New energy automobile charging pile

A technology of new energy vehicles and charging piles, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of inconvenient disassembly, different voltage levels, etc., and achieve the effect of saving time, saving energy, and avoiding accidental sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

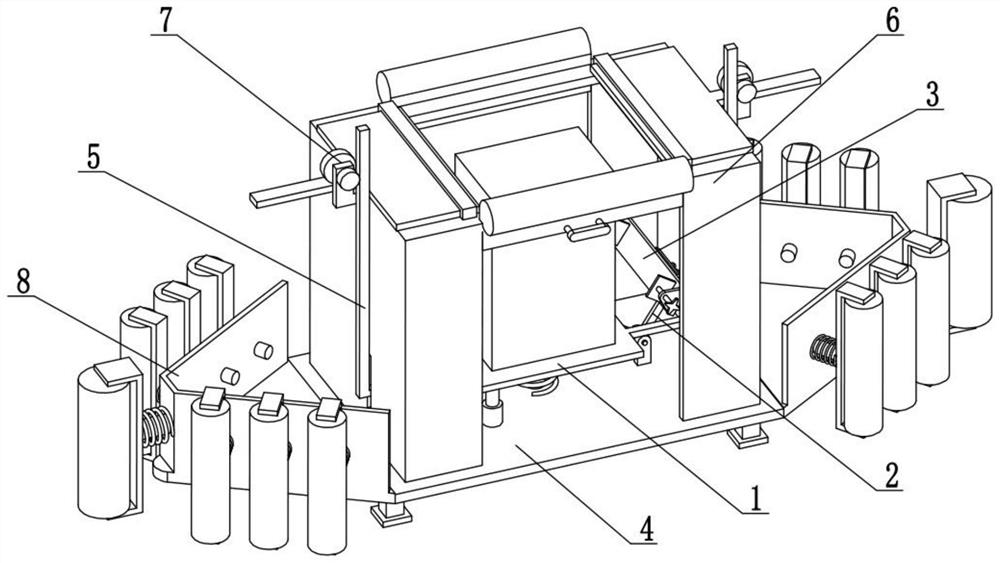

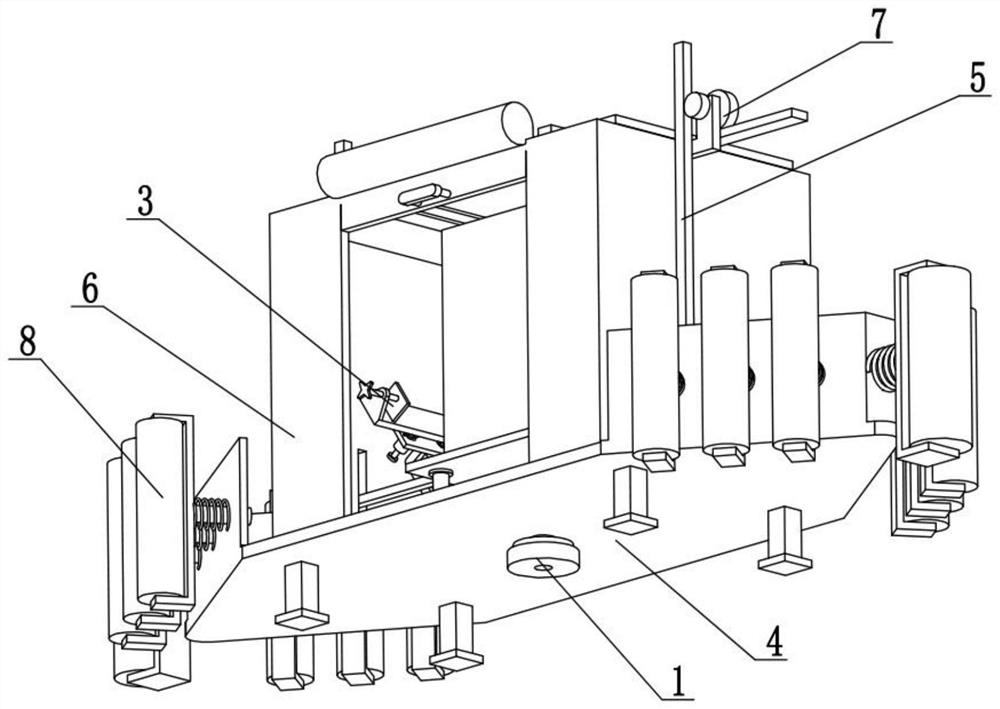

[0028] Combine below Figure 1-10 Describe this embodiment. The present invention relates to the technical field of automobile charging piles, more specifically, new energy automobile charging piles, including a lifting load-bearing mechanism 1, a linkage arm mechanism 2, a clamping and stabilizing mechanism 3, a supporting base mechanism 4, a follow-up Drive mechanism 5, protective cover mechanism 6, follow-up opening and closing mechanism 7 and anti-collision guiding mechanism 8, described two anti-collision guiding mechanisms 8 are respectively connected to the left and right ends of supporting base mechanism 4, and protective cover mechanism 6 is connected on On the support base mechanism 4, the lifting load-bearing mechanism 1 is connected to the support base mechanism 4, and the two linkage arm mechanisms 2 are connected to the lifting load-bearing mechanism 1 and the support base mechanism 4, and the two clamping and stabilizing mechanisms 3 are respectively connected to...

