Drilling machine with functions of automatically replacing and cleaning drilling rods

An automatic replacement and drill pipe technology, applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problems of increasing the work intensity of workers, destroying the structural strength of drill pipes, and enhancing labor intensity, so as to achieve rapid replacement and prolong service life. , the effect of speeding up the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

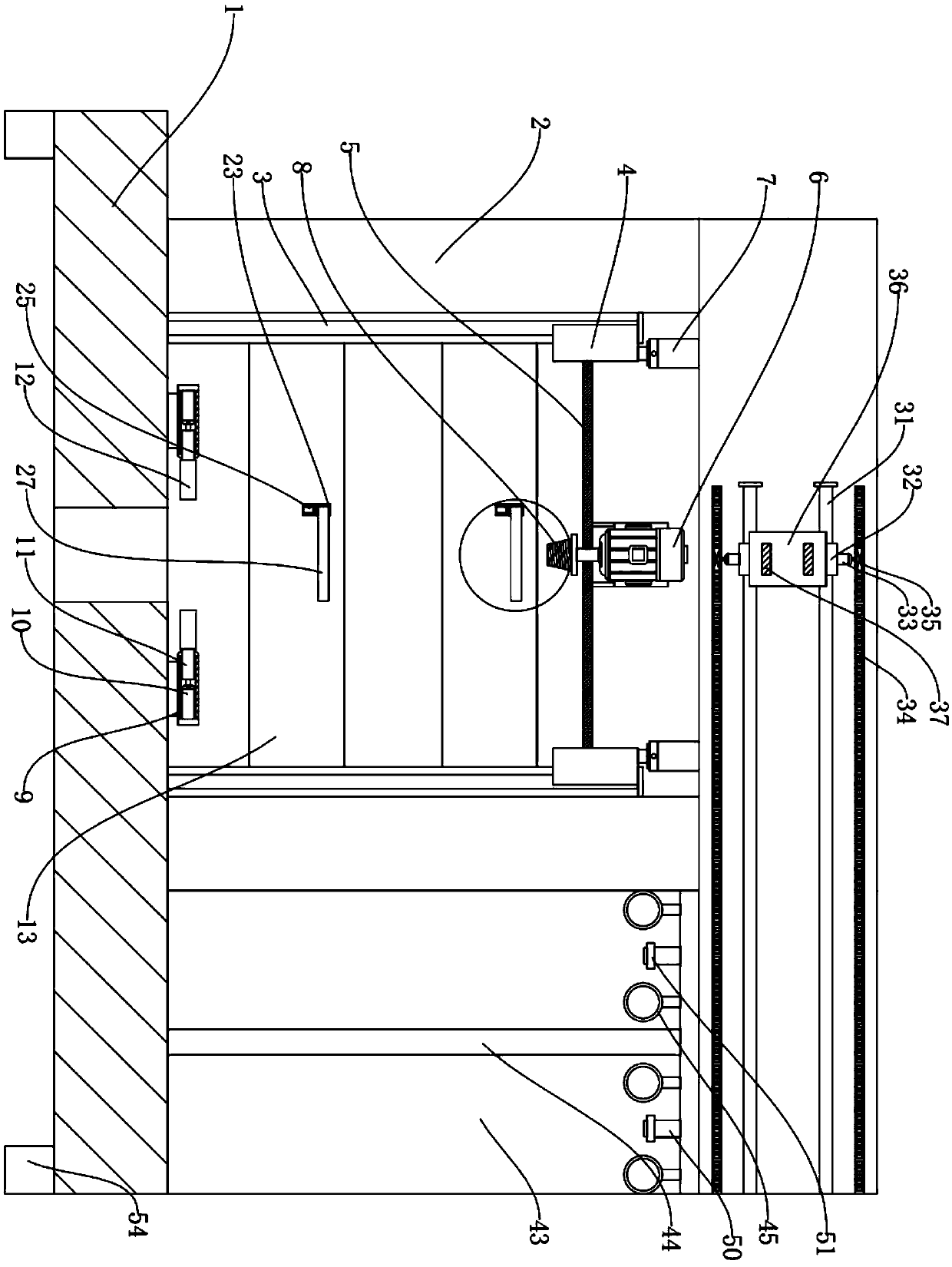

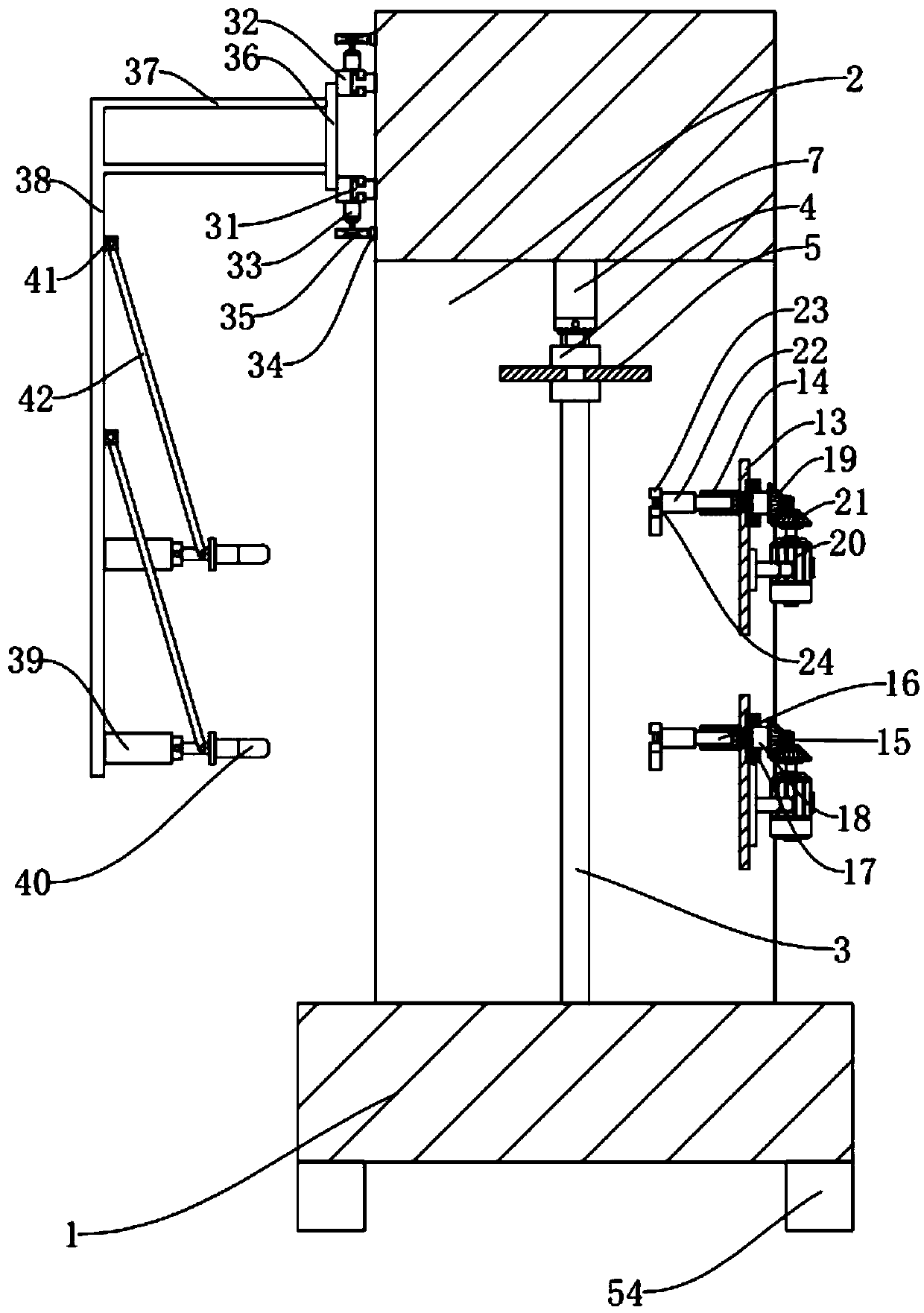

