Patents

Literature

67results about How to "Quick and efficient replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

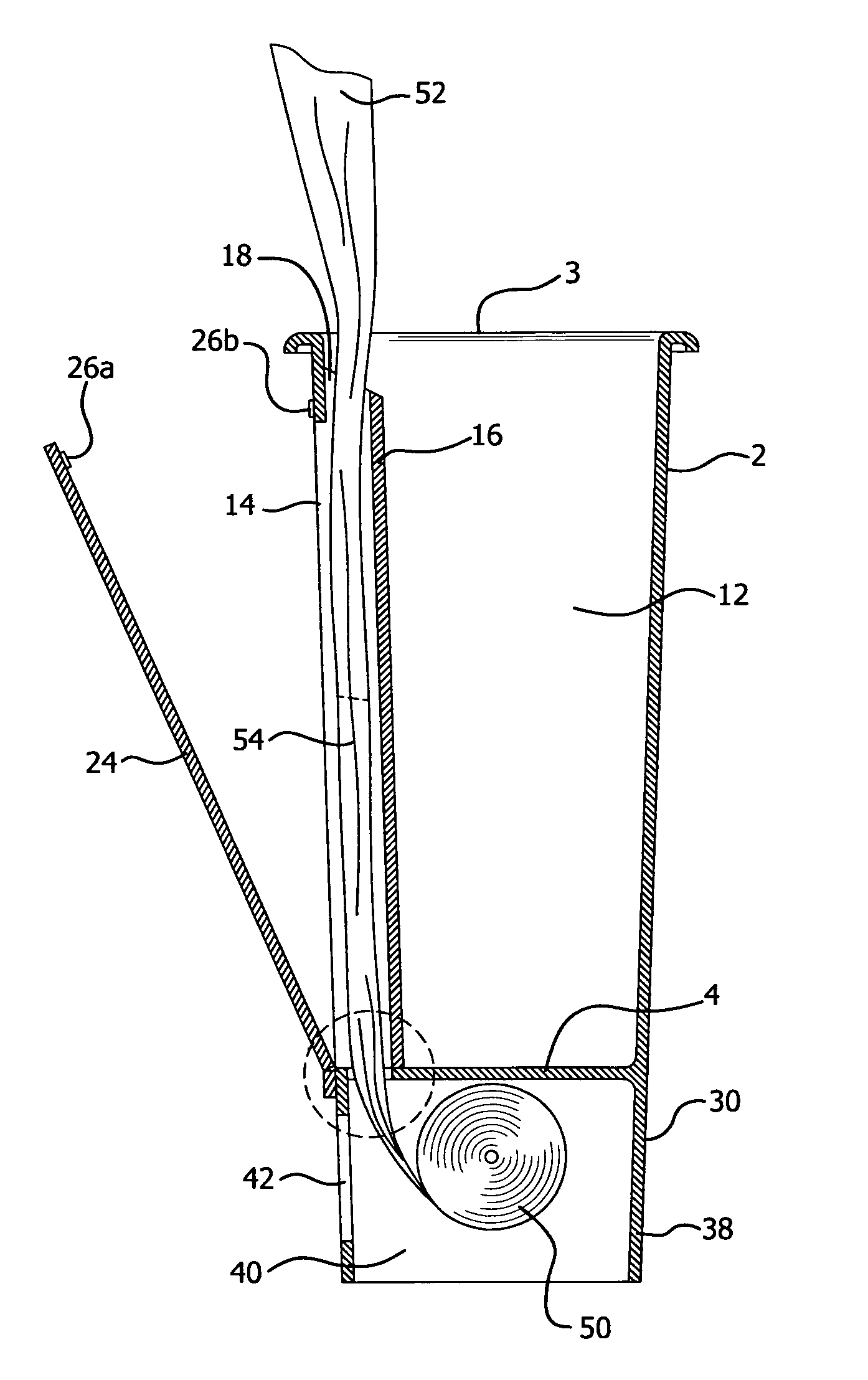

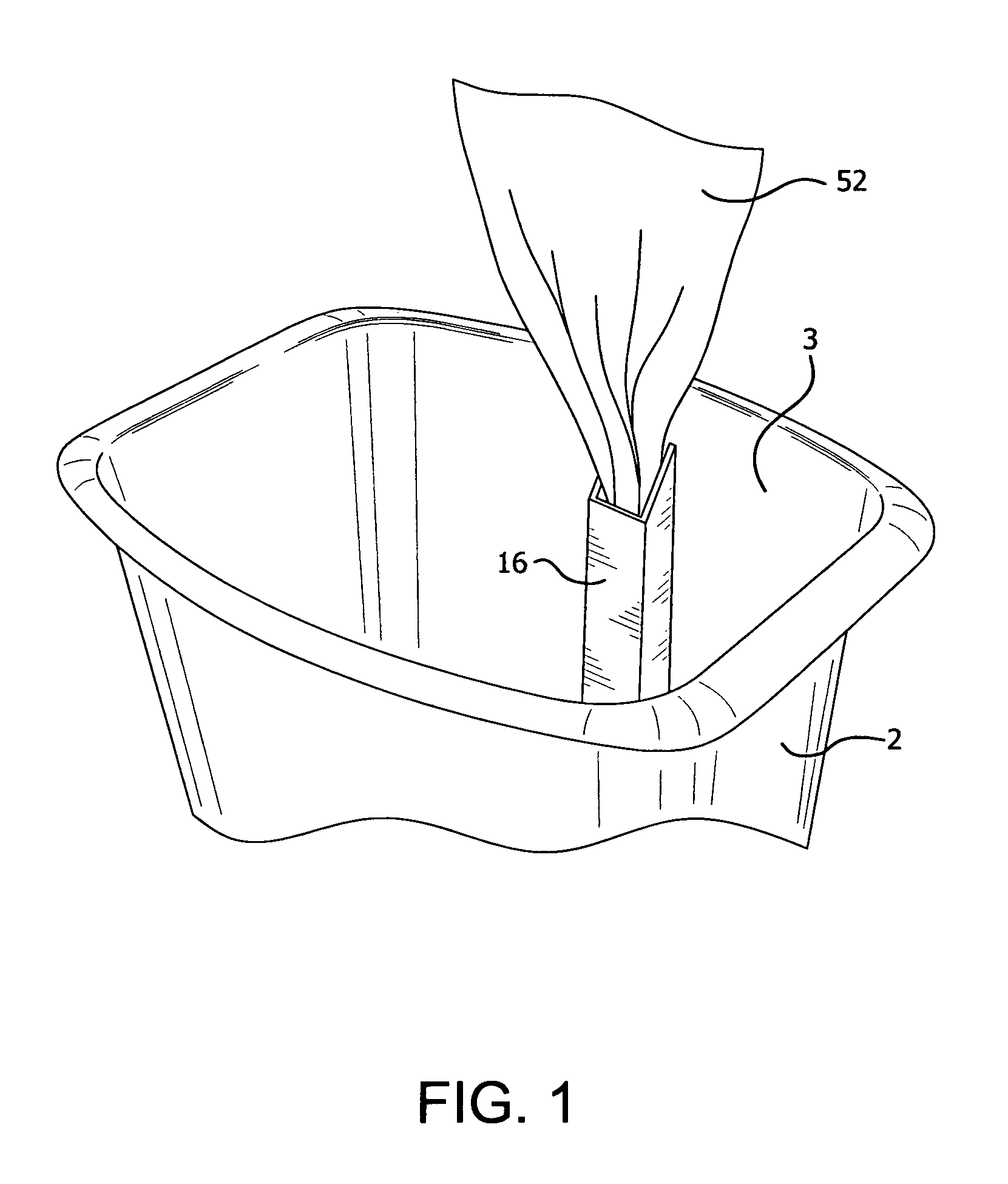

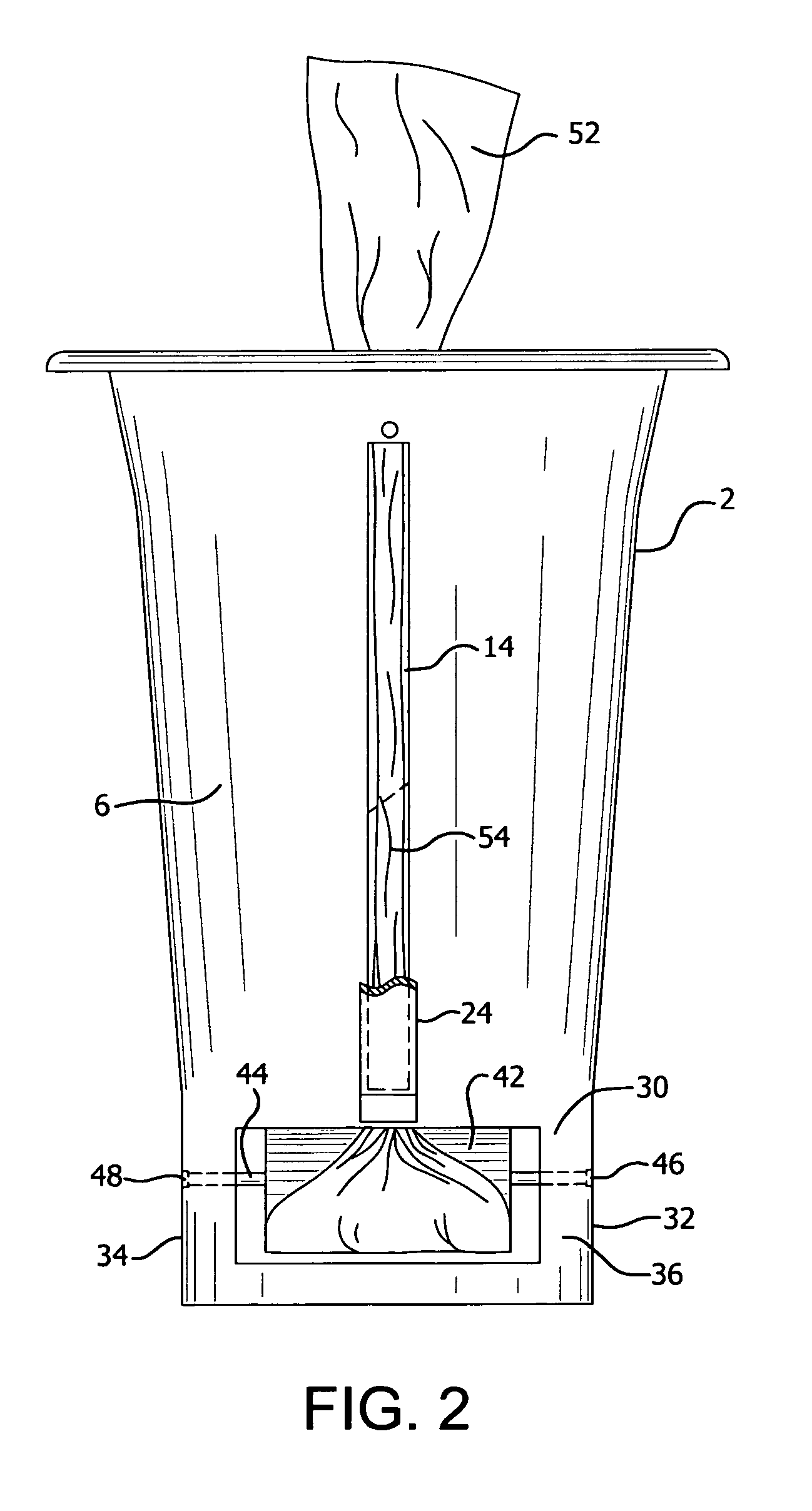

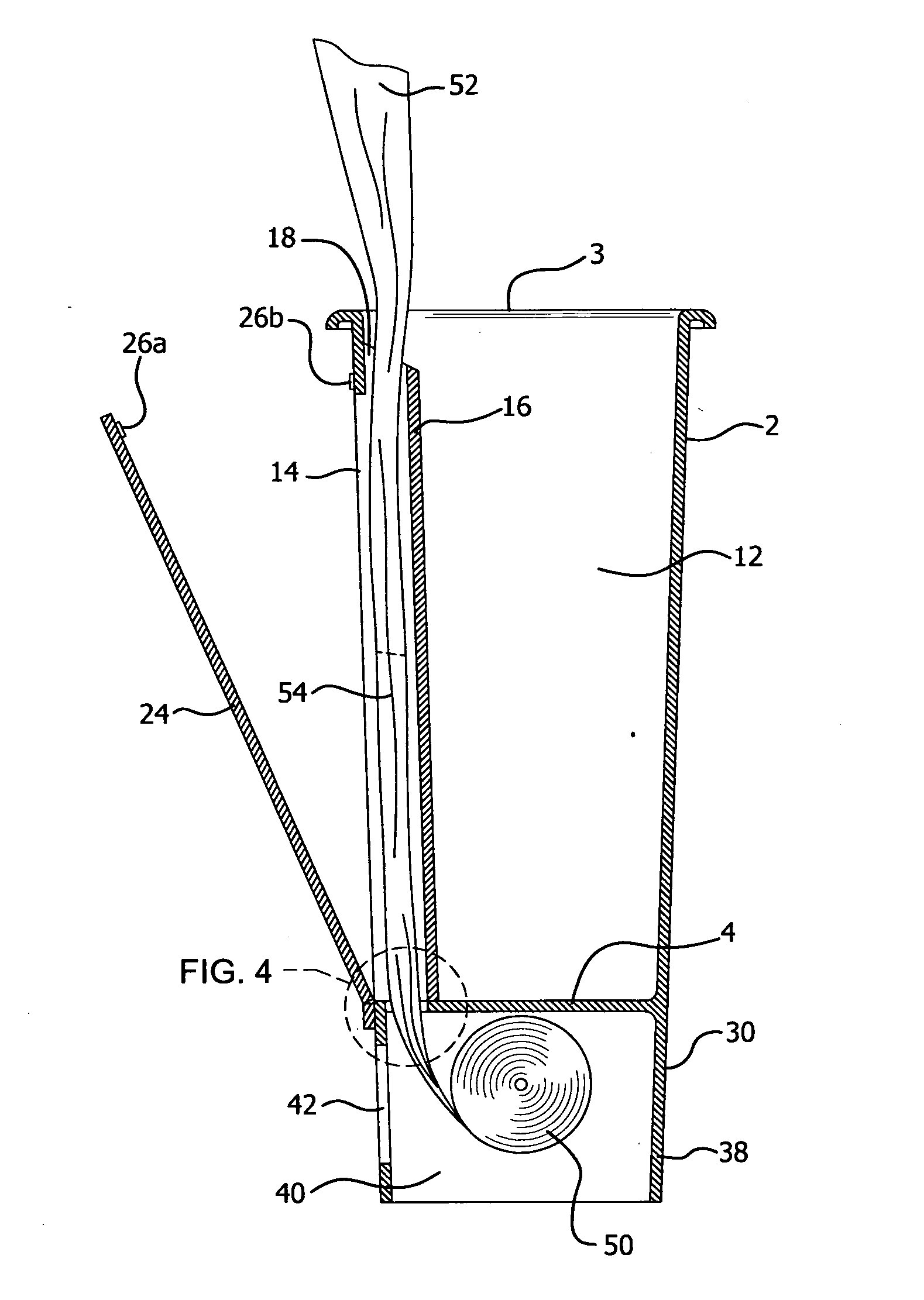

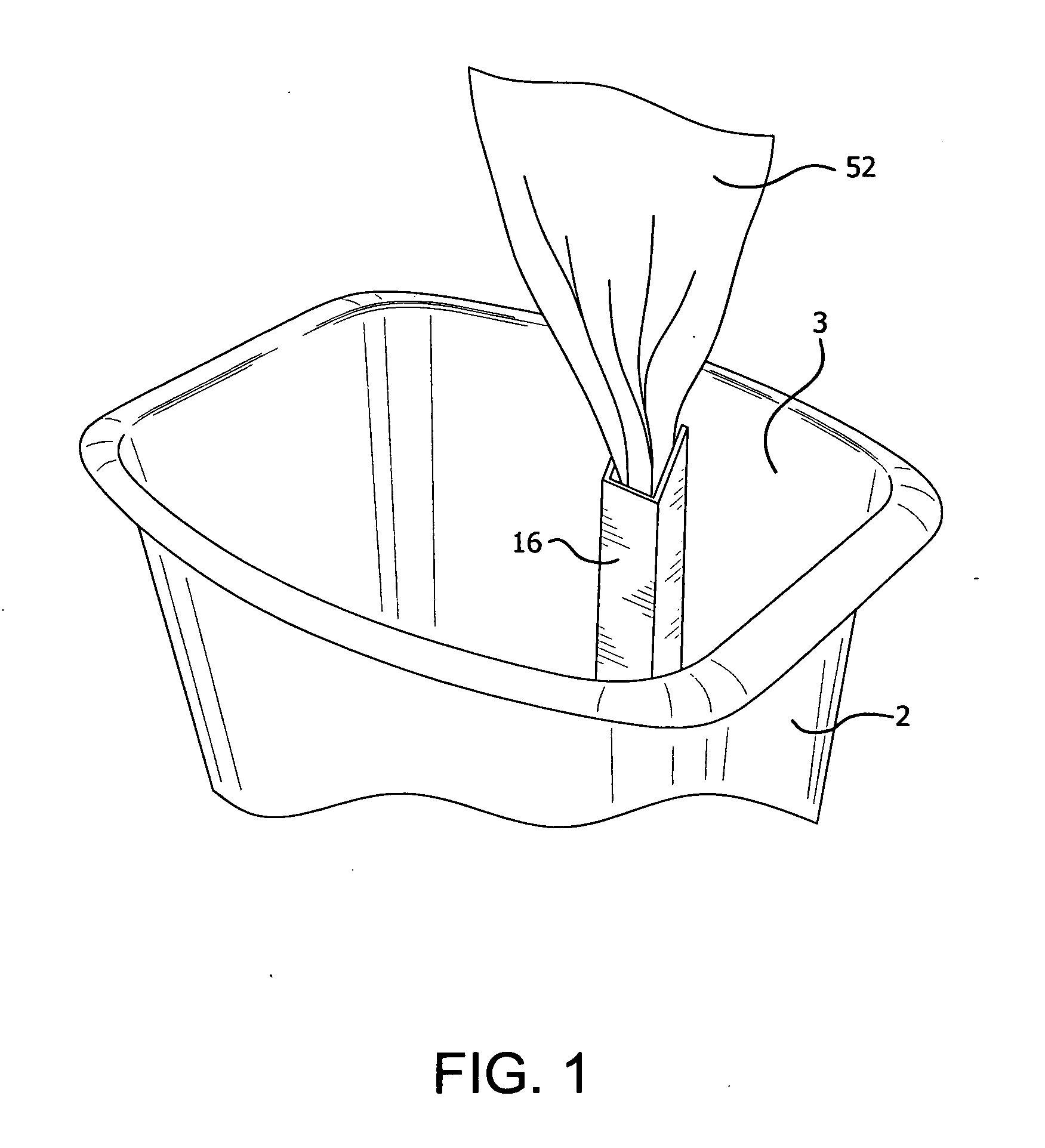

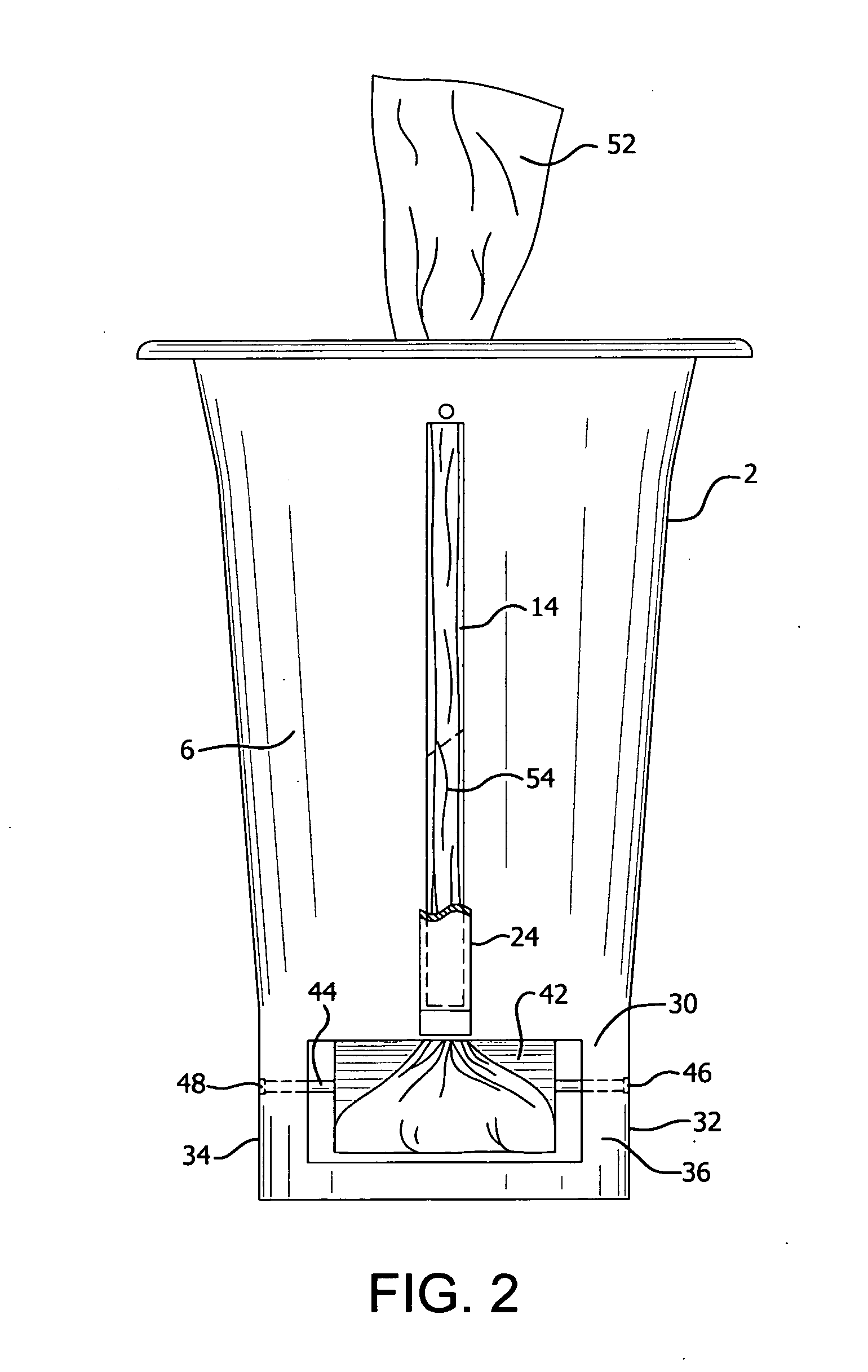

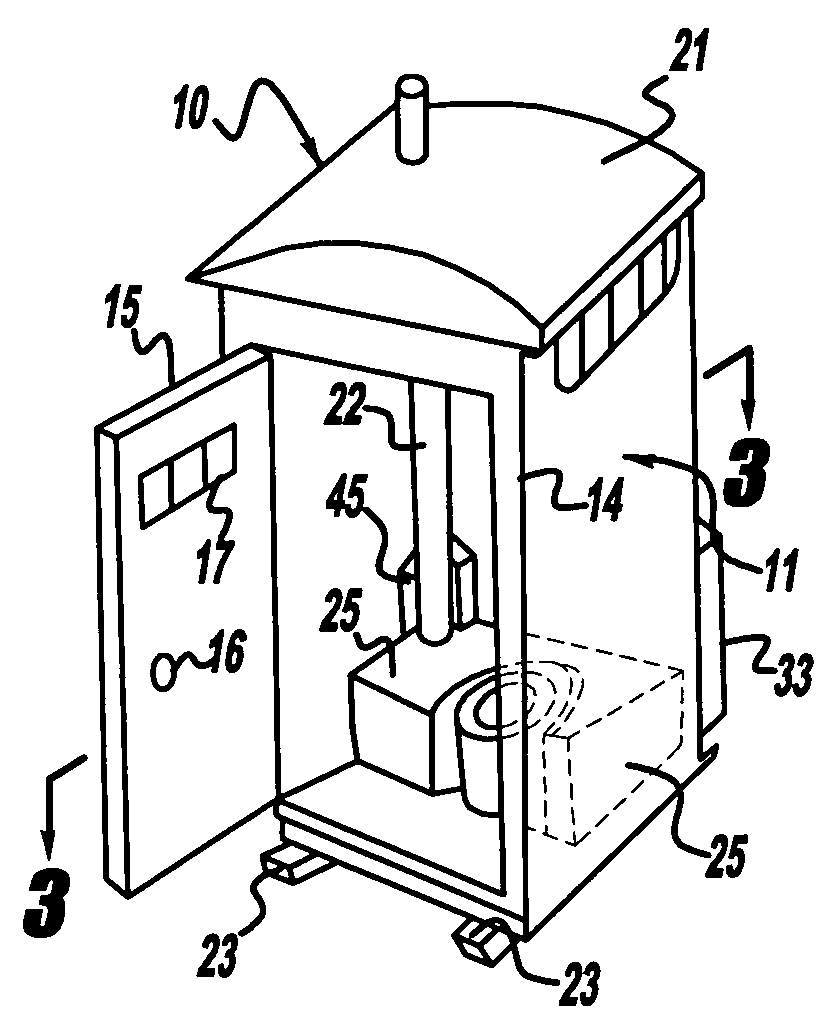

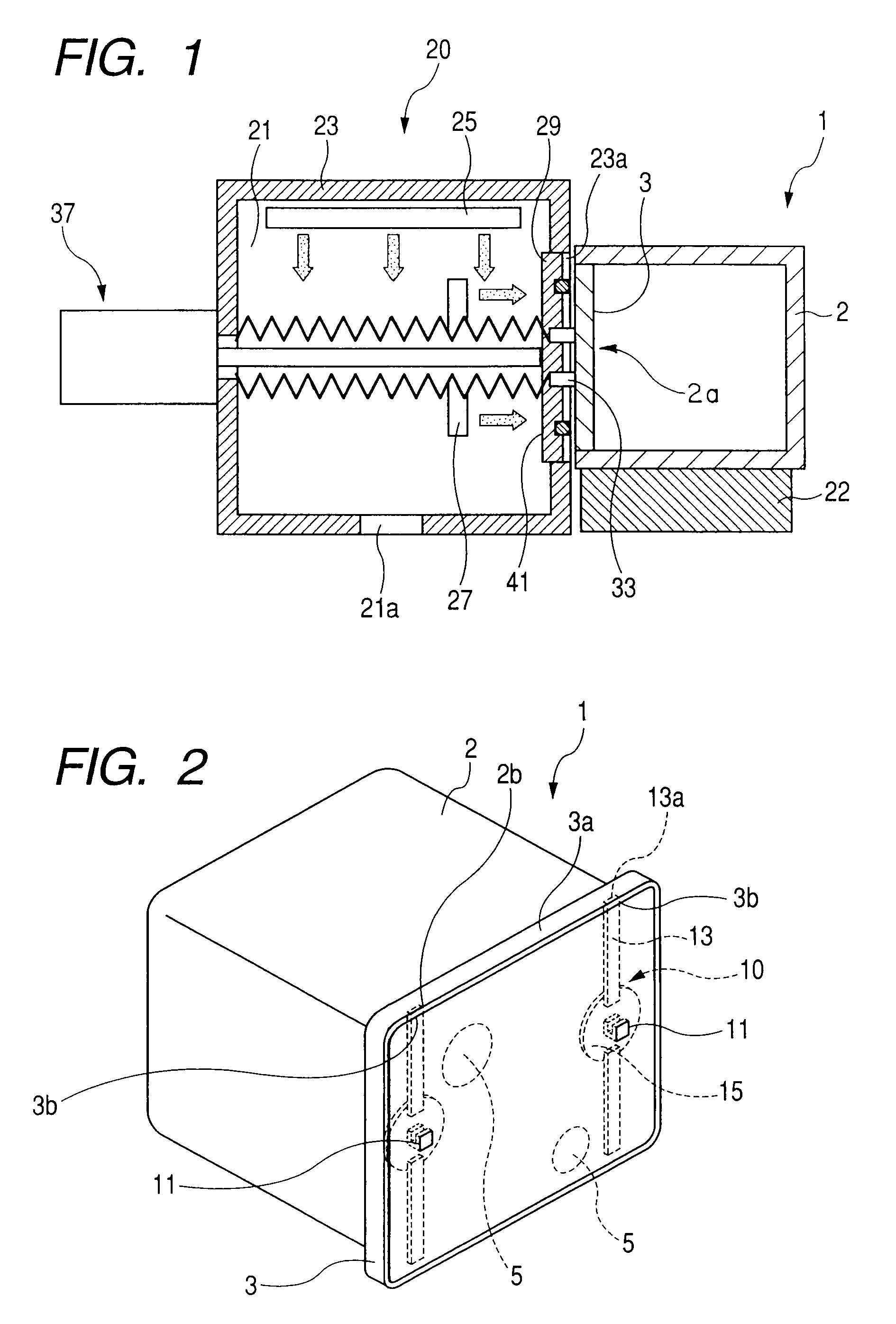

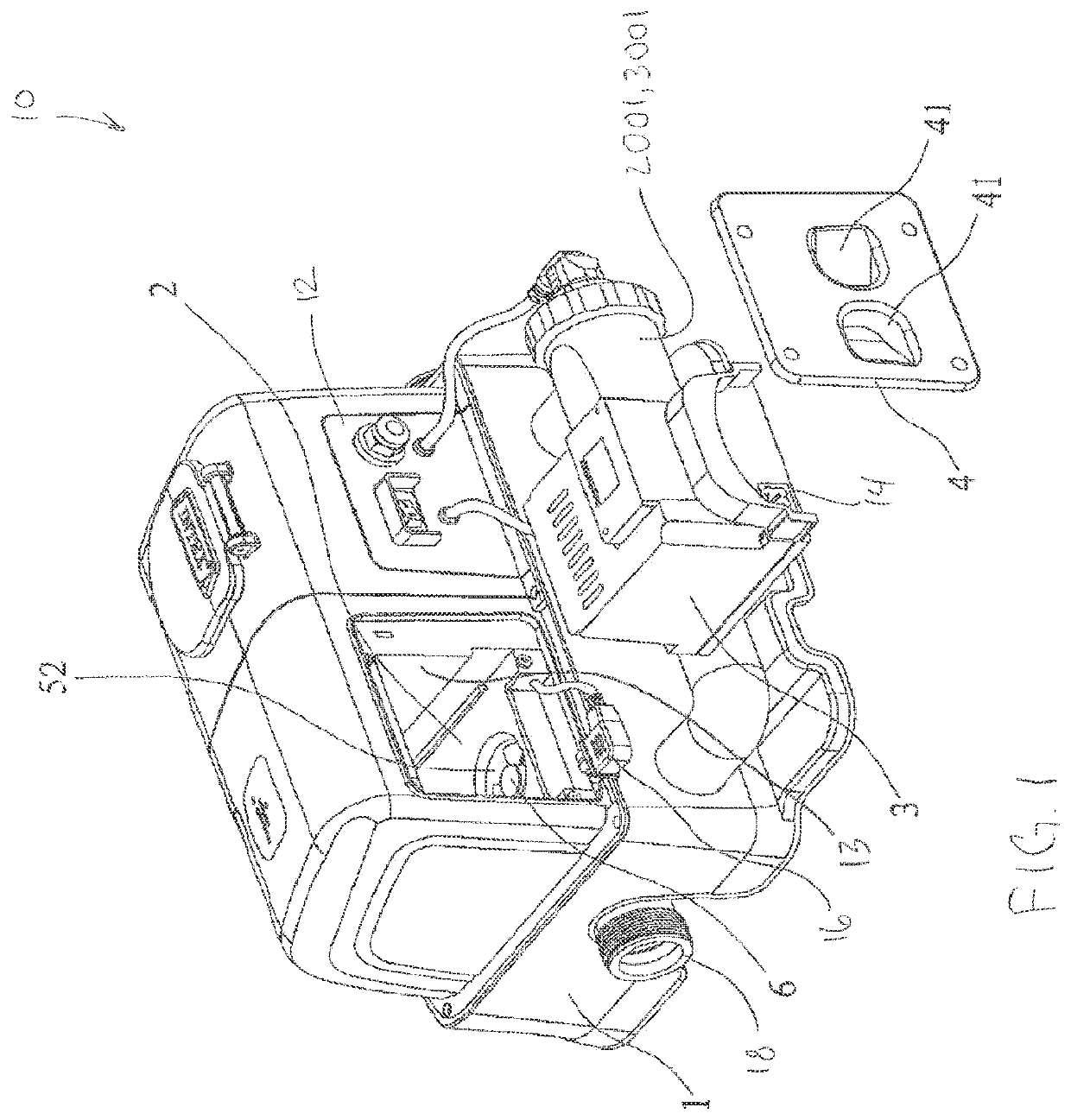

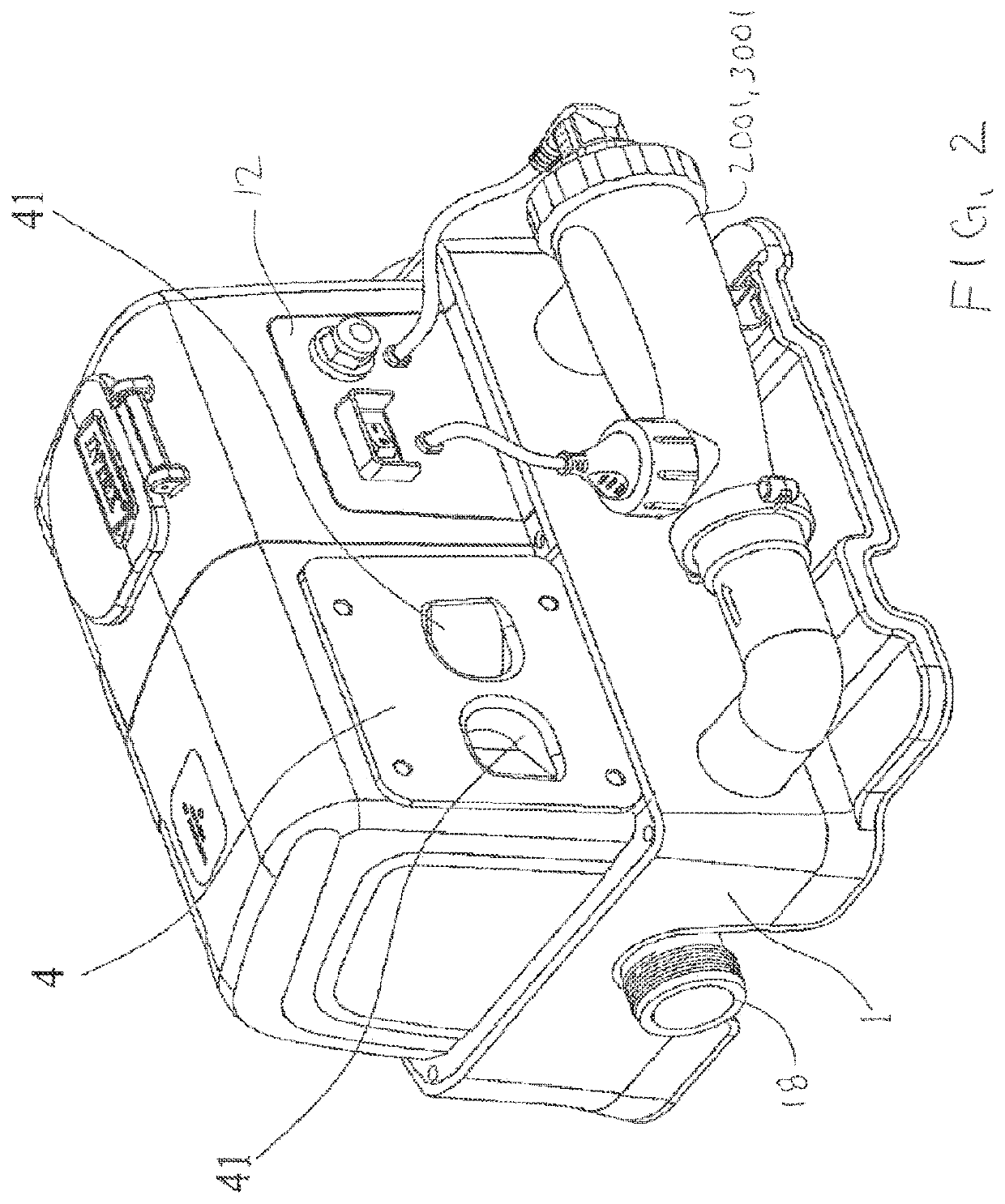

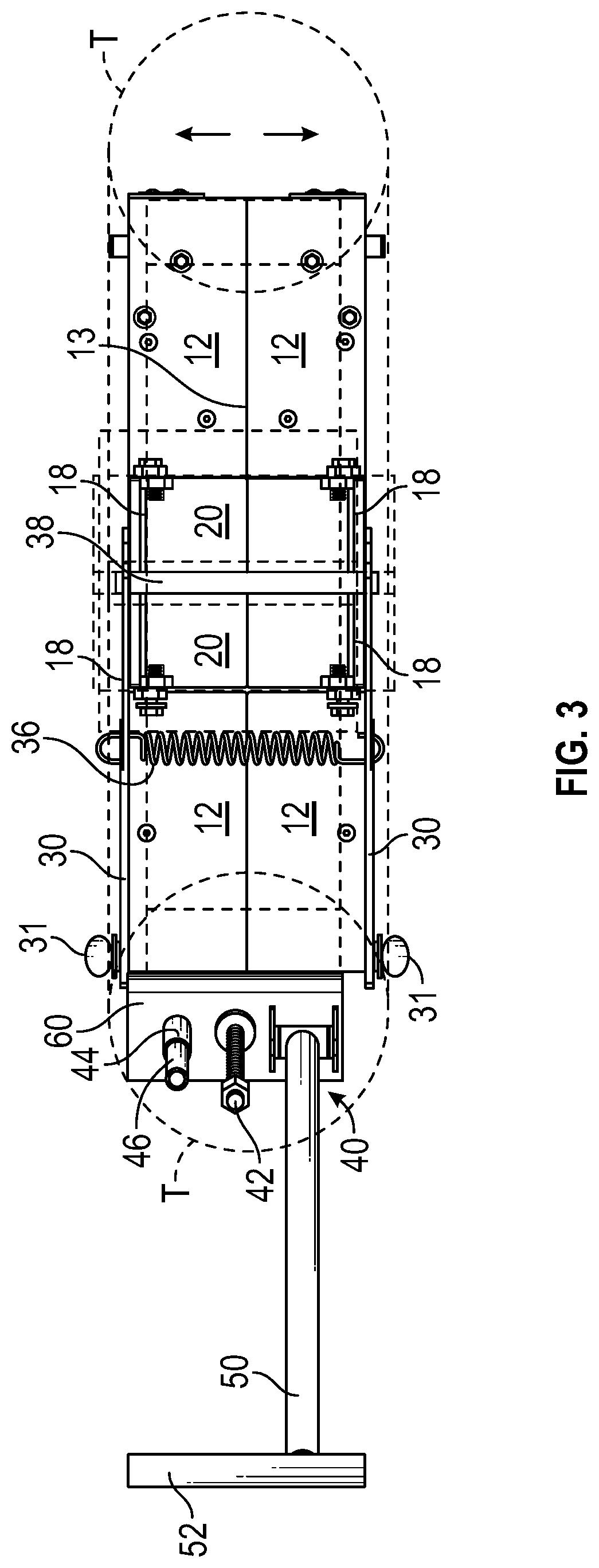

Trash receptacle with trash bag dispenser system

InactiveUS8317055B2Effectively and efficiently guidesEasy and economical to manufactureContainers for annular articlesFilament handlingInterior spaceMaterial Perforation

A trash bag receptacle with trash bag dispenser system has an open top, a bottom floor, and a front wall. The front wall of the container has a slotted opening which extends from the bottom floor upwards along substantially the entire length of the front wall. A channel member with an open top and bottom extends inward into the container, enclosing the slotted opening within the container. A base section supporting the container has an interior space in which a roll of trash bags is rotatably mounted. A single trash bag from the roll is threaded from the interior space and through the channel. The trash bag exits from the open top of the channel where its perforation is separated from the roll of trash bags. The adjacent, next trash bag on the roll remains in the channel member. A new, clean trash bag is thus easily accessible to the user by simply pulling the next trash bag which is exposed through the open top of the channel member.