specific Embodiment approach 2

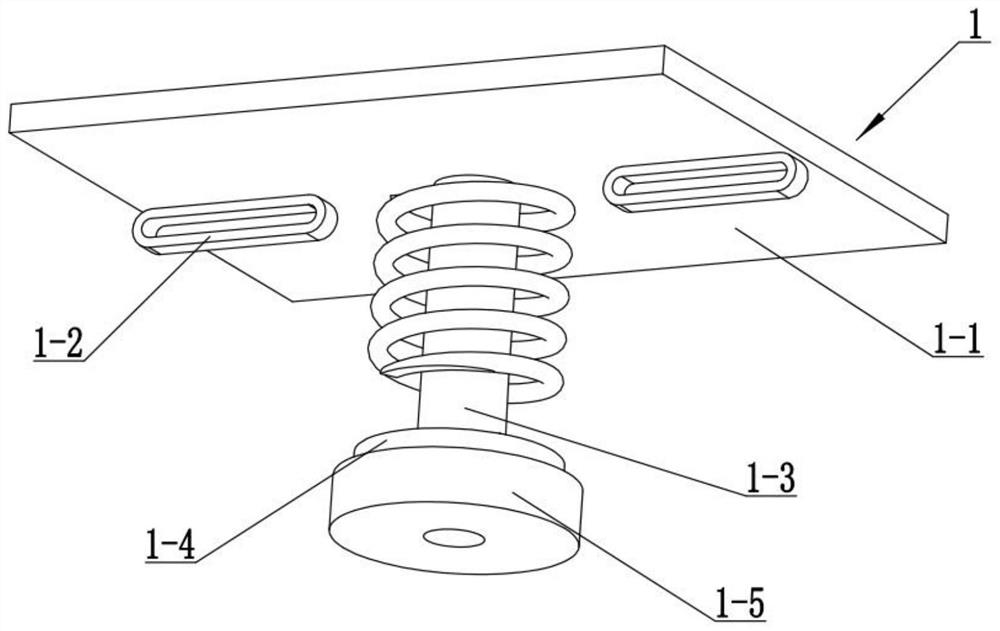

[0031] Combine below Figure 1-10Describe this embodiment, this embodiment will further explain the first embodiment, the lifting load-bearing mechanism 1 includes a load-bearing plate 1-1, a follow-up slide 1-2, a hollow tube 1-3, a circular disc 1- 4 and the annular rubber pad 1-5, the annular rubber pad 1-5 is fixedly connected to the bottom end of the ring disc 1-4, the ring disc 1-4 is fixedly connected to the bottom end of the hollow tube 1-3, and the hollow tube 1-3 is fixedly connected to the bottom end of the load-bearing plate 1-1, and the two follow-up slideways 1-2 are respectively fixedly connected to the left and right ends of the bottom end of the load-bearing plate 1-1.

[0032] Place the charging pile on the load-bearing plate 1-1, and connect the power cord on the charging pile to the power supply through the hollow tube 1-3. When the load-bearing plate 1-1 falls, it will drive the hollow tube 1-3 to drop , the hollow tube 1-3 drives the ring disc 1-4 to pre...

specific Embodiment approach 3

[0034] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the linkage arm mechanism 2 includes a rotating force arm 2-1, a sliding shaft 2-2, a limit plate 2-3 and a sliding sleeve 2-4 , the two sliding sleeves 2-4 are fixedly connected to the limiting plate 2-3, the limiting plate 2-3 is fixedly connected to the limiting plate 2-3, and the bottom end of the limiting plate 2-3 is fixedly connected to the sliding shaft 2-2, the two sliding shafts 2-2 are respectively slidably connected in the two follow-up slideways 1-2.

[0035] When the load-bearing plate 1-1 descends, it will drive the two accompanying slideways 1-2 to descend together, while the two sliding shafts 2-2 will slide in the two accompanying slideways 1-2 respectively, and the two rotating forces will simultaneously The arm 2-1 rotates on the two rotating seats 4-4, so that the two rotating force arms 2-1 rotate to the middle at the same time, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com