Tunnel lining thickness-lack reinforcing structure and construction method

A construction method and lining technology, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve problems such as tunnel lining thickness, and achieve the effects of saving maintenance investment, ensuring safety, and quickly replacing lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

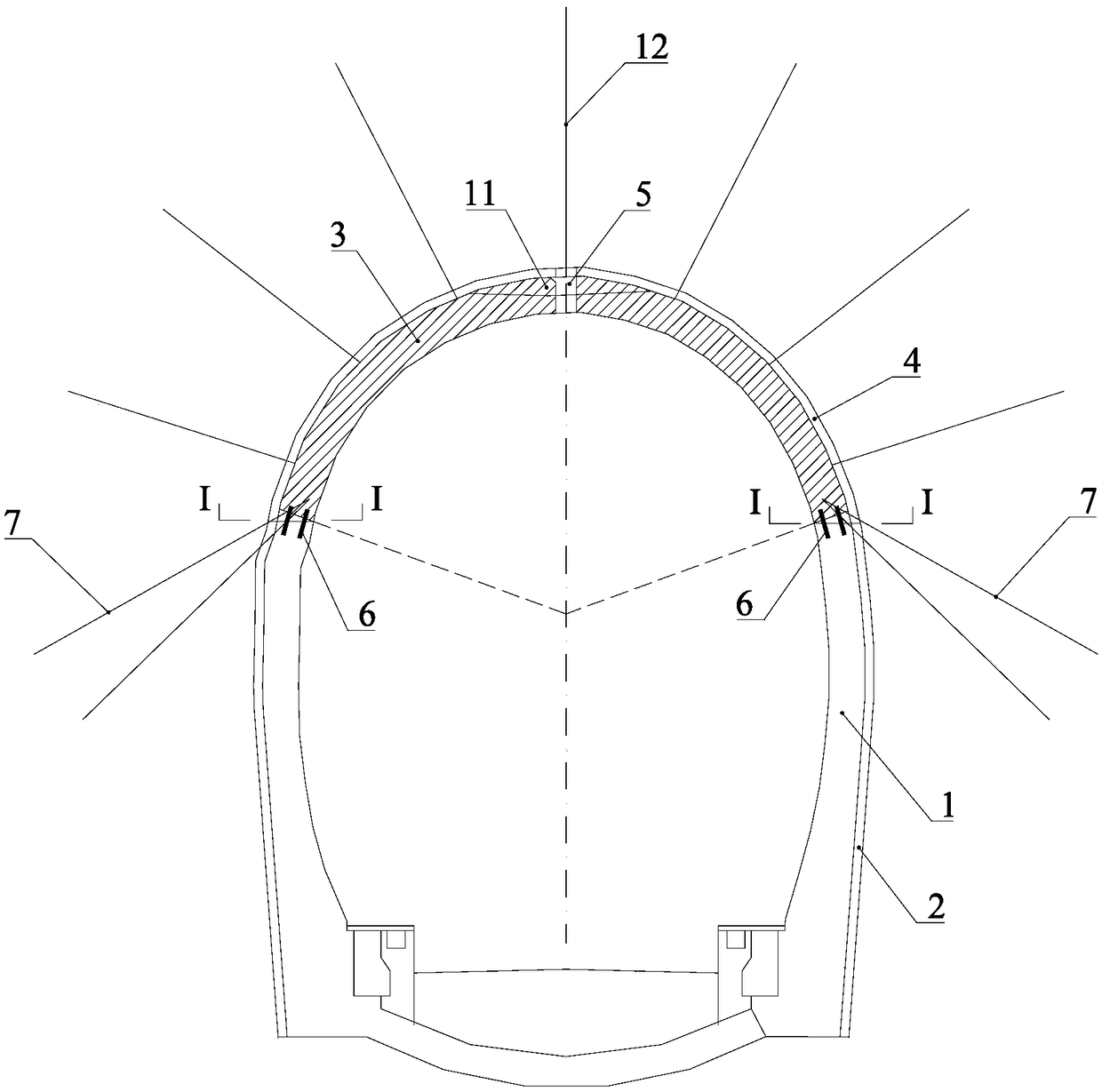

[0033] Such as Figure 1-Figure 3 As shown, a tunnel lining underthick reinforcement structure includes newly-built secondary lining 3 and newly-built primary support 4 in the underthick area of tunnel lining.

[0034] The newly-built initial support 4 is connected with the existing initial support 2, and several mortar anchors 7 are arranged at the junction of the newly-built initial support 4 and the existing initial support 2, through which the mortar anchor 7 to enhance the stability of the connection.