Owner:ZAWROTNY LEANNE +1

Trash receptacle with trash bag dispenser system

InactiveUS20120261423A1Effectively and efficiently guidesEasy and economical to manufactureContainers for annular articlesFilament handlingInterior spaceEngineering

A trash bag receptacle with trash bag dispenser system has an open top, a bottom floor, and a front wall. The front wall of the container has a slotted opening which extends from the bottom floor upwards along substantially the entire length of the front wall. A channel member with an open top and bottom extends inward into the container, enclosing the slotted opening within the container. A base section supporting the container has an interior space in which a roll of trash bags is rotatably mounted. A single trash bag from the roll is threaded from the interior space and through the channel. The trash bag exits from the open top of the channel where its perforation is separated from the roll of trash bags. The adjacent, next trash bag on the roll remains in the channel member. A new, clean trash bag is thus easily accessible to the user by simply pulling the next trash bag which is exposed through the open top of the channel member.

Owner:ZAWROTNY LEANNE +1

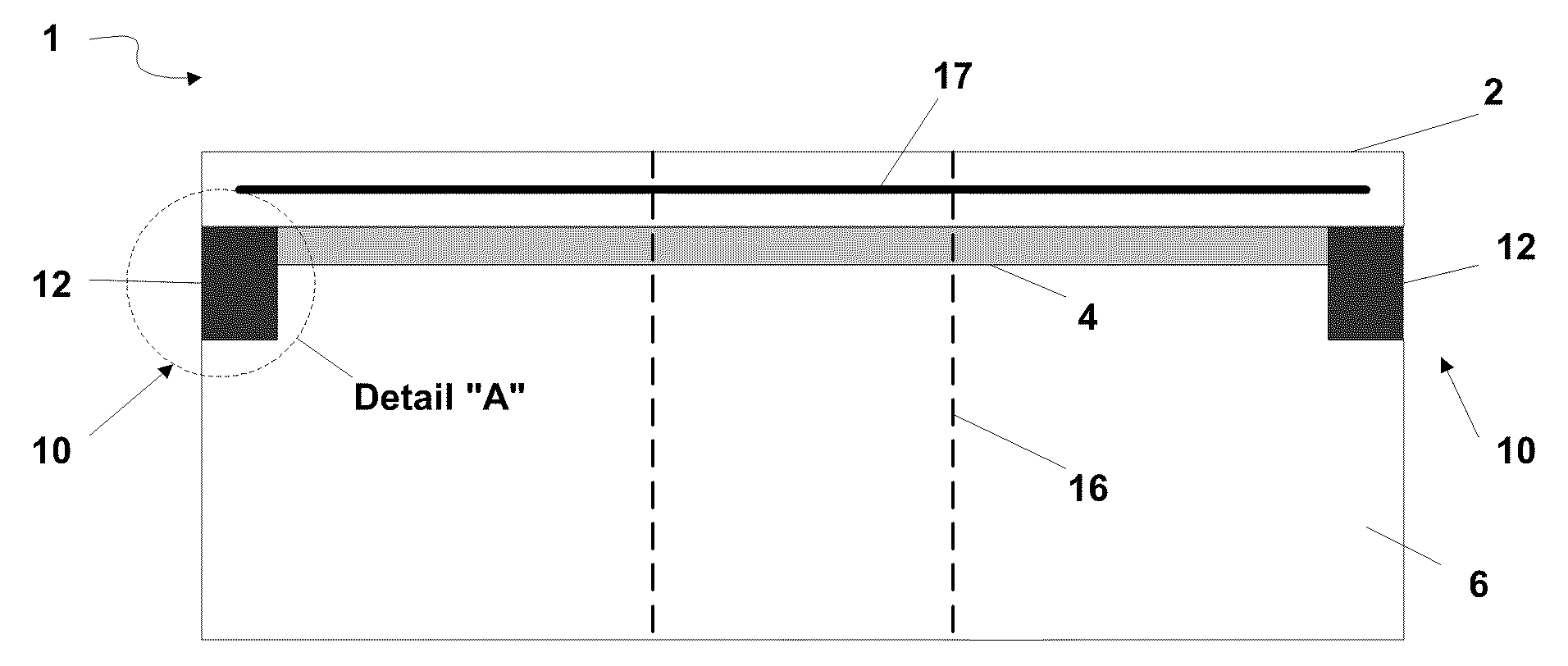

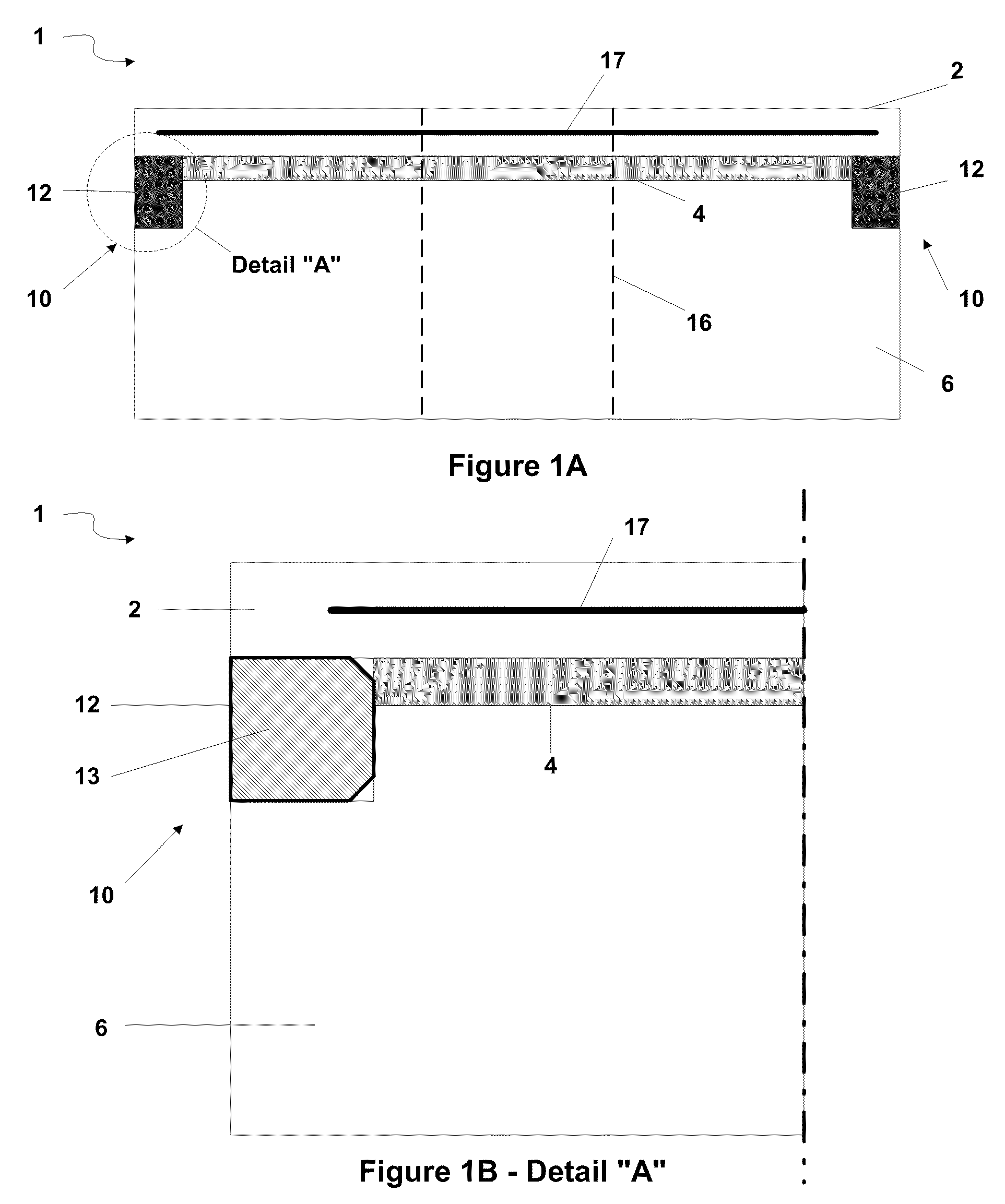

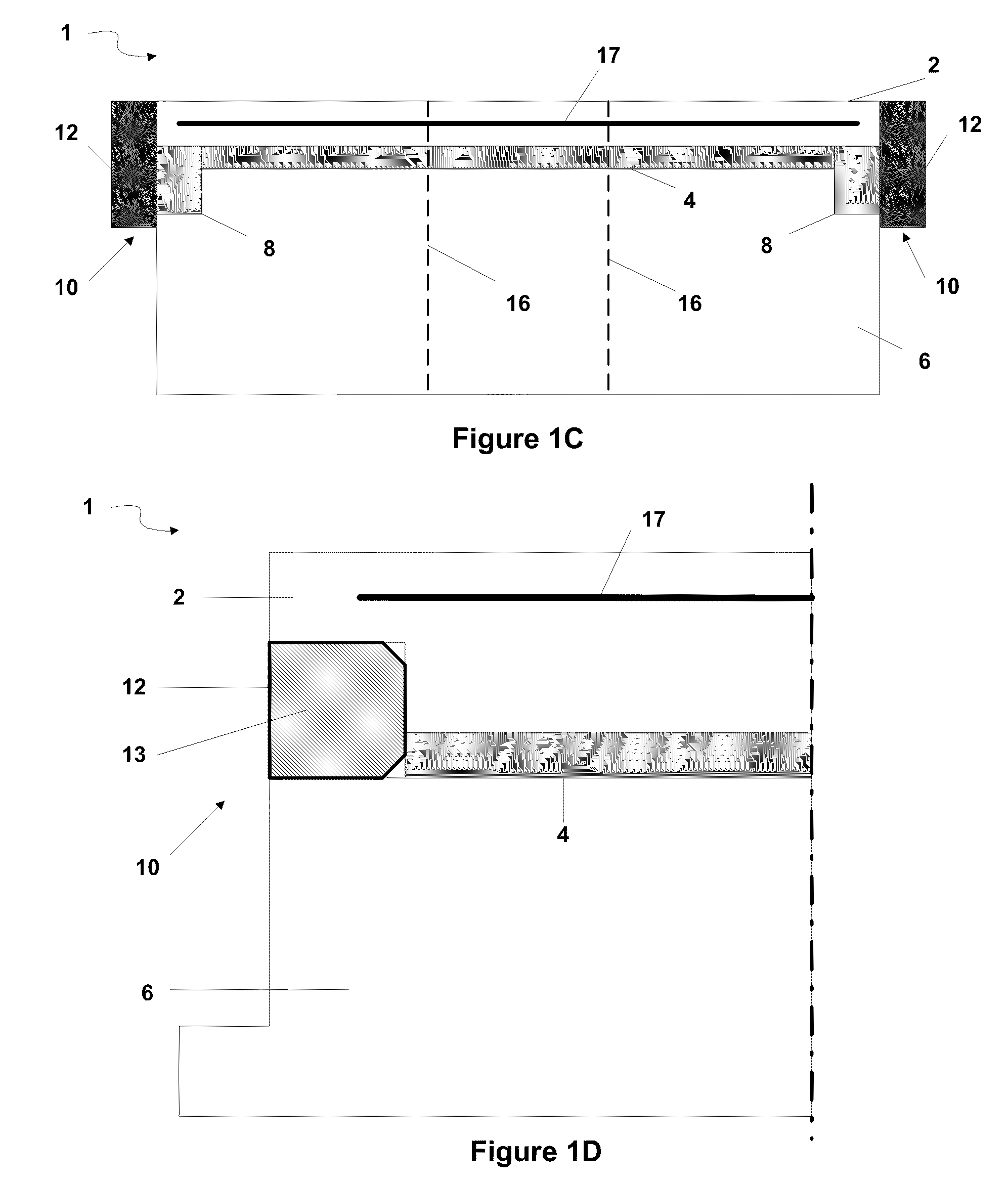

Replaceable Electrostatic Chuck Sidewall Shield

ActiveUS20100027188A1Improve performanceSolution to short lifeSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A replaceable electrostatic chuck sidewall shield is provided. The replaceable electrostatic chuck sidewall shield fills or partially fills an indentation located between a base member and a top member of an electrostatic chuck, such that the replaceable electrostatic chuck sidewall shield may protect an epoxy in the indentation or may replace the epoxy within the indentation. The replaceable electrostatic chuck sidewall shield may be fully contained with the indentation. The replaceable electrostatic chuck sidewall shield may also cover an epoxy in the indentation such that the replaceable electrostatic chuck sidewall shield protrudes beyond the indentation. In an alternate embodiment, the replaceable electrostatic chuck sidewall shield substantially covers the area in which a conductive pole is embedded in a bipolar electrostatic chuck.

Owner:TAIWAN SEMICON MFG CO LTD

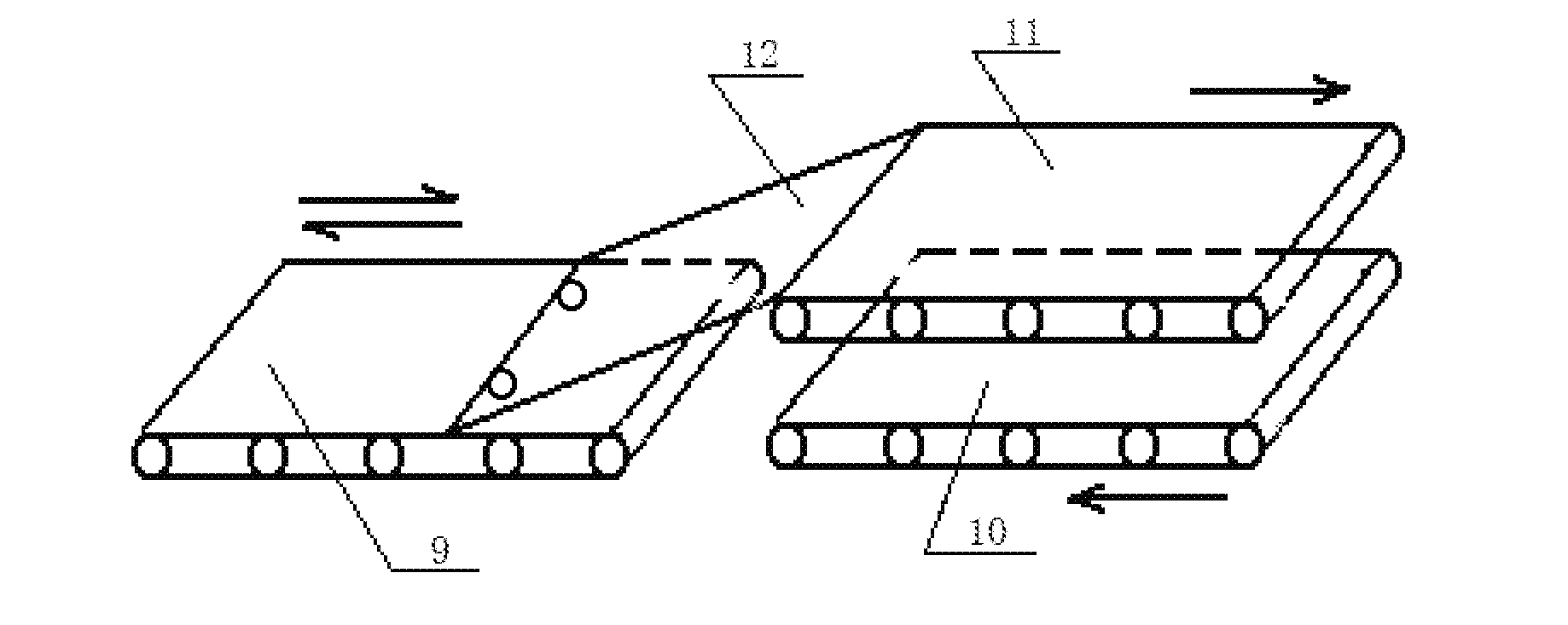

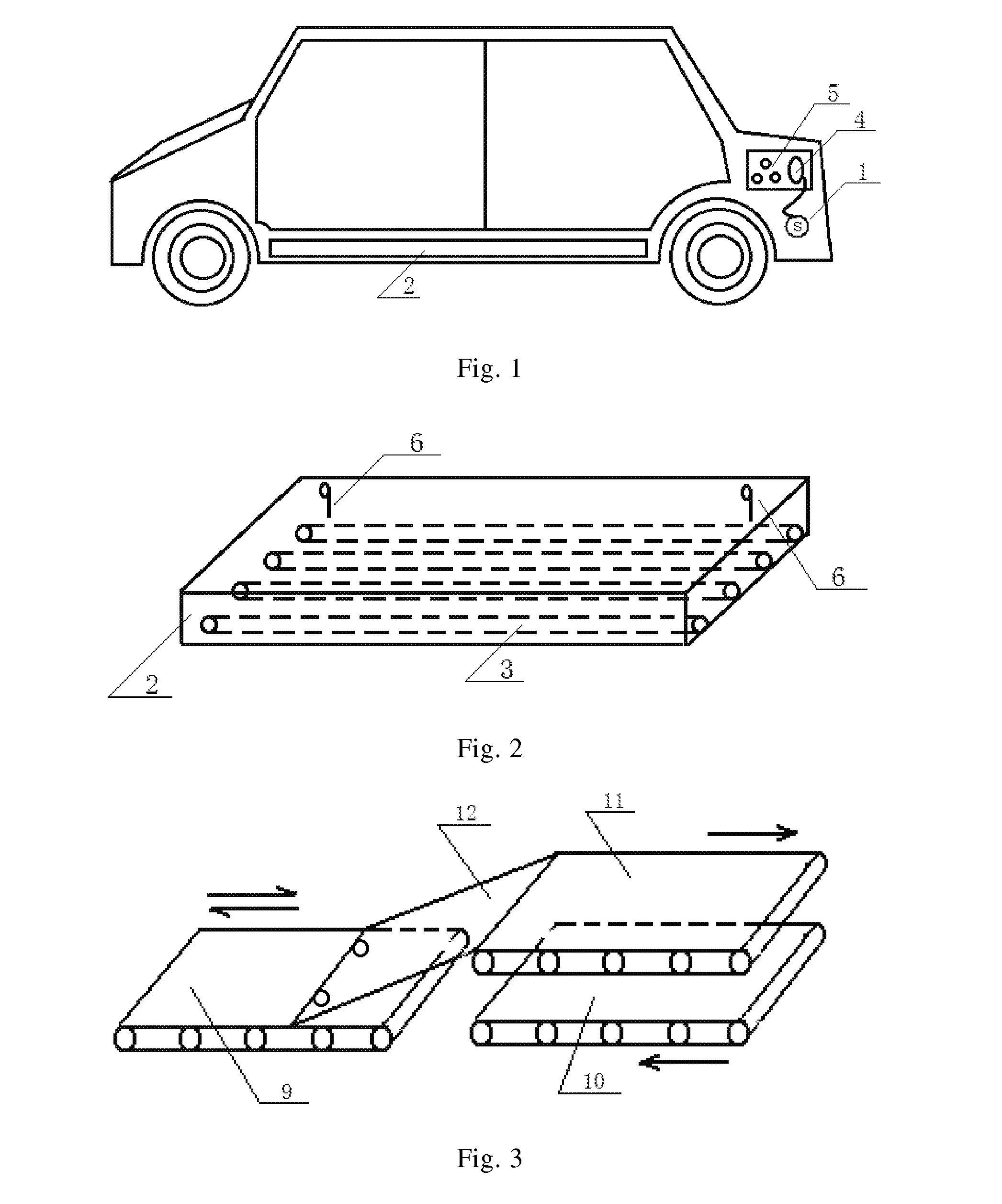

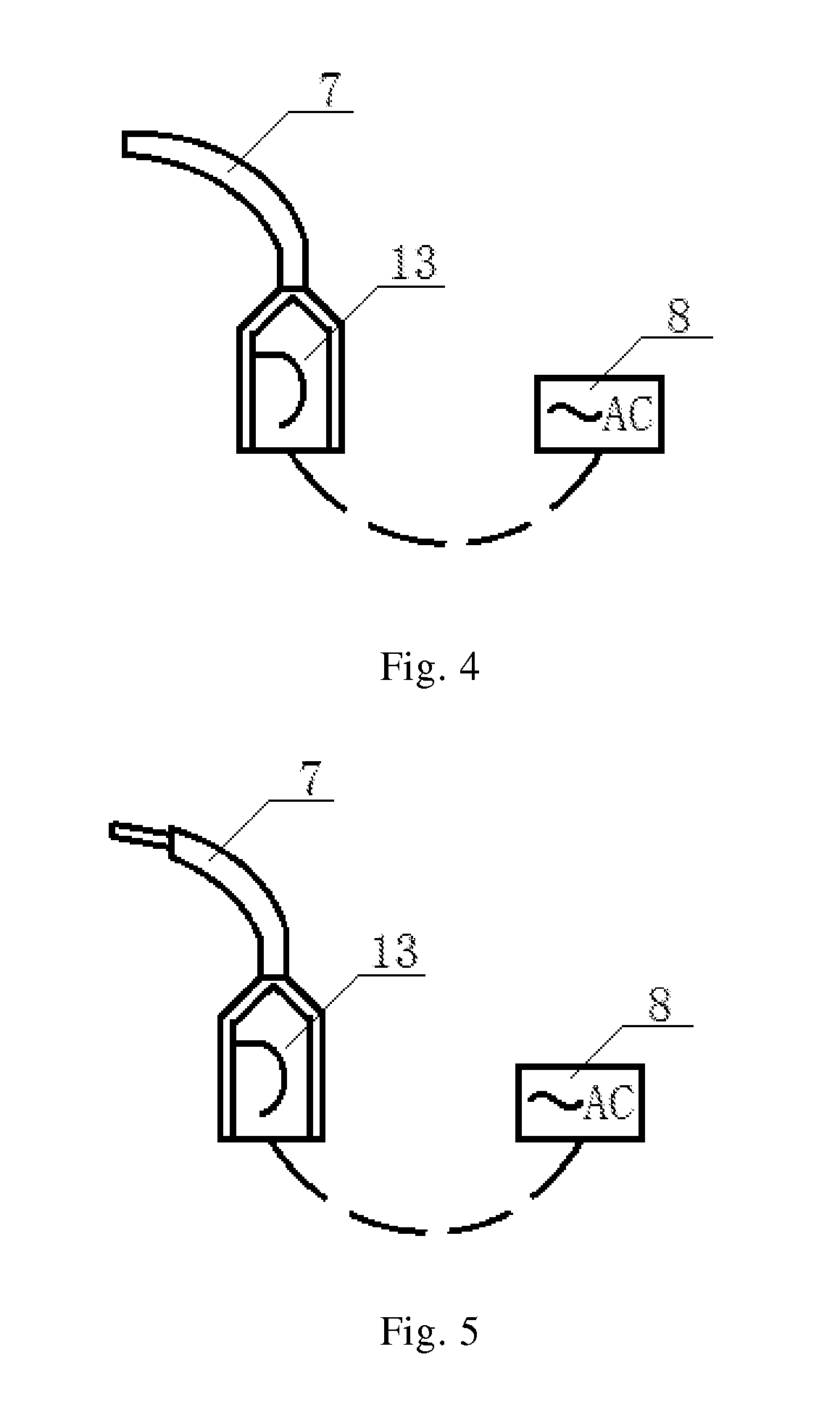

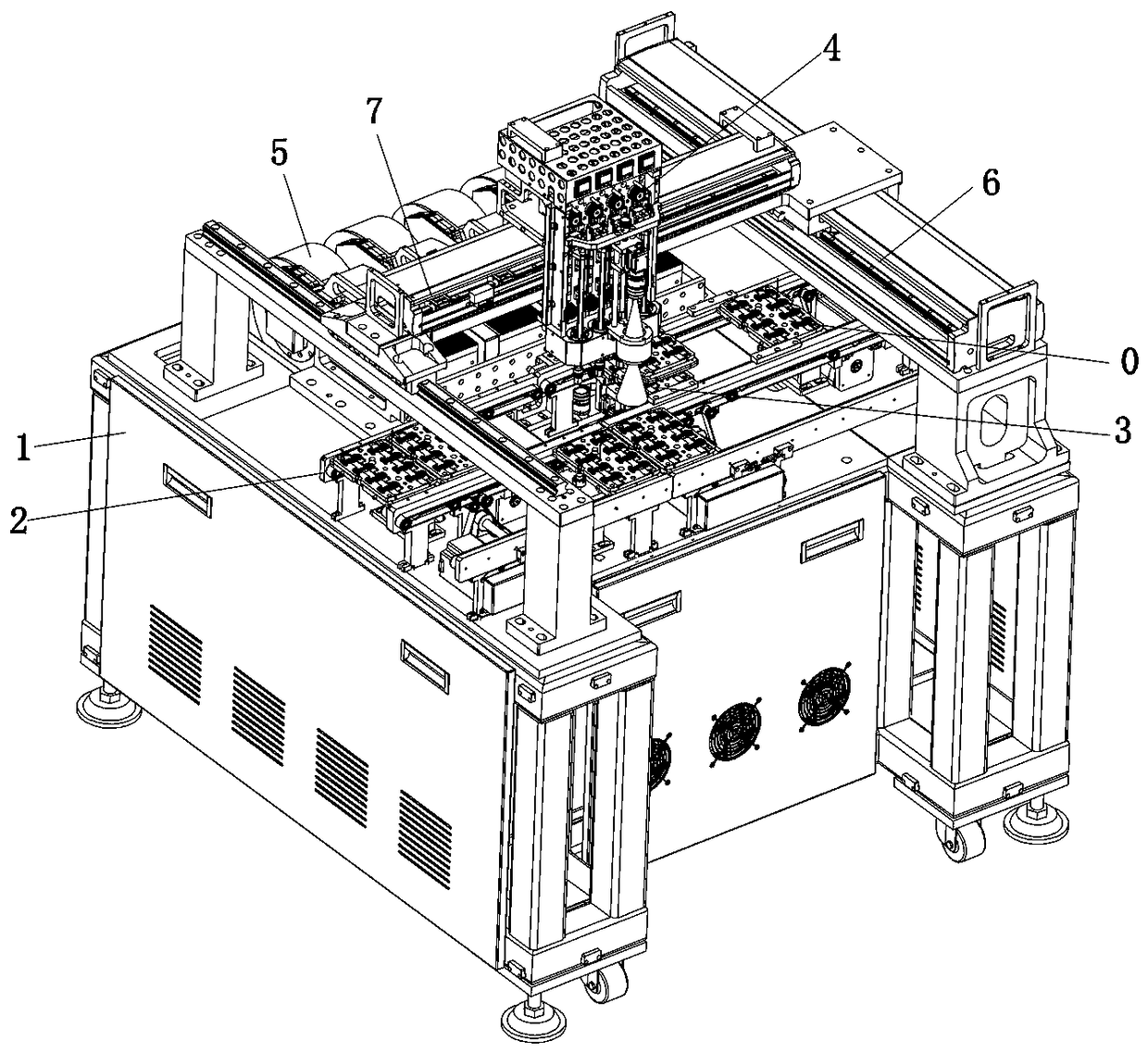

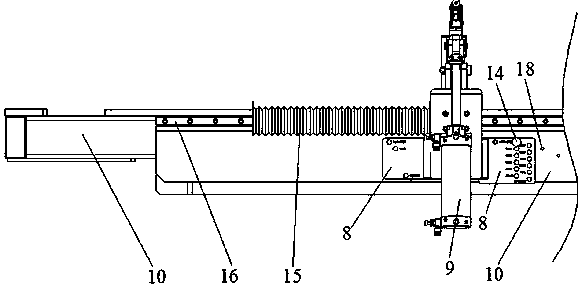

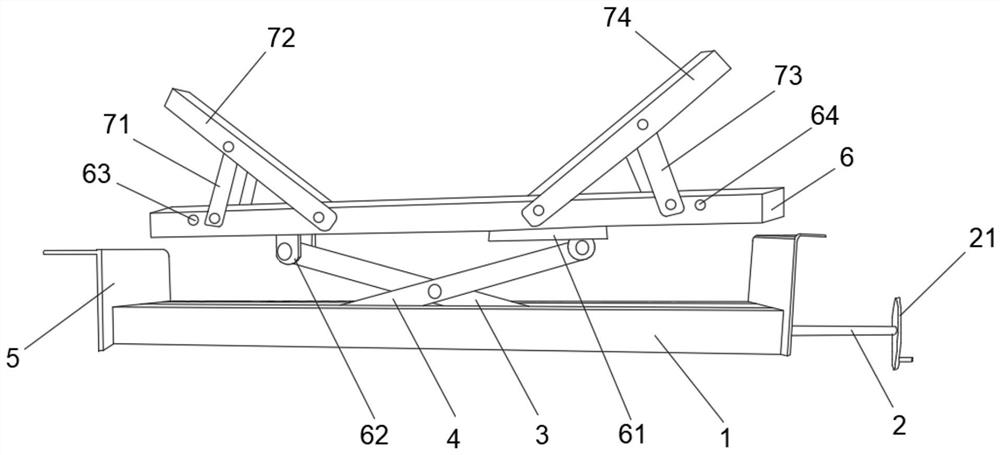

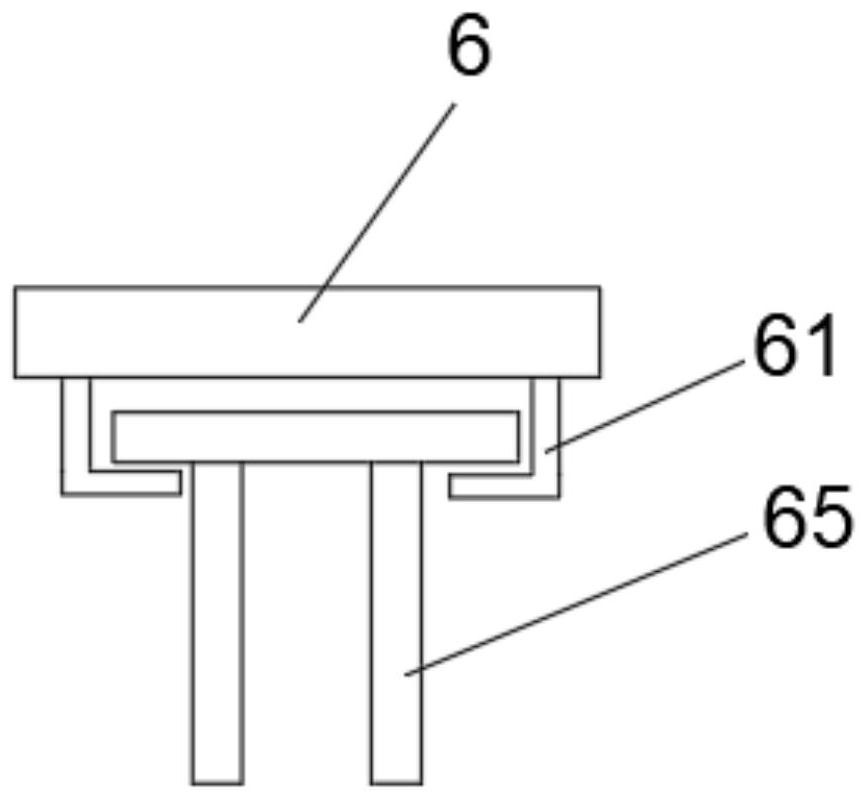

An electronic vehicle battery replacement system

InactiveUS20150298661A1Reduce power sourceElectric shock preventionCharging stationsElectric propulsion mountingElectric-vehicle batteryElectrical battery

The present disclosure discloses an electric vehicle battery replacement system comprising a vehicle-mounted battery driving device and a battery conveying device outside of the vehicle. The vehicle-mounted battery driving device comprises a drive roller configured to carry a battery and connected with a drive motor. The battery conveying device outside of the vehicle comprises three conveying belts each connected to one of three conveying motors, respectively. The drive roller, a first conveying belt, and a second conveying belt are arranged successively on a same horizontal plane along a direction of conveying. The third conveying belt is located above the second conveying belt and connected with the first conveying belt via a sliding plate. One end of the sliding plate connects flexibly to a front end of the third conveying belt, and the other end of the sliding plate is placed on the first conveying belt. The battery replacement system provided in the present disclosure solves such problems as long charging time and low efficiency in public charging stations by using the current charging method of existing electric vehicles, and meets the growing demand of the increasing number of electric vehicles.

