Electric commercial vehicle battery pack, charging pile matched with electric commercial vehicle battery pack and battery replacing trolley

A technology for battery packs and commercial vehicles, which is applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems that cannot be popularized and popularized, many battery specifications, and complicated battery replacement equipment, and achieve efficient horizontal plug-in replacement, The effect of high power exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

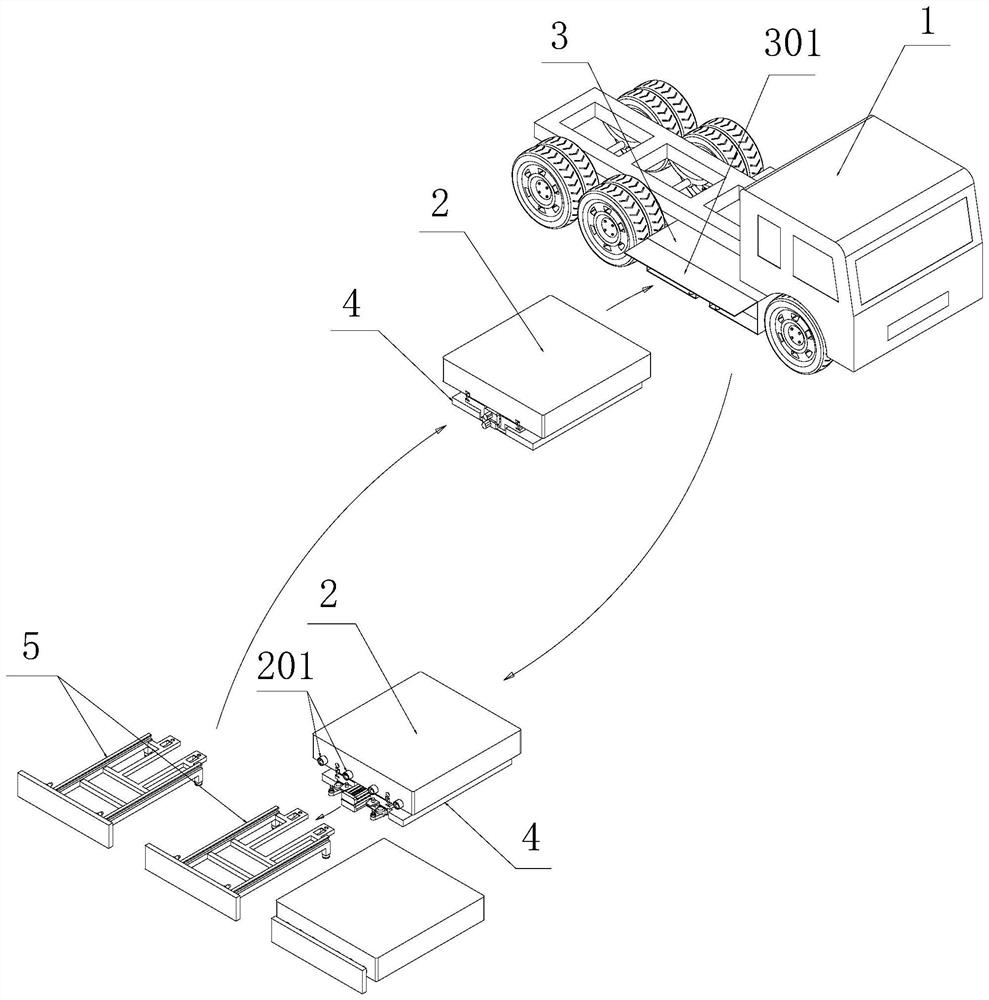

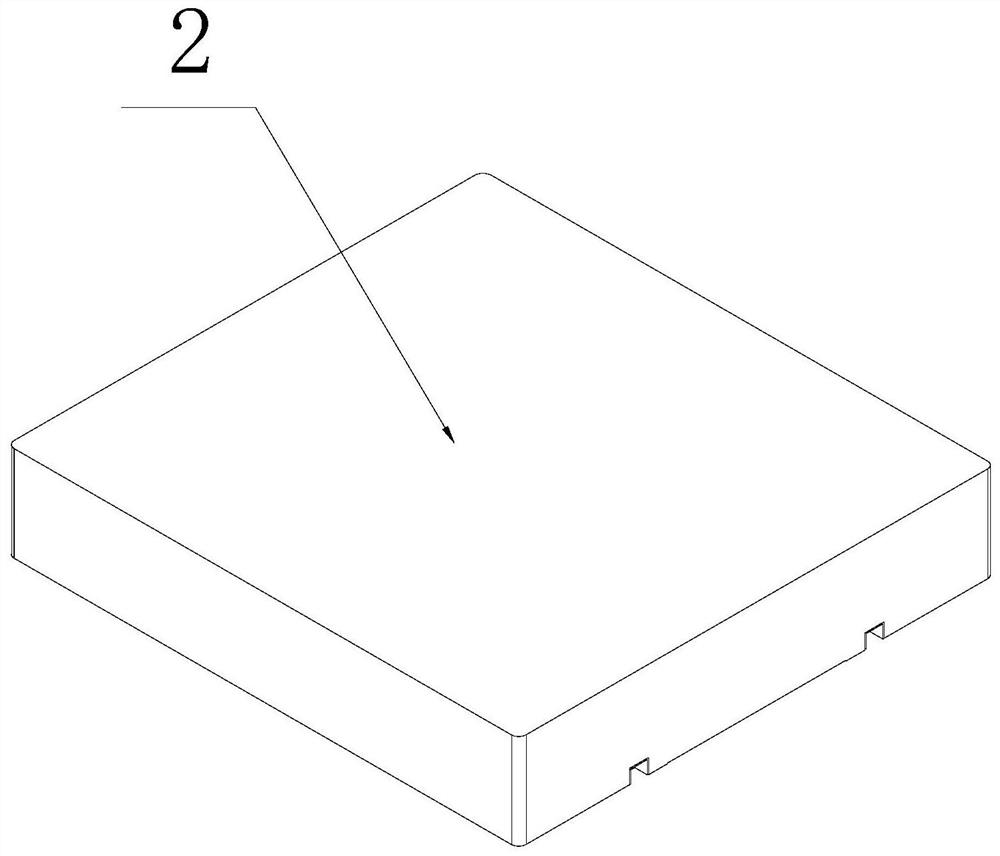

[0068] Example 1: Combine first Figure 2~4To illustrate the battery pack 2, the battery pack 2 in the present invention is designed in a cuboid shape, and is made into multiple sizes and specifications according to the load capacity of the electric commercial vehicle 1, and corresponds to battery compartments 3 of different sizes and specifications. For example, the electric commercial vehicle 1 exemplified in this embodiment is a conventional electric container semi-trailer tractor with a total mass of 49 tons, and the size specification of the corresponding battery pack 2 is made as 2150x2000x400, and the unit is mm .

