Carriage plate cylinder swing arm pressing quick positioning mechanism

A technology for positioning mechanism and carriage board, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of installation and fixing, troublesome operation, waste of time, etc., and achieves convenient movement, convenient and effective operation, and simplified operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

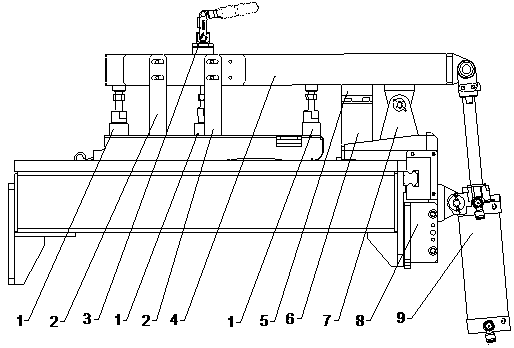

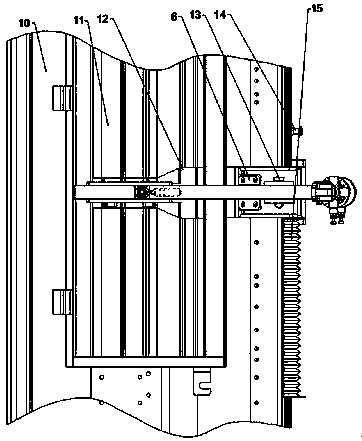

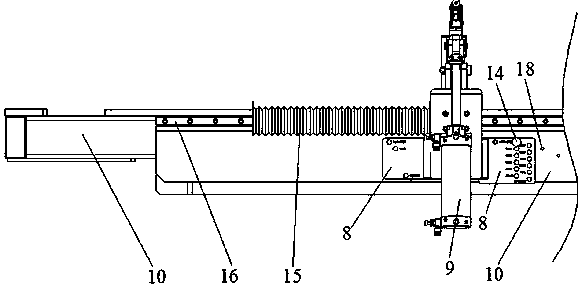

[0018] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a carriage plate cylinder swing arm pressing fast positioning mechanism is composed of a tooling chassis 10, a press fit 3, a cylinder swing arm 4, a turning cylinder connecting seat 7, a welding clamping cylinder 9 and a pressing fast positioning mechanism. The welding clamping cylinder 9 is connected with the cylinder swing arm 4, and the turning cylinder connecting seat 7 at the bottom of the front end of the cylinder swing arm 4 is connected to the pressing quick positioning mechanism. The positioning block is arranged at the rear, and the positioning block 5 is connected to the positioning adjustment block 6, and the positioning adjustment block 6 is fixed on the tooling chassis 10, and the pressing fast positioning mechanism includes a linear slide rail 16, a ball slider 17 and a guide rail protective cover 15 , the linear slide rail 16 is fixed on the tooling chassis 10, the ball slider 17 is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com