Owner:ZHANG WUJIE

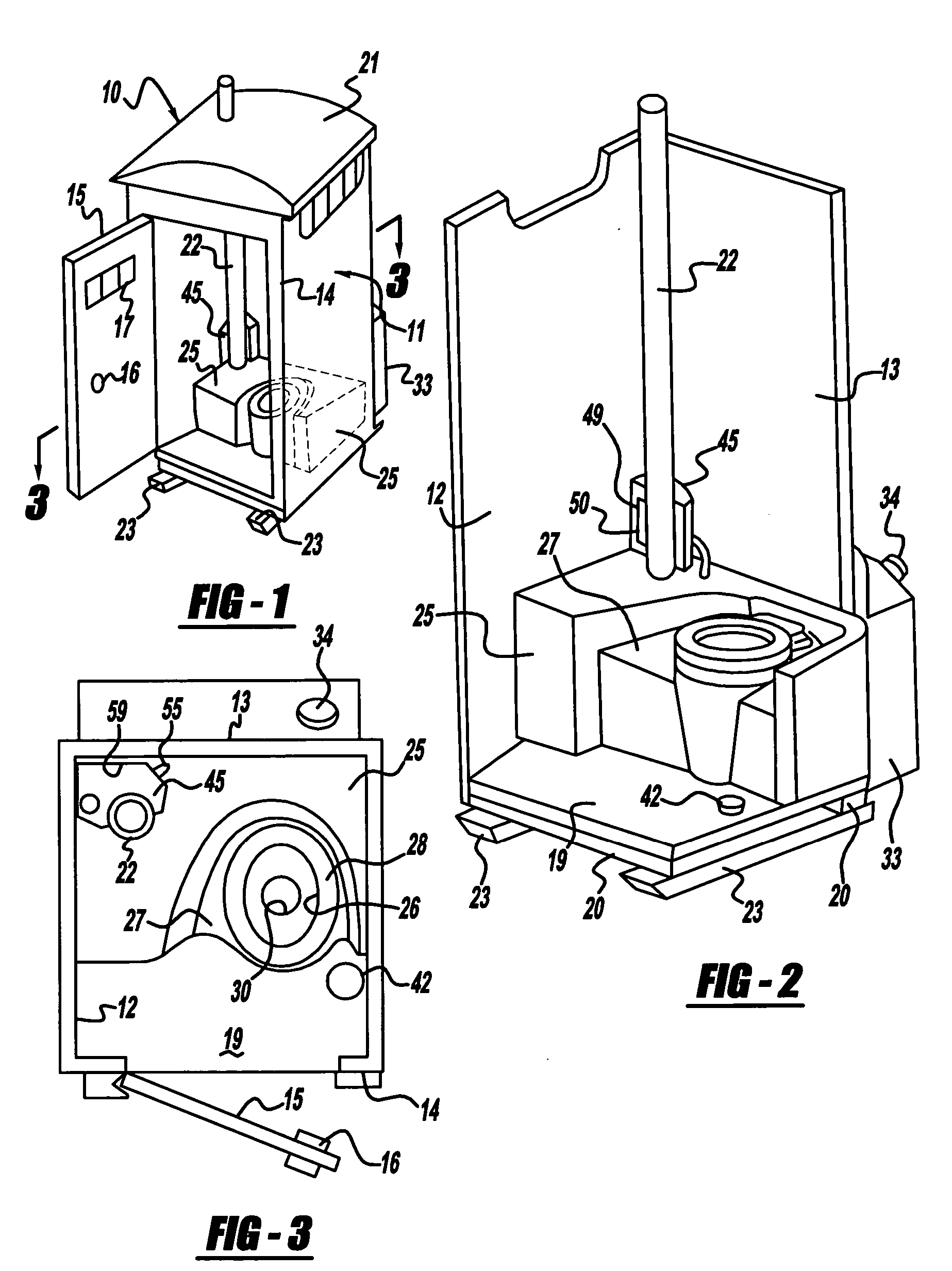

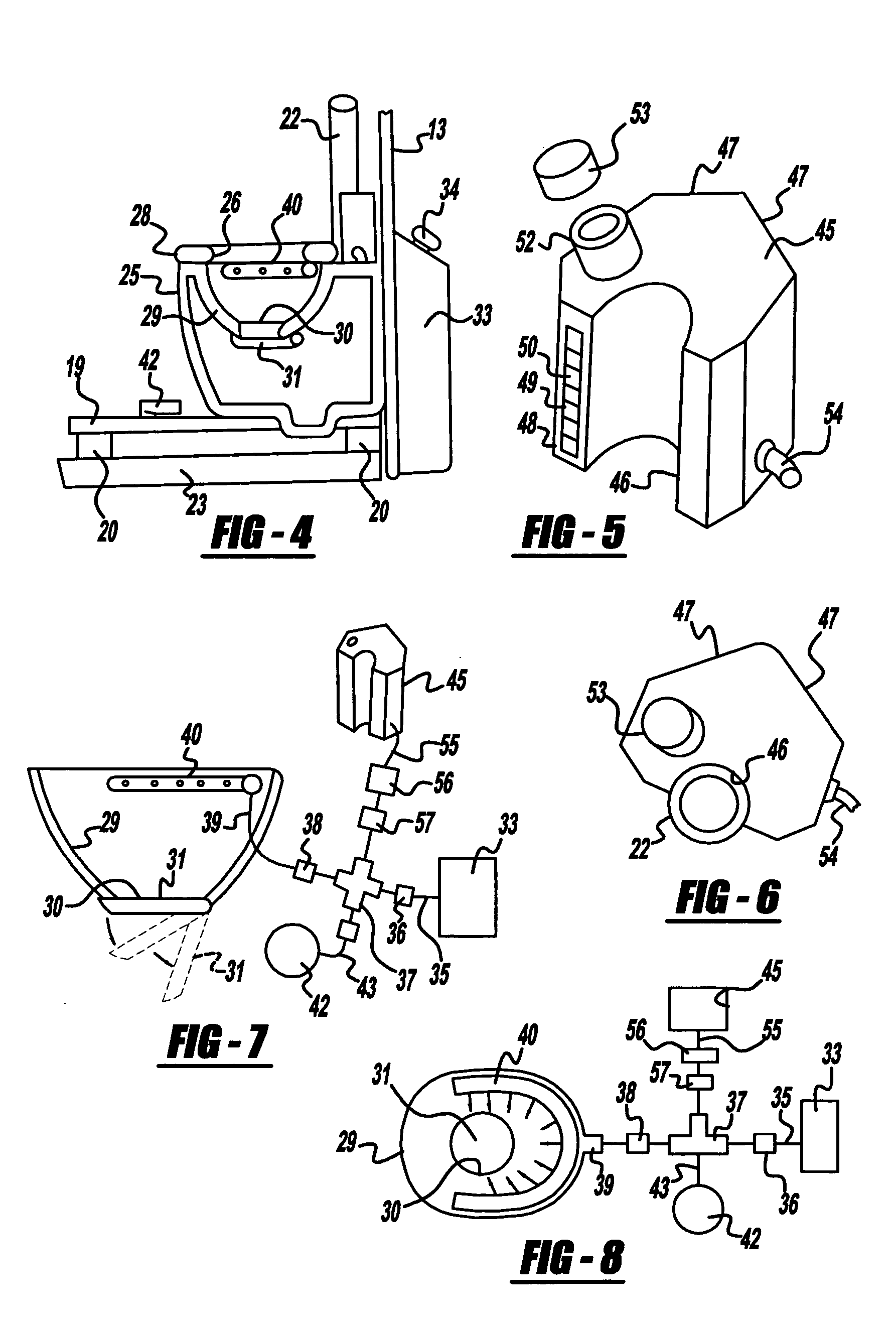

Portable restroom toilet chemical charging system

InactiveUS20050241055A1Efficient and quick removalQuick and efficient replacementFlushing devicesBathroom accessoriesPortable toiletWater source

A portable toilet chemical additive charging system comprises a restroom cabana containing a toilet bowl which opens into a waste-holding tank. A water source, such as a separate water tank, is connected by a conduit to the toilet bowl for delivering flush water to the bowl when a flush pump, that is connected to the conduit, is actuated. The flush water passes through a control valve in the conduit. A chemical additive container is removably positioned near the toilet bowl and is connected by a tube to the control valve. The control valve injects a pre-determined amount of additive to the flush water when flush water is flowed through the control valve to the bowl. Preferably, the container is shaped to closely fit within a space between a vent pipe extending upwardly from the waste-holding tank and the adjacent interior surface of a wall of the cabana. A portion of the container is substantially transparent and exposed so that an observer may view the level of additive content in the container, while the remainder of the container is substantially concealed by the vent pipe.

Owner:POLYJOHN ENTERPRISES LLC

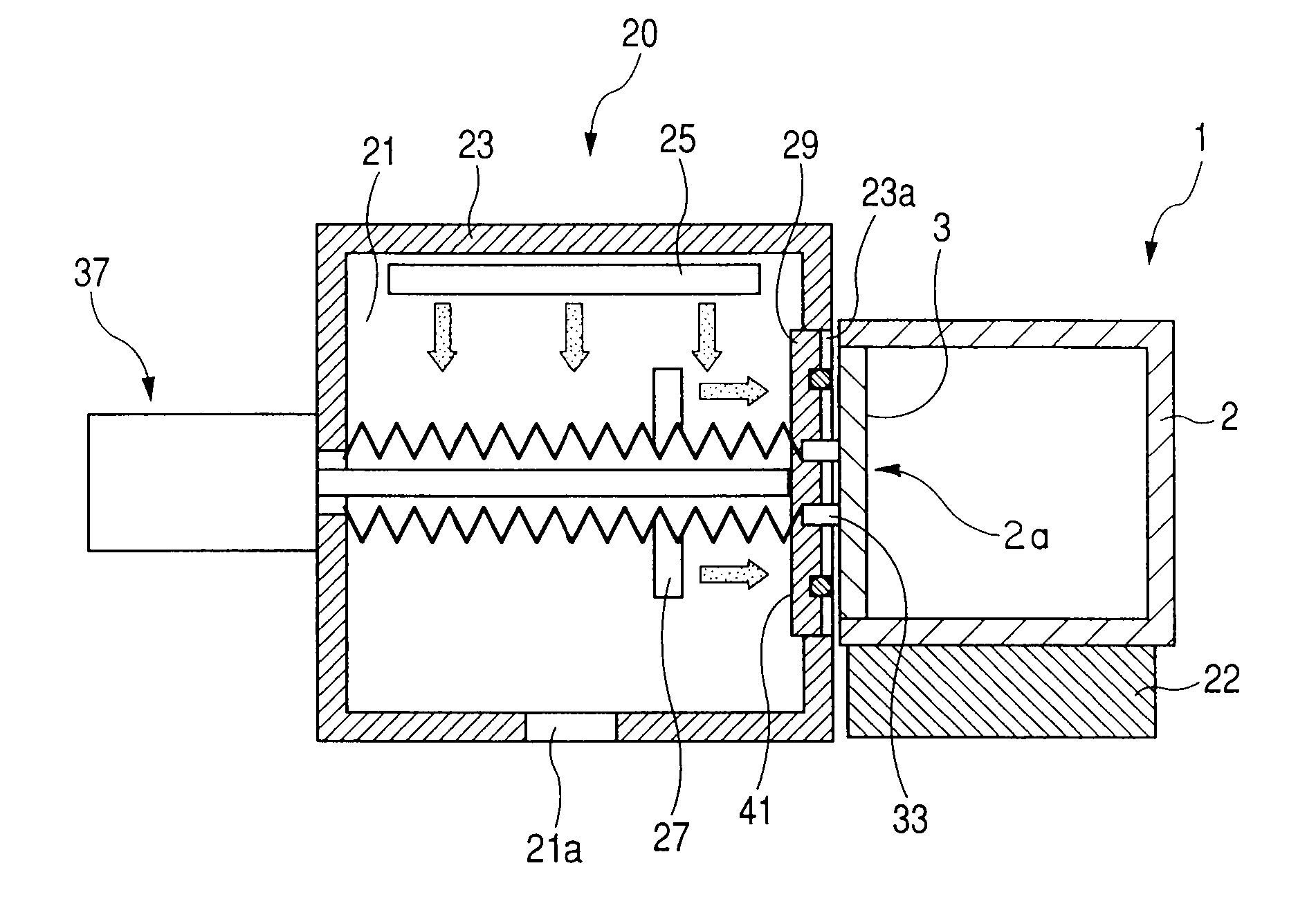

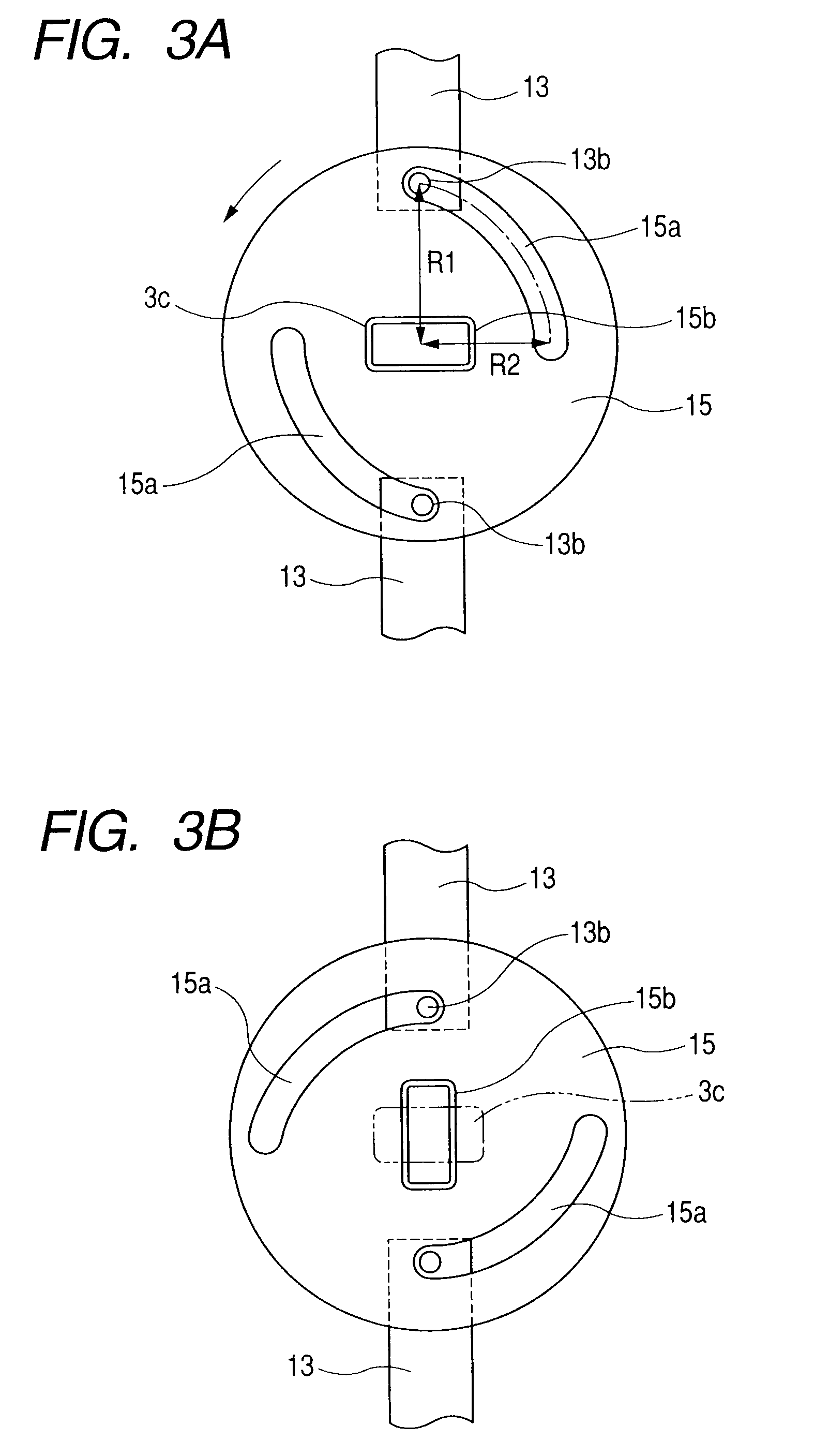

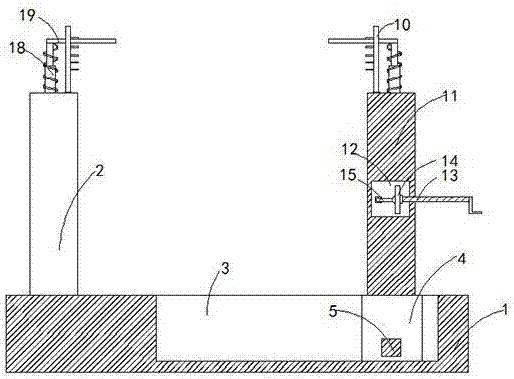

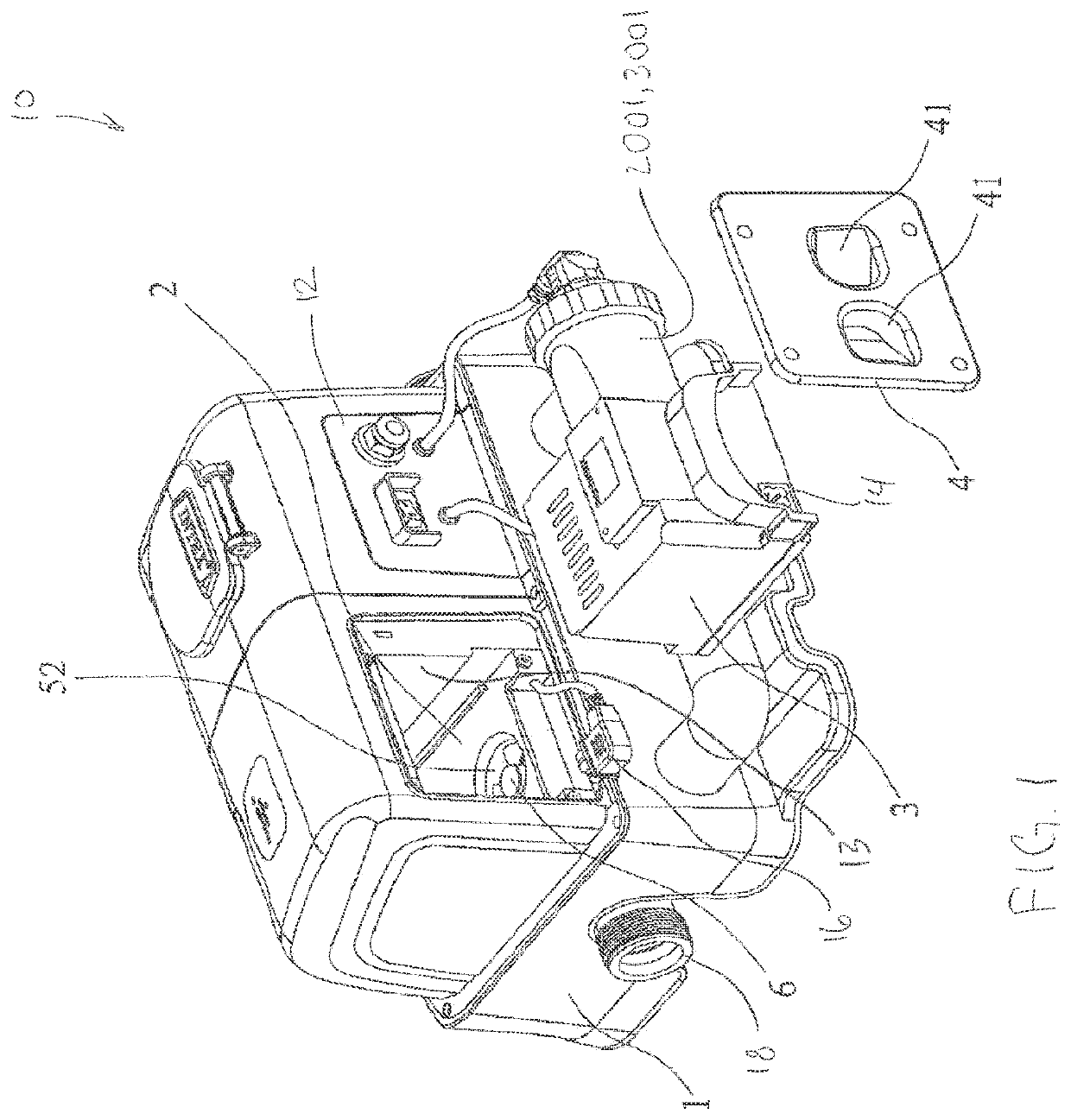

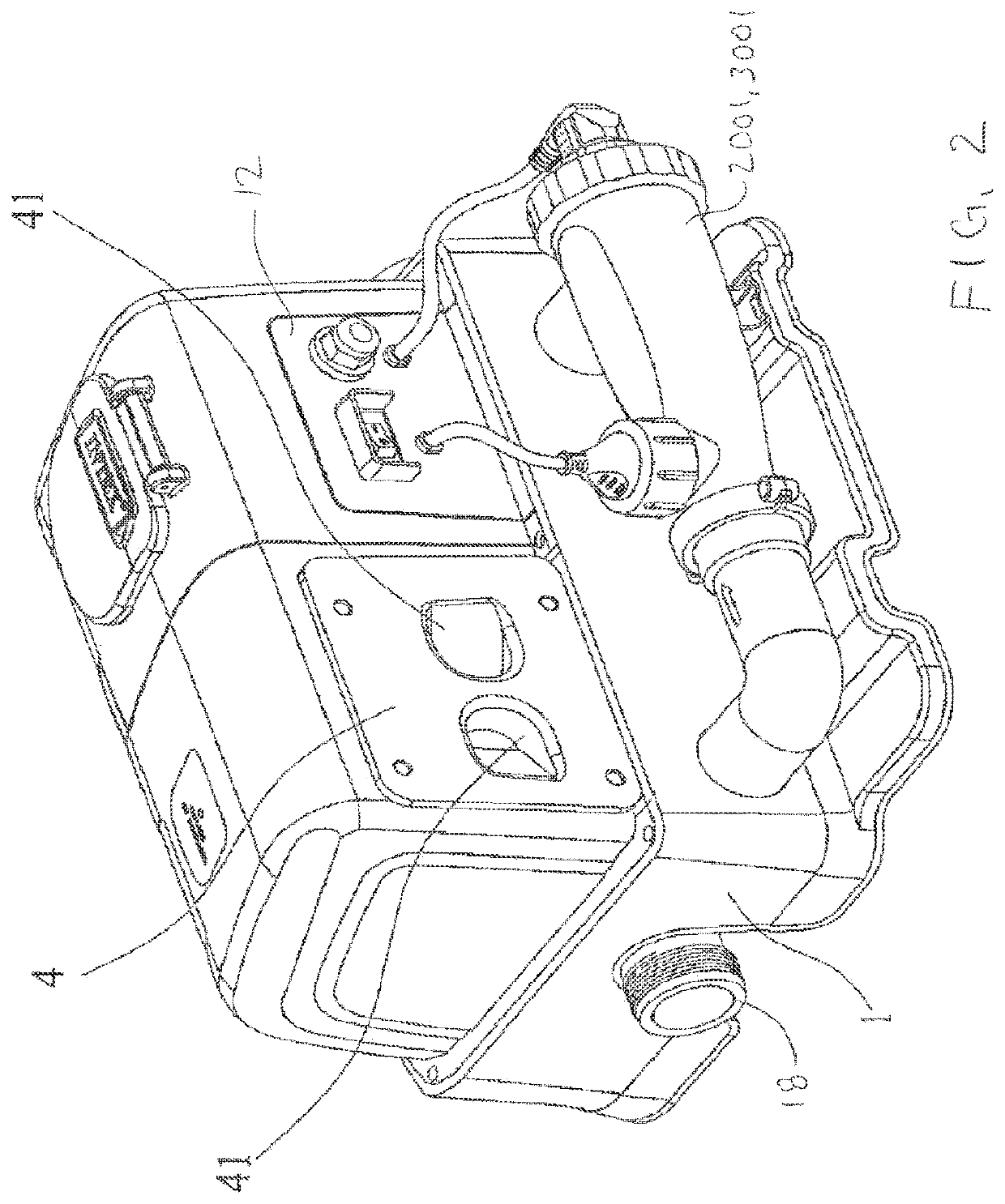

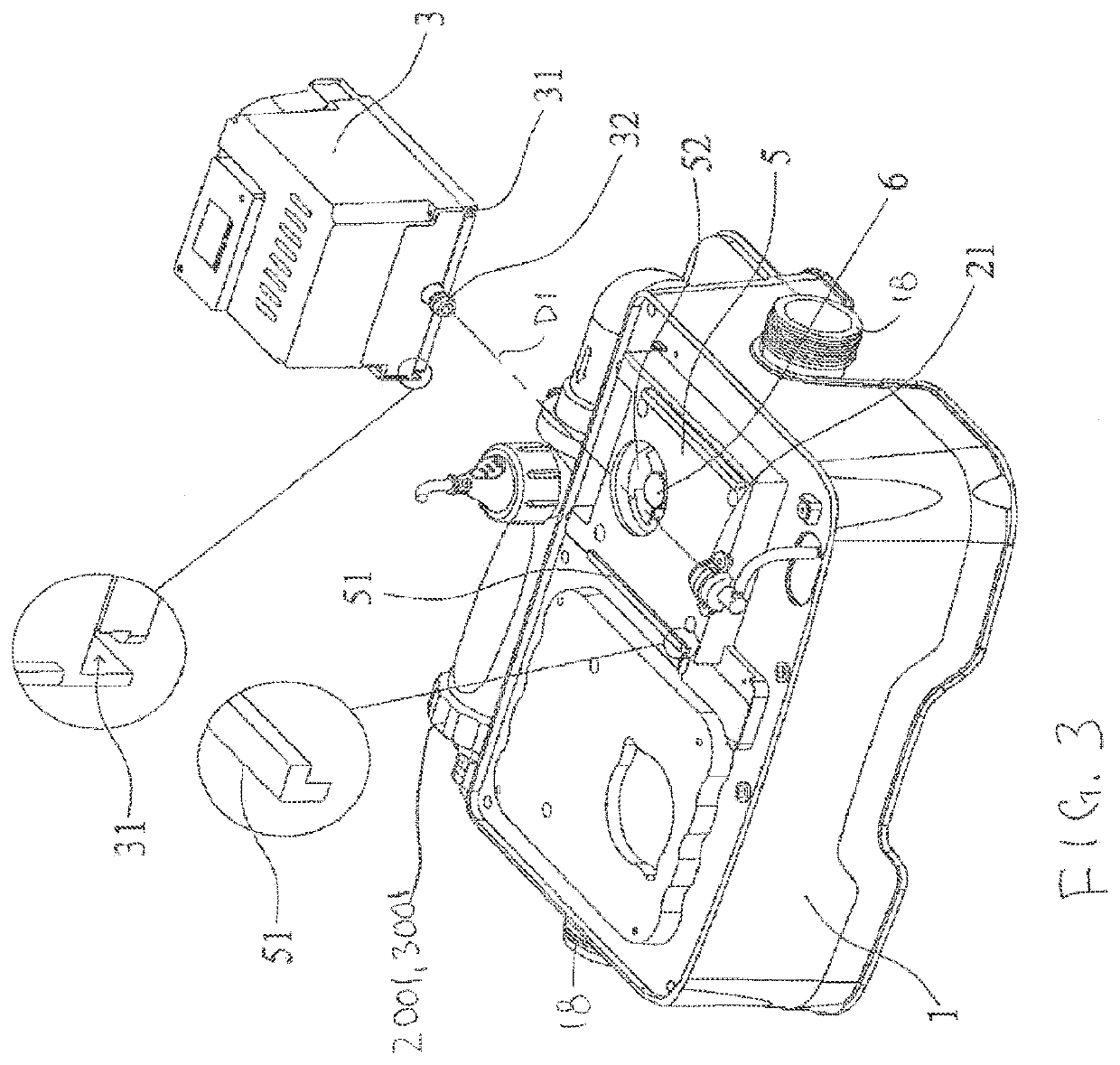

Apparatus and method for opening/closing lid of closed container, gas replacement apparatus using same, and load port apparatus

ActiveUS8171964B2Reduce the possibilityQuick and efficient replacementLiquid fillingSemiconductor/solid-state device manufacturingEngineeringGas supply

The invention provides a purge apparatus that purges the gas in the interior of a FOUP with a high purging efficiency and an apparatus for opening / closing the lid of a FOUP for use in the purge apparatus. The purge apparatus has a cabinet having an opening portion through with the lid of the FOUP can pass, a door that can close the opening portion and hold the lid, and a gas supply nozzle provide in the cabinet. In this apparatus, a seal member is provided in such a way as to surround an element that is provided on the surface of the door and adapted to actuate a latch mechanism of the lid. The seal member spatially separates the element that is adapted to actuate the latch mechanism from the external space in a state in which the door is holding the lid.

Owner:TDK CORPARATION

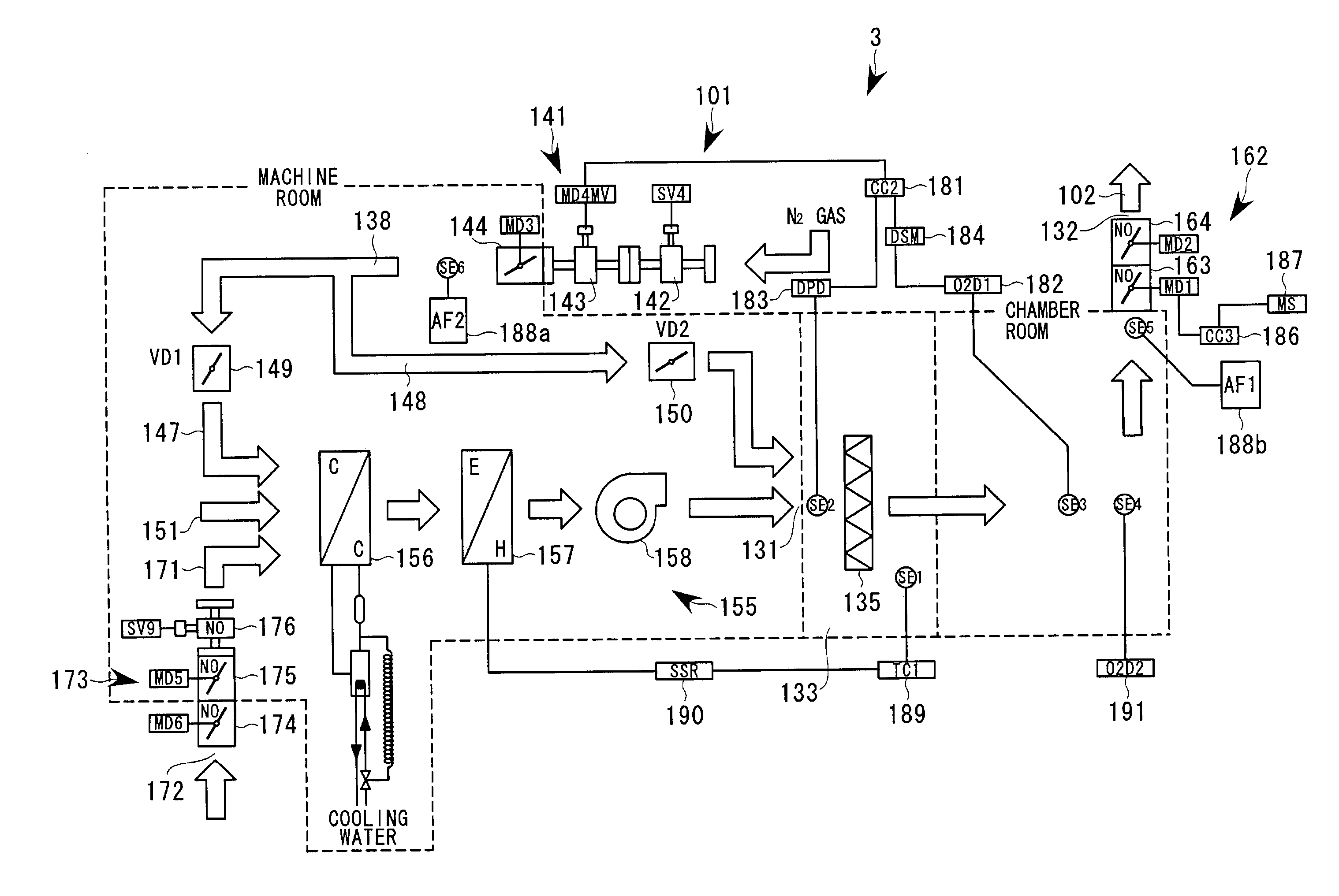

Method of replacing atmosphere of chamber apparatus, chamber apparatus, electro-optic apparatus, and organic EL device

ActiveUS7037810B2Quick and efficient replacementLow costElectroluminescent light sourcesSolid-state devicesEngineeringGas supply

An atmosphere of an inert gas inside a chamber room in a chamber apparatus is replaced with an outside air by opening a discharge passage in the chamber room and by closing a gas supply passage for supplying the inert gas. The outside air is thus forcibly sent to the chamber room to thereby replace the inert gas remaining inside the chamber room with the outside air.

