Auxiliary device for upper carrier roller replacement of belt conveyor

A belt conveyor and auxiliary device technology, which is applied to conveyor objects, transportation and packaging, rollers, etc., can solve the problems of difficulty in effectively and quickly replacing the upper rollers, poor construction conditions, and limited working space. Sophisticated design, lightweight structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

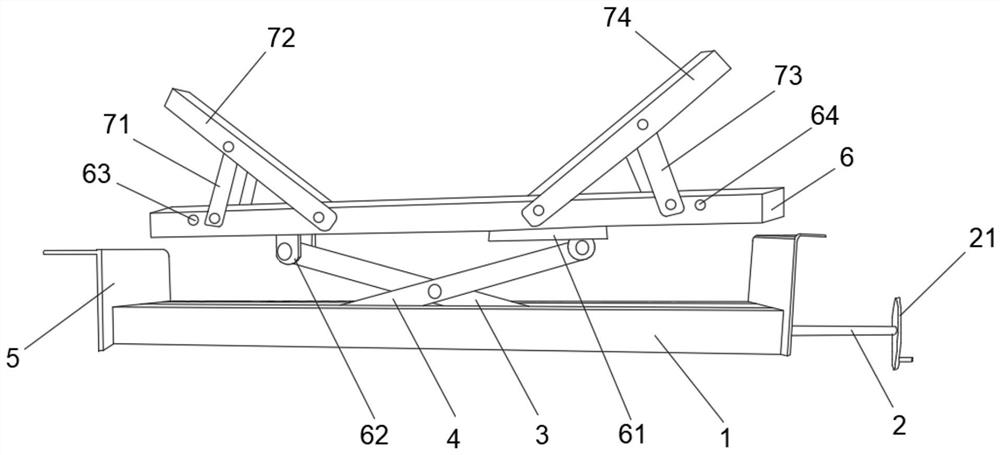

[0031] Such as figure 1 and 2 As shown, the auxiliary device for replacing idler rollers on a belt conveyor provided in this specific embodiment includes a supporting belt assembly for supporting the conveyor belt of the belt conveyor, a lifting assembly for driving the lifting of the supporting belt assembly, and a lifting assembly for The supporting assembly supporting the lifting assembly, the supporting assembly can be suspended and installed on the intermediate frame of the belt conveyor, the lifting assembly is arranged on the supporting assembly, the supporting belt assembly is connected with the lifting assembly, and the supporting belt assembly is driven by the lifting assembly to be replaced The conveyor belt at the upper idler roller is lifted up so that the working space for replacing the upper idler roller is formed between the upper idler roller and the conveyor belt.

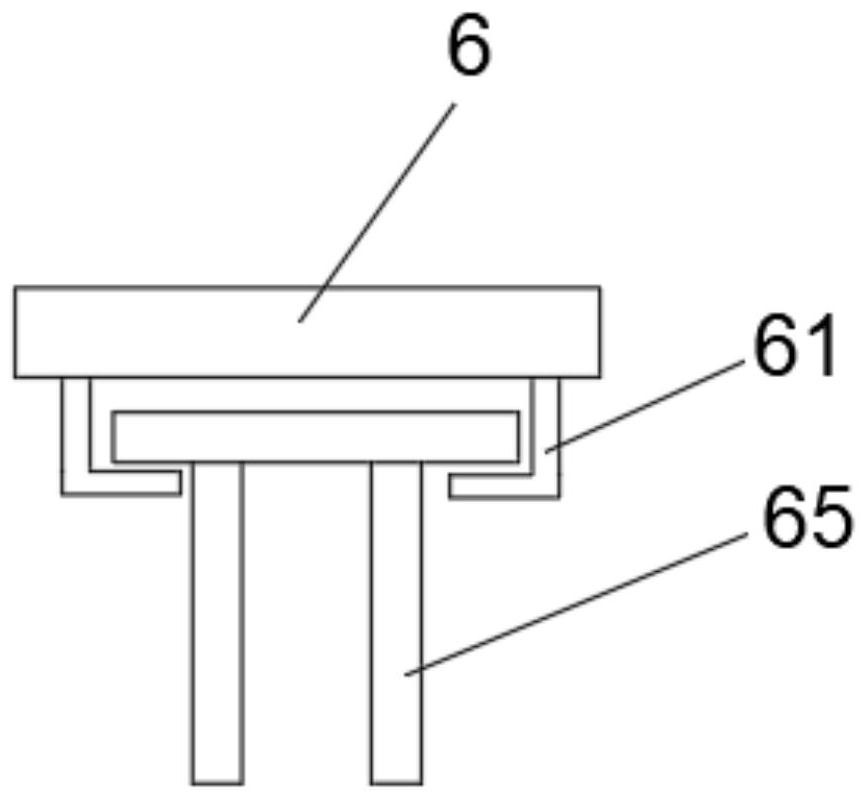

[0032] The support assembly includes a connecting frame 1 and a hanging plate 5 arranged at b...

Embodiment 2

[0046] This specific embodiment provides another auxiliary device for replacing idler rollers on a belt conveyor. The structure of this auxiliary device is basically the same as that of the auxiliary device in Embodiment 1. Plate 5 is buckled on the intermediate frame, the first connecting plate and the second connecting plate have the same structure, the first connecting plate includes an outer square steel pipe and a built-in square steel pipe, the outer square steel pipe is slidably sleeved on the built-in square steel pipe, two The hanging plate 5 is respectively arranged on the outer end of the outer square steel pipe and the inner square steel pipe. The auxiliary device can be applied to the upper roller of the conveyor with a bandwidth of 650-2000mm through the telescopic setting of the connecting frame 1. Replacement, of course, the change of the length of the connecting frame 1 can also be realized by replacing the connecting frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com