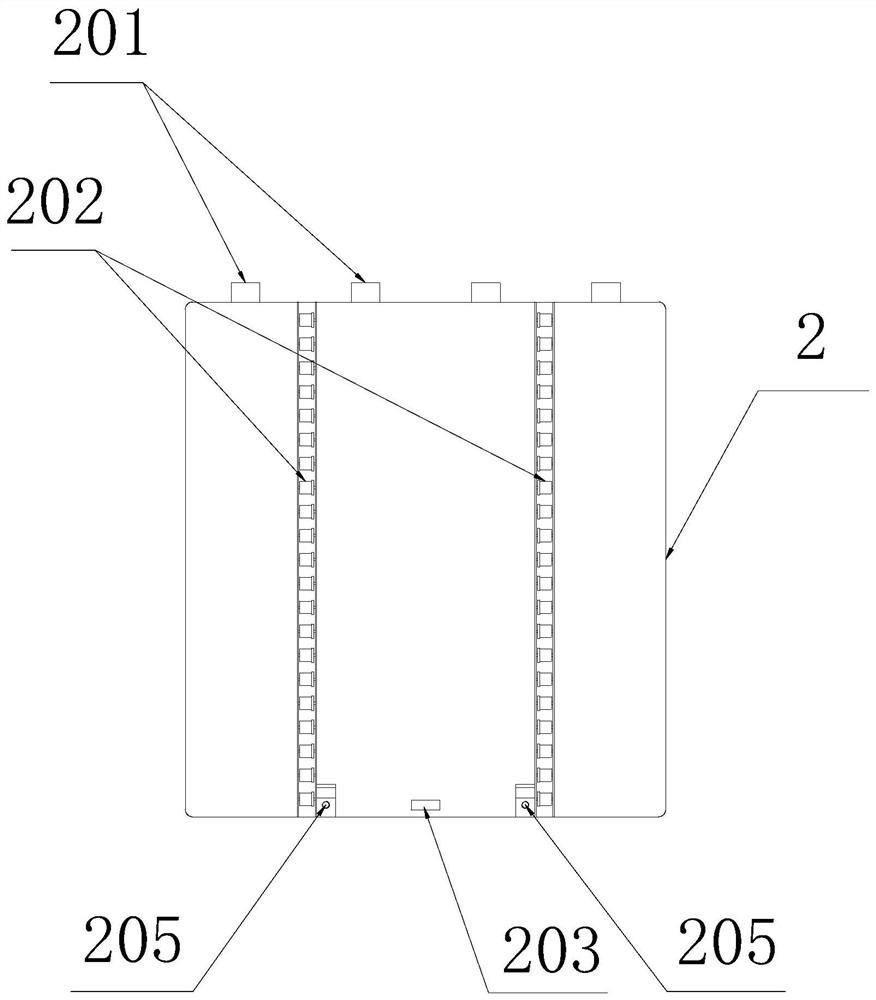

[0069] Such as image 3 and Figure 4 As shown, the bottom of the battery pack 2 is symmetrically and parallelly provided with two rows of rollers 202 along the centerline of its length direction. At the same time, one end wall of the battery pack 2 is provided with four plugs 201 side by side, which are used to cooperate with the connecting socket 302 in...

Embodiment 2

[0073] Example 2: Combining Figure 8~10 As shown, the battery exchange trolley 4 is further described. The battery exchange trolley 4 in this embodiment has a base 401 provided with a traveling mechanism and a lifting frame 403 driven up and down by a lifting mechanism 402 provided on the base 401. The lifting frame 403 is provided with There is a frame track 404 that cooperates with the battery pack 2 roller 202, and the telescopic frame 408 is connected to the lifting frame 403 via the second translation drive mechanism 407. The telescopic frame 408 is provided with a device for pushing and pulling the battery pack 2 to move along the frame rail 404 to enter and exit the battery compartment. 3, the battery pack push-pull mechanism includes a first translation drive mechanism 405 and a translation block 406 driven by it. The translation block 406 and the bottom end of the battery pack 2 are designed with a keyway structure that can be fitted and connected. The telescopic fra...

Embodiment 3

[0077] Embodiment 3: as Figure 11~Figure 13 The charging pile 5 is illustrated as shown. The charging pile 5 is composed of a bracket 501 , a pile rail 502 arranged horizontally on the bracket 501 for sliding the battery pack 2 , and a plug-in panel 503 connected to the end of the pile rail 502 . The pile rails 502 are two parallel ones, which also cooperate with the rollers 202 on the battery pack 2 . The plug-in panel 503 at the end of the pile rails 502 is provided with four charging sockets 504 connected side by side with the plug 201 on the battery pack 2 . At the same time, the plug-in panel 503 is also provided with charging pile guiding and positioning posts 505 corresponding to the two guiding and positioning holes 204 on the aforementioned battery pack 2 for guiding and positioning when the battery pack 2 is inserted.

[0078] and if Figure 11 and Figure 12 As shown, the bracket 501 is provided with two pile positioning holes 501a, which are used to cooperate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com