Owner:TOKYO ELECTRON LTD

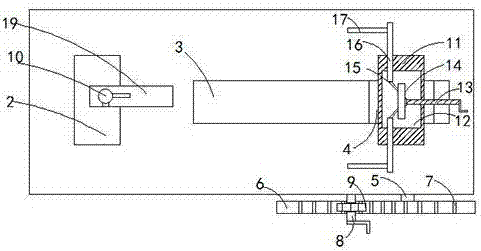

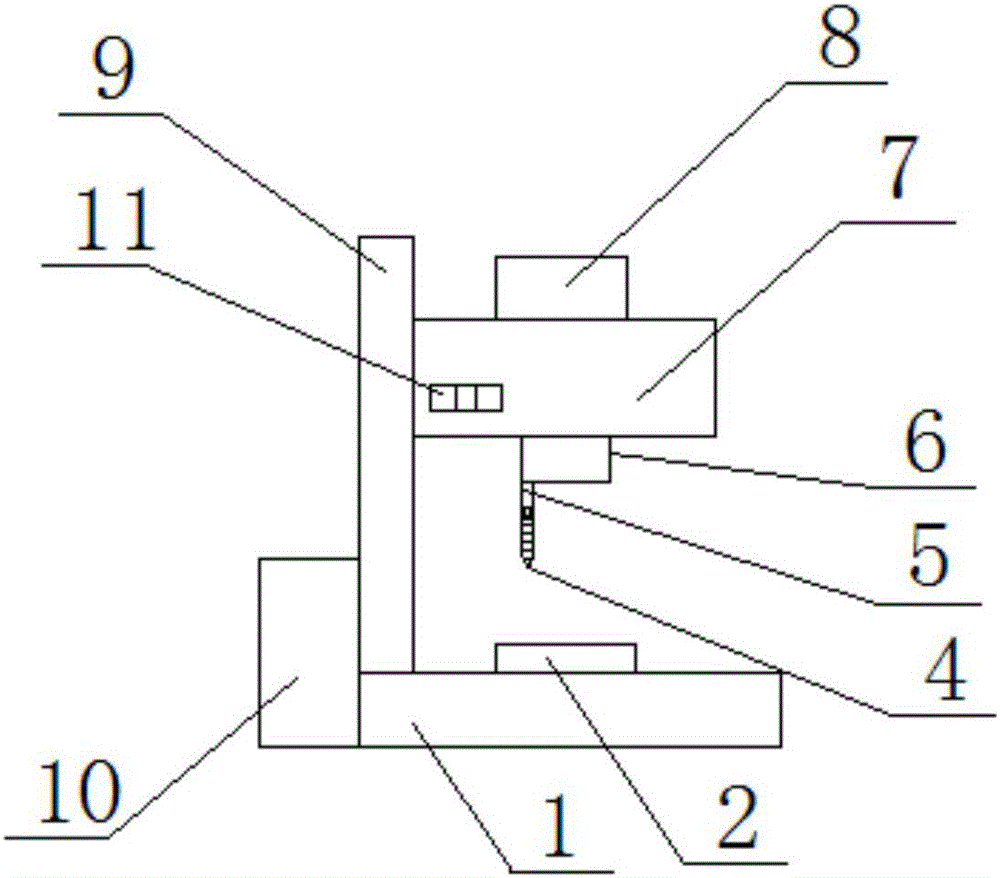

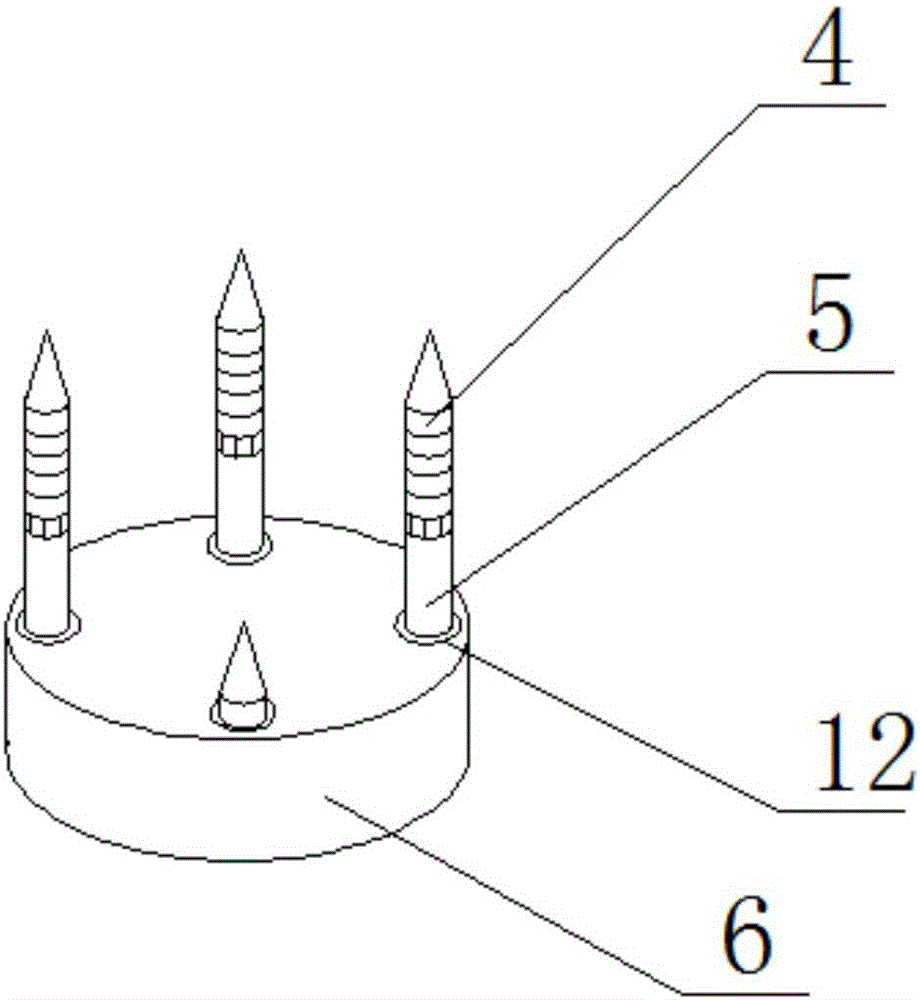

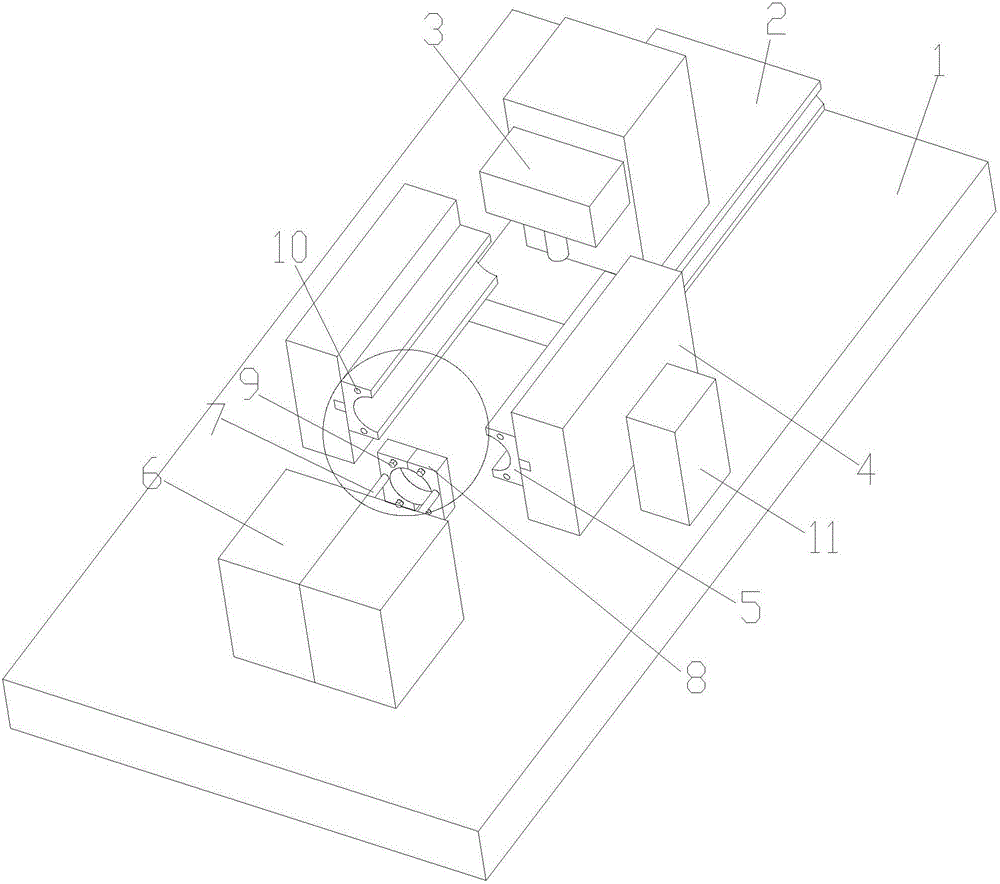

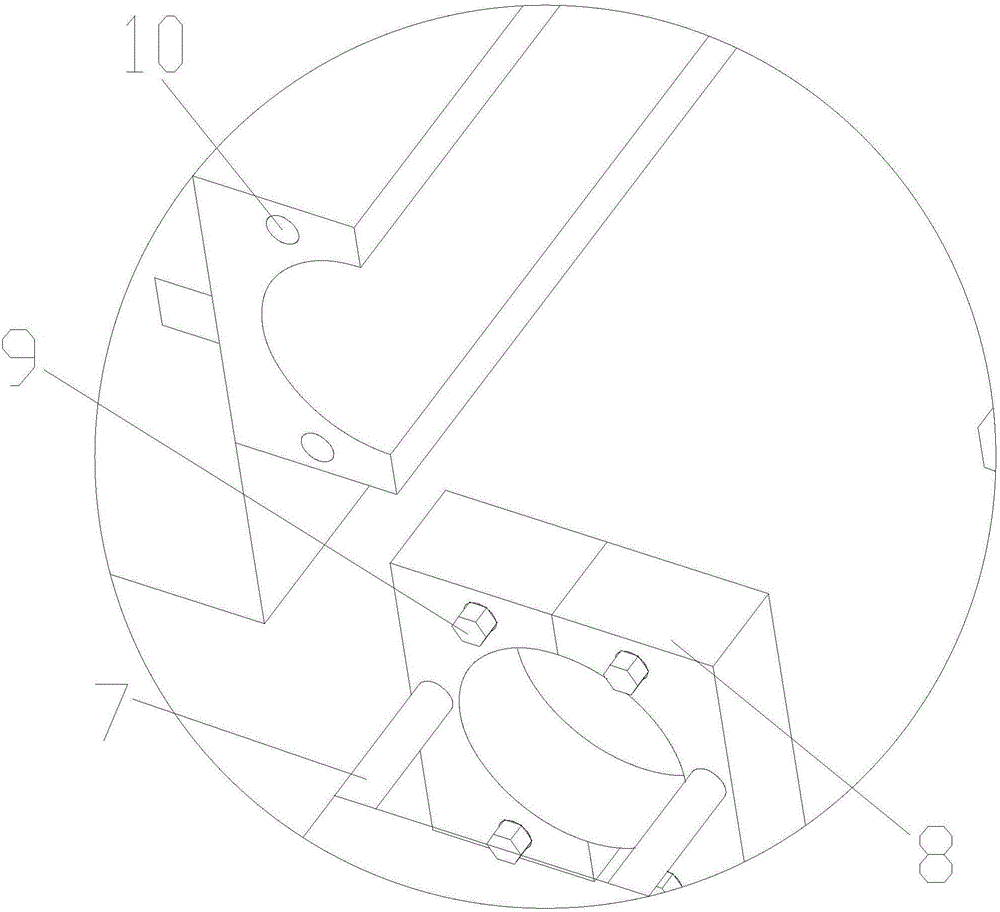

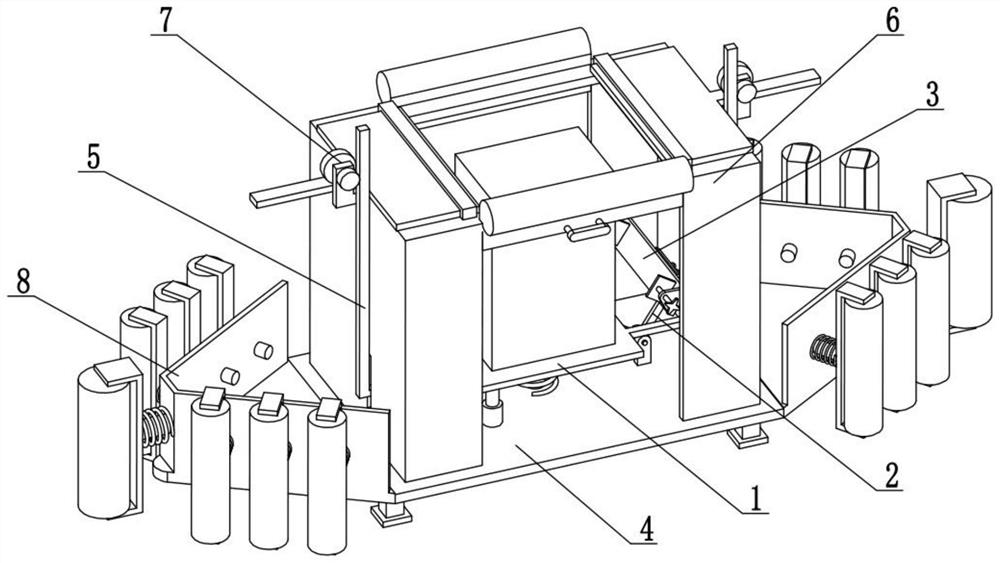

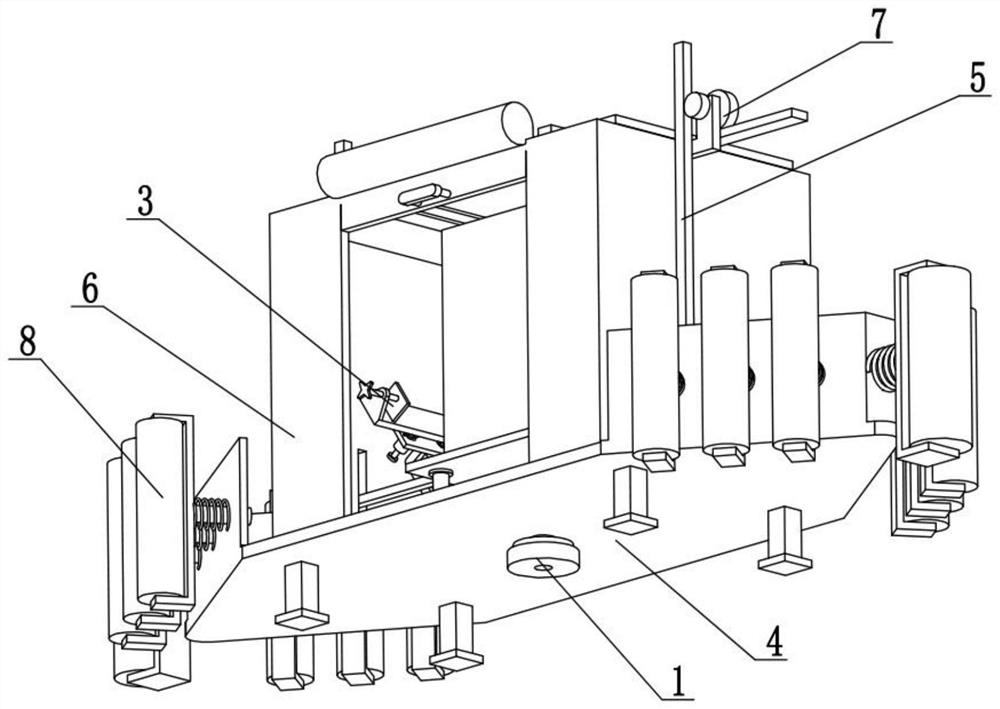

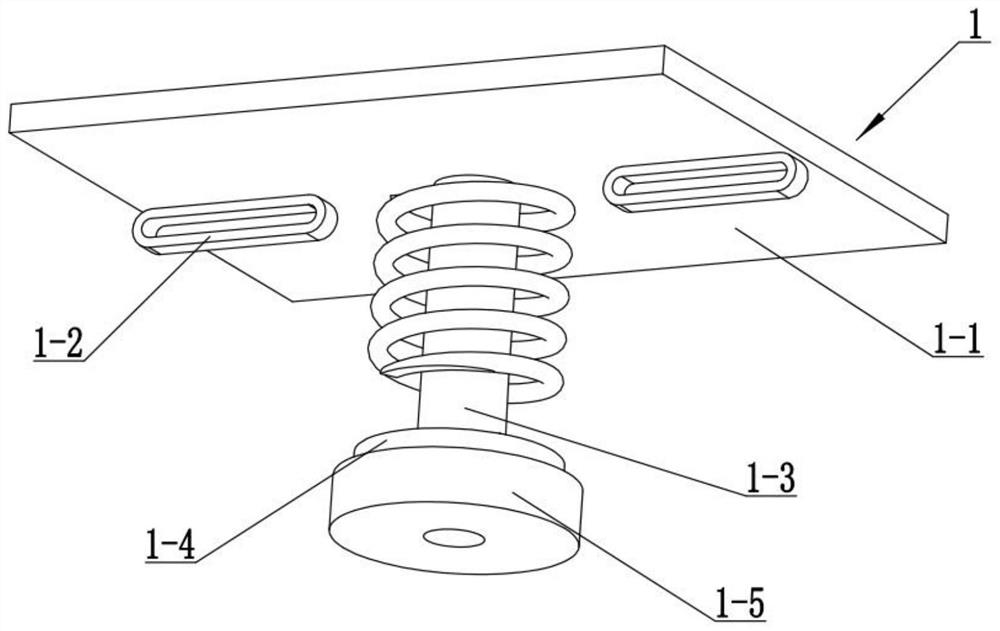

Novel machining positioning device

PendingCN107457583AEffective clampingEffective positioning operationPositioning apparatusMetal-working holdersGear wheelEngineering

The invention discloses a novel machining positioning device. The novel machining positioning device comprises a base; a first fixing plate is arranged on the base which is provided with a slide groove; a slider is arranged in the slide groove; a connecting rod is connected to the side wall of the slider; the end, away from the slider, of the connecting rod penetrates the side wall of the slide groove and extends to the exterior of the base; a movable plate is connected to the end, located outside the slide groove, of the connecting rod; a rack is arranged at the upper end of the movable plate; a first rotating rod is rotationally connected to the side wall of the base, and is located above the movable plate; the first rotating rod is sleeved with a gear which is engaged with the rack; a second fixing plate is arranged at the upper end of the slider, and is internally provided with a cavity; an interior and exterior communicated threaded rod is arranged on the inner wall of one end, away from the first fixing plate, of the cavity; and the end, located in the cavity, of the threaded rod is rotationally connected with a connecting plate. The novel machining positioning device can effectively clamp a workpiece, positioning of the workpiece can be more accurate, the machining quality of the workpiece is improved, and fast replacement of the workpiece is also facilitated.

Owner:TONGDA HARDWARE SHENZHEN

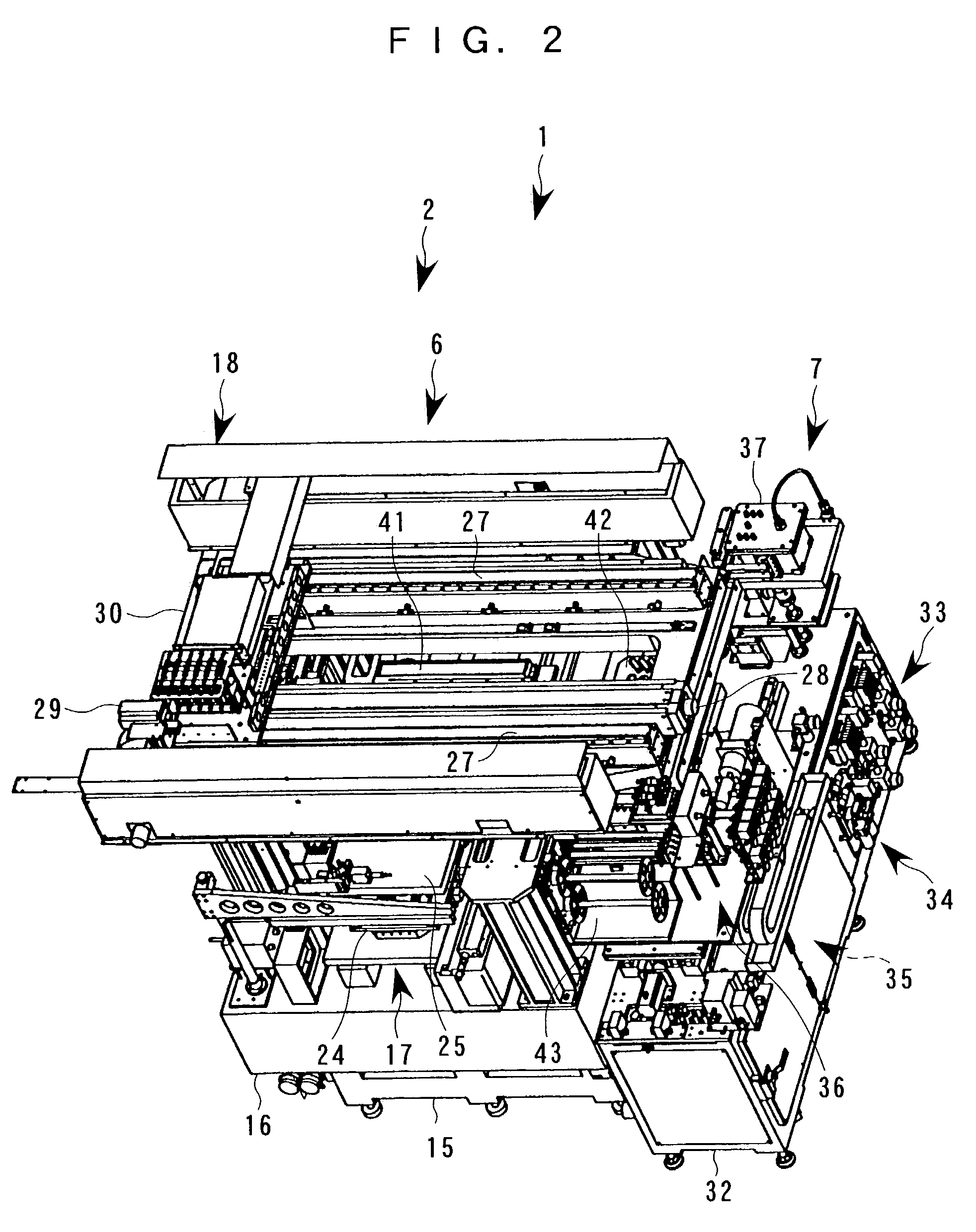

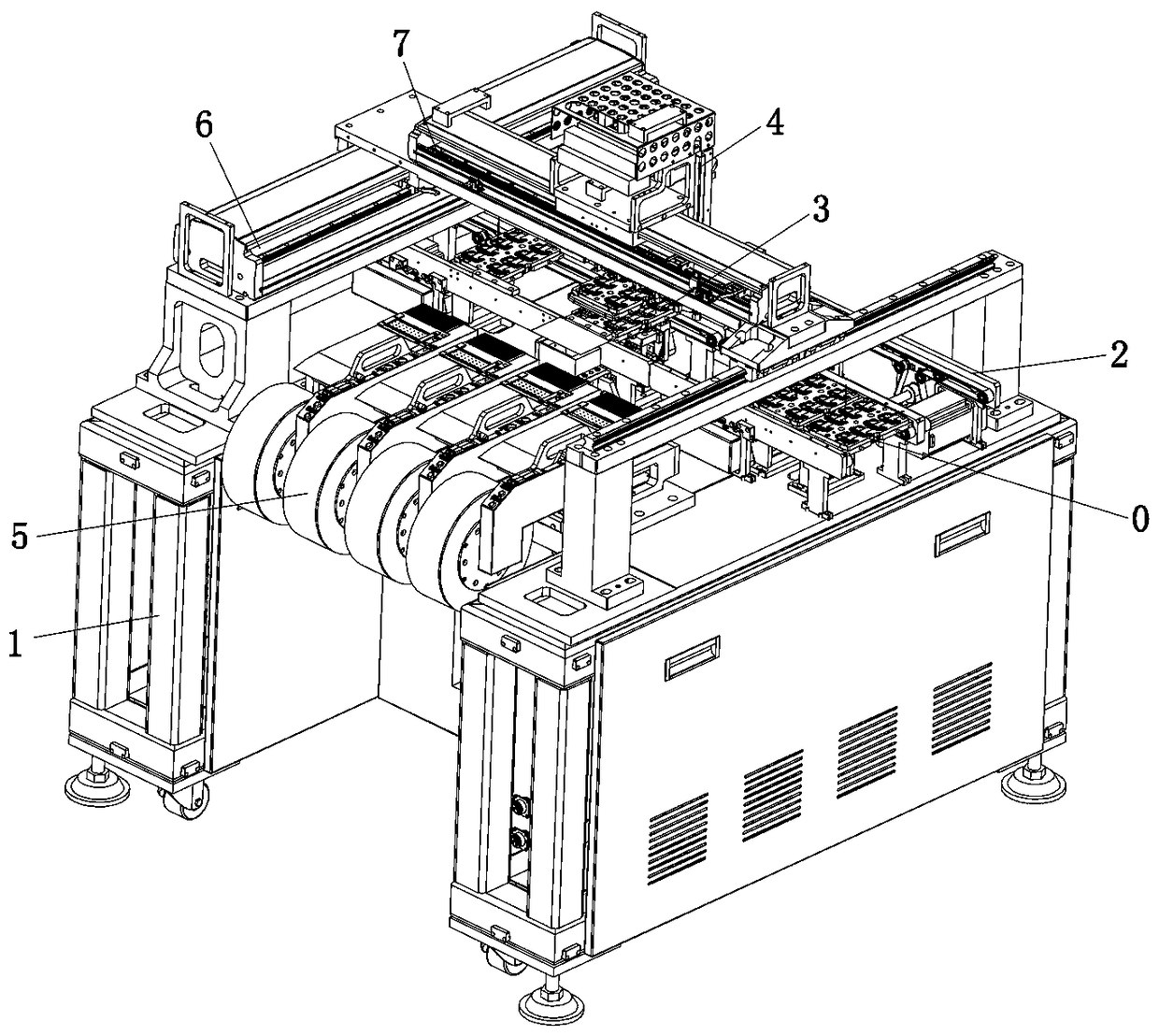

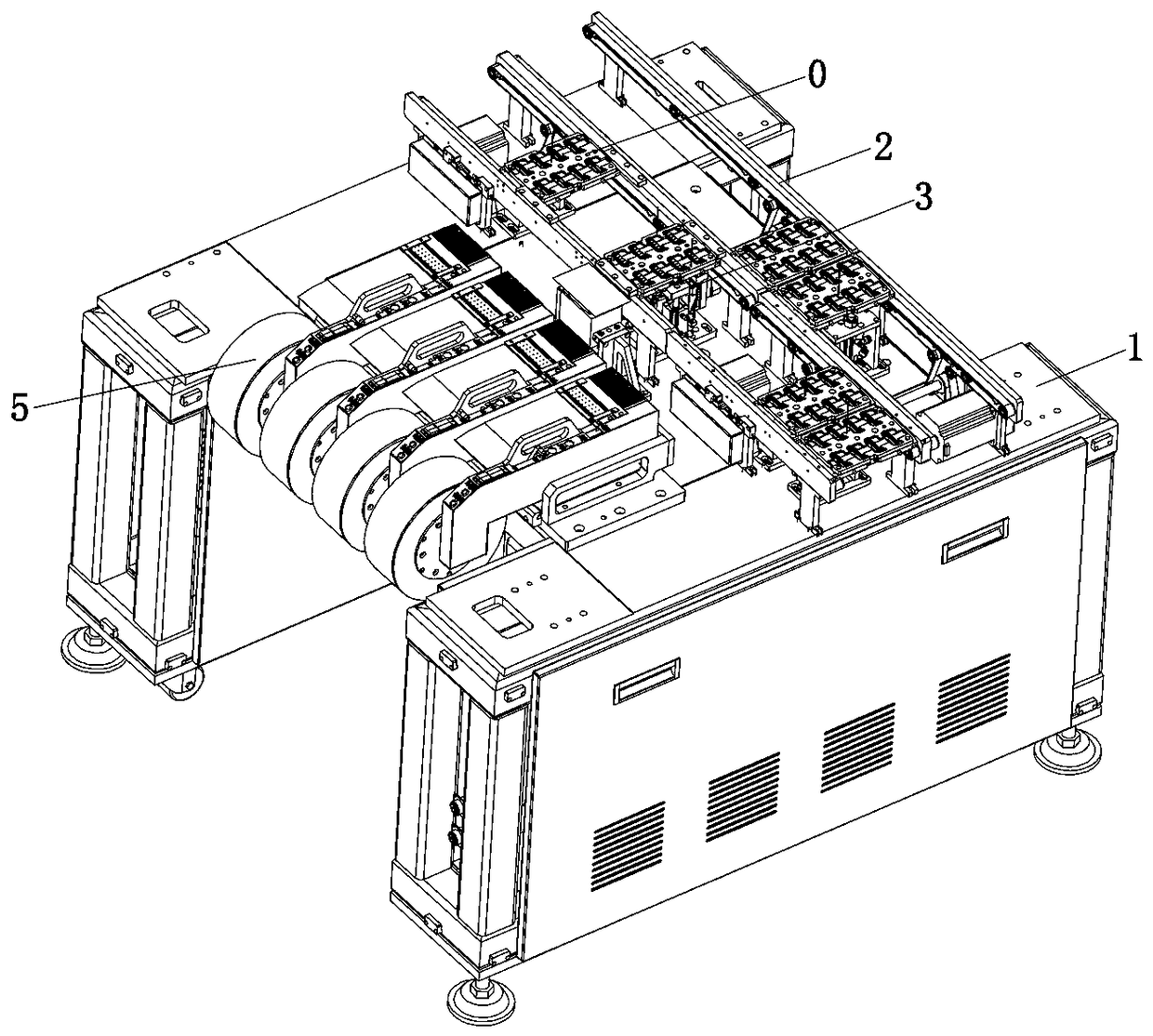

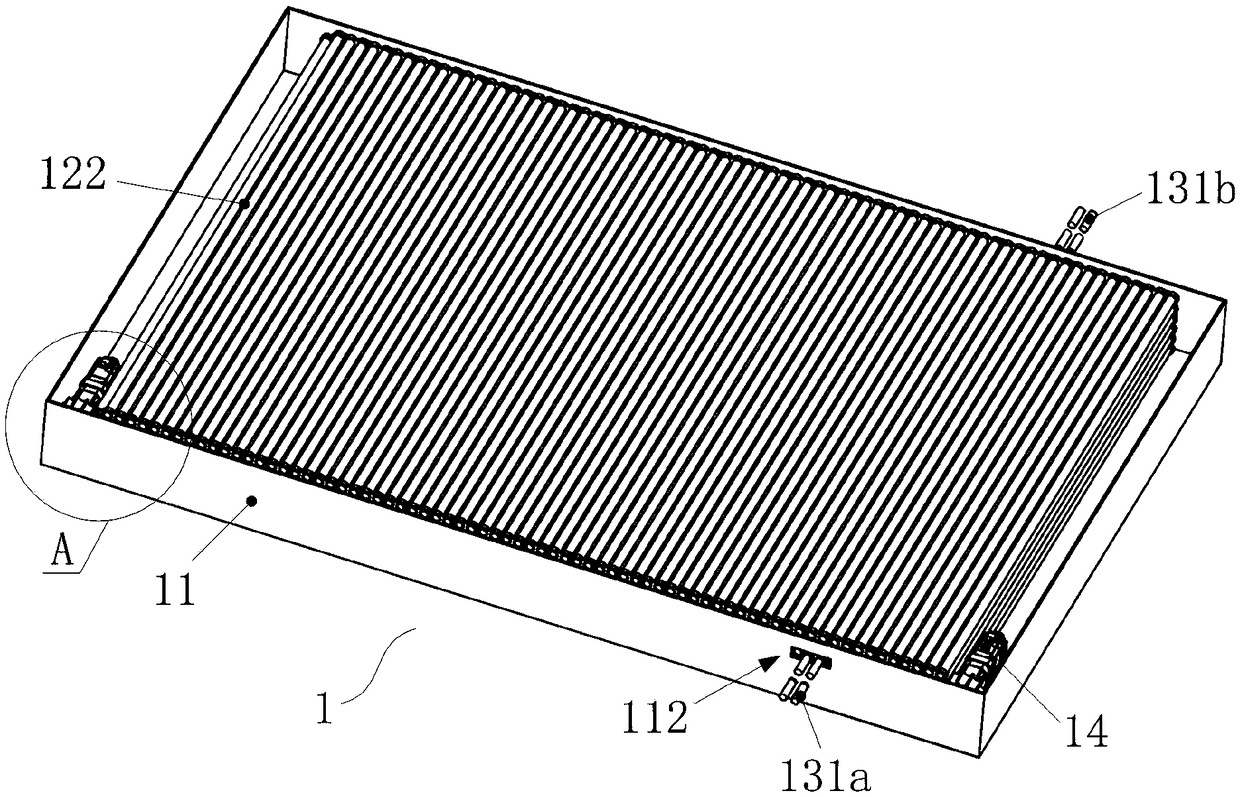

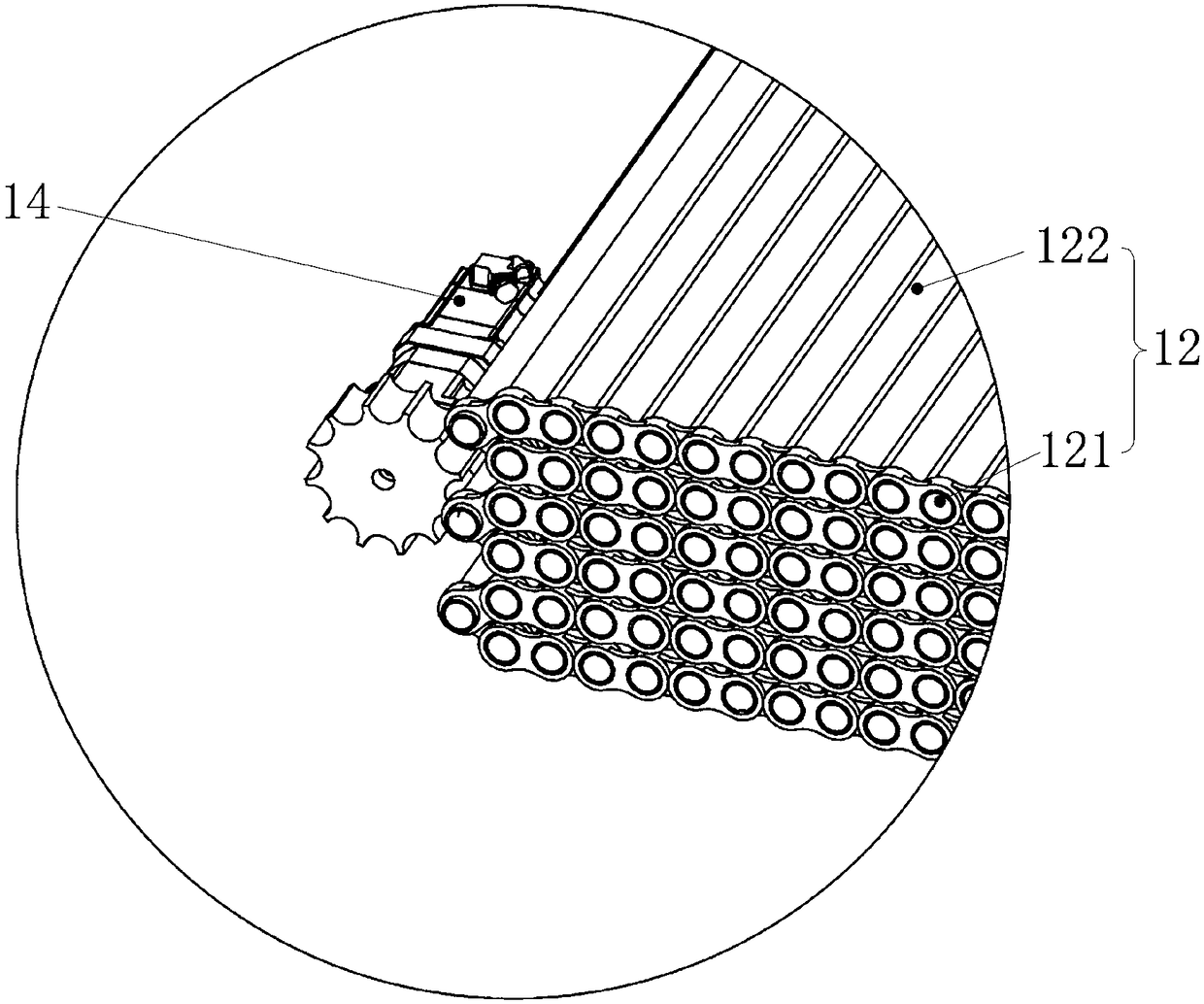

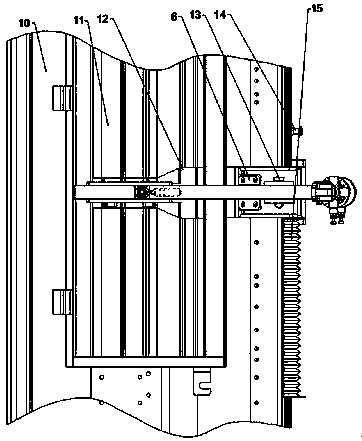

Automatic attaching machine for electronic product auxiliary materials

PendingCN109340233AReduce stuck and broken situationsHigh replaceabilityPlastic deformation fasteningMaterial gluingMulti materialEngineering