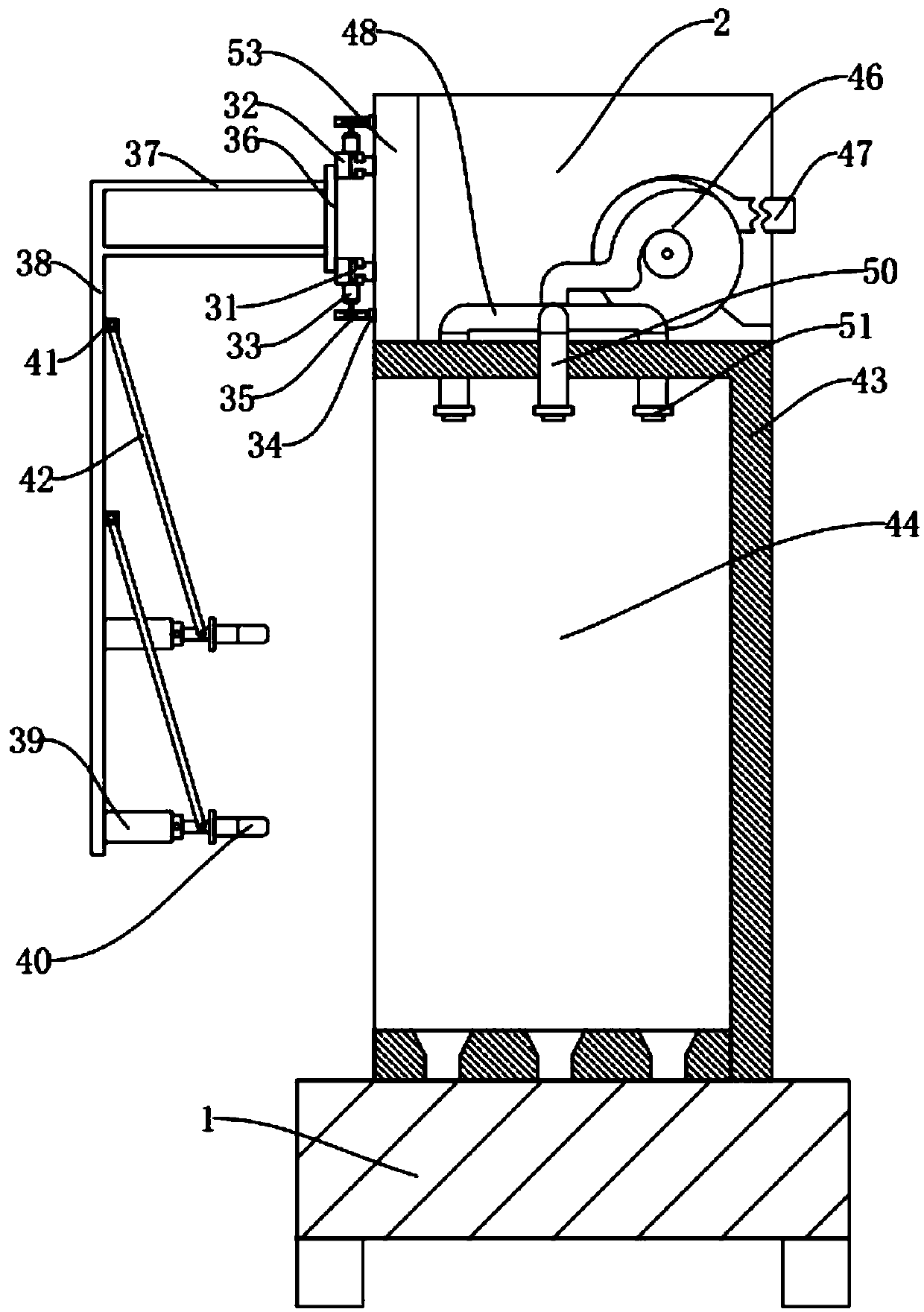

[0051] Example: When in use, the drilling rig is parked next to the drilling hole, and is fixed by the drilling rig base 1 equipment. The drilling rig base 1 has drilling holes, the device is supported by the portal frame 2, and the controller sends a signal to the driver. After the signal is detected, the motor of the drilling rig is controlled to rotate, the threaded block 8 is connected to the driving end of the drilling motor 6, the solenoid valve is controlled by the controller, and the telescopic end of the multi-stage hydraulic cylinder 7 is extended or retracted. Block 4, make it descend on the vertical slide rail 3, and then drive the horizontal plate 5 to move down, and the thread block 8 of the drilling motor 6 is engaged with the internal thread of the rear end of the drill pipe, so that the two are locked tightly, and the pressure is pressed while rotating. When the drill rod is drilled above the drilling rig base 1, the telescopic end of the electric push rod 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com