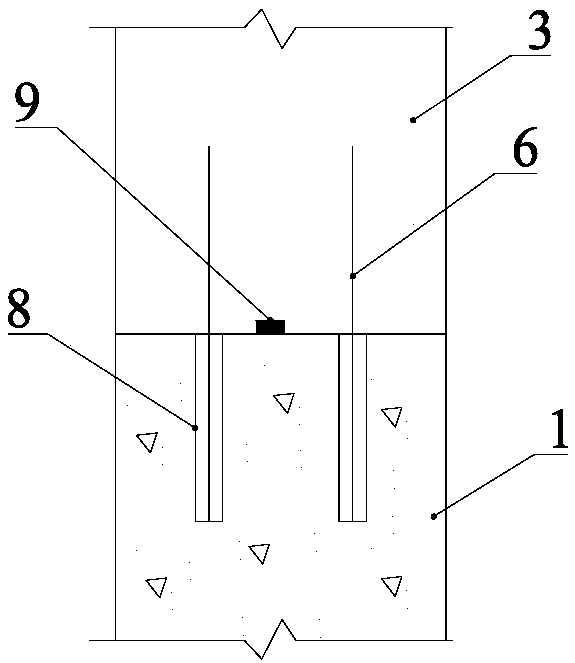

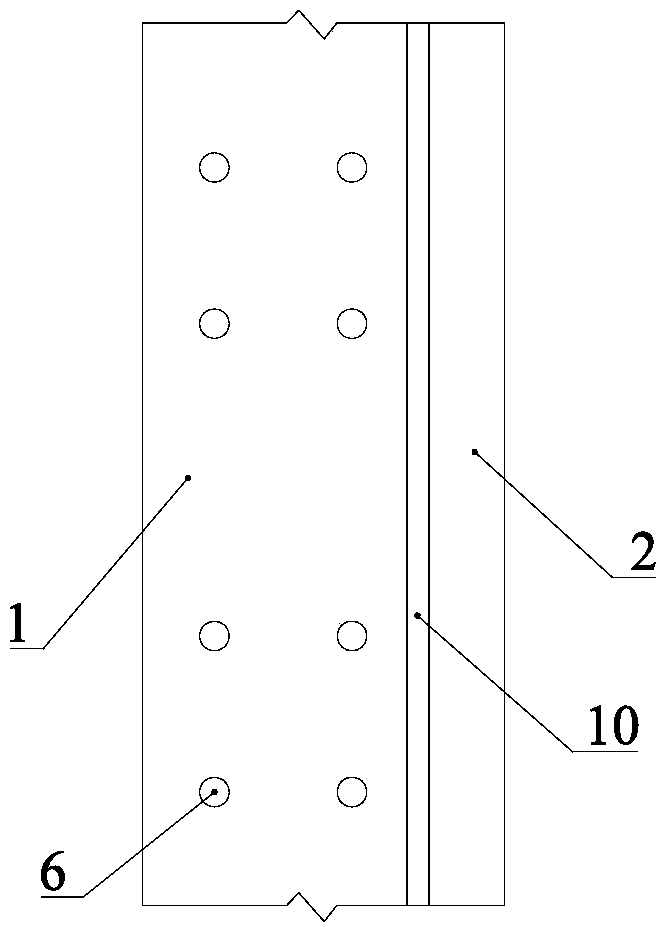

[0035] The newly-built secondary lining 3 and the existing secondary lining 1 are connected by several brazing nails 6, and the brazing nails 6 are connected on the connection surface between the newly-built secondary lining 3 and the existing secondary lining 1 Longitudinal and transverse intervals are arranged, and a planting glue 8 is provided at each of the brazing nails 6 . Specifically, holes are drilled on the existing secondary lining 1 , brazing nails 6 are im...

Embodiment 2

[0039] A construction method for underthickness reinforcement structure of tunnel lining, comprising the following steps:

[0040] Step 1: Before replacing the under-thick section of the lining, the defect rectification of the adjacent section should be completed first, and temporary steel frame supports 14 are installed at the under-thick section of the tunnel lining and on both sides, and the temporary steel frame supports 14 are arranged at longitudinal intervals;

[0041] Step 2: Use grouting steel flower pipes 12 to reinforce the surrounding rock in the area where the tunnel lining is not thick enough, and the grouting steel flower pipes 12 are arranged at plum blossom-shaped intervals in the replacement section;

[0042] Step 3: Dismantling several replacement sections 13 in the under-thick area of the tunnel lining at intervals, erecting permanent steel frame support 15 in the replacement section 13, and spraying concrete to form new primary support 4, such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com