The invention discloses an automatic attaching machine for electronic product auxiliary materials. The automatic attaching machine comprises a conveying mechanism, a positioning and supporting mechanism, an attaching mechanism and a material supplying mechanism; the conveying mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at an attaching stationin the conveying mechanism, when a fixture moves to the attaching station, the fixture is positioned by the positioning and supporting mechanism, and a product in the fixture penetrates through the fixture upwards to be jacked and supported and adsorbed and fixed downwards through the positioning and supporting mechanism; the material supplying mechanism is arranged on one side of the conveying mechanism and used for guiding out at least two auxiliary materials; and the attaching mechanism is arranged between the attaching station and the material supplying mechanism in a crossing mode and used for attaching the auxiliary materials to the product after the auxiliary materials guided out of the material supplying mechanism are adsorbed, fixed and moved to the attaching station. According tothe automatic attaching machine for the electronic product auxiliary materials, the functions of multi-product bearing, fixture positioning, product jacking and supporting and adsorbing and heating are achieved, the material supplying assembly achieves quick disassembling and replacing, the condition that a material belt is jammed and pulled to be broken is reduced, a multi-material automatic material taking and attaching function is achieved, the universality is high, and the part replaceability is high.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

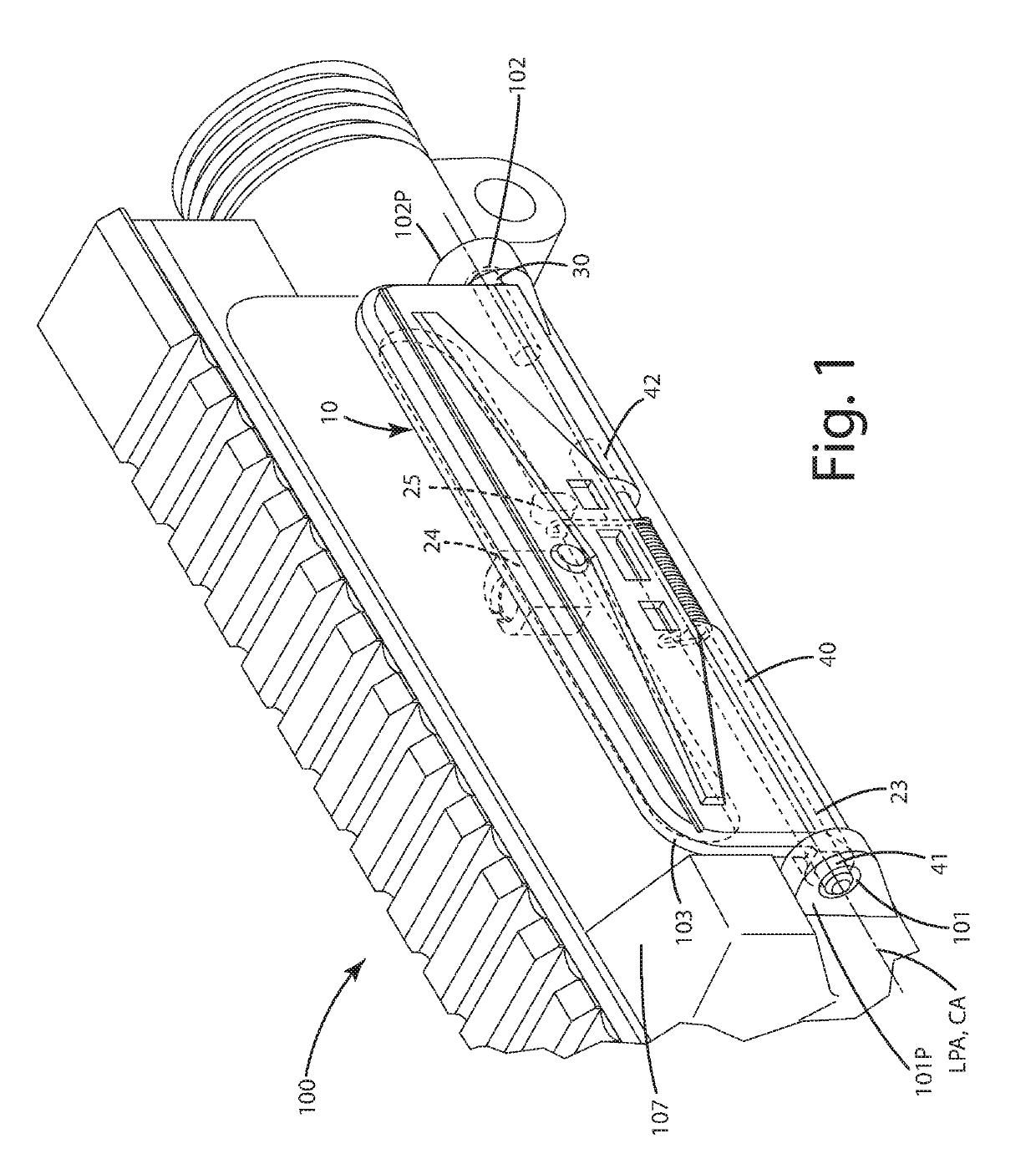

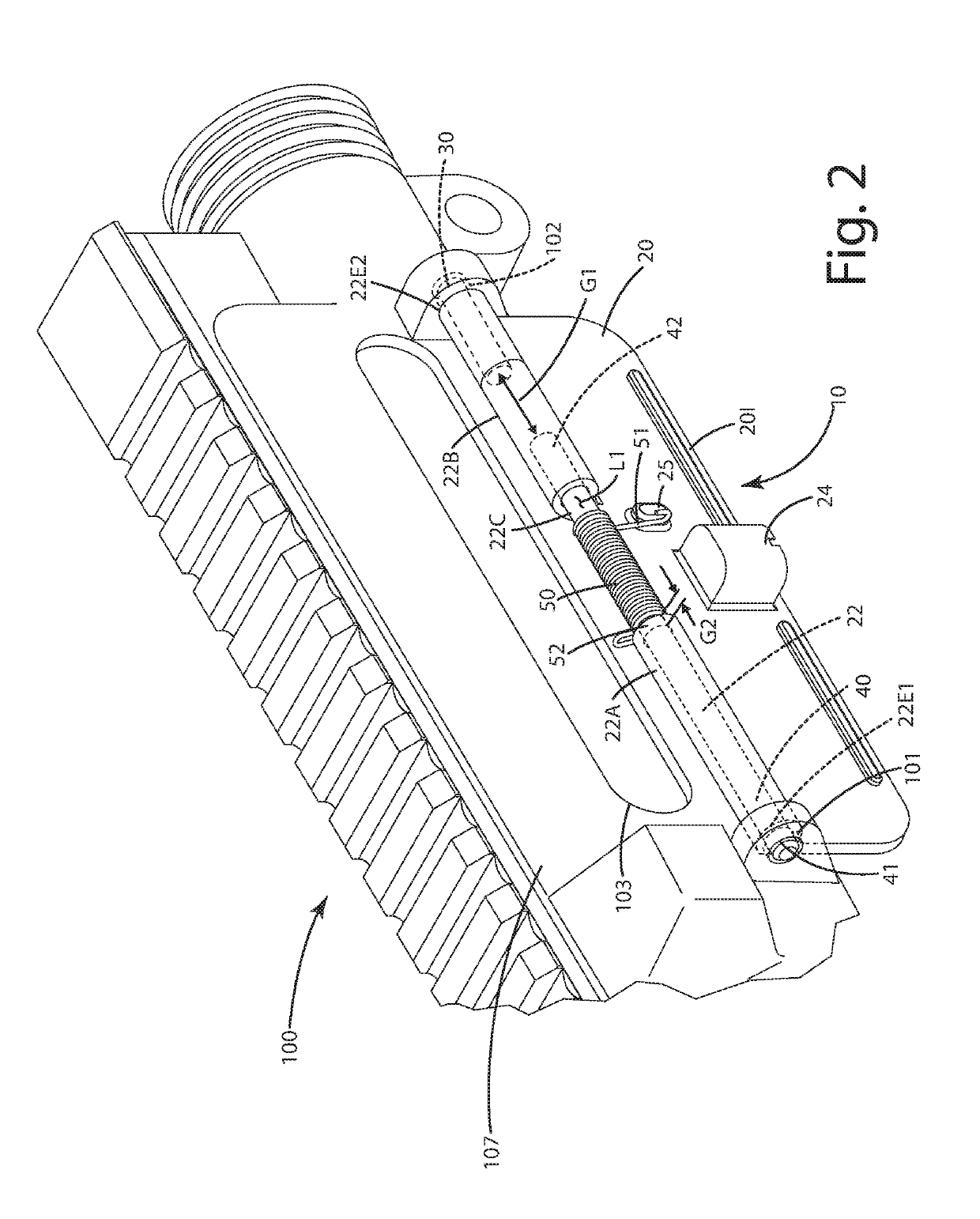

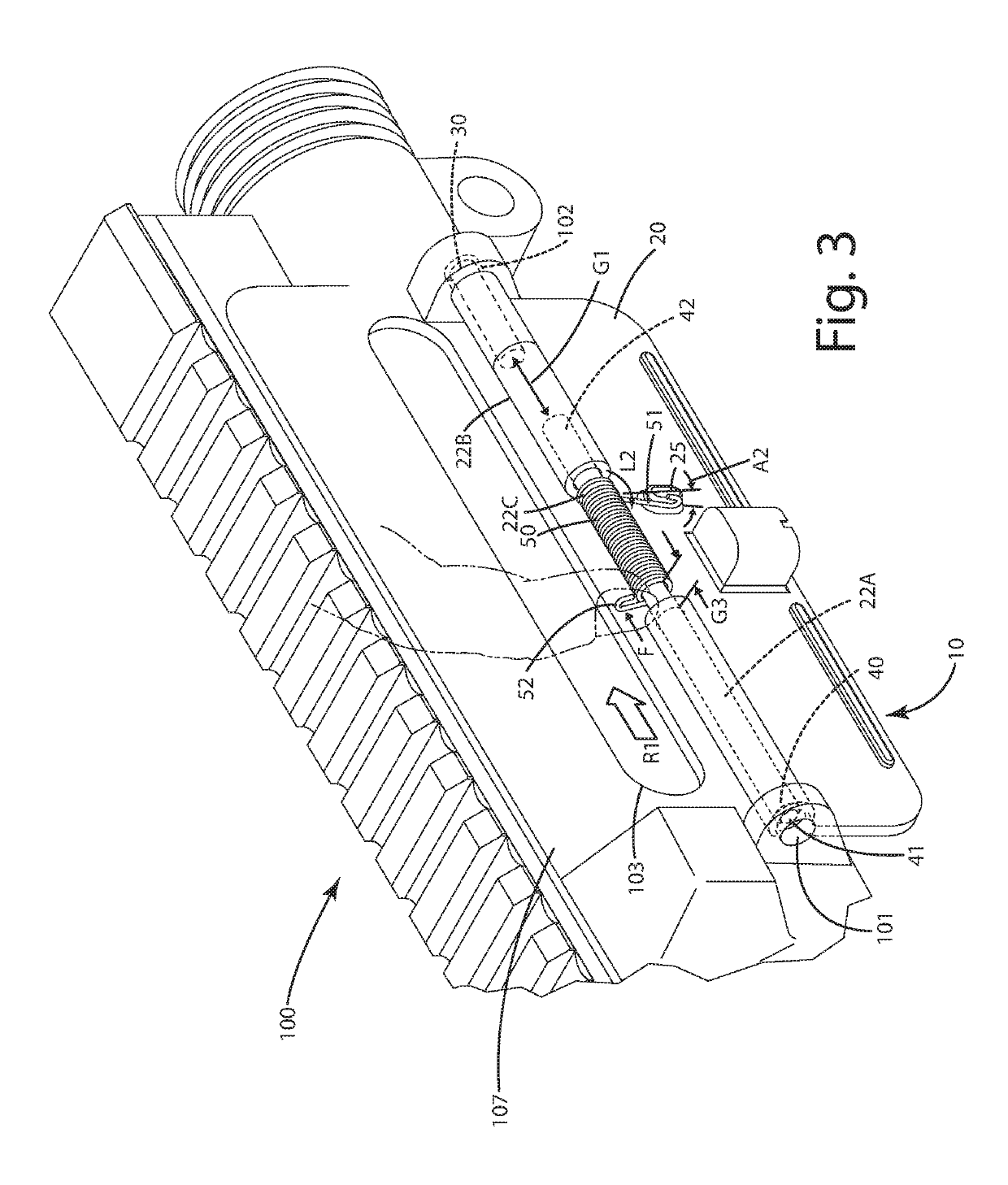

Firearm dust cover

ActiveUS10393467B1Quickly and efficiently removeQuickly and efficiently and replaceWeapon componentsEngineeringMechanical engineering

Owner:LEAPERS

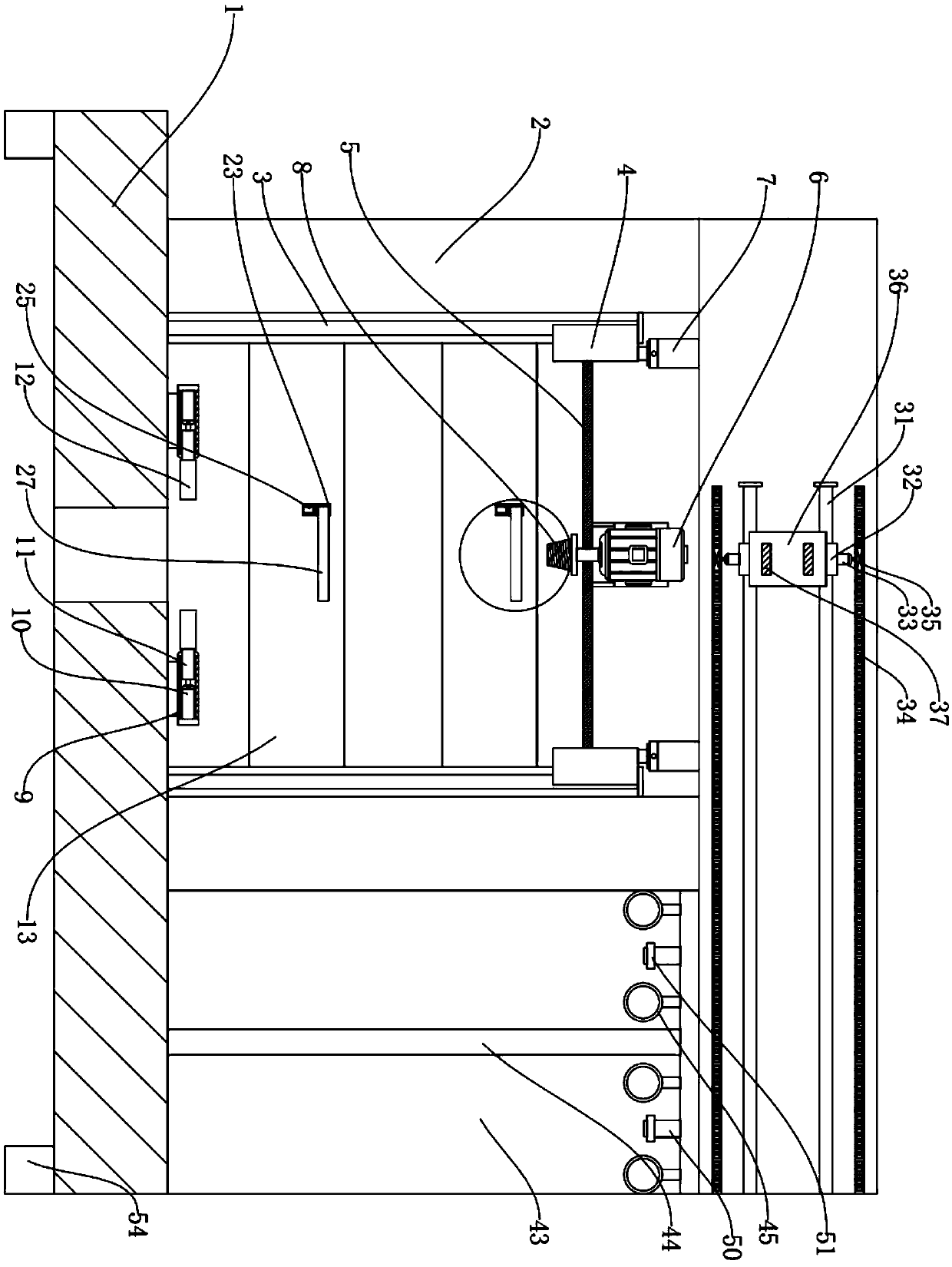

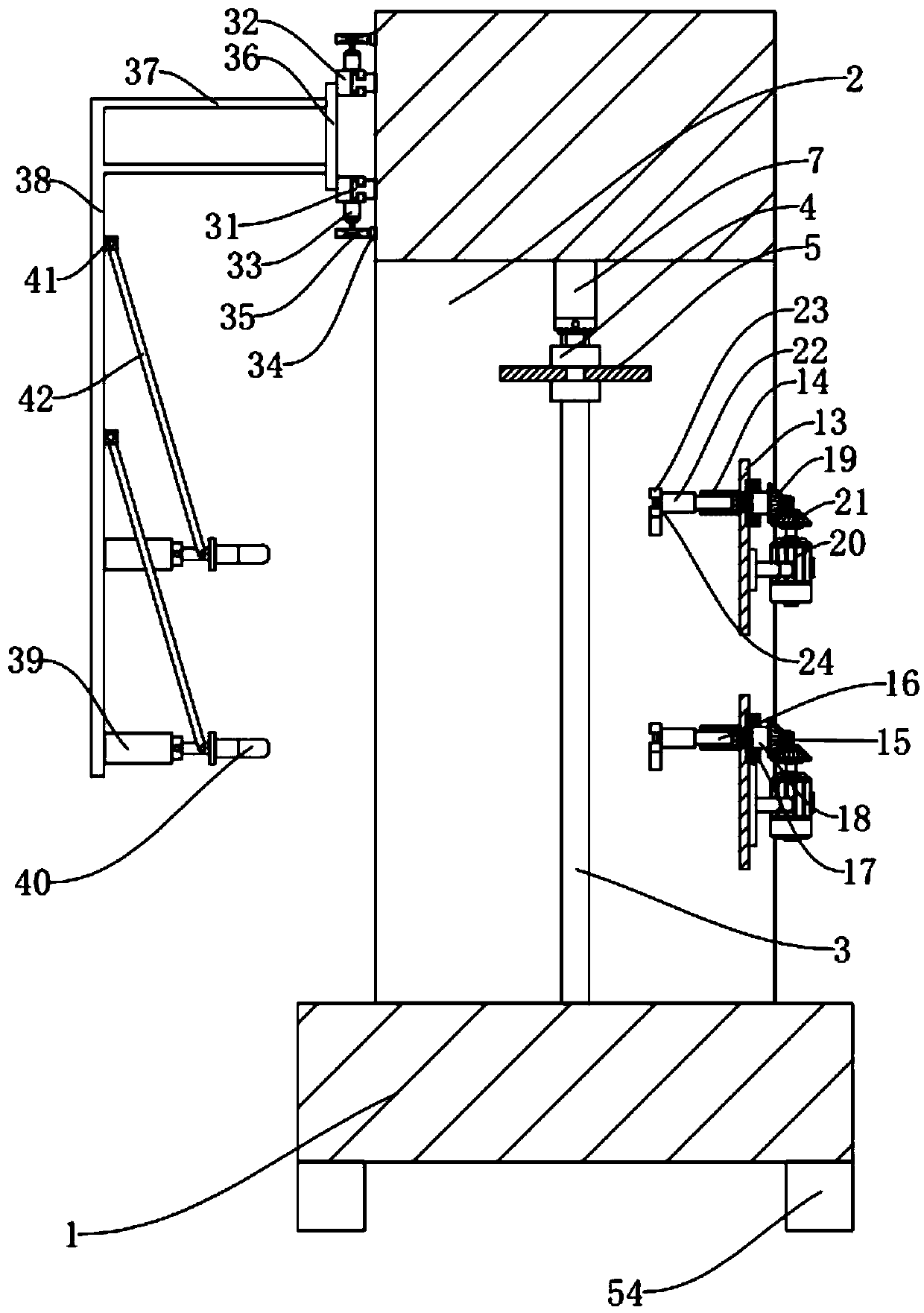

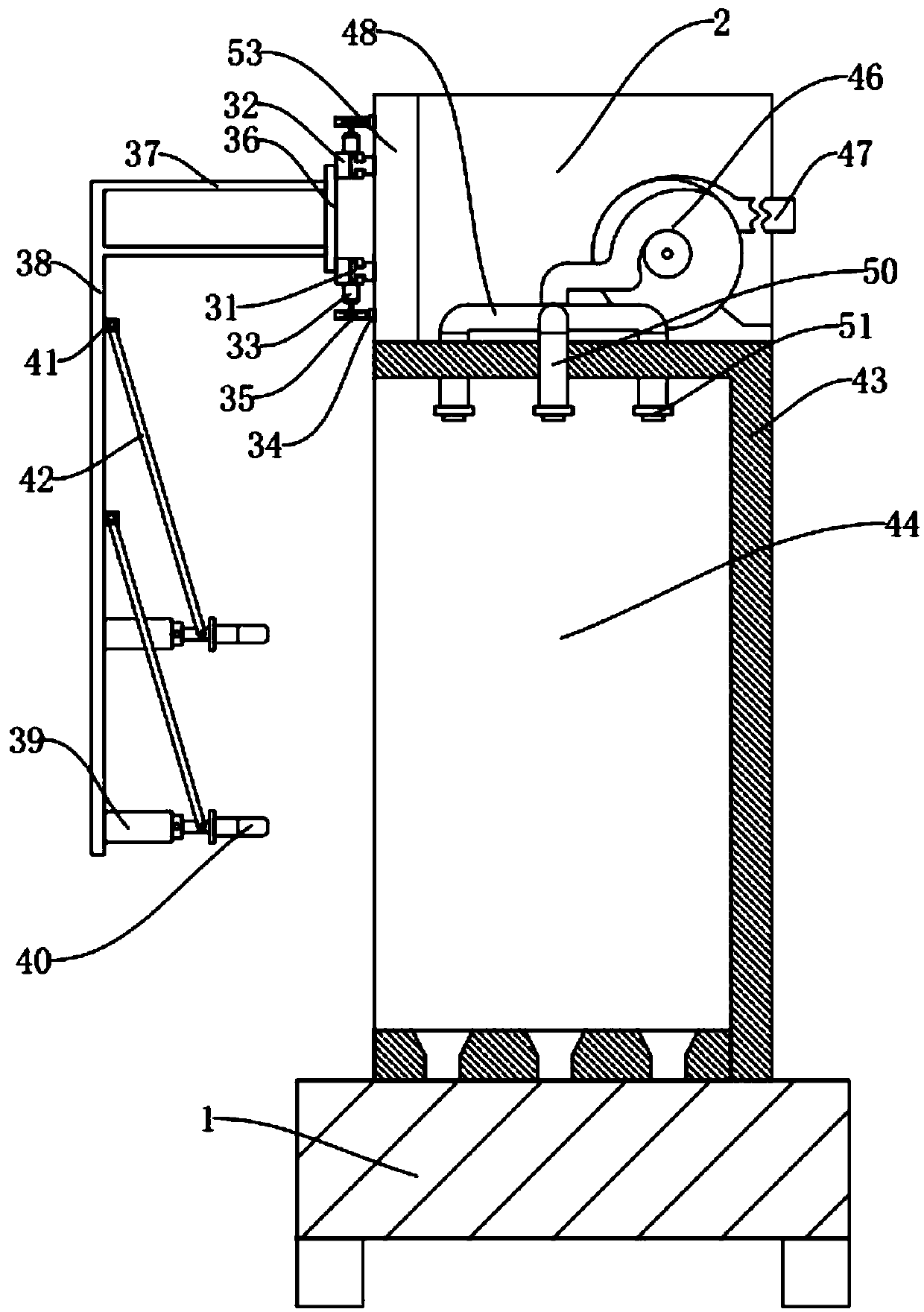

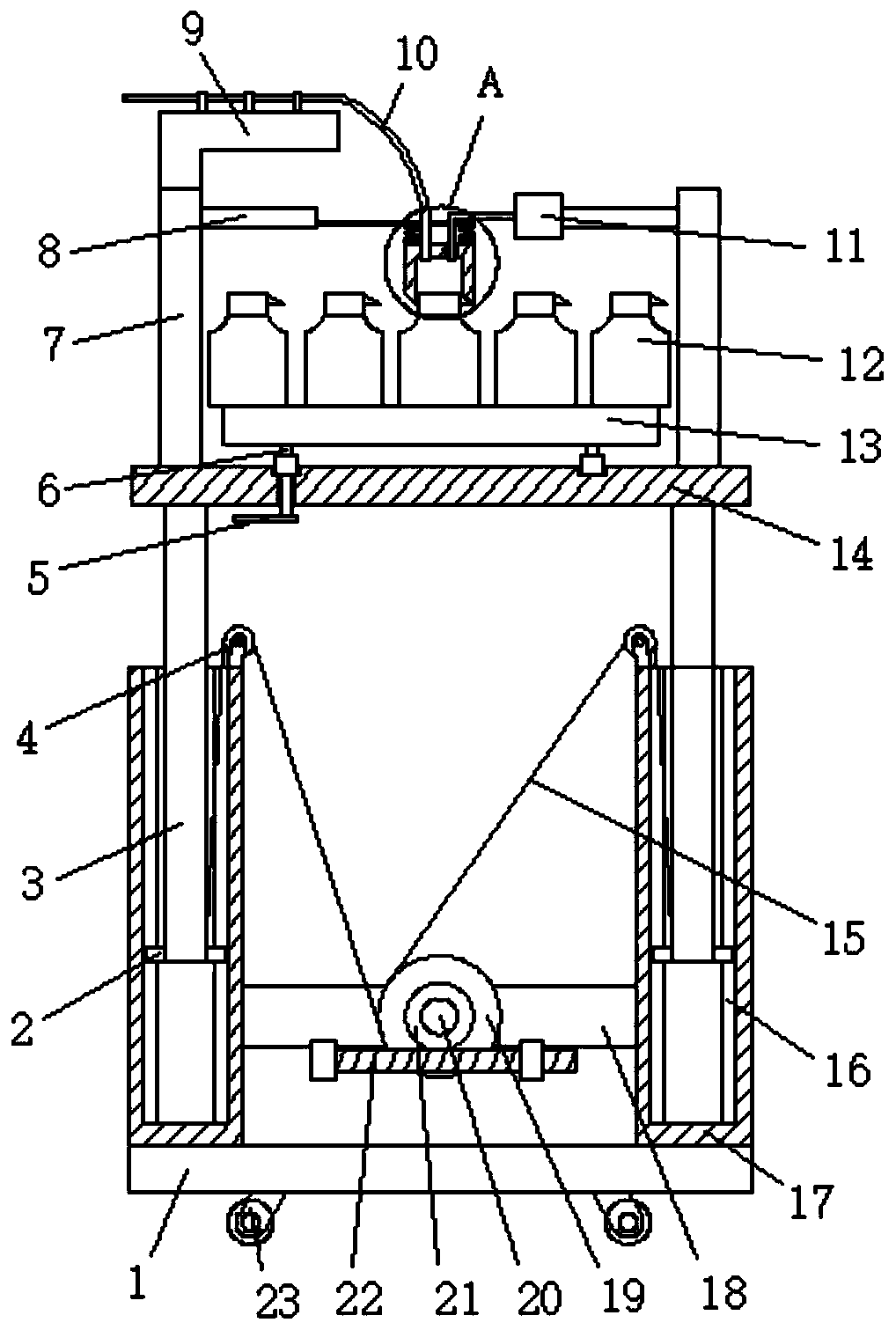

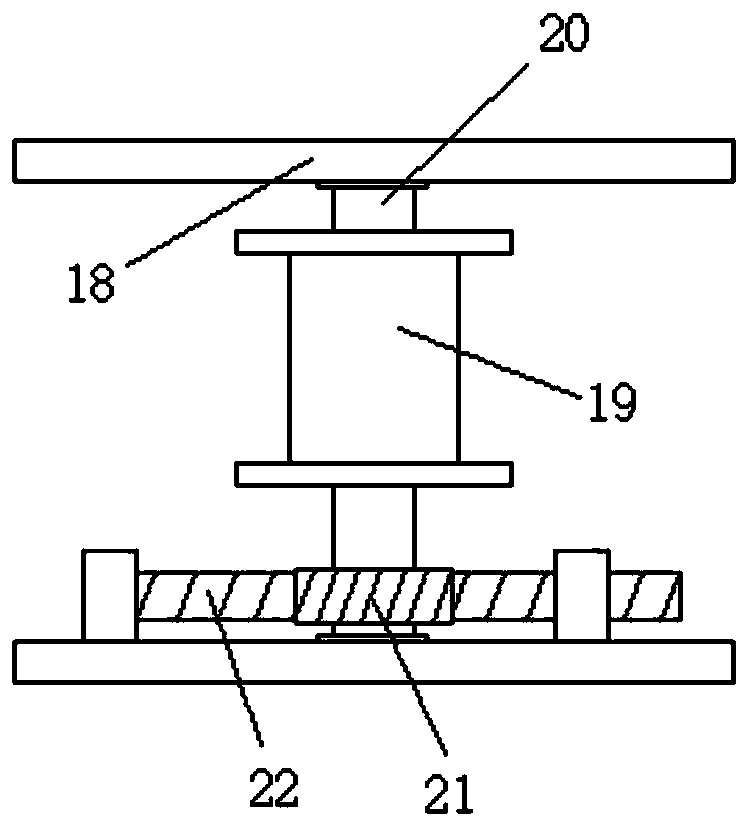

Drilling machine with functions of automatically replacing and cleaning drilling rods

InactiveCN109667553AEasy to useEasy to operateDrilling rodsCleaning using liquidsAutomatic controlPortal frame

The invention discloses a drilling machine with functions of automatically replacing and cleaning drilling rods. The drilling machine comprises a drilling machine base, a portal frame, a pair of vertical slide rails with same structure, a pair of lifting slide blocks with same structure, a horizontal plate, a drilling motor, a pair of multilevel hydraulic cylinders with same structure and a threaded block. The drilling machine has the beneficial effects of convenience in use, simple operation and high speed of replacement; drilling rods can be quickly and effectively replaced through a drilling rod automatic replacing mechanism on the drilling machine; during the process of replacing the drilling rods, manual carrying is not required; efficiency is greatly increased in the manner of automatic control; a cleaning mechanism arranged on the drilling machine is capable of storing and cleaning the recycled drilling rods, so that the drilling rods can be conveniently used next time and can be prevented from rusting, and the service life of the drilling rods can be prolonged.

Owner:四川言诺科技有限公司

Drilling machine

InactiveCN105855592AQuick and efficient replacementIncrease productivityPositioning apparatusMetal-working holdersExpansion jointControl switch

The invention discloses a drilling machine which comprises a workbench, a drilling mechanism, a supporting rod, a drill bit containing platform, a plurality of expansion links and a drill bit, wherein the supporting rod is vertically arranged on the upper surface of the workbench; the drilling mechanism is arranged on the supporting rod; the drilling mechanism can slide along the length direction of the supporting rod; the upper end of the drill bit containing platform is connected with the drilling mechanism; the lower end face part of the drill bit containing platform is inwards sunken and formed into a plurality of containing tanks matched with the drill bit; one end of each expansion link is fixed in each containing tank while the other end of the expansion link is connected with the drill bit; at least three containing tanks are arranged; the expansion links are arranged in the containing tanks; a control switch is arranged on the drilling mechanism, and is used for separately controlling a plurality of expansion links to stretch and rotate. The drilling machine can be used for solving the problem of low production efficiency caused by inconvenience in exchanging the drill bit and inconvenience in operation of detaching the original drill bit and replacing the required drill bit in the prior art.

Owner:YINFENG CASTING WUHU CO LTD

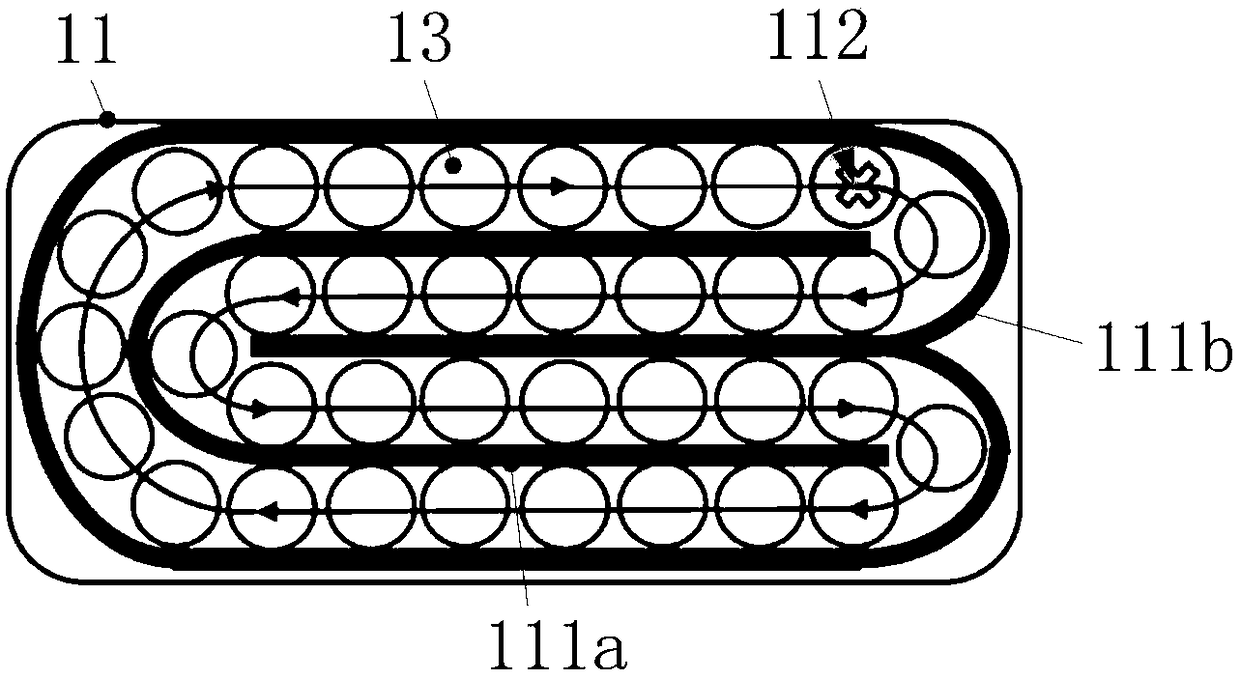

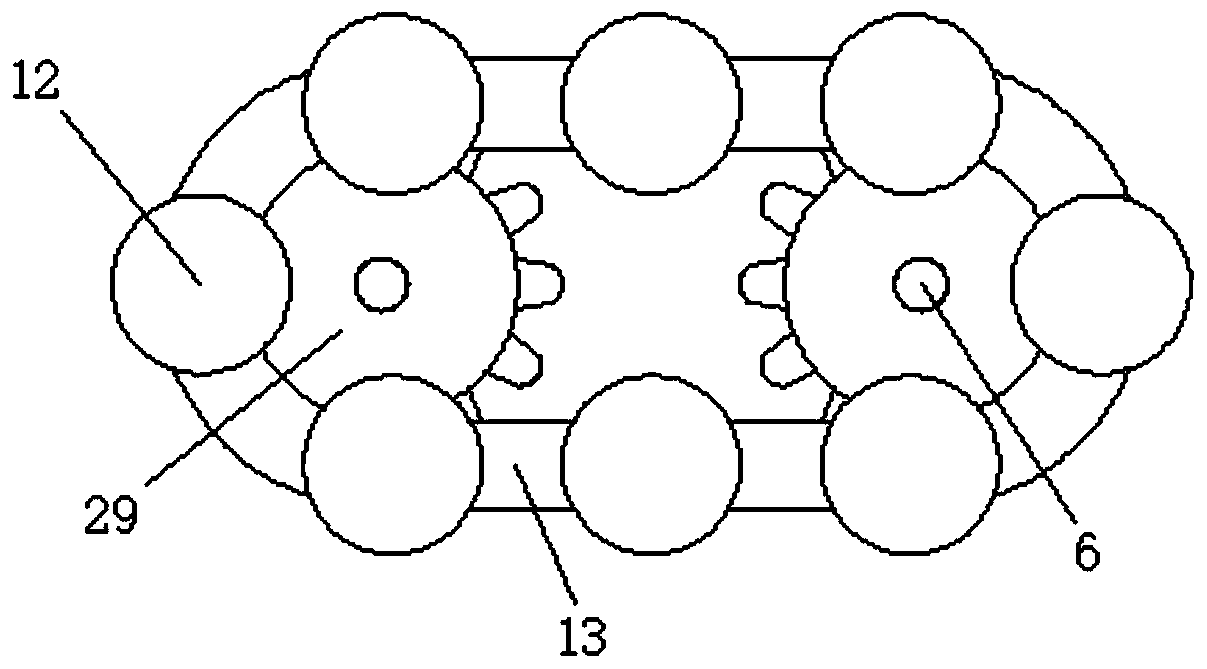

Battery pack and battery filling system

ActiveCN109037513ASimple internal structureImprove structural stabilityCell component detailsElectricityEngineering

The invention relates to the field of charging and battery placing, in particular to a battery pack and a battery filling system. The invention aims to solve the problems of low replacement efficiencyand low reliability in an existing battery unit replacement scheme. For this purpose, the battery pack of the present invention comprises a housing, and a transmission mechanism and a plurality of battery units disposed within the housing, each battery unit comprising at least one cylindrical battery; a circulation channel is arranged in the housing, and a battery inlet and a battery outlet are also arranged on the housing, and the battery inlet and the battery outlet are arranged on both sides of the housing along the axial direction of the battery; and the transmission mechanism is arrangedto drive the plurality of battery unis to move to the battery inlet in sequence along the circulation channel. The battery inlet and the battery outlet are arranged on both sides of the shell along the axial direction of the battery, so that when the battery is replaced, the transmission mechanism does not need to be replaced together, only a fully charged battery is used to eject a power-lack battery, the replacement efficiency of the battery is improved, and the replacement of the battery is convenient and quick.

