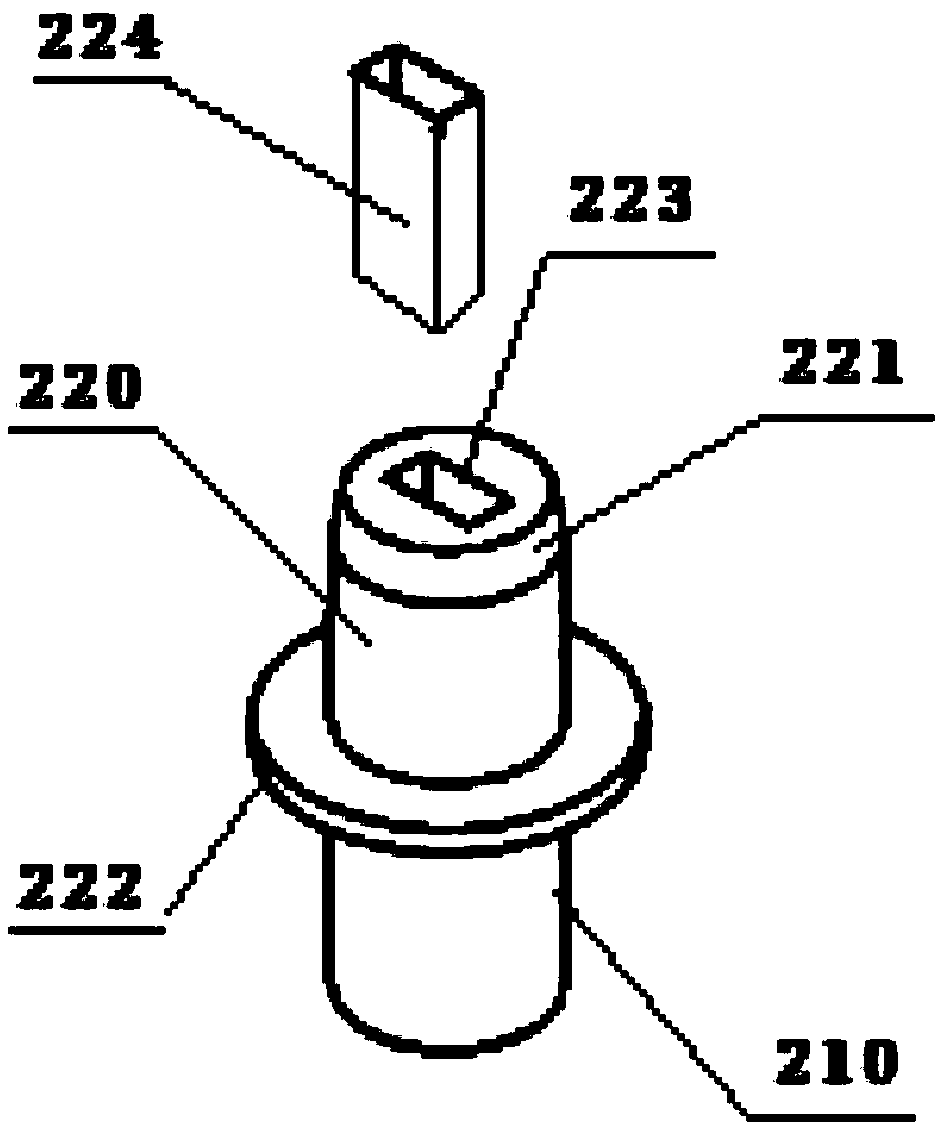

[0037] Please refer to figure 1 with figure 2 As shown, the embodiment of the present invention provides an embedded sleeve 001 for channel installation, which includes a sleeve body 100 and a positioning member 200. One end of the sleeve body 100 is provided with a pan head 110, and the other end is provided with a threaded hole. 120, one end of the positioning member 200 has a screw 210 corresponding to the threaded hole 120, and the other end is provided with a positioning column 220, the material of the sleeve body 100 in this embodiment is stainless steel, and the material of the positioning member 200 is polyethylene.

[0038] The embedded sleeve 001 for channel installation provided by the present invention includes a sleeve body 100 and a positioning piece 200 detachably connected thereto. One end of the sleeve body 100 has a threaded hole 120 for connecting the positioning piece 200, and the other end is provided The pan head 110 is used to improve the pull-out resi...

