Wave airfoil blade and wind turbine

An airfoil blade and wave technology, which is applied in the field of wind power generation equipment, can solve problems such as poor stability of wave airfoil blades, and achieve the effects of improving price competitiveness, increasing power generation and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

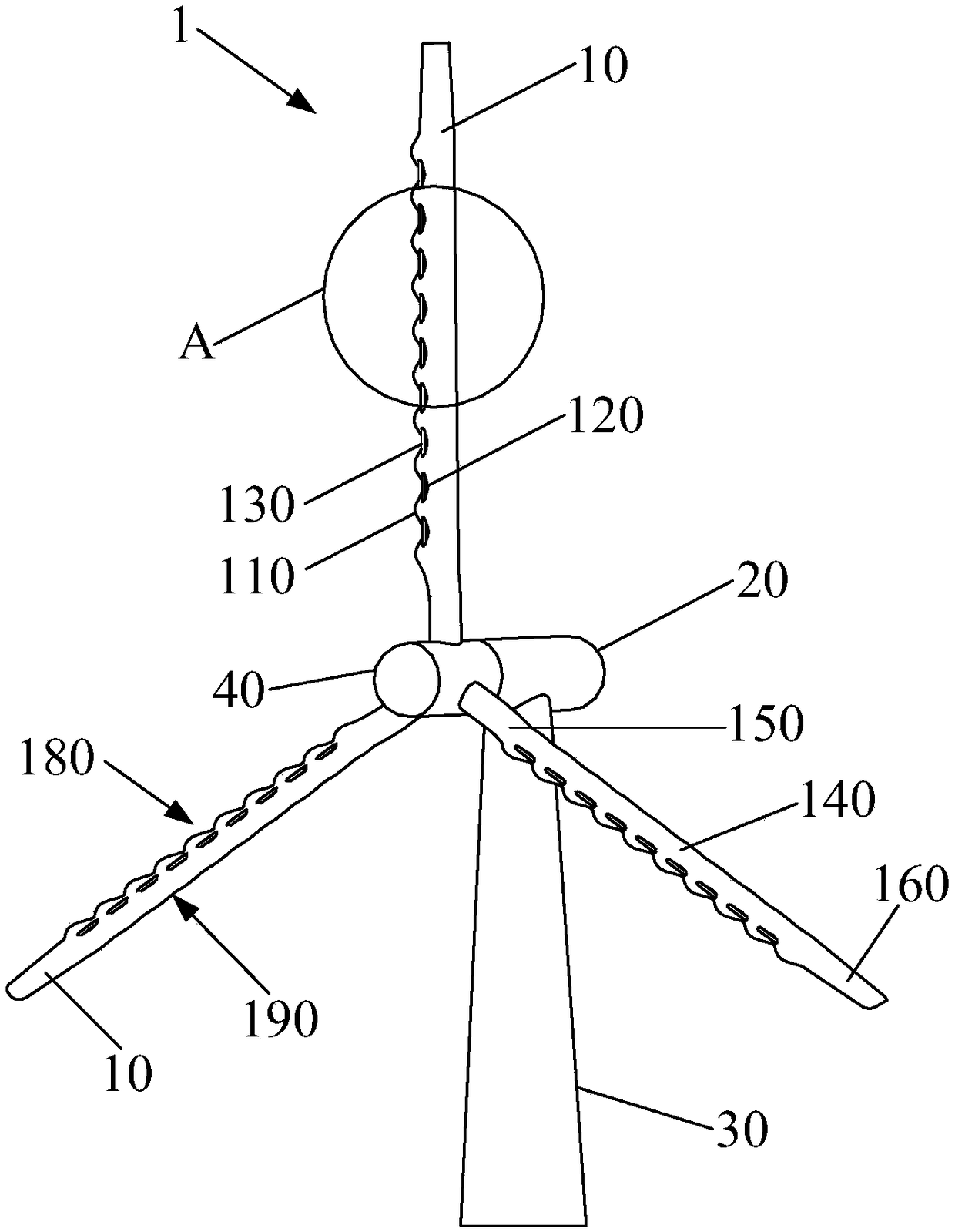

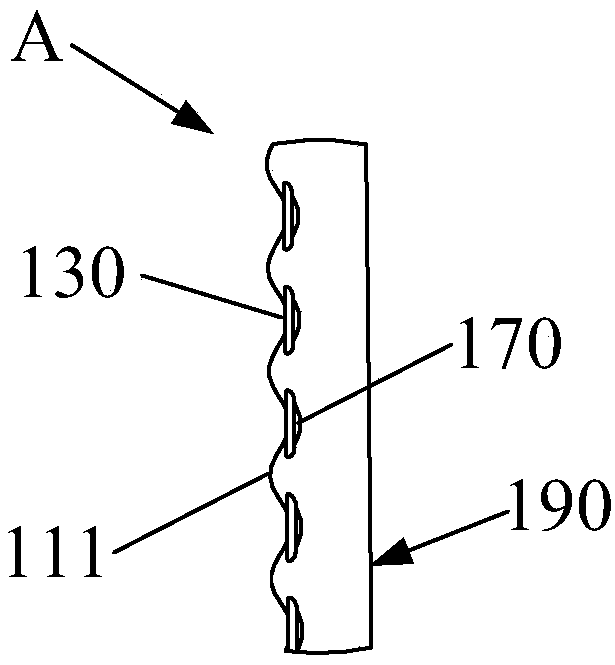

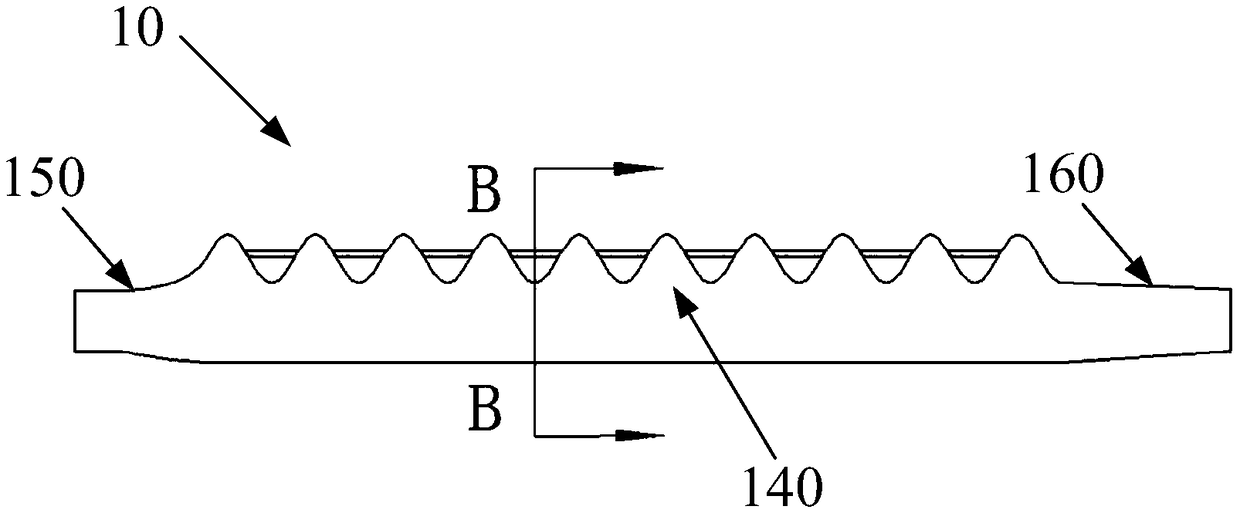

[0055] Such as Figure 1-4As shown, the embodiment of the present application provides a wave airfoil blade 10, the wave airfoil blade 10 is used as a blade of a wind turbine for wind power generation, the wave airfoil blade 10 includes a front edge 180 along the blade 10 A plurality of crests 110 and a plurality of troughs 120 distributed continuously in the stretching direction, the plurality mentioned in this application is at least two or more than a specific number, and a column 130 is connected between two adjacent crests 110 The arrangement direction of the adjacent two crests 110 is the same as the axial direction of the cylinder 130 connected to the above two, and the cross-sectional area of the cylinder 130 is much smaller than that of the opposite surface of the connected wave crest 110 It can also be said that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com