Owner:NIO ANHUI HLDG CO LTD

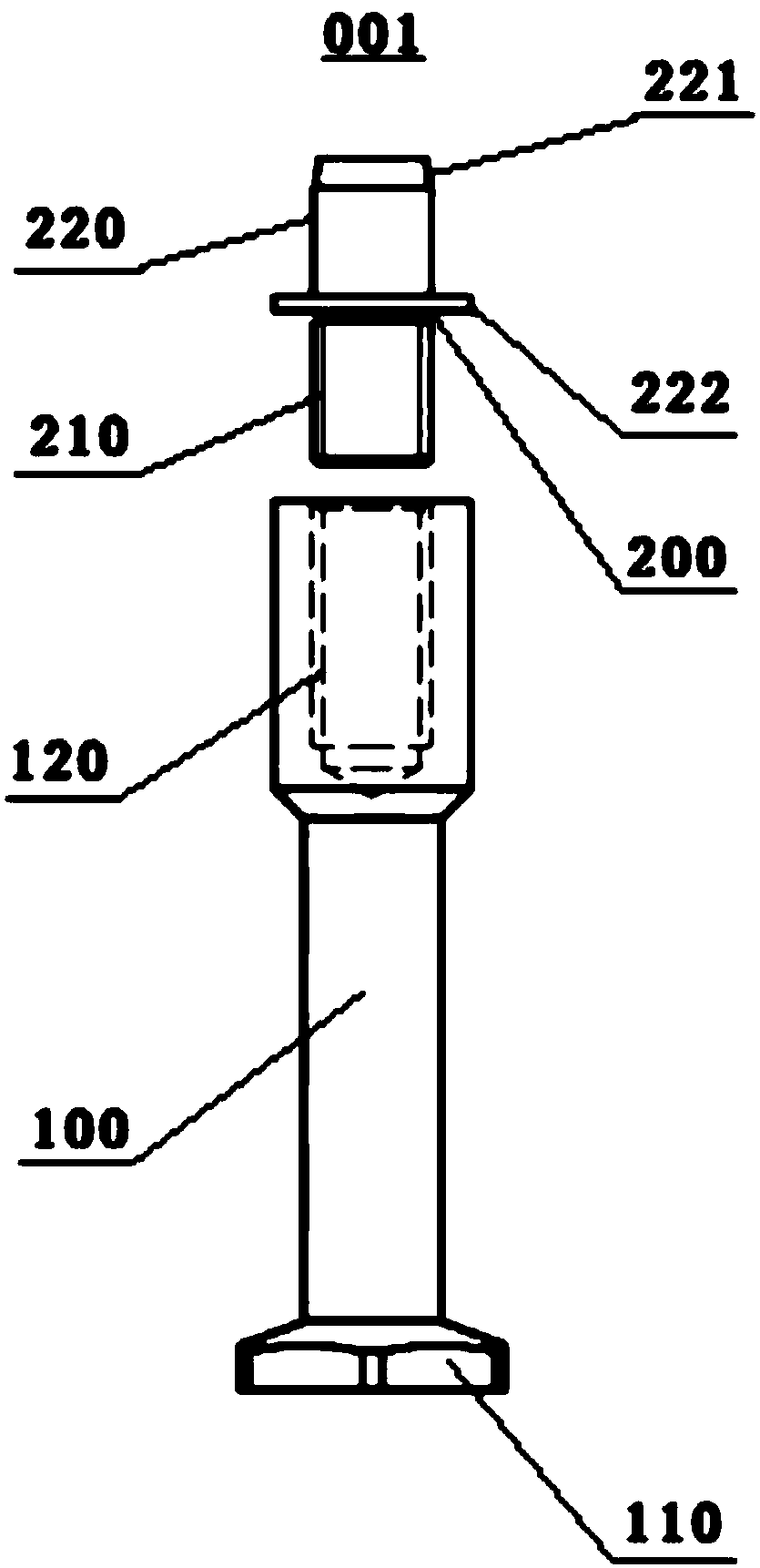

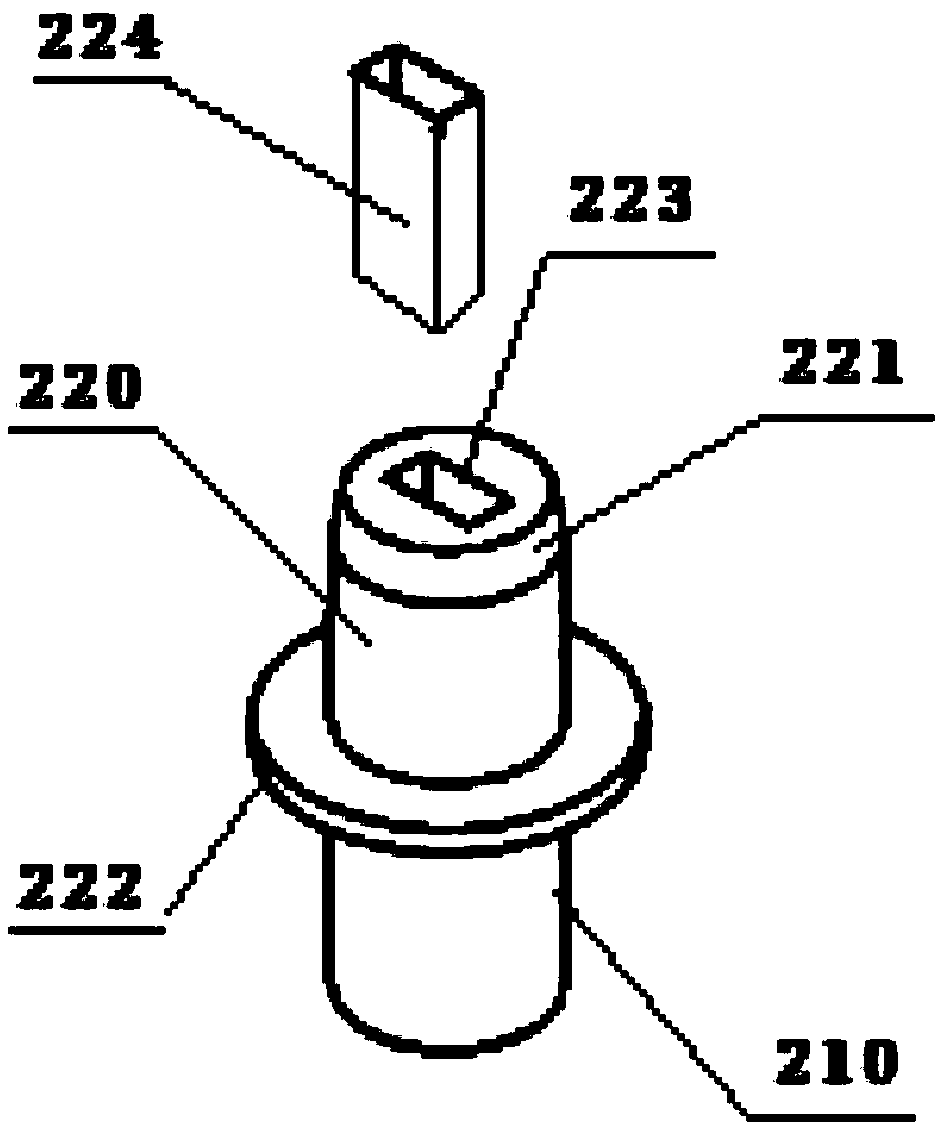

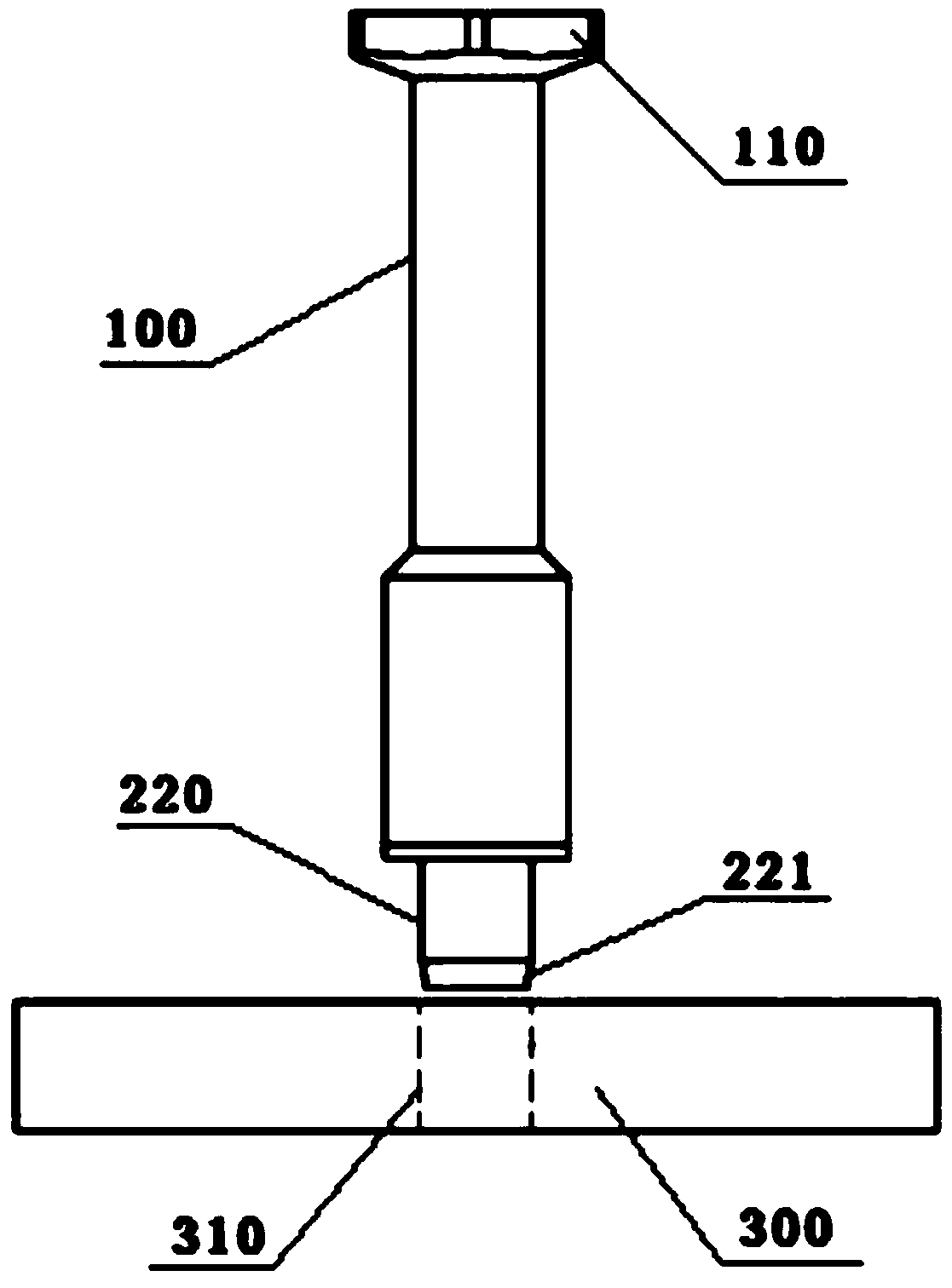

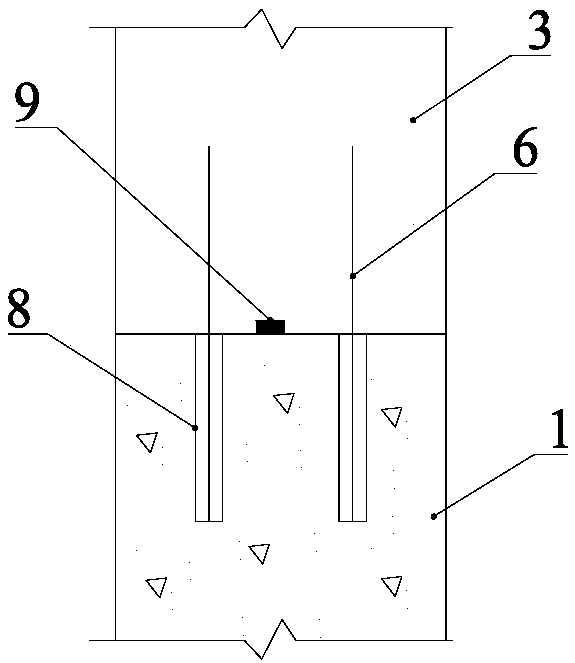

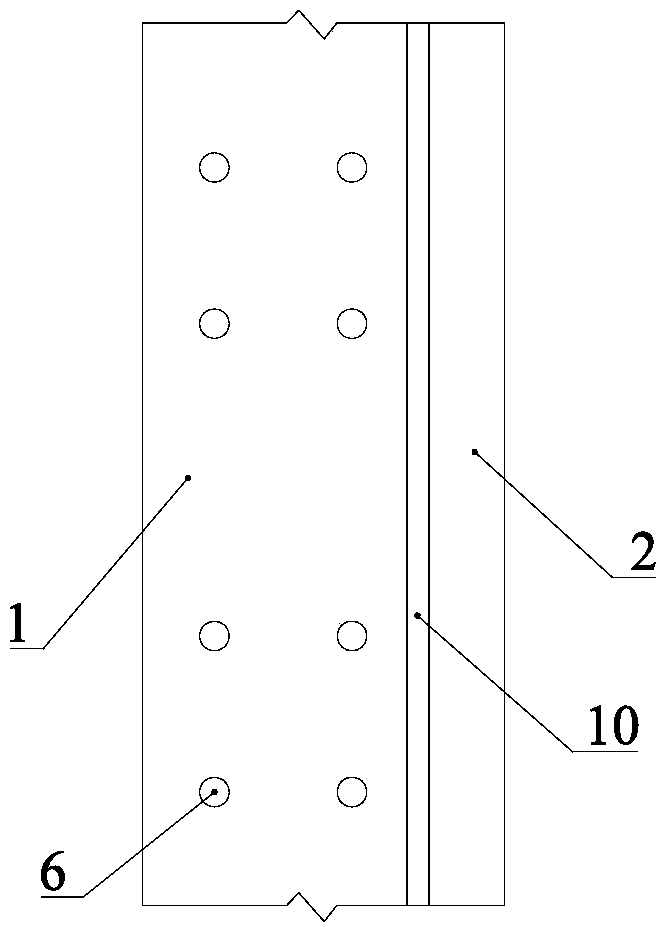

Pre-buried sleeve used for channel installation and channel positioning method

PendingCN109083285AQuick and efficient installationQuick and efficient replacementBuilding constructionsArchitectural engineeringBuilding construction

The invention discloses a pre-buried sleeve used for channel installation and a channel positioning method, and belongs to the technical field of building construction. The pre-buried sleeve used forchannel installation comprises a sleeve body and a positioning part, a pan head is arranged at one end of the sleeve body, and a threaded hole is formed in the other end of the sleeve body; a screw rod corresponding to the threaded hole is arranged at one end of the positioning part, and a positioning pillar is arranged at the other end of the positioning part. In the channel positioning method, apre-buried sleeve used for channel installation, a concrete pouring formwork with one or more positioning holes and a channel with one or more installing holes are involved. The positioning part is connected with the sleeve body, the pre-buried sleeve used for channel installation is fixed to the concrete pouring formwork through the positioning holes, concrete is poured onto the concrete pouringformwork, and the positioning part and the sleeve body are separated after the concrete is solidified to connect the channel with the pre-buried sleeve used for channel installation through the installing holes. With the channel positioning method, the channel can be conveniently and rapidly installed and replaced.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

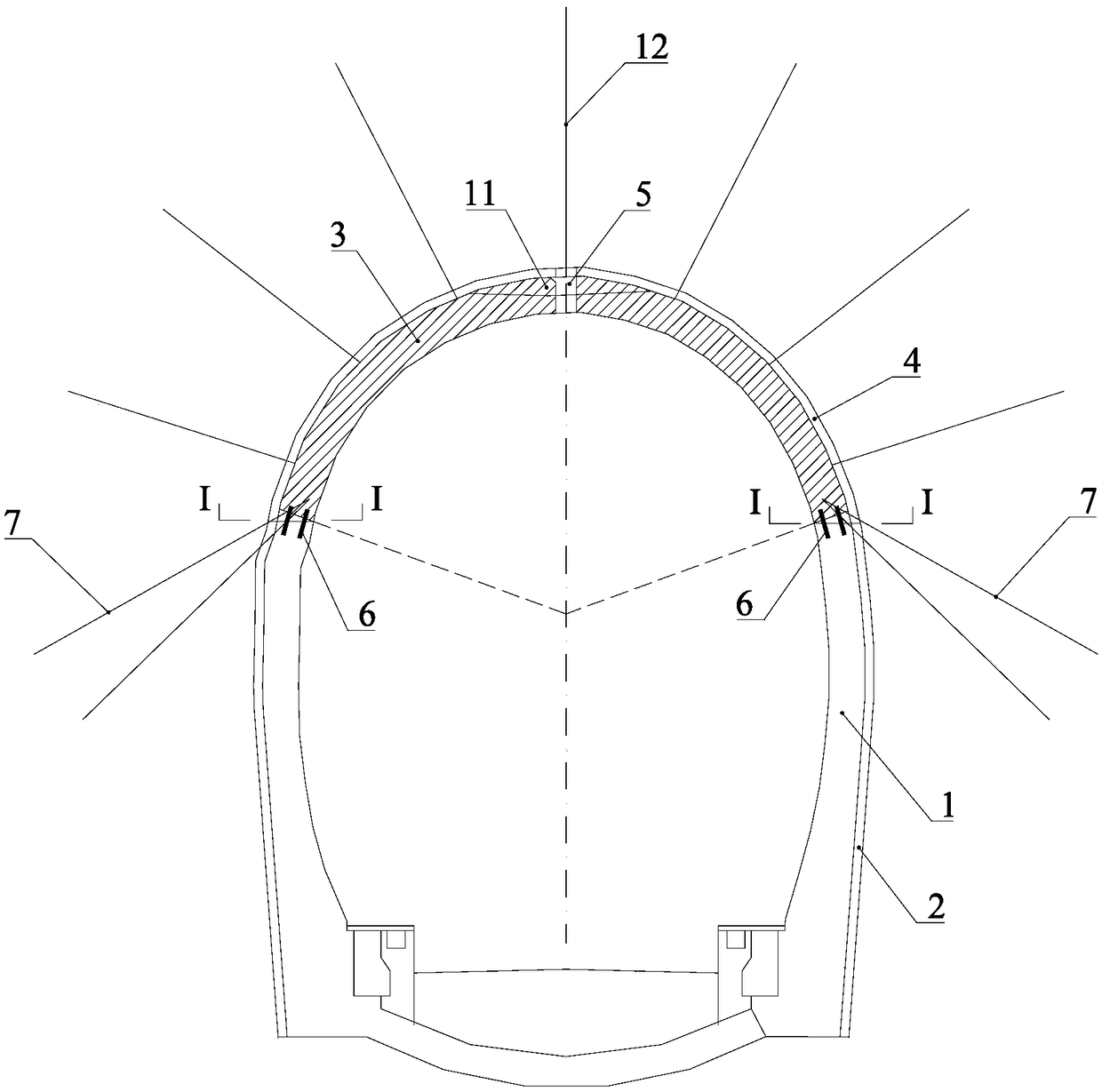

Tunnel lining thickness-lack reinforcing structure and construction method

PendingCN109372543AReasonable reinforcement designSecurity Reinforcement DesignUnderground chambersTunnel liningShotcreteSteel frame

The invention discloses a tunnel lining thickness-lack reinforcing structure and a construction method. The reinforcing structure comprises a newly constructed secondary lining and a newly constructedpreliminary support arranged on a tunnel lining thickness-lack area, multiple mortar anchor rods, and multiple grouting steel flower pipes arranged in the tunnel lining thickness-lack area, wherein the newly constructed secondary lining is connected with an existed secondary lining; the newly constructed preliminary support is connected with an existed preliminary support; and the multiple mortaranchor rods are arranged on the connecting part of the newly constructed preliminary support and the existed preliminary support. The construction method comprises the steps of arranging a temporarysteel frame support; adopting the grouting steel flower pipes for reinforcing a surrounding rock; disassembling a disassembling and replacing section of the tunnel lining thickness-lack area, erectinga permanent steel frame support on the disassembling and replacing section, spraying concrete, and forming the newly constructed preliminary support; and driving the mortar anchor rods, constructingdrill nails and a water stop adhesive on the connecting surface of the newly constructed secondary lining and the existed secondary lining, paving a lining waterproof layer between the newly constructed secondary lining and the newly constructed preliminary support, then modelling, and pouring the newly constructed secondary lining.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

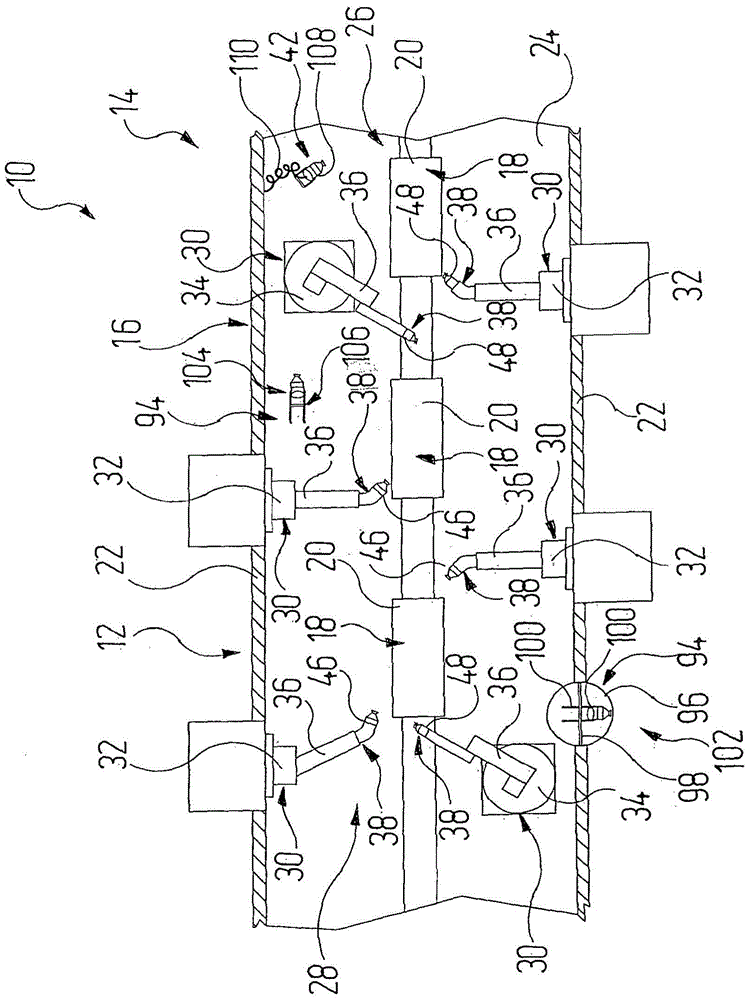

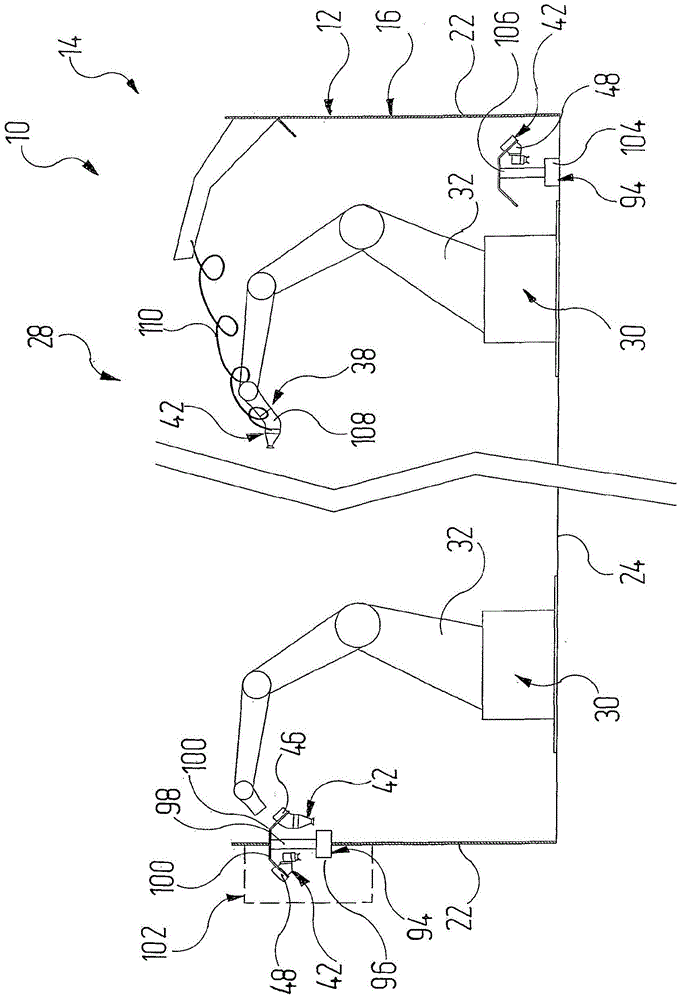

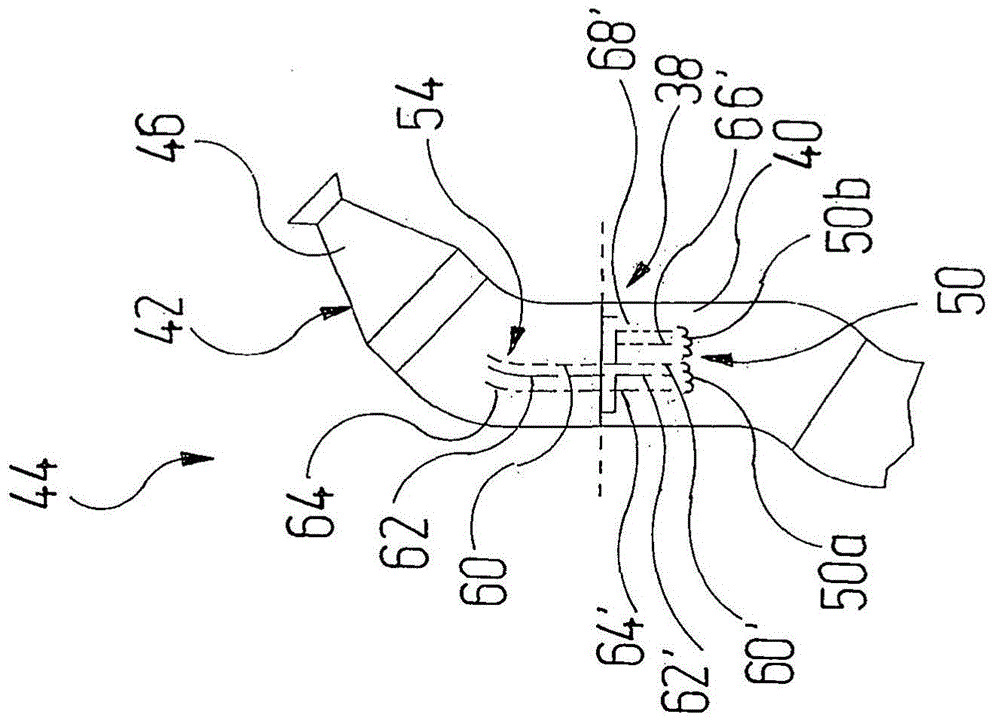

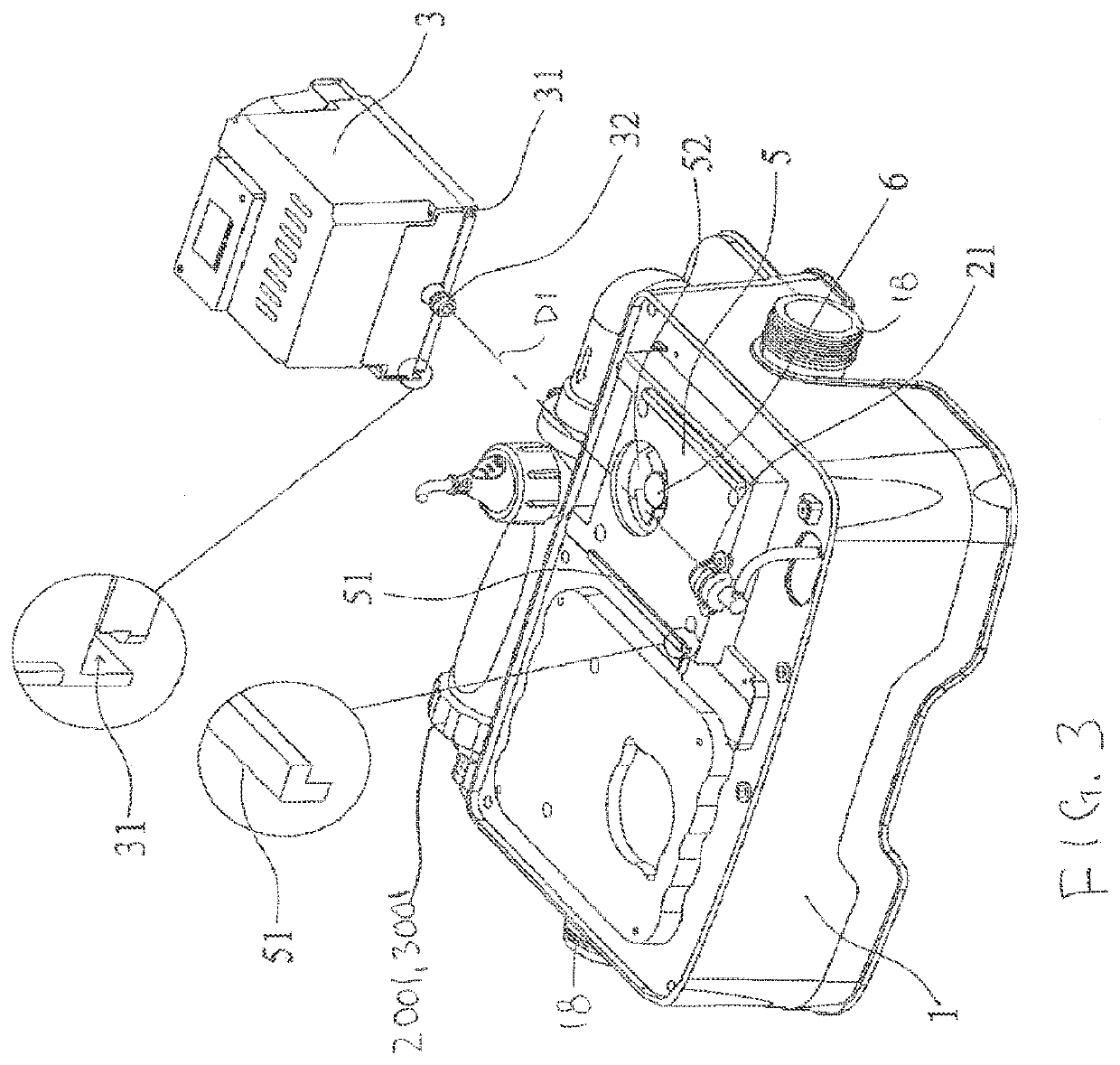

Application robot having a connection unit for different applicators

InactiveCN104797348AQuick changeReduce consumptionGripping headsSpraying apparatusEngineeringCoating

The invention relates to an applicator connection unit for an application robot for coating objects (18) comprising supply lines (50) for an applicator (42). An applicator (42) can be fastened on the applicator connection unit in such a way that working lines (54) of the applicator (42) are connected to the supply lines (50) of the applicator connection unit (40). The applicator connection unit (40) is formed as an adapter unit (58) in such a way that at least one applicator (46) of a first mode of operation and one applicator (48) of a second mode of operation can be releasably and replaceably fastened to the applicator connection unit (40). The invention further relates to an application robot and a system for coating objects, wherein such an applicator connection unit is used.

Owner:EISENMANN SE

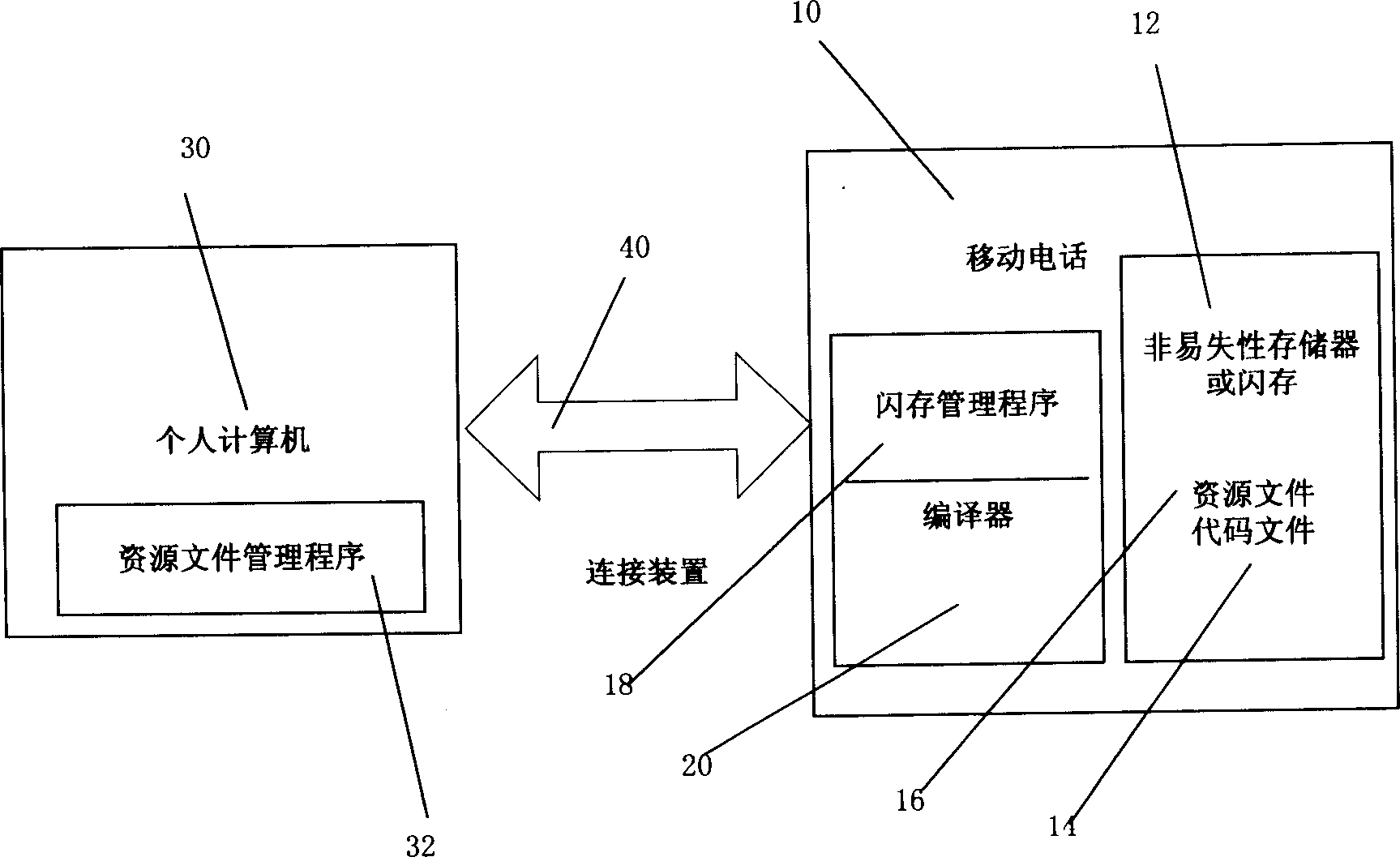

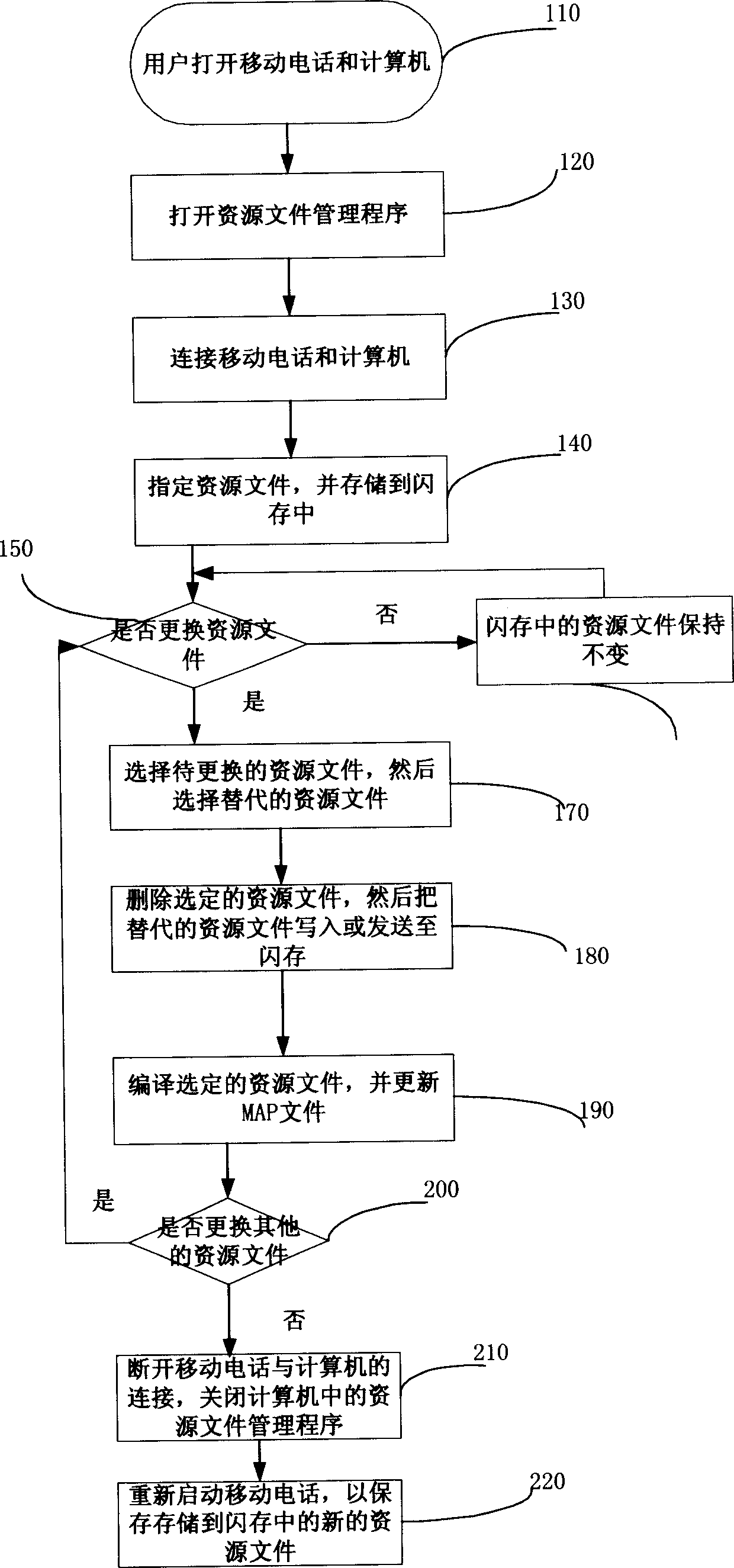

System and method for customizing mobilephone resource file

InactiveCN1863353AAvoid complexityQuick and efficient replacementSubstation equipmentWireless commuication servicesMobile telephonyResource file

A system and method is provided for efficiently modifying or changing resource files in a mobile phone. The resource files, such as ring tone, font, and wallpaper files, are preferably stored in one or more memory segments, which are separate from one or more code file memory segments, of the phone's nonvolatile, or flash, memory. A resource file management program is used to read, write, modify, and / or erase resource files separately from the code files and other files stored in the phone's nonvolatile memory. Accordingly, resource files can be written or otherwise delivered into the nonvolatile memory of the phone without the need to re-download, rewrite, or otherwise update the code files and other non-resource files stored in the phone's nonvolatile memory.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

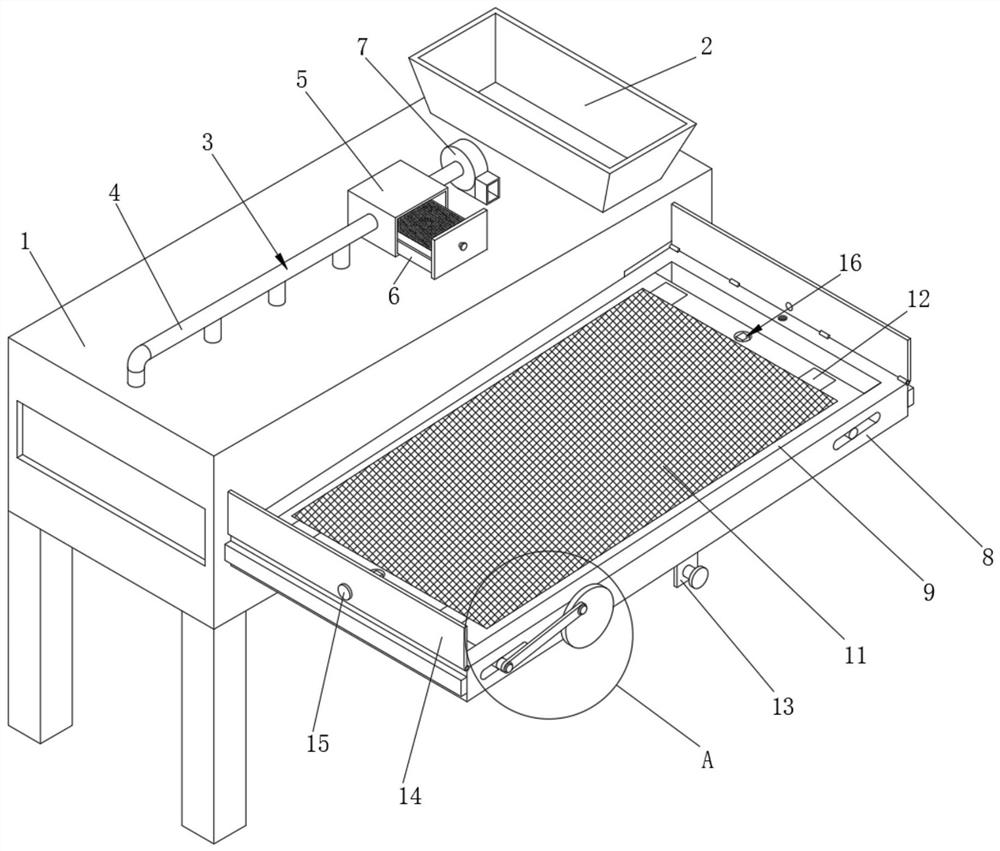

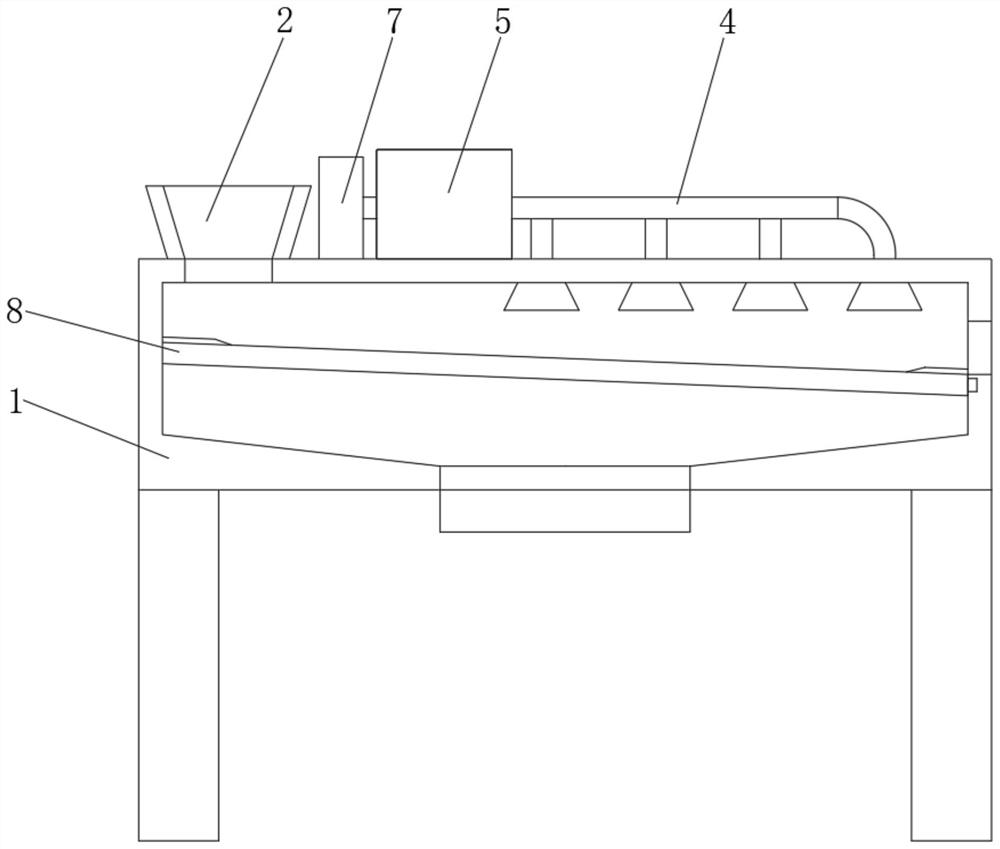

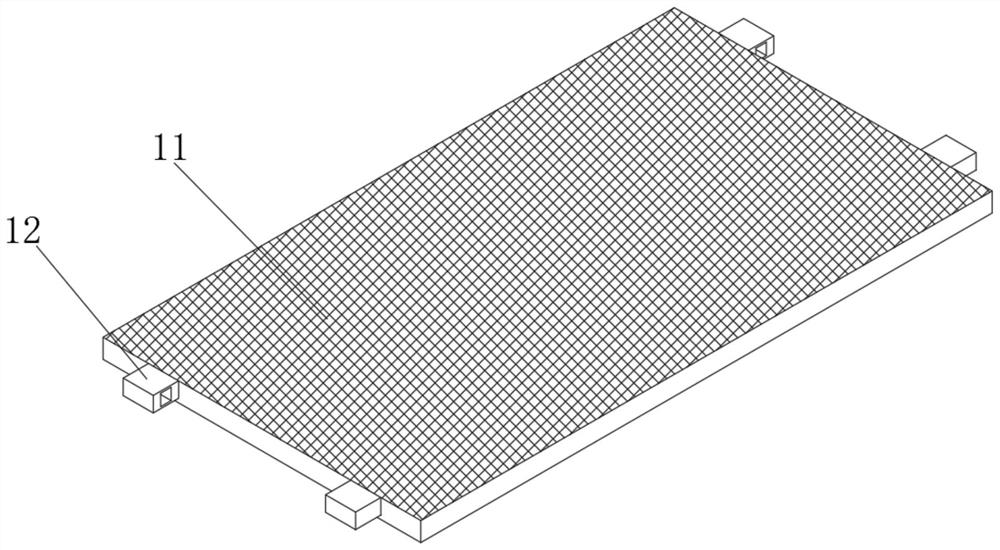

Vibration screening device for carbon production

PendingCN112570258AReasonable designQuick and efficient replacementSievingScreeningStructural engineeringMechanical engineering

The invention discloses a vibration screening device for carbon production. The vibration screening device comprises a screening box, a purification structure, a mounting frame and a filter screen; the screening box is of a rectangular box-shaped structure, four supporting legs are fixed to the four corners of the bottom of the screening box, a screening cavity is formed in the screening box, a funnel-shaped feeding port is formed in one end of the top of the screening box, and a purification structure for assisting in purifying air in the screening box is arranged at the top of the screeningbox; a mounting frame is obliquely inserted into the screening cavity, fastening blocks are arranged in clamping cavities, a fastening cavity is formed between the two clamping cavities on the same side, and a fastening structure is arranged in each fastening cavity; and a slag discharging opening is formed in the end, corresponding to the oblique bottommost portion of the mounting frame, of the screening box, and a discharging opening is formed in the bottom of the screening box. The vibration screening device for carbon production is reasonable in design, the filter screen in the screening box can be rapidly and effectively replaced according to needs, the problem that the filter screen is not convenient to replace is avoided, and the vibration screening device is suitable for application and popularization.

Owner:HUNAN HONGYU CARBON NEW MATERIAL

Die fixing seat of punching machine

The invention relates to a die fixing seat of a punching machine. A base is provided with a sliding guide rail which is provided with a punching mechanism; two positioning blocks are symmetrically arranged on the base and located on one side of the punching mechanism; the base is provided with a sliding cylinder which is located on one side of the positioning blocks and used for enabling the positioning blocks to slide on the base; the side face of each positioning block is provided with a slidable pipe half die body which is provided with a U-shaped groove, and the U-shaped grooves are formed in the two pipe half die bodies in a mutually corresponding mode; one side of the positioning blocks is provided with two cylinder fixing blocks which are connected in an abutted mode; a compaction cylinder is arranged in each cylinder fixing block, a telescopic rod of each compaction cylinder is fixedly provided with a connecting block, and each connecting block is provided with multiple locking screws; the pipe half die bodies are provided with screw holes corresponding to the locking screws. According to the die fixing seat of the punching machine, operation is convenient, by means of the compaction cylinders and the locking screws, the pipe half die bodies can be replaced rapidly and efficiently, time and labor are saved, and good practicability is achieved.

Owner:SUZHOU CITY XIANGCHENG CITY LUMUXINCHENG PRECISION MOLD FACTORY

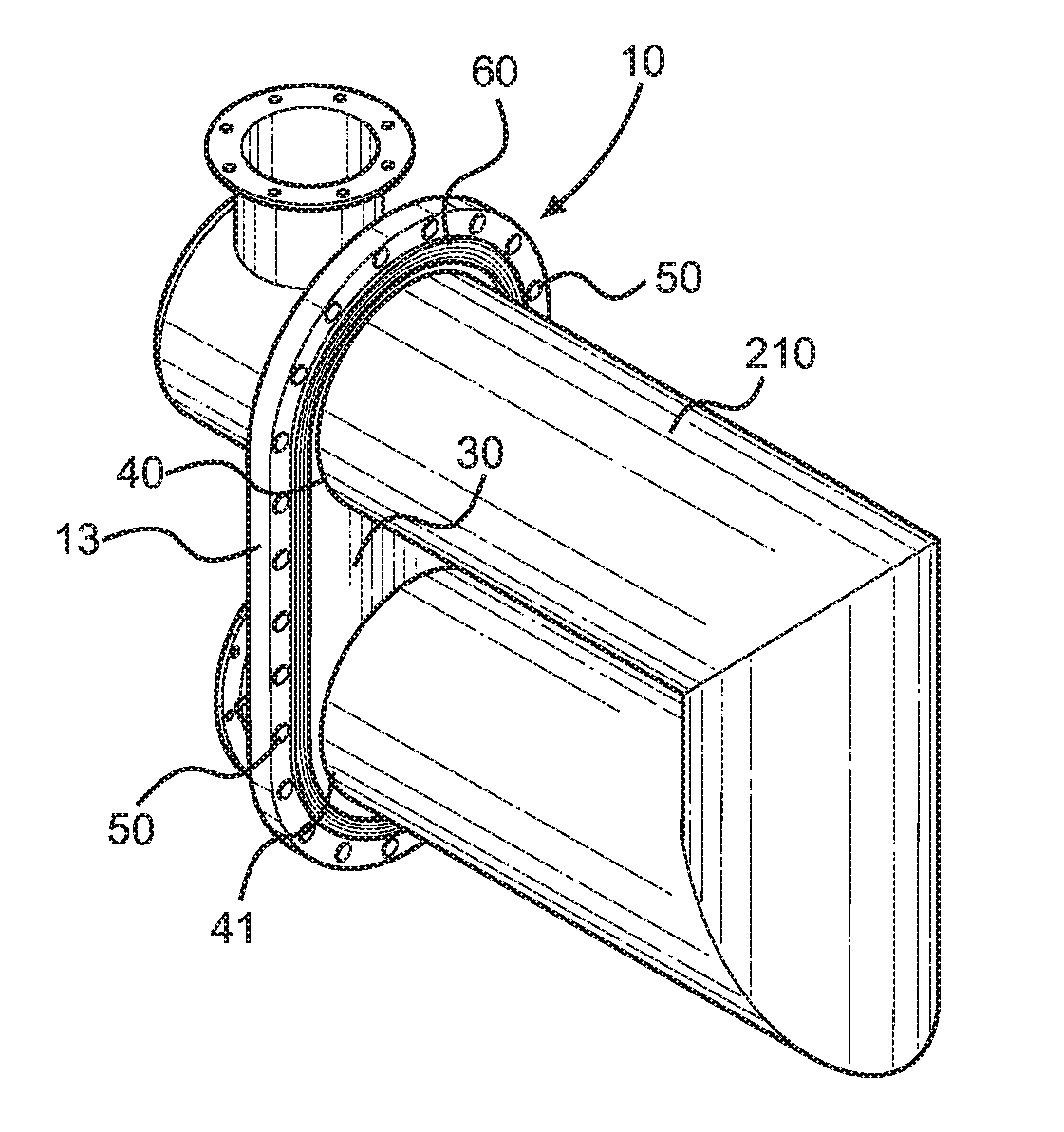

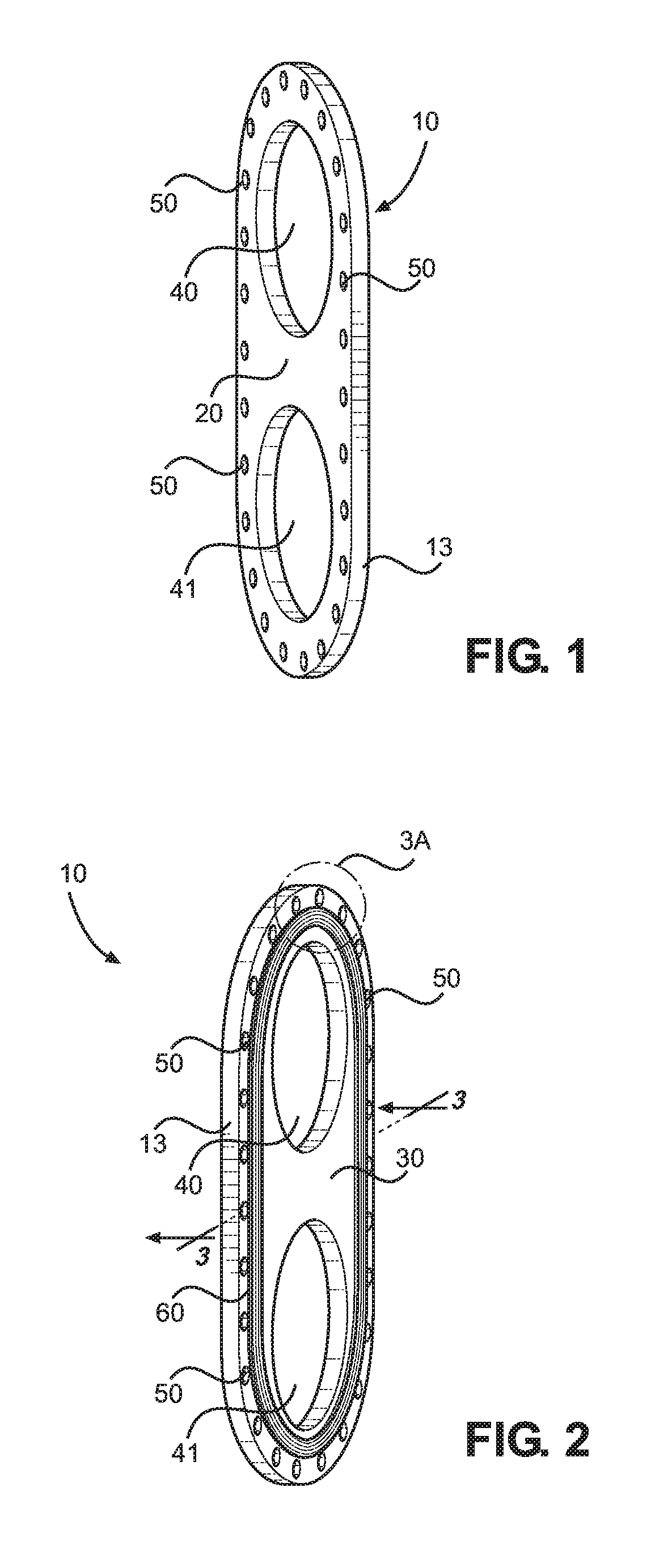

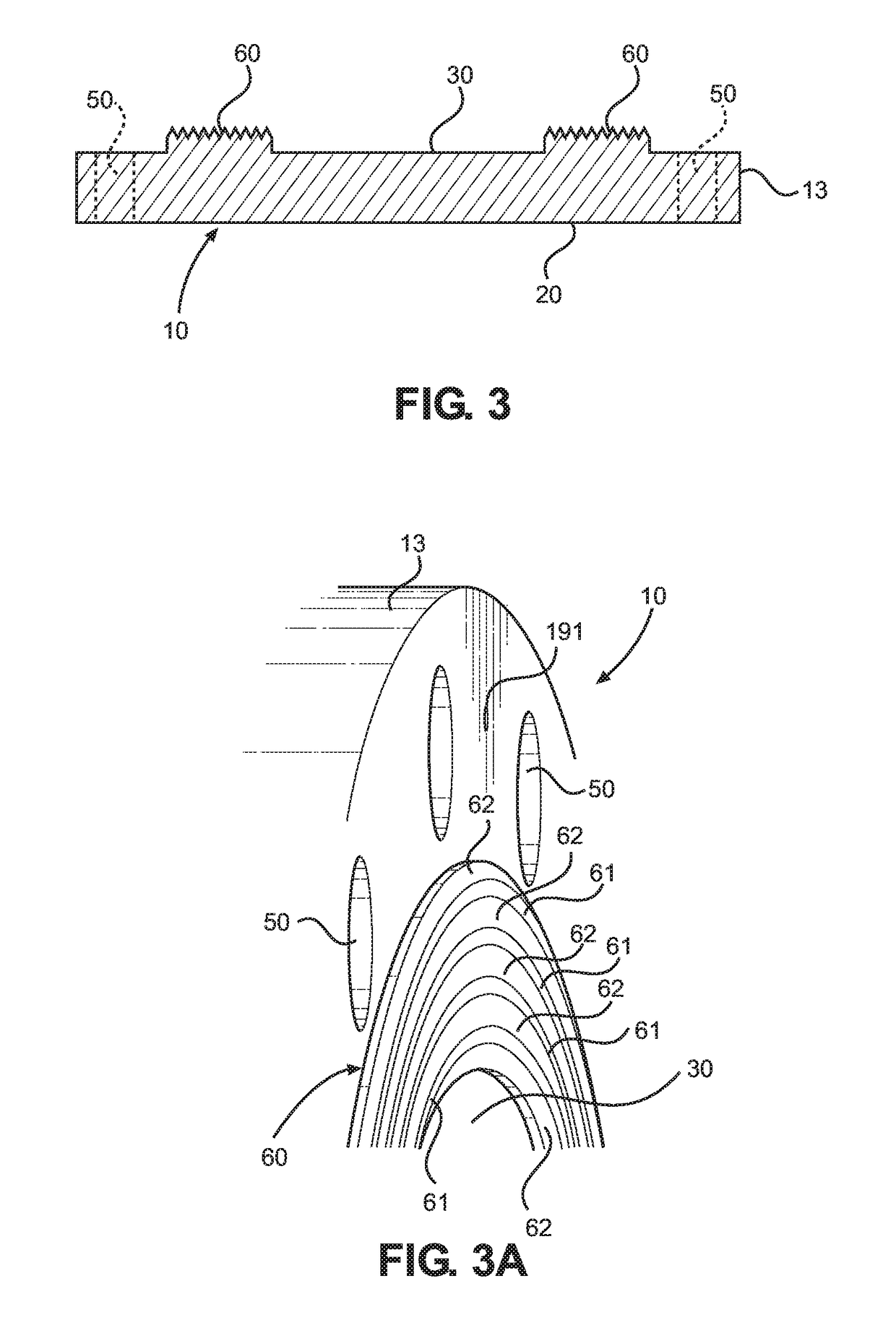

Flange Assembly for Heater Treaters and Other Vessels

InactiveUS20170355006A1Eliminates current riskEliminate limitationsDucting arrangementsLighting and heating apparatusEngineeringFlange

An oval-shaped flange assembly for use on heater treaters and other heated and / or pressurized separation vessels. A first substantially oval-shaped, raised face blind flange member operationally attached to a fire tube mates with an opposing oval-shaped, raised face slip-on flange member attached to a heater treater or other pressurized vessel. An alignment guide pin facilitates fast and efficient connection and disconnection of the flange members.

Owner:GLOBAL VESSEL & TANK LLC

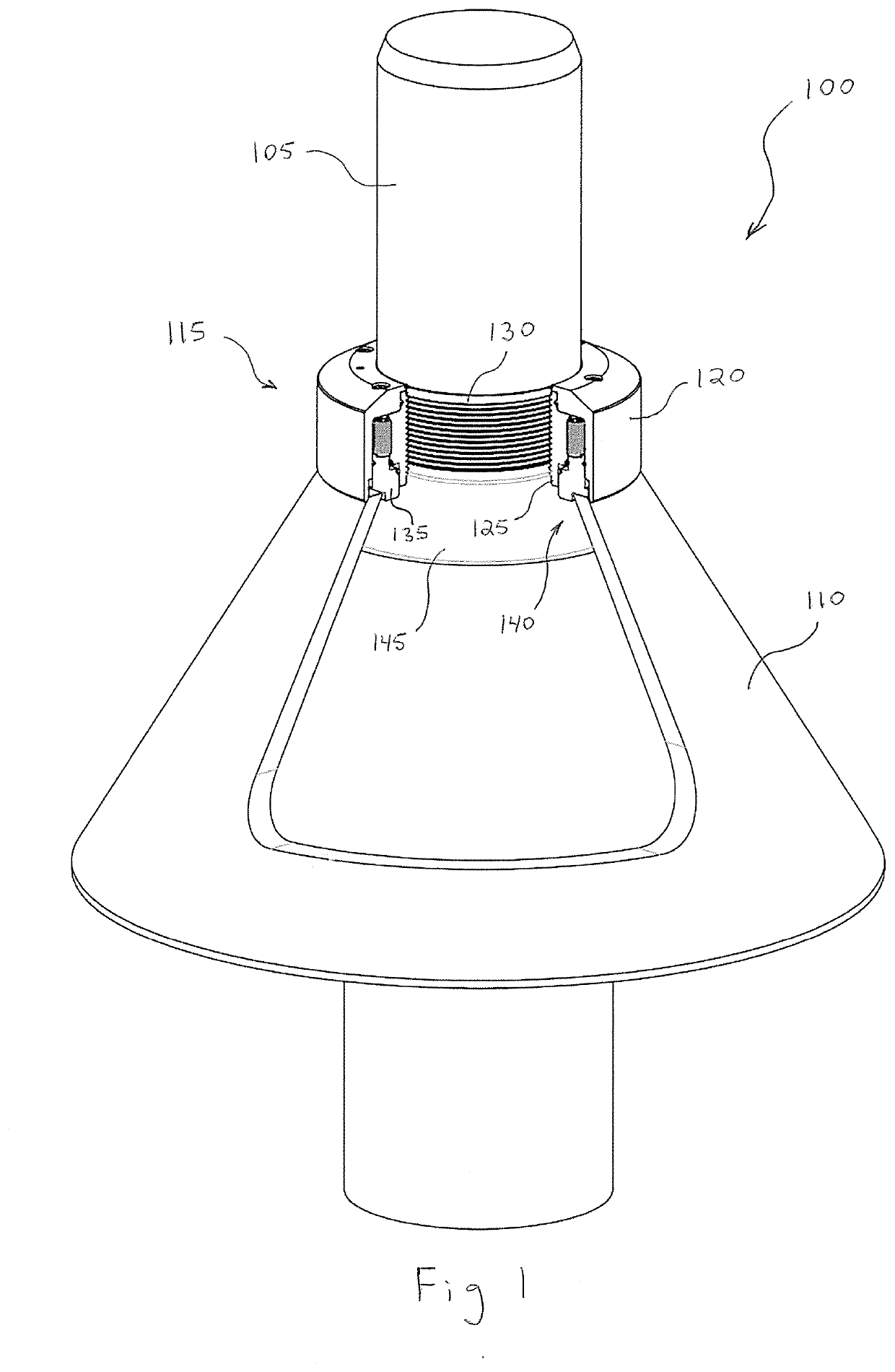

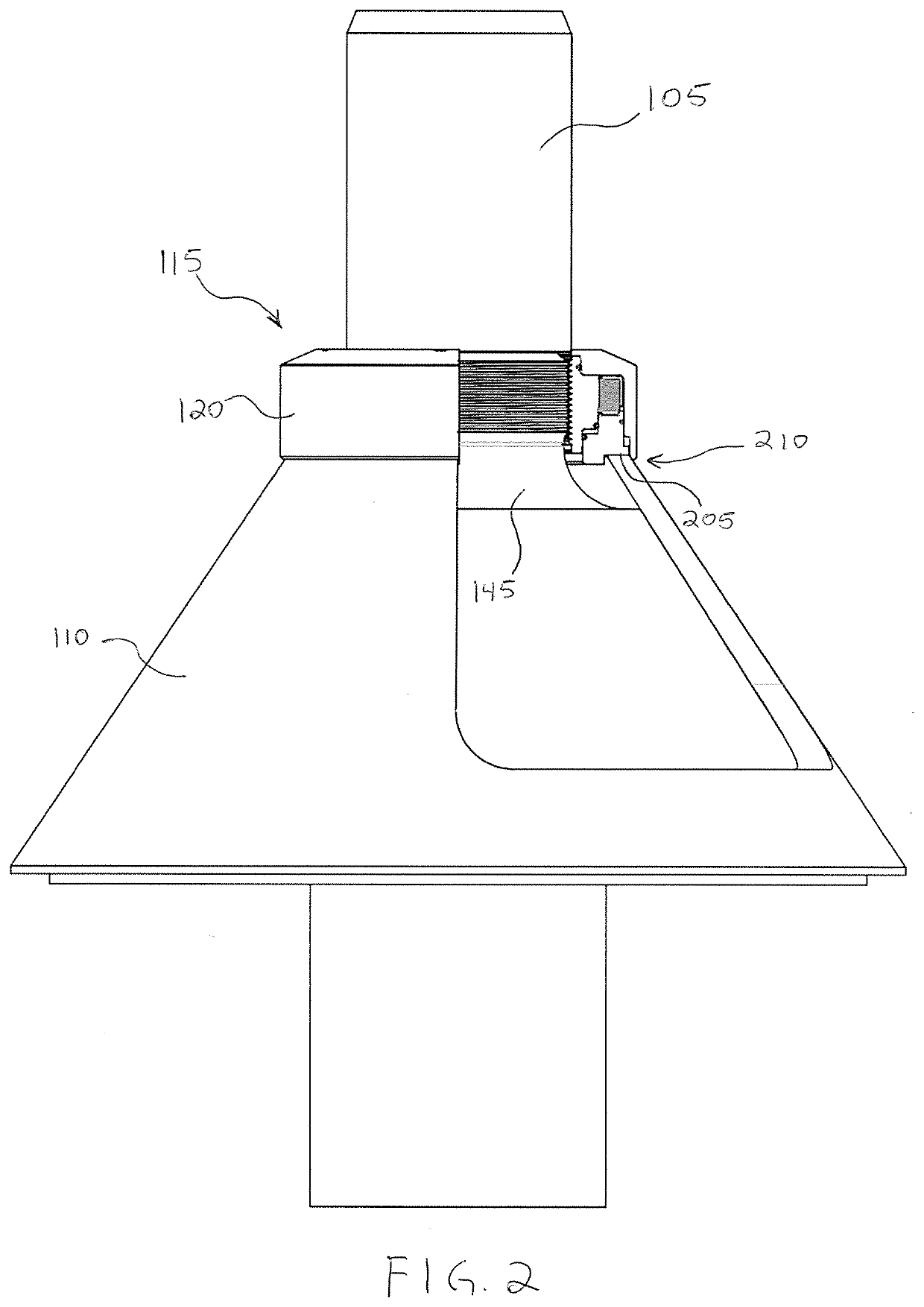

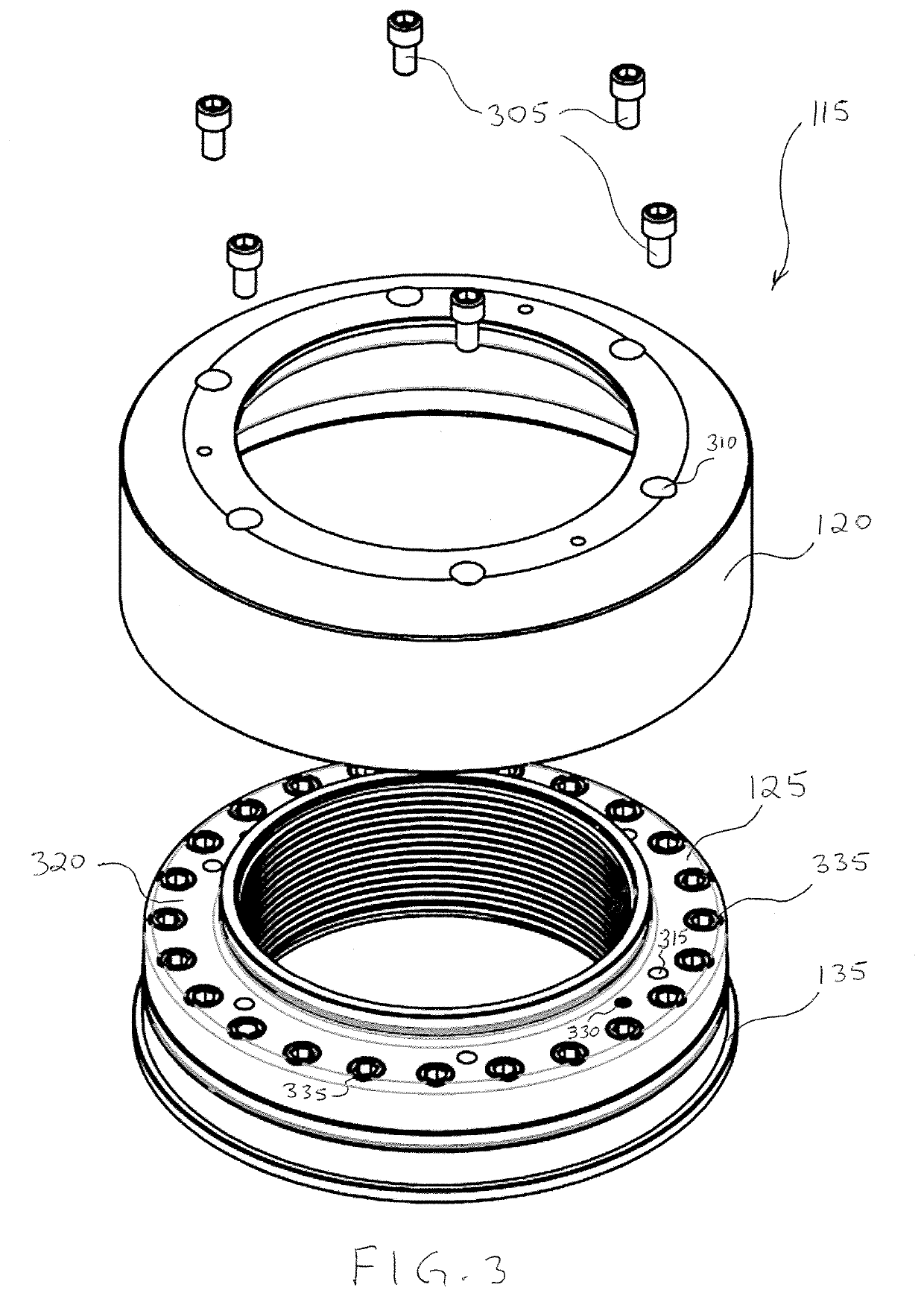

Hydraulic Mantle Assembly System for a Gyratory Rock Crusher

PendingUS20210322995A1Quick and efficient replacementEasy to remove and replaceGrain treatmentsClassical mechanicsCrusher

A hydraulic mantle system for a gyratory rock crusher enables the safe, quick and efficient replacement of a worn or deformed mantle. The system includes a main shaft, an annular nut, an annular hydraulic piston and an annular mantle. The main shaft has a flange and external threads adjacent the flange. The annular nut body has side surfaces and internal threads that are threaded onto the external threads of the main shaft. The annular hydraulic piston has side surfaces that slidingly engage the side surfaces of the annular nut body. The annular mantle has an upper neck portion and a lower edge portion. The main shaft extends extending through the upper neck portion. The upper neck portion of the annular mantle is compressed between the flange of the main shaft and the annular hydraulic piston.

Owner:TECHNOFAST IND

New energy automobile charging pile

InactiveCN112248858AAvoid accidental slidingFor quick replacementCharging stationsElectric vehicle charging technologyNew energyClassical mechanics

The invention relates to the technical field of automobile charging piles, in particular to a new energy automobile charging pile. Old, damaged or different voltage levels of charging piles can be replaced by quick disassembly; the charging pile comprises a lifting bearing mechanism, a linkage rotating arm mechanism, a clamping stabilizing mechanism, a supporting base mechanism, a follow-up driving mechanism, a protective cover mechanism, a follow-up opening and closing mechanism and an anti-collision guide mechanism, a bearing plate is pressed to move downwards through the weight of the charging pile, and two rotating force arms are driven to rotate in the downward moving process of the bearing plate; the left end and the right end of the charging pile are clamped and fixed through the two left clamping plates and the two right clamping plates, meanwhile, the four front clamping plates and the four rear clamping plates clamp and fix the four corners of the charging pile in the front-back direction, accidental sliding of the charging pile on the bearing plate is avoided, and meanwhile bolts or other fasteners do not need to be used for fixing the charging pile.

Owner:张杰

Drainage device for clinical use in neurosurgery

InactiveCN109718405AQuick and efficient replacementImprove convenienceSuction devicesVertical tubeEngineering

The invention relates to the technical field of medical instruments, and especially relates to a drainage device for clinical use in neurosurgery. The device includes a base plate; two vertical tubesare symmetrically arranged on the two sides on the upper end of the base plate; support bars are inserted in the vertical tubes; a pulling device matching the support bars is connected between the twovertical tubes; a supporting plate is arranged on the upper ends of the support bars; the upper end of the supporting plate is connected to supporting shafts through bearings; the upper ends of the supporting shafts are connected to gears; a gear belt is connected between the two gears; the upper end of the gear belt is equidistantly provided with multiple drainage bottles; the output end of a negative pressure pump is connected to a negative pressure pipe; a drainage tube is inserted in the upper end of a connection board; and the lower end of the connection board is provided with a connecting device matching the drainage bottles. The device can adjust the height of the drainage tube, and can efficiently and rapidly replace the drainage bottles, so that the device is strong in practicality.

Owner:周涛

Water treatment system

ActiveUS20210395119A1Quick and efficient replacementMitigates and eliminates leakageWater treatment parameter controlWaste water treatment from bathing facilitiesWater treatment systemElectrolysis

A water treatment system includes an ozone generator combined with an electrolytic chlorine generator in a compact, efficient and serviceable assembly. The system may include a modular and replaceable ozone generator, which allows a damaged or non-functional ozone generator to be quickly and efficiently replaced. In order to protect the ozone generator from damage, a fail-safe drain valve assembly may also be provided which will expel backflowing pool water before it is allowed to backflow into the ozone generator. The water treatment system may further include an insulated electrolytic chlorine generator that mitigates or eliminates current leakage for efficient operation.

Owner:INTEX MARKETING

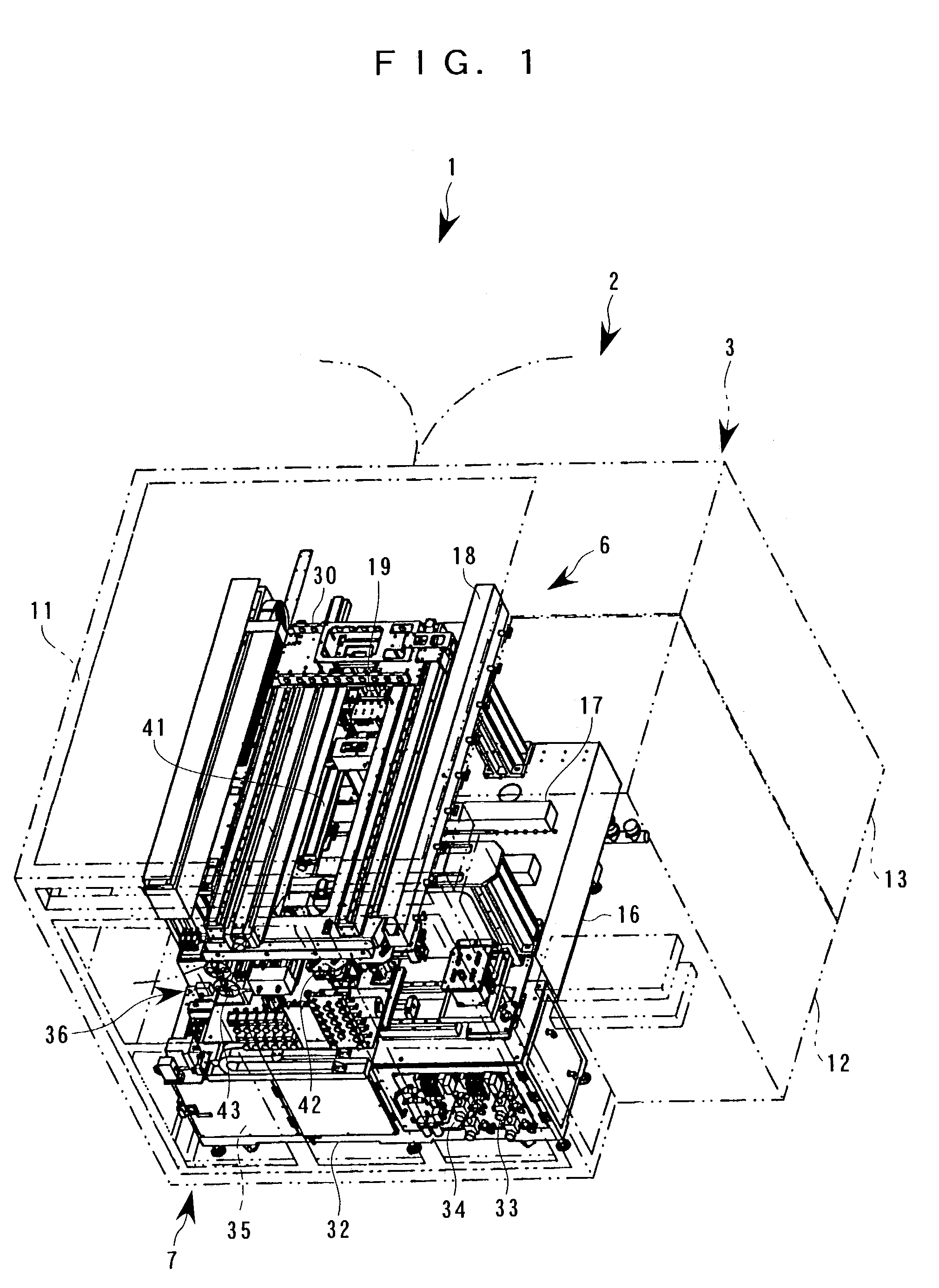

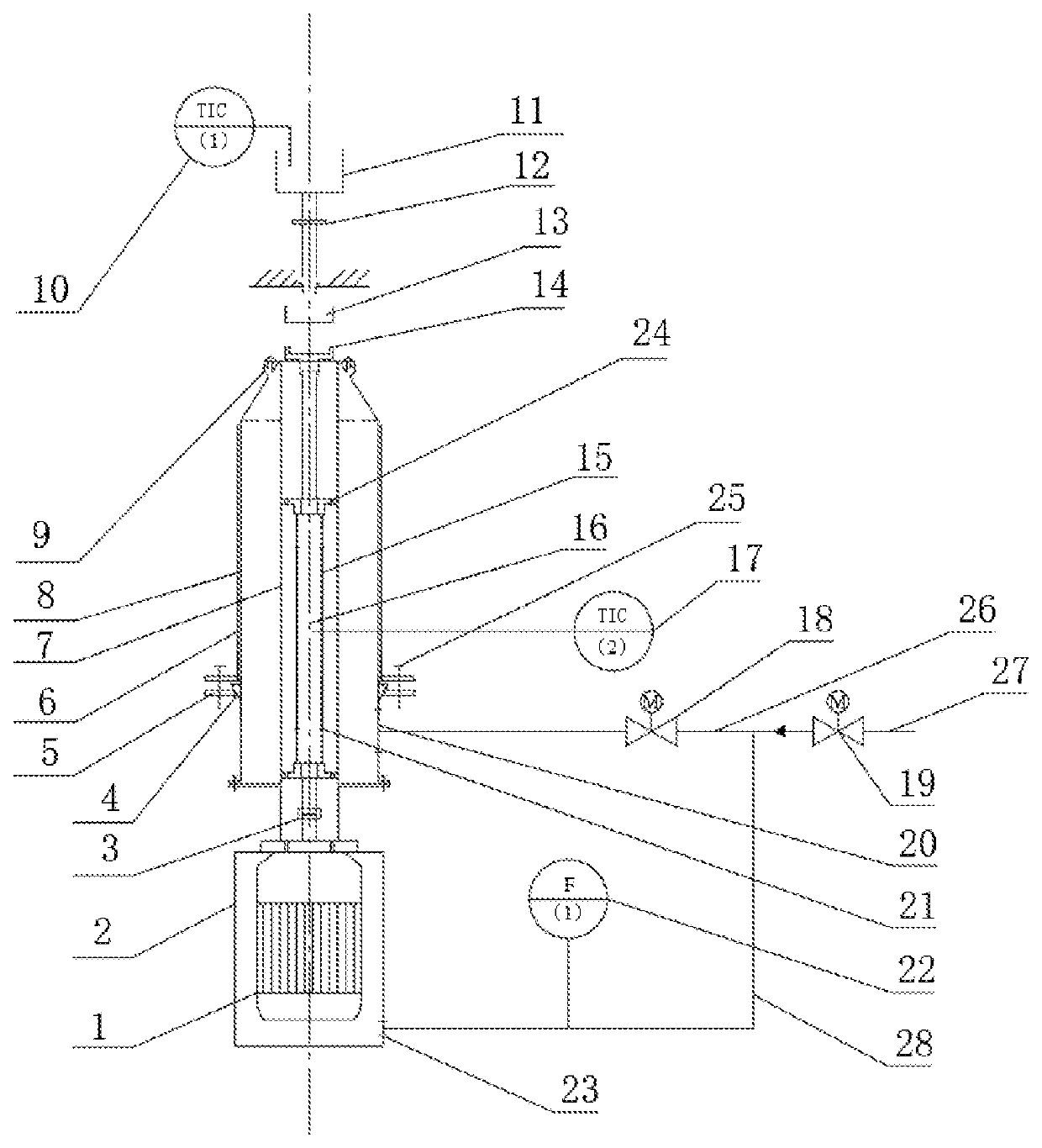

Control System and Method for Dry Centrifugal Granulation of Liquid Slag

ActiveUS20200232064A1Lower working temperatureSafe and stable operationProcess efficiency improvementThermodynamicsLiquid slag

A control system and method for dry centrifugal granulation of liquid slag are provided. The control system includes a granulator cold-air control unit and a feeding unit. The granulator cold-air control unit includes a granulator, a rotating shaft, a motor, and a cold-air supply unit. The granulator is fixed to the motor; the cold-air supply unit includes a shaft cooling air channel and an annular cooling air channel; the shaft cooling air channel consists of an inner duct sleeve and a shaft sleeve; the annular cooling air channel consists of the inner duct sleeve and an outer duct sleeve arranged at periphery of the inner duct sleeve, which have different external diameters; the feeding unit includes a slag dropping pipe arranged above the granulator; a sliding gate is arranged at a lower section of the slag dropping pipe, and an accident diversion spout is equipped.

Owner:XI AN JIAOTONG UNIV

Water treatment system

ActiveUS20210395118A1Quick and efficient replacementMitigates and eliminates leakageWater treatment parameter controlWaste water treatment from bathing facilitiesWater treatment systemElectrolysis

A water treatment system includes an ozone generator combined with an electrolytic chlorine generator in a compact, efficient and serviceable assembly. The system may include a modular and replaceable ozone generator, which allows a damaged or non-functional ozone generator to be quickly and efficiently replaced. In order to protect the ozone generator from damage, a fail-safe drain valve assembly may also be provided which will expel backflowing pool water before it is allowed to backflow into the ozone generator. The water treatment system may further include an insulated electrolytic chlorine generator that mitigates or eliminates current leakage for efficient operation.

Owner:INTEX MARKETING

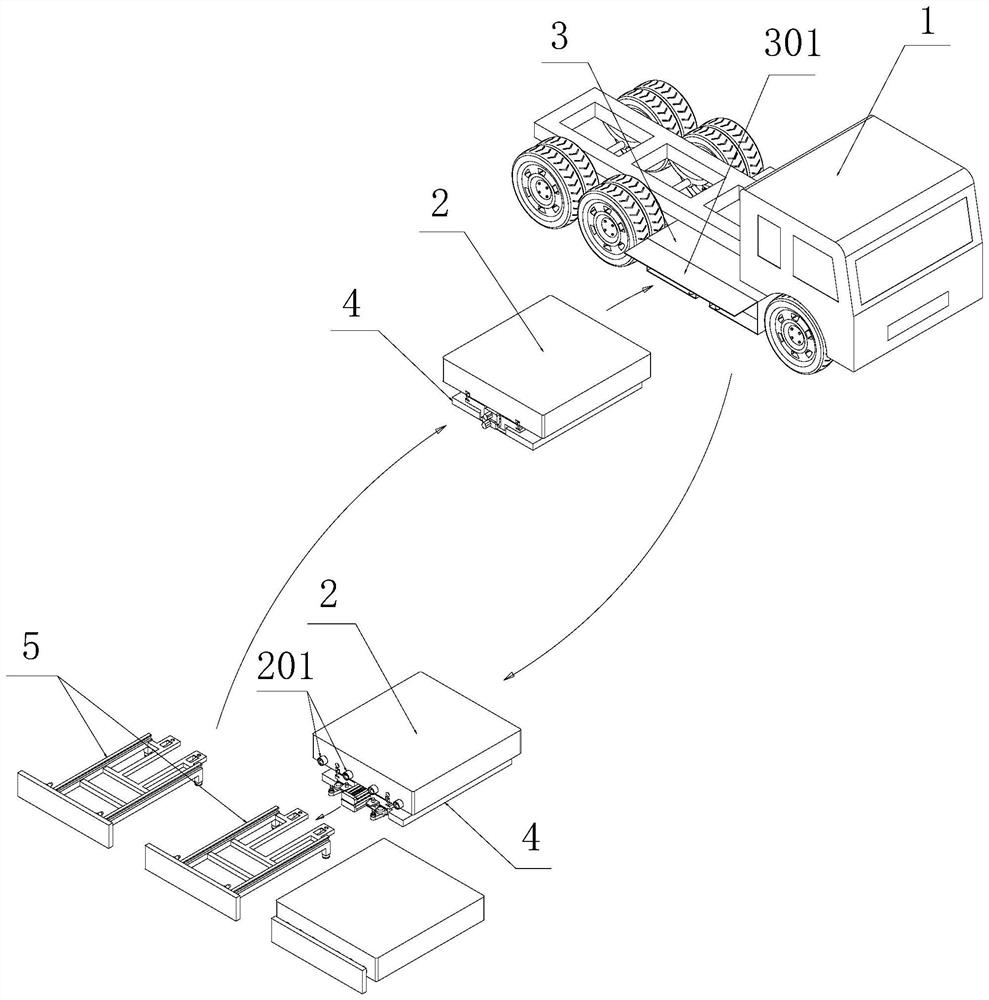

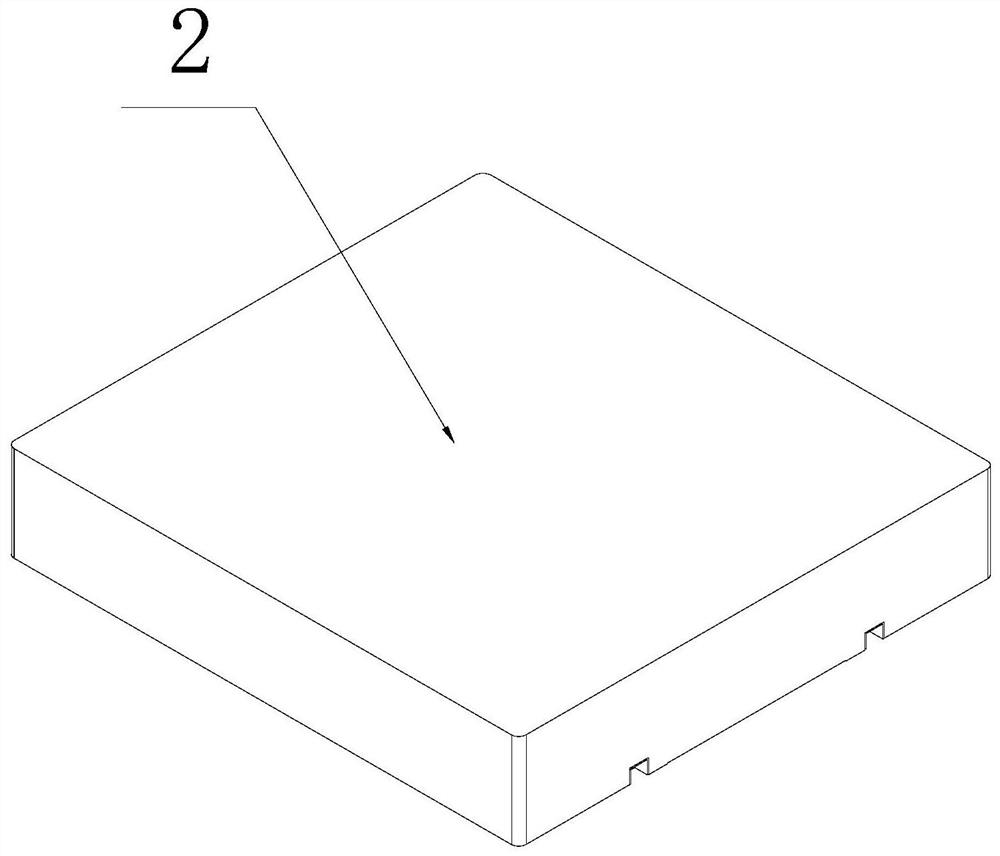

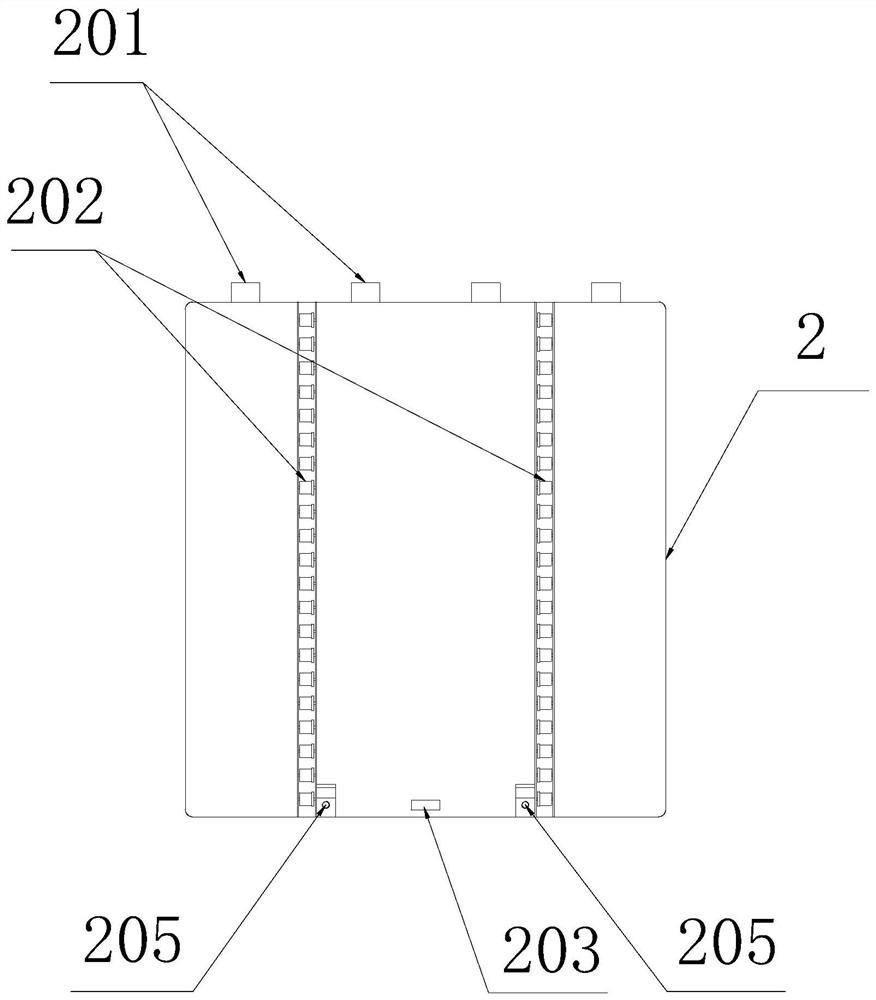

Electric commercial vehicle battery pack, charging pile matched with electric commercial vehicle battery pack and battery replacing trolley

PendingCN112319201AImprove power exchange efficiencyEfficient lateral plug replacementCharging stationsElectric propulsion mountingElectrical batteryMechanical engineering

The invention discloses a battery pack of an electric commercial vehicle, which is cuboid-shaped, is manufactured into a plurality of sizes and specifications according to different load capacities ofthe electric commercial vehicle, and is matched with battery cabins with corresponding sizes and specifications on the electric commercial vehicle. The battery pack is characterized in that a plug isarranged on the front end wall surface of the battery pack, and a connecting groove or a connecting bulge convenient to drag is arranged at the bottom of the battery pack close to the tail end wall surface; meanwhile, multiple rows of rollers or sliding blocks are arranged on the surface of the battery pack, and a plurality of screw holes are further formed in the bottom surface of the battery pack and used for being matched with screws to be fixed into the battery bin; and a plurality of guide positioning holes or guide positioning columns are also arranged on the wall surface of the front end of the battery pack. The invention further discloses a charging pile and a battery replacing trolley which are used in cooperation with the battery pack, transverse plugging charging and battery replacing of the battery pack of the electric commercial vehicle can be achieved, efficiency is improved, standardization and unification of battery replacing of the battery packs of different specifications are facilitated, and the problem that the electric commercial vehicle cannot be popularized can be solved.

Owner:陈维加

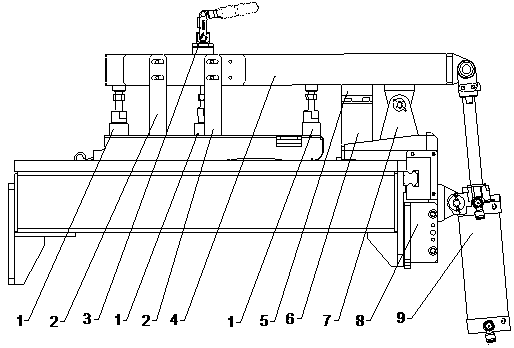

Carriage plate cylinder swing arm pressing quick positioning mechanism

InactiveCN108237328AQuick and efficient replacementEasy to moveLaser beam welding apparatusEngineeringBar pressing

The invention discloses a carriage plate cylinder swing arm pressing quick positioning mechanism. A welding clamping cylinder is connected with a cylinder swing arm; an overturning cylinder at the bottom of the front end of the cylinder swing arm is connected to a pressing quick positioning mechanism; a rotating pin shaft is arranged on an overturning cylinder connecting base; a positioning blockis arranged at the back part of the overturning cylinder connecting base, and is connected to a positioning adjusting block; the positioning adjusting block is fixed on a tool chassis; the pressing quick positioning mechanism comprises a linear slide rail, a ball slide block and a guide rail protective cover; the linear slide rail is fixed on the tool chassis; the ball slide block is movably connected to the linear slide rail; multiple pressing rod and pressing block mechanisms and multiple positioning baffle plates are arranged at the back end of the cylinder swing arm for fixing plate coresof carriage plate parts and reinforcing ribs on the tool chassis; and presses are arranged at the top of the cylinder swing arm, and are connected with the pressing rod and pressing block mechanisms.The carriage plate cylinder swing arm pressing quick positioning mechanism greatly shortens the operation time, greatly improves the repeated positioning precision, obviously saves the labor time, andis effective and convenient to operate.

Owner:昆山德系智能装备有限公司

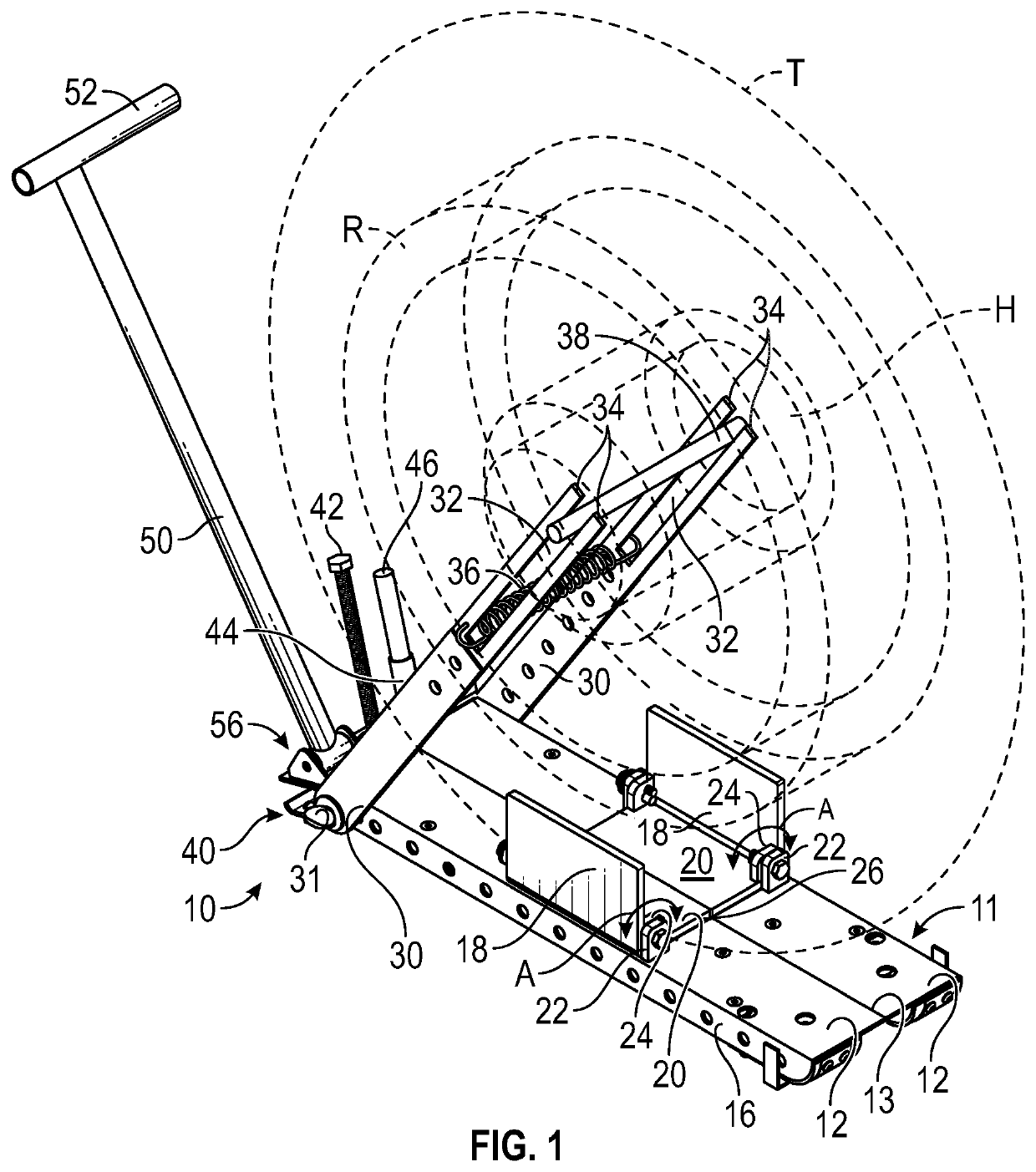

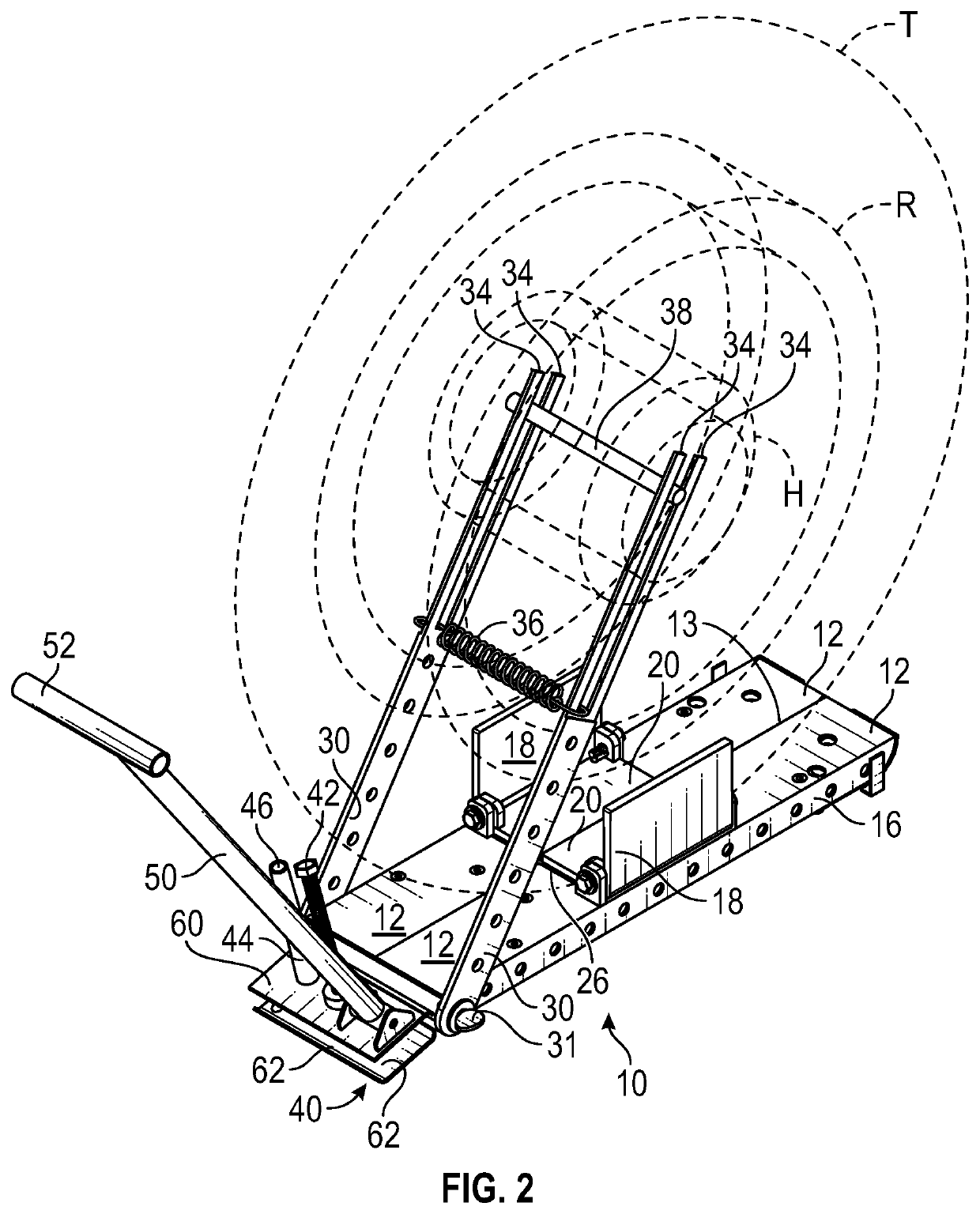

Vehicle Tire/Wheel Changing Device

ActiveUS20210252911A1Quick and efficient replacementSpin easilyWheel mounting apparatusMotorcyclesControl theoryCarriage

A device is provided for changing a wheel of a vehicle comprising a carriage assembly including two platform elements running longitudinally with one another and substantially parallel. First and second swingarms are connected to respective platform elements. The swingarms are rotatably positionable at a desired height above the carriage. A lift mechanism selectively raises or lowers the carriage during use. A tow bar allows the carriage to be pushed or pulled on wheels mounted to the carriage. A method of the invention includes mounting the wheel on the platform elements, raising free ends of the swingarms to a desired height so a knock out bar may be placed through a hub of the wheel, operating the lift mechanism to raise the wheel to a desired height, and aligning the wheel with the vehicle so the wheel may be secured to the vehicle.

Owner:COMBS SAM

Auxiliary device for upper carrier roller replacement of belt conveyor

InactiveCN112298954AExquisite structure designQuick and efficient replacementRollersEngineeringUltimate tensile strength

The invention discloses an auxiliary device for upper carrier roller replacement of a belt conveyor. The auxiliary device comprises a belt supporting assembly used for supporting and lifting a conveying belt of the belt conveyor, a lifting assembly used for driving the belt supporting assembly to ascend and descend and a supporting assembly used for supporting the lifting assembly, wherein the supporting assembly can be arranged on a middle frame of the belt conveyor in a hung mode; and the lifting assembly is arranged on the supporting assembly, the belt supporting assembly is connected withthe lifting assembly, and the belt supporting assembly is driven by the lifting assembly to lift the conveying belt upwards, so that an operation space for replacing an upper carrier roller is formedbetween the upper carrier roller and the conveying belt. The auxiliary device is ingenious in structural design, the belt supporting assembly is driven by the lifting assembly to ascend and descend tolift the conveying belt upwards, so that the operation space for replacing the upper carrier roller is formed between the upper carrier roller and the conveying belt, the upper carrier roller is effectively and rapidly replaced, and operation can be achieved by one person, so that labor force is greatly saved, labor intensity is reduced, and the efficiency of replacing the upper carrier roller isimproved.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com