Embodiment 2

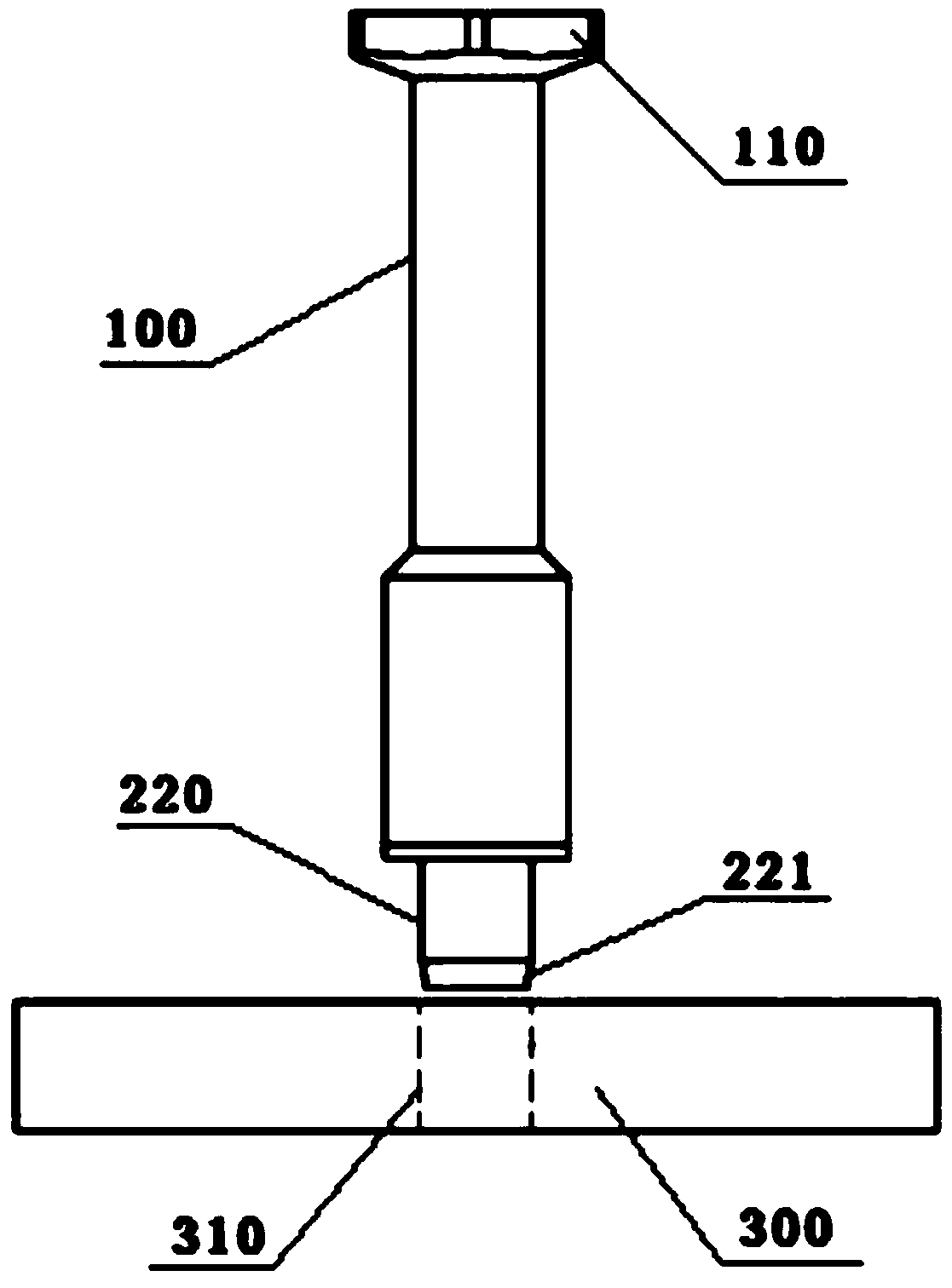

[0047] Please refer to figure 1 , figure 2 , image 3 with Figure 4 As shown, the embodiment of the present invention also provides a channel positioning method, which includes the following steps:

[0048] Provide two pre-embedded sleeves 001 for channel installation, and connect the positioning part 200 with the sleeve body 100, wherein the positioning part 200 in the two pre-embedded sleeves 001 for channel installation is connected to the sleeve body through a screw 210 Threaded hole 120 on 100 is connected by thread;

[0049] A concrete pouring formwork 300 is provided, and the concrete pouring formwork 300 is provided with two positioning holes 310 for fixing the positioning columns. Said, the aperture of the positioning hole 310 is 90%-95% of the diameter of the positioning post 220, in this embodiment, the aperture of the positioning hole 310 is 90% of the diameter of the positioning post 220;

[0050] Insert the positioning columns 220 of the